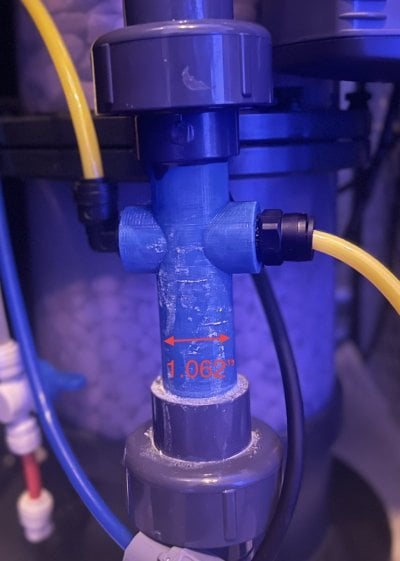

I did some sleuthing. Using my ACR, I have Spears schedule 80 fittings for the PVC parts, that I can see. The unions on my reactor are Spears schedule 40 3/4" unions (457-007G), I think. I can't see a logo on the union, but based on the Spears logos on the other fittings, I looked up the union on the Spear's site, and I am able to match the dimensions provided for the collar OD, and dimension M from Spears site. I am unable to match the length (dimension L) though. That may just be down to the difficulty of measuring a fitting already in place though.

I was able to pull PN16 off the collar, but that does not pulls up anything on the Spears site. So it is still possible that he is using a complexly different brand of fitting from the other PVC parts.

So not totally conclusive, and may or may not, match your fitting. Perhaps try to confirm the details about your fitting.

I was able to pull PN16 off the collar, but that does not pulls up anything on the Spears site. So it is still possible that he is using a complexly different brand of fitting from the other PVC parts.

So not totally conclusive, and may or may not, match your fitting. Perhaps try to confirm the details about your fitting.