8 year update: https://www.reef2reef.com/threads/ledbrick-diy-led-pendant-with-pucks.243746/page-12#post-10936553

New design underway

-------------------------------------------

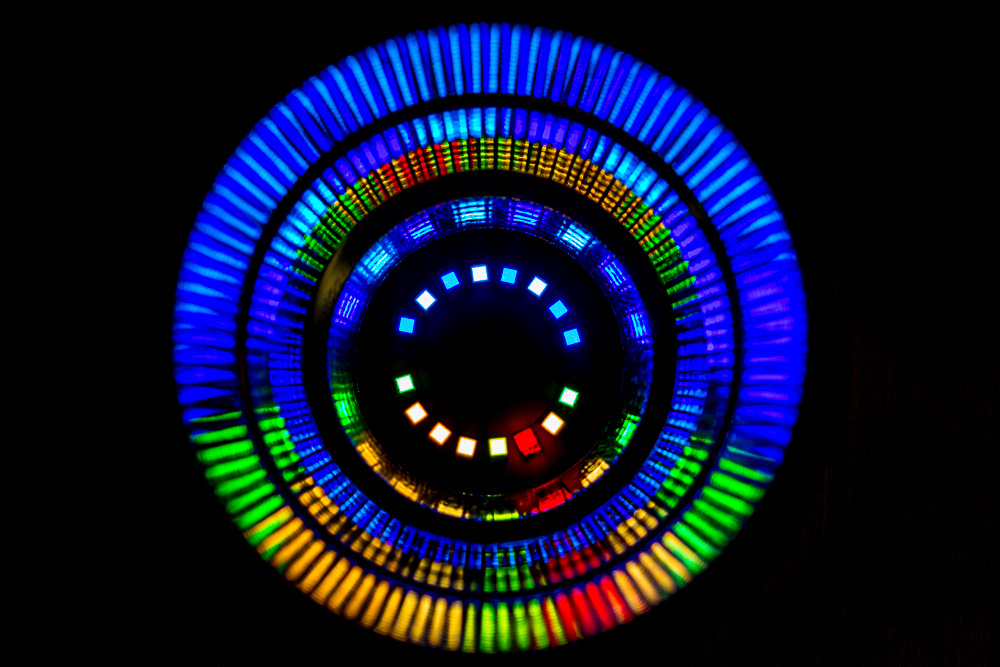

(This is my summary of a project I did over the past ~ year, in condensed form, for others to be inspired by across the reef forum community. I'm also actively working on new components, LED emitters, and drivers, but the first series of posts is on the original version).

