Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with tiny plumbing leak.

- Thread starter terraincognita

- Start date

- Tagged users None

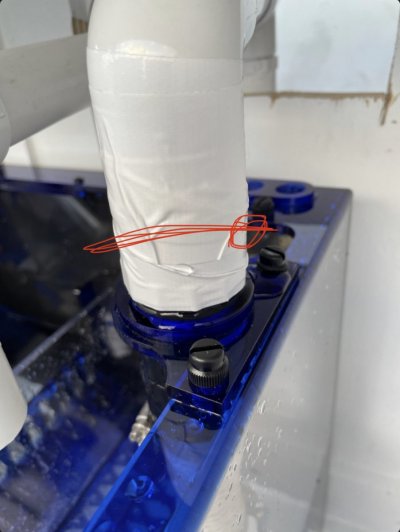

Where in the plumbing is this "pin hole?" There is so much duct tape it's hard to figure if this is in a joint or a tiny hole in pipe as you are describing it?

Turn off your return pump. Dry the area add silicone to hole. It appears to be a drain yes? Not under pressure? Good luck.

Best bet is do what they said above then cut a small section of larger pipe... only needs to be 1".

Cut a slit so you can snap it around the pipe just below the joint. Glue the pipe and joint area, slide up the new piece with a twist. Apply pressure and hold against the joint.

Cut a slit so you can snap it around the pipe just below the joint. Glue the pipe and joint area, slide up the new piece with a twist. Apply pressure and hold against the joint.

The leak is right where’s the return pump connects to the sump/piping.

I have the platinum trigger 34 sump.

I have 1” vinyl tubing going to 1” PVC.

I think I didn’t put the piece of PVC between the sump outport and the 90 degree long enough.

but it’s already cemented.

It’s a return pump line so it is under pressure.

the leak is between the joint of the 90 degree elbow and the sump port. There’s a 2inch piece of PVC plugged into both. Shoulda made it 3…..

but now what without buying a new sump port and cutting the pipe?

or is that the only and best option?

part of the problem is my vinyl braided tubing was like 1/4 inch too long and because it’s so dense I think it added kink pressure on that joint…

If that makes any sense. I can get photos and illustrations later.

also there’s a small leak between my emergency and the bulkhead, but I imagine silicon will be the perfect fix for that.

I have the platinum trigger 34 sump.

I have 1” vinyl tubing going to 1” PVC.

I think I didn’t put the piece of PVC between the sump outport and the 90 degree long enough.

but it’s already cemented.

It’s a return pump line so it is under pressure.

the leak is between the joint of the 90 degree elbow and the sump port. There’s a 2inch piece of PVC plugged into both. Shoulda made it 3…..

but now what without buying a new sump port and cutting the pipe?

or is that the only and best option?

part of the problem is my vinyl braided tubing was like 1/4 inch too long and because it’s so dense I think it added kink pressure on that joint…

If that makes any sense. I can get photos and illustrations later.

also there’s a small leak between my emergency and the bulkhead, but I imagine silicon will be the perfect fix for that.

Where in the plumbing is this "pin hole?" There is so much duct tape it's hard to figure if this is in a joint or a tiny hole in pipe as you are describing it?

it’s at the seam between 90’ elbow and coupling.

I think the 2 inches of PVC cementing them together should’ve been 3”… but it’s cemented already soooooo

If it is a supply line that is under pressure it will continue to leak till you properly fix it. Since it’s a small leak for now keep it taped till you buy the proper parts to fix it.So basically this photo.

the red line is where the 90 degree elbow connects with the trigger black pre-provided coupling.

the leak was right at the seam. About 1 drop every 5 seconds.

it’s a L2 vectra return pump

If it is a supply line that is under pressure it will continue to leak till you properly fix it. Since it’s a small leak for now keep it taped till you buy the proper parts to fix it.

yeah it’s my new build so it’s dry was just running the leak test.

guess I’ll have to chop it up and re do it

Omg yes if there is no fish or corals this is the time to fix it. I thought this was on a system that was establishedyeah it’s my new build so it’s dry was just running the leak test.

guess I’ll have to chop it up and re do it

Remove the tape. Turn the pump off. Dry area. Add pvc glue in a circular motion around any joints. Let dry. This will seal up any leaks.

Hths you!

-d

Hths you!

-d

Being a pressure supply line and the fact tank is empty of coral and fish it’s time to fix it right IMO why half butt itRemove the tape. Turn the pump off. Dry area. Add pvc glue in a circular motion around any joints. Let dry. This will seal up any leaks.

Hths you!

