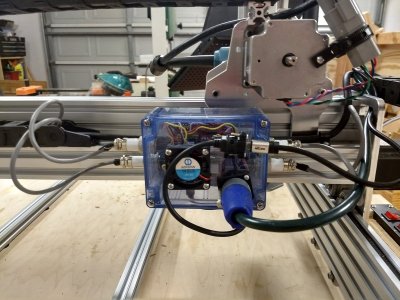

if your planning on using that shop-vac for dust collection get shielded cables! i have seen steppers do some weird stuff because of static. maybe even splurge for a low/no static hose for it. cant wait to see your first projects! more and more hobby based machines hitting the market making cnc accessible to those who want to use it.;Bookworm

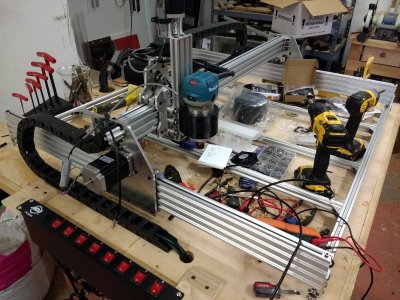

Glad you mentioned the static from the shop-vac. I am going with shielded motor cables, mostly to reduce noise, but that should help deal with static buildup. I also want to run a ground wire with the vac hose to try and reduce static as well. Getting to the point where all these small details need to be fleshed out. Can't wait to get this thing started up and running!