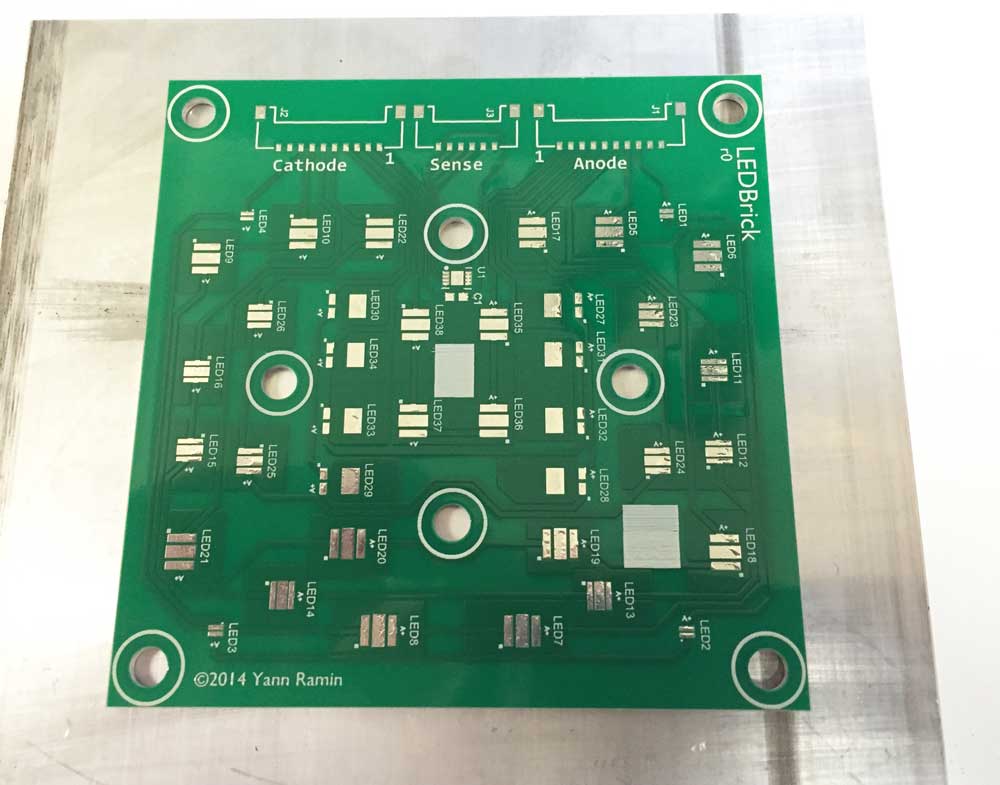

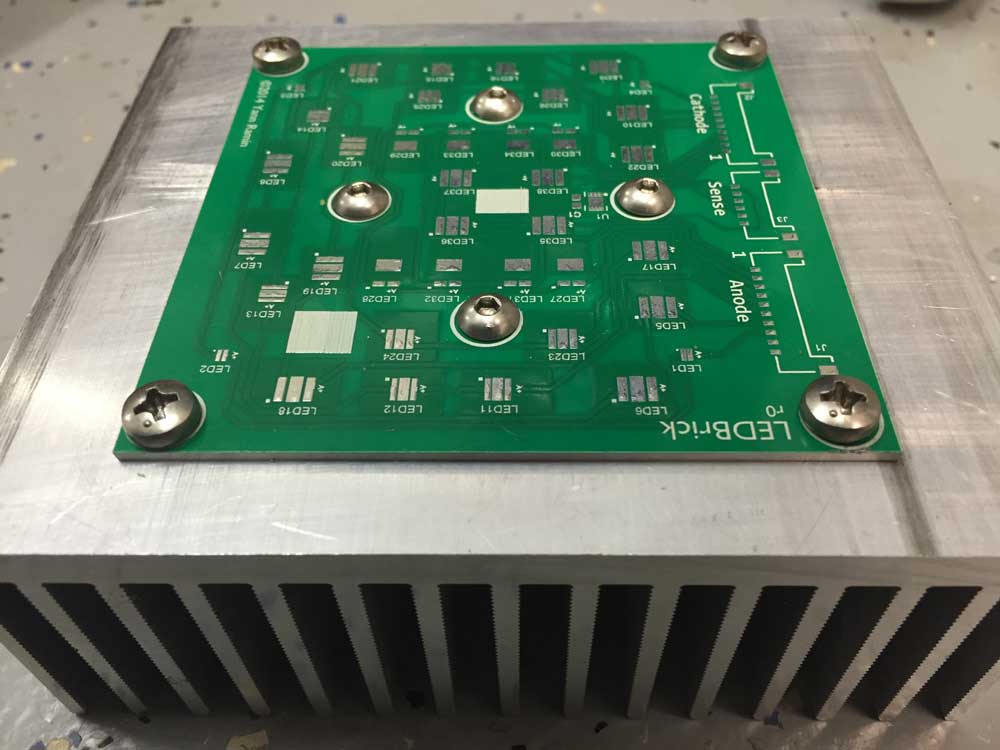

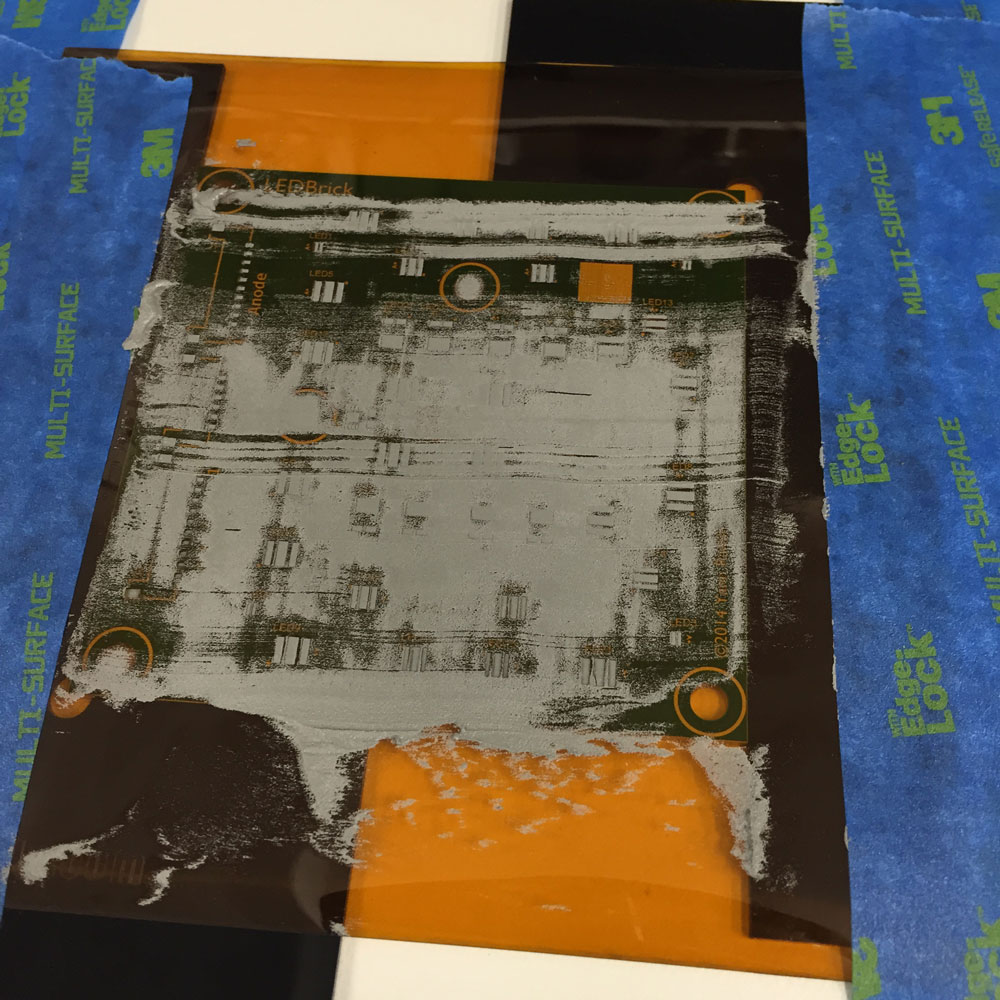

