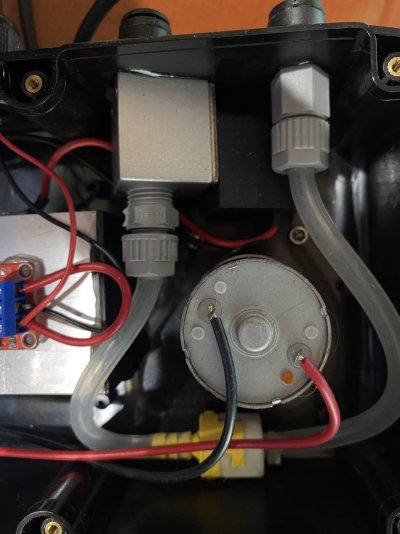

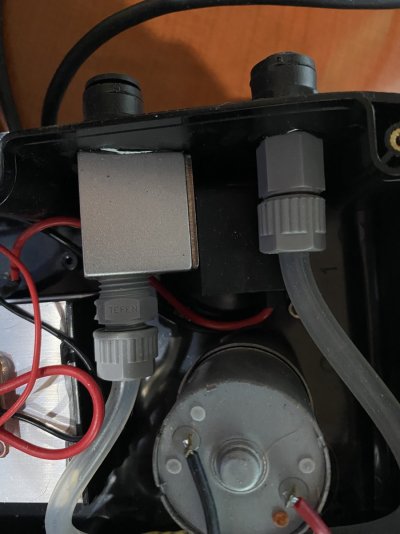

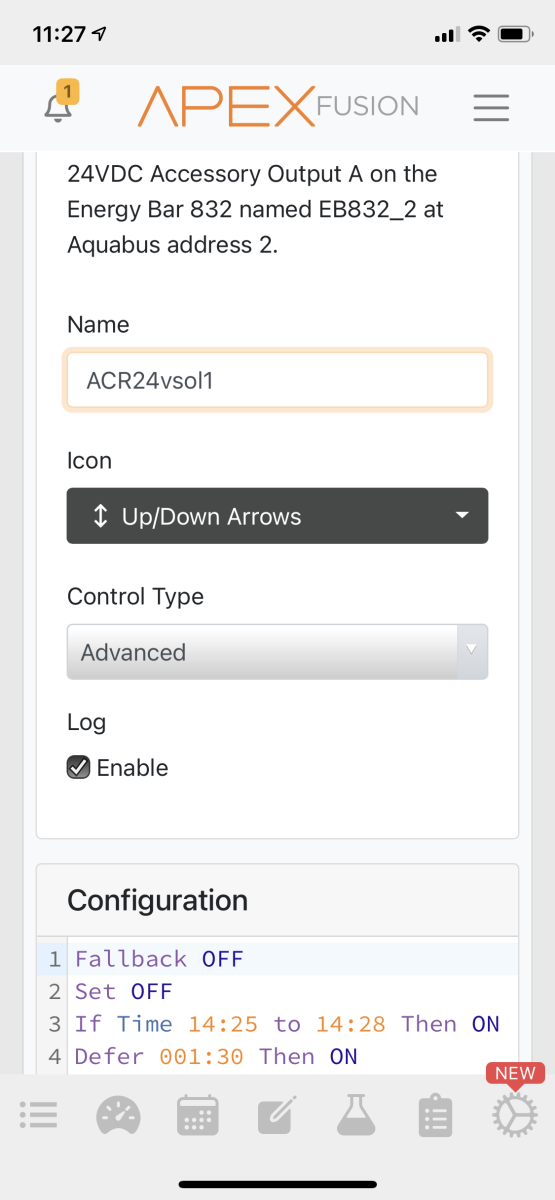

I have a Neptune solenoid on one of the 3 holes in the too cap that handles the purge using this command:

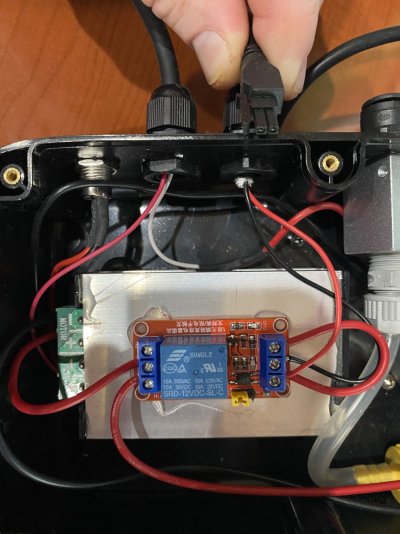

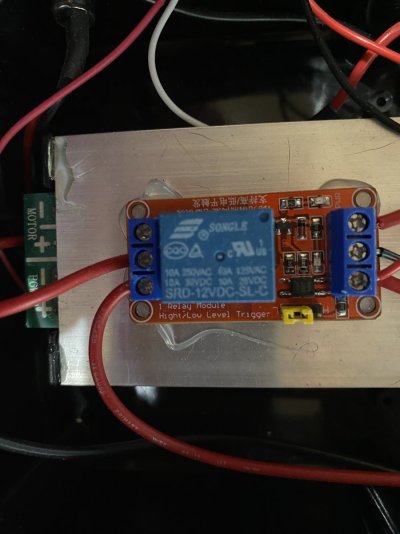

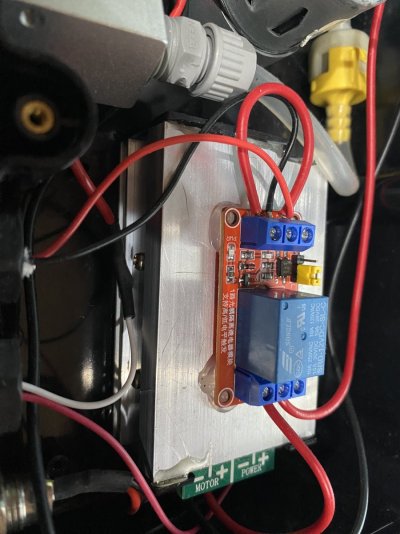

then I have the opposite command at the same time on a plug to delete power to the ACR controller to close co2 going to the reactor.

edit: I just realized that this does nothing now that I don’t have a feed pump going in to the reactor since I have the peristaltic pump on the effluent side

then I have the opposite command at the same time on a plug to delete power to the ACR controller to close co2 going to the reactor.

edit: I just realized that this does nothing now that I don’t have a feed pump going in to the reactor since I have the peristaltic pump on the effluent side

Last edited: