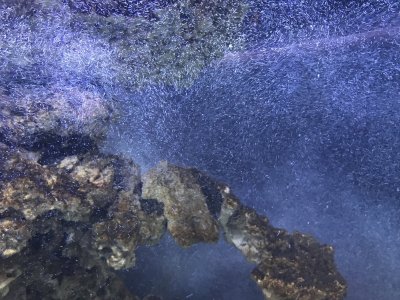

COULD USE SOME HELP WITH MICROBUBBLES

So since the beginning of my tank in March I have had a boatload of micro bubbles in the big display and it is driving me nuts. I have attached a video. The come right out of the return line. Interestingly the don’t come out of the return line on my secondary display and that water is crystal clear. RFG nozzles not the sucking air either as I have removed all of them and problem still exists,

Plumbing Description

Let me explain my plumbing set up. Water enter the pump via a 2" line with the water level approximately 14" above the feed bulkhead. Water exits the pump via 1 1/2" pipe. At approximately 40" above the outlet there is a Tee. About 15-20% (valved) of the flow heads out one side to a 90 gallon display through a 1" return line. The other side of the T stays 1 1/2" travels horizontal for 48" then elbows up 10" and elbows and travels horizontal for 25 feet until another elbow to vertical piping up 8' to top of 650 display tank. At the top it enters another Tee that reduces down to two 1" outputs. The outputs terminate into 2 outlets atone end of the tank and two outlets at the far end of the tank. Tank is a peninsula.

Potential causes and actions taken

Split to 2 tanks a problem? No -cut off flow to secondary and no change

Bubbles from sump entering pump intake -Don’t think so as out a sponge/intake screen over pump outflow.

Air getting sucked in plumbing between sump and pump - don’t think so...redid this run twice now for this reason.

is the pump to big? Maybe....it is a Tigershark which is 8500gph with high head. Could switch out the impeller to the hammerhead which will reduce output. - Today switched to Reeflo Manta Ray impeller and which lowered gah to 6500 and no change.

Does anyone else have any other thoughts?

So since the beginning of my tank in March I have had a boatload of micro bubbles in the big display and it is driving me nuts. I have attached a video. The come right out of the return line. Interestingly the don’t come out of the return line on my secondary display and that water is crystal clear. RFG nozzles not the sucking air either as I have removed all of them and problem still exists,

Plumbing Description

Let me explain my plumbing set up. Water enter the pump via a 2" line with the water level approximately 14" above the feed bulkhead. Water exits the pump via 1 1/2" pipe. At approximately 40" above the outlet there is a Tee. About 15-20% (valved) of the flow heads out one side to a 90 gallon display through a 1" return line. The other side of the T stays 1 1/2" travels horizontal for 48" then elbows up 10" and elbows and travels horizontal for 25 feet until another elbow to vertical piping up 8' to top of 650 display tank. At the top it enters another Tee that reduces down to two 1" outputs. The outputs terminate into 2 outlets atone end of the tank and two outlets at the far end of the tank. Tank is a peninsula.

Potential causes and actions taken

Split to 2 tanks a problem? No -cut off flow to secondary and no change

Bubbles from sump entering pump intake -Don’t think so as out a sponge/intake screen over pump outflow.

Air getting sucked in plumbing between sump and pump - don’t think so...redid this run twice now for this reason.

is the pump to big? Maybe....it is a Tigershark which is 8500gph with high head. Could switch out the impeller to the hammerhead which will reduce output. - Today switched to Reeflo Manta Ray impeller and which lowered gah to 6500 and no change.

Does anyone else have any other thoughts?