-d

Monkey be right. Has worked for me on more than one occasion. And, sometimes, has not. You will know in 24 hours. If it still drips, break out the saw.

If its a slow drip. Thats how i fix it. Unless u forgot to glue that 1 fitting. That happens too and salt creep will form. Than u really know. Lol.

Its already sealed and glued and under pressure. Just need the leak addressed. I usually use so much glue that it forms a ring where the join is. It will seal it. Np.

-d

Its already sealed and glued and under pressure. Just need the leak addressed. I usually use so much glue that it forms a ring where the join is. It will seal it. Np.

-d

Joint*

Specially if its a vertical fitting and bot horizontal. The glue will settle and form

D

D

Not* jeesh

Thanks @monkeyCmonkeyDo & @((FORDTECH))

I might try that glue option on the small bulkhead leak uptop, it's literally the same thing right where my bulkhead and pvc seam, drip, drip, drip, and there's no pressure on that one either (It's also the bulkhead of my bean animal emergency return drain which never gets any water.....

But I'm gonna go ahead and replace the return line cause it's high pressure. I'm gonna run that L2 pump at about 80% 14 hours a day.

Shouldn't take me any longer than 3 mintutes. I have extra PVC, and elbows.... I just need to cut it at the 90, grab a 1" to 1" coupler, and reglue about 3 inches of PVC and a 90 Degree elbow. Un--hose clamp return, remove from adapter, (I didn't cement the adapters in actually, but they're not even leaking lol. May cement them this time)

I have a PVC cutting ratchet so it's just snip, snip, snip, the unscrew union, adjust angle into the sump a little, re-tighten union, dry fit 3 pieces, looks good, prime, cement, paste. done.

TBH... I'm gonna skip the trigger systems coupler next time.

It's kind of redundant. I should just go straight from 1" braided Vinyl to Barber Adapter into 1" PVC then into 90" Elbow.

So to me that coupler is redundant.

I'll use plumbers tape to hold the weight to the top of the cabinet inside. No reason to use that coupler tbh, my pump head doesn't sit close enough to the edge and 1" Braided vinyl is so inflexible it's stupid, so it just makes everything uncomfortable in that chamber.

I might've been mistaken and the real purpose of the coupler may be for the Emergency Drain Connection.

In which case oops on me. But I have mine sitting high so it makes "splashy noises" in the case it goes into action. (Bean Animal system)

in the case it goes into action. (Bean Animal system)

I'll document it in my build thread

I might try that glue option on the small bulkhead leak uptop, it's literally the same thing right where my bulkhead and pvc seam, drip, drip, drip, and there's no pressure on that one either (It's also the bulkhead of my bean animal emergency return drain which never gets any water.....

But I'm gonna go ahead and replace the return line cause it's high pressure. I'm gonna run that L2 pump at about 80% 14 hours a day.

Shouldn't take me any longer than 3 mintutes. I have extra PVC, and elbows.... I just need to cut it at the 90, grab a 1" to 1" coupler, and reglue about 3 inches of PVC and a 90 Degree elbow. Un--hose clamp return, remove from adapter, (I didn't cement the adapters in actually, but they're not even leaking lol. May cement them this time)

I have a PVC cutting ratchet so it's just snip, snip, snip, the unscrew union, adjust angle into the sump a little, re-tighten union, dry fit 3 pieces, looks good, prime, cement, paste. done.

TBH... I'm gonna skip the trigger systems coupler next time.

It's kind of redundant. I should just go straight from 1" braided Vinyl to Barber Adapter into 1" PVC then into 90" Elbow.

So to me that coupler is redundant.

I'll use plumbers tape to hold the weight to the top of the cabinet inside. No reason to use that coupler tbh, my pump head doesn't sit close enough to the edge and 1" Braided vinyl is so inflexible it's stupid, so it just makes everything uncomfortable in that chamber.

I might've been mistaken and the real purpose of the coupler may be for the Emergency Drain Connection.

In which case oops on me. But I have mine sitting high so it makes "splashy noises"

I'll document it in my build thread

TBH the way I plumbed this thing, even if it was up and running, would still take me 15 seconds to do the same thing. Super happy with how it came out.

Now that it doesn't have water, I just might make 100% sure i leave enough space to ensure I could replumb the whole thing just by shutting down the pump if I needed. threaded unions are genius.

Now that it doesn't have water, I just might make 100% sure i leave enough space to ensure I could replumb the whole thing just by shutting down the pump if I needed. threaded unions are genius.

Similar threads

- Replies

- 18

- Views

- 390

- Replies

- 2

- Views

- 113

- Replies

- 7

- Views

- 203

- Replies

- 31

- Views

- 565