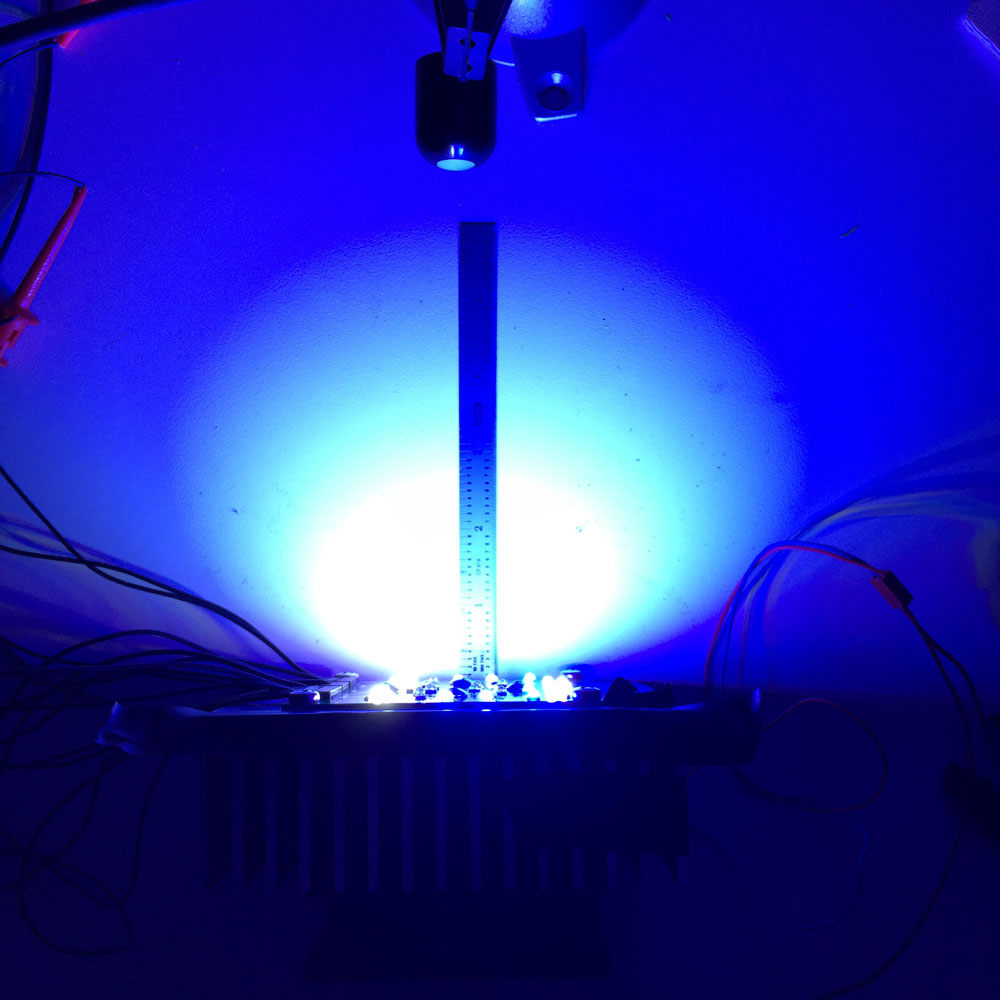

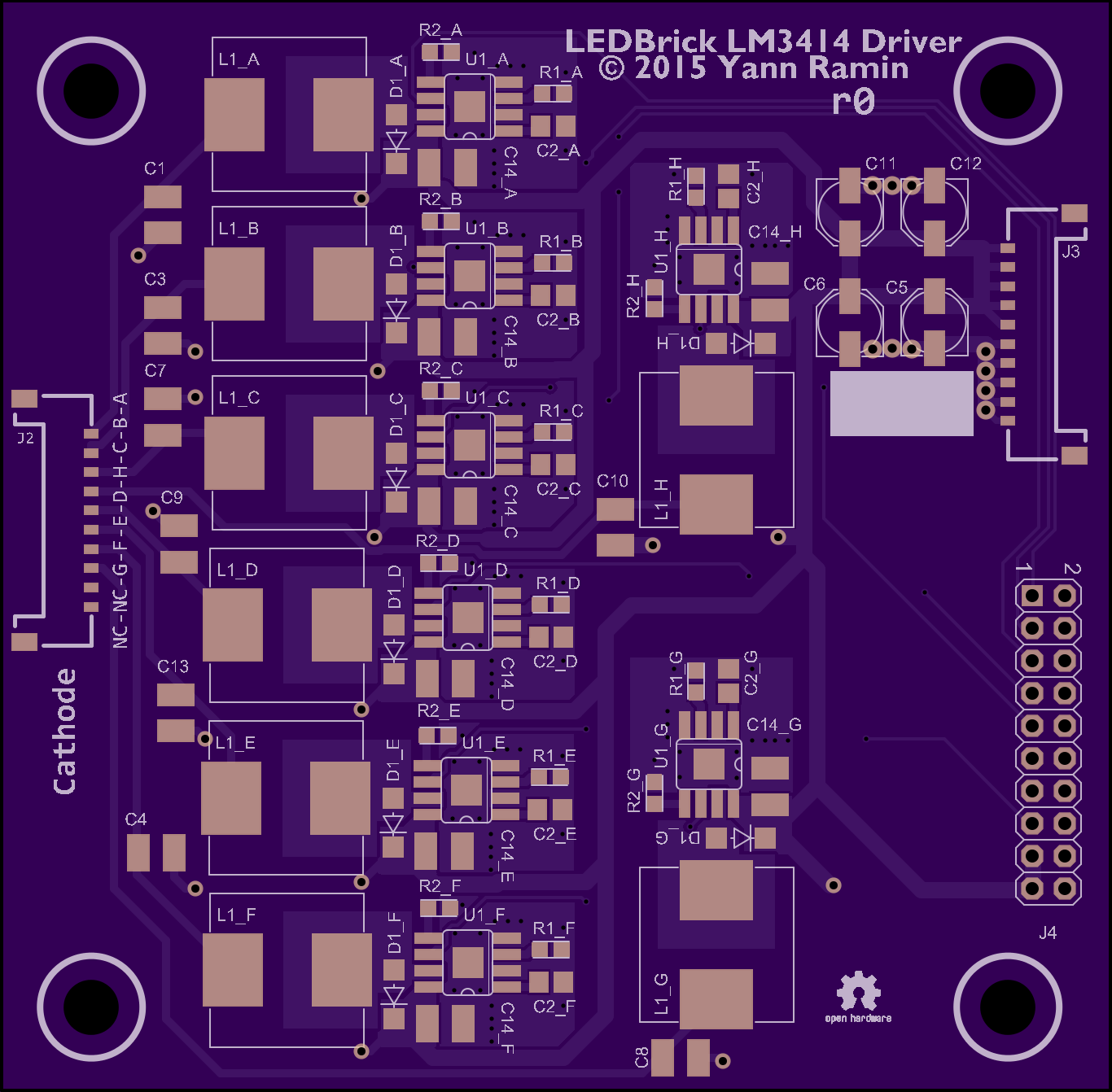

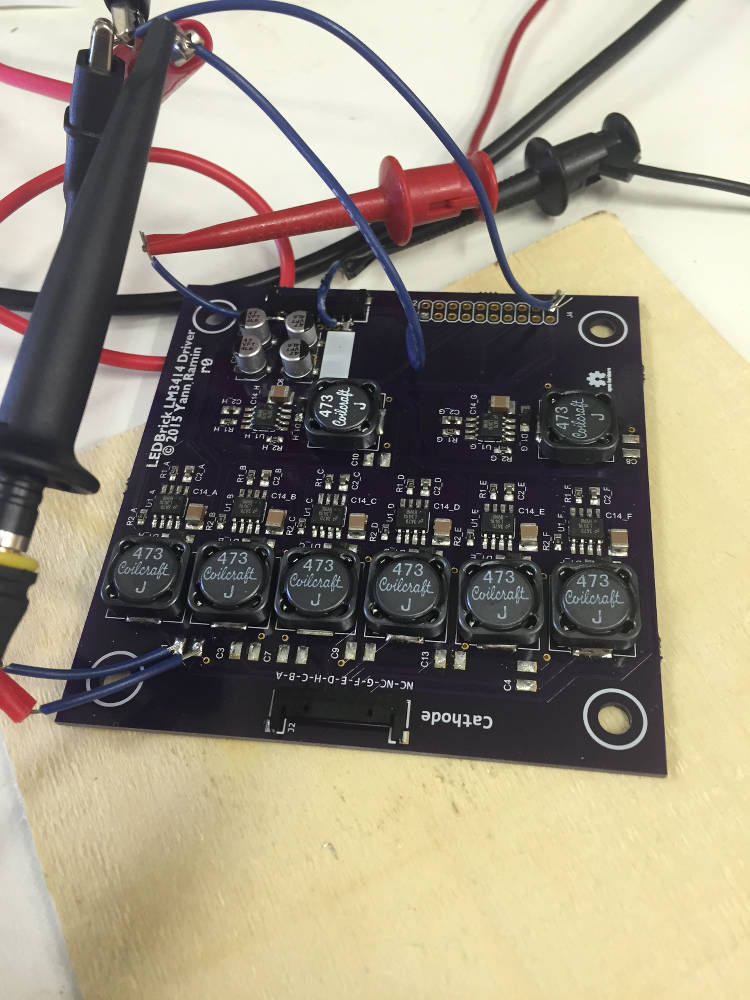

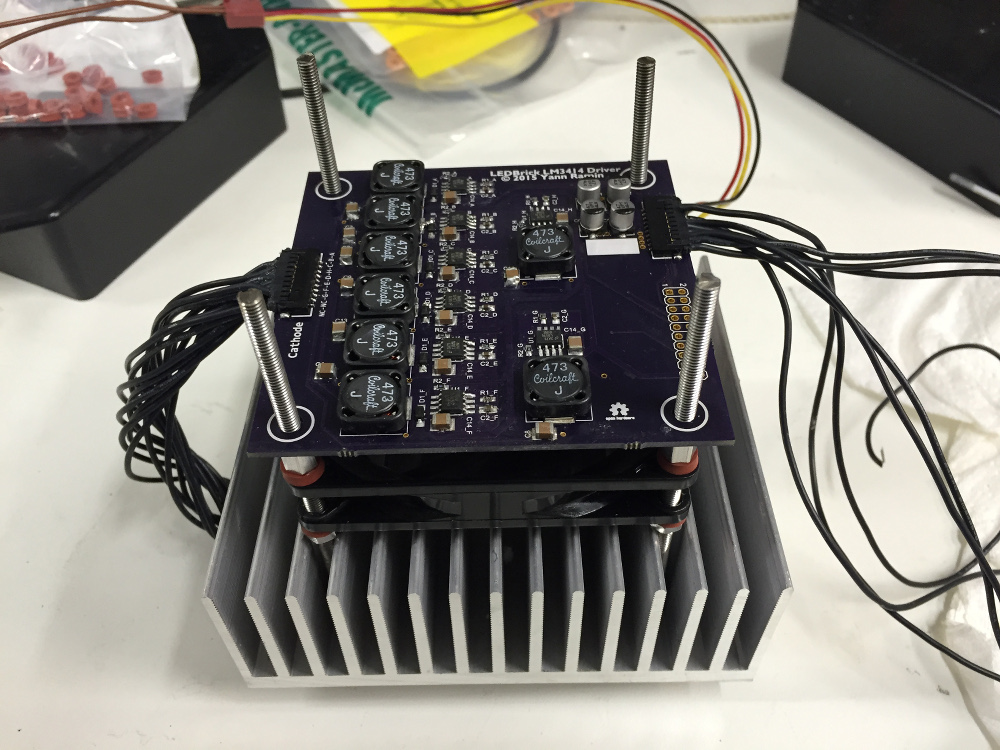

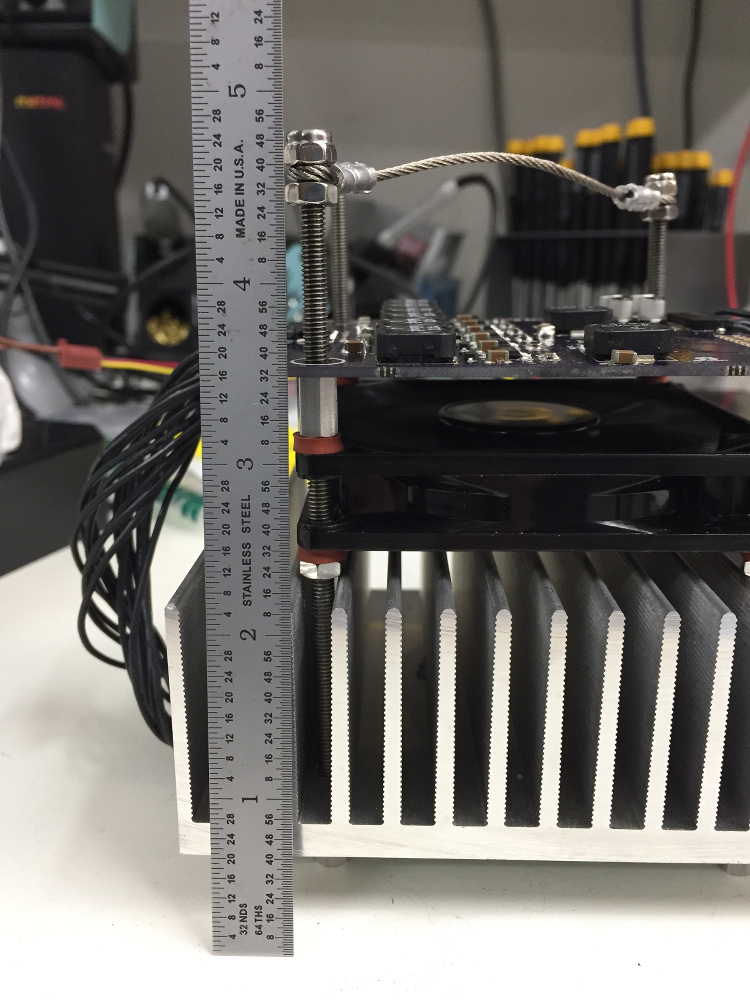

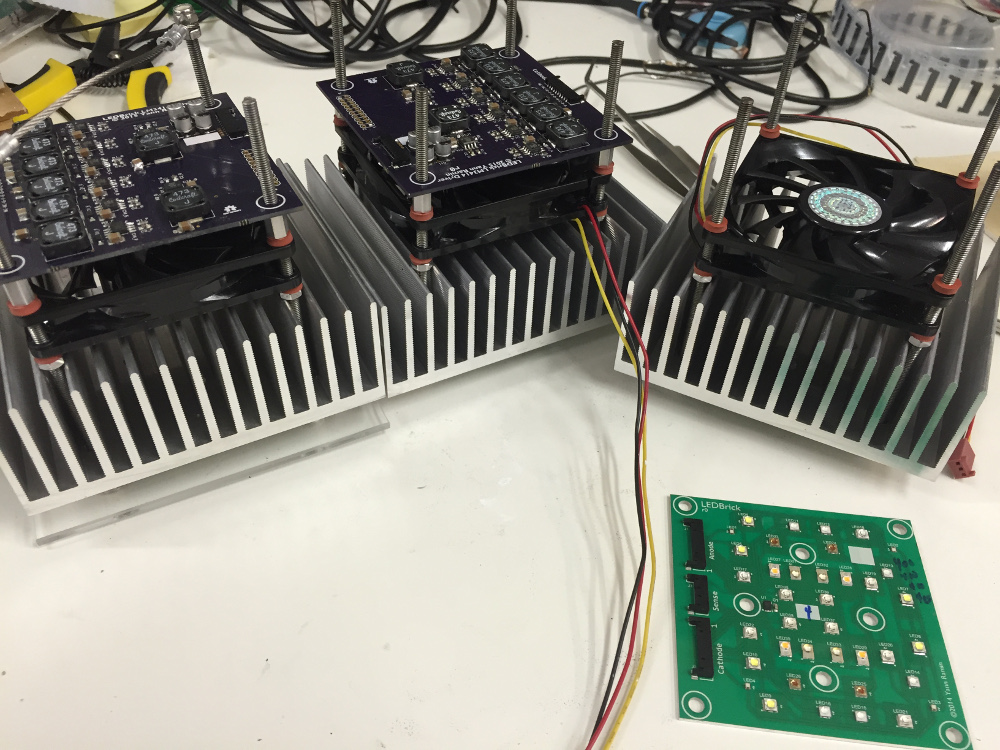

