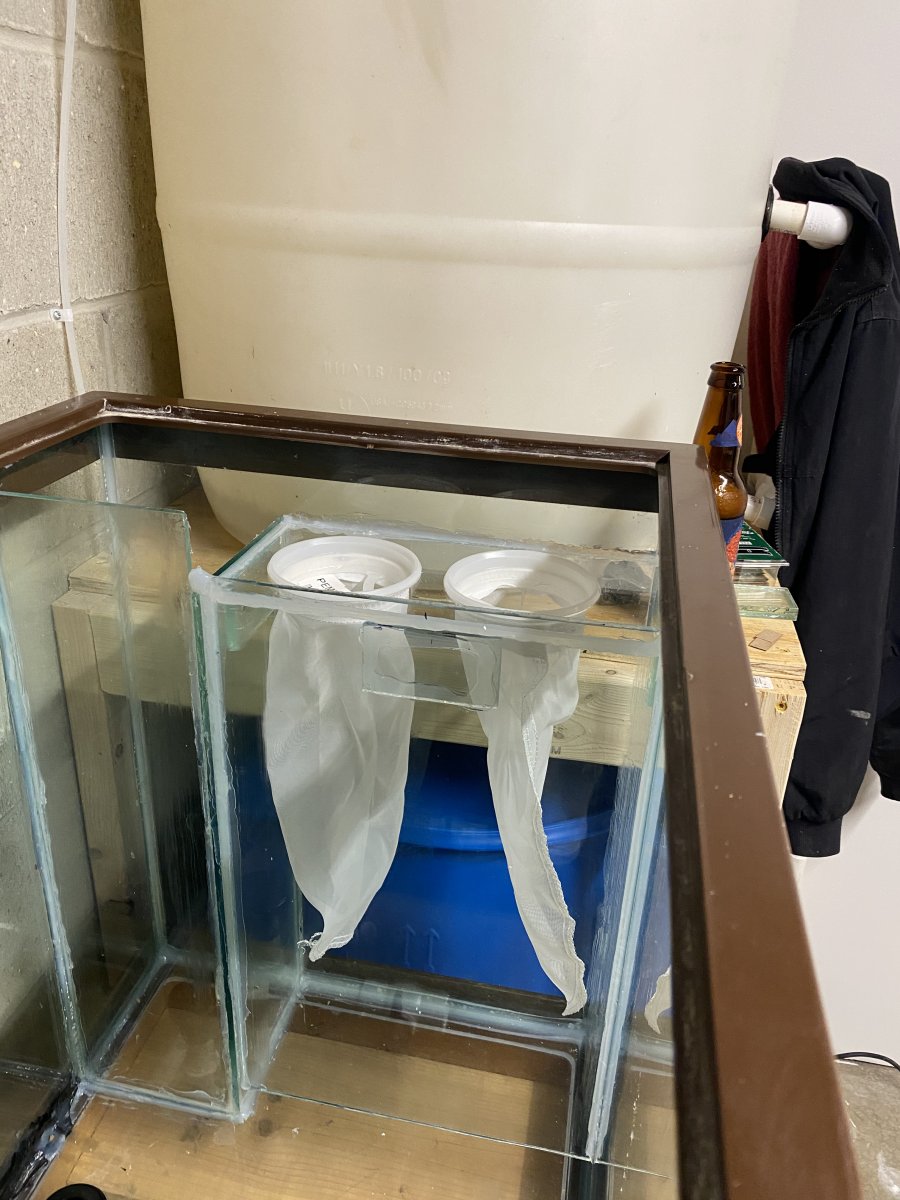

Next I got a piece of acrylic cut and drilled holes in it for my filter socks and siliconed that in place in my sump. The only hole saw any local place had was a 4", which while it works, it leaves a little more play around the filter sock than I was hoping. I think it will work, but if it doesn't, I have a plan on how to fix it.

Next I cut a piece of plywood and mounted it behind the sump in order to have a place to mount my electrical/controller stuff to. This makes it super convenient to have everything plugged in right there. Everything will be on the GHL controller, but it is still nice to have it all convenient for unplugging stuff for maintenance/ect.

I also pulled a wire from the breaker box over to this location, but didn't get a pic of that.

I also finally got a pump to be able to handle the head pressure of coming out of the RO degassing station, through the DI canister and then through the RO tubing to the fish room. The original plan was to use a maxijet, but because of all the restriction it would not push water all the way to the fish room. So I tried a tunze osmolator pump. This would push water all the way there, but it was slow. It only was able to empty the 44 gal brute container about halfway in 7 hours. At this point I was still not happy with that, but it did get a little bit of water in the sump.

Next I cut a piece of plywood and mounted it behind the sump in order to have a place to mount my electrical/controller stuff to. This makes it super convenient to have everything plugged in right there. Everything will be on the GHL controller, but it is still nice to have it all convenient for unplugging stuff for maintenance/ect.

I also pulled a wire from the breaker box over to this location, but didn't get a pic of that.

I also finally got a pump to be able to handle the head pressure of coming out of the RO degassing station, through the DI canister and then through the RO tubing to the fish room. The original plan was to use a maxijet, but because of all the restriction it would not push water all the way to the fish room. So I tried a tunze osmolator pump. This would push water all the way there, but it was slow. It only was able to empty the 44 gal brute container about halfway in 7 hours. At this point I was still not happy with that, but it did get a little bit of water in the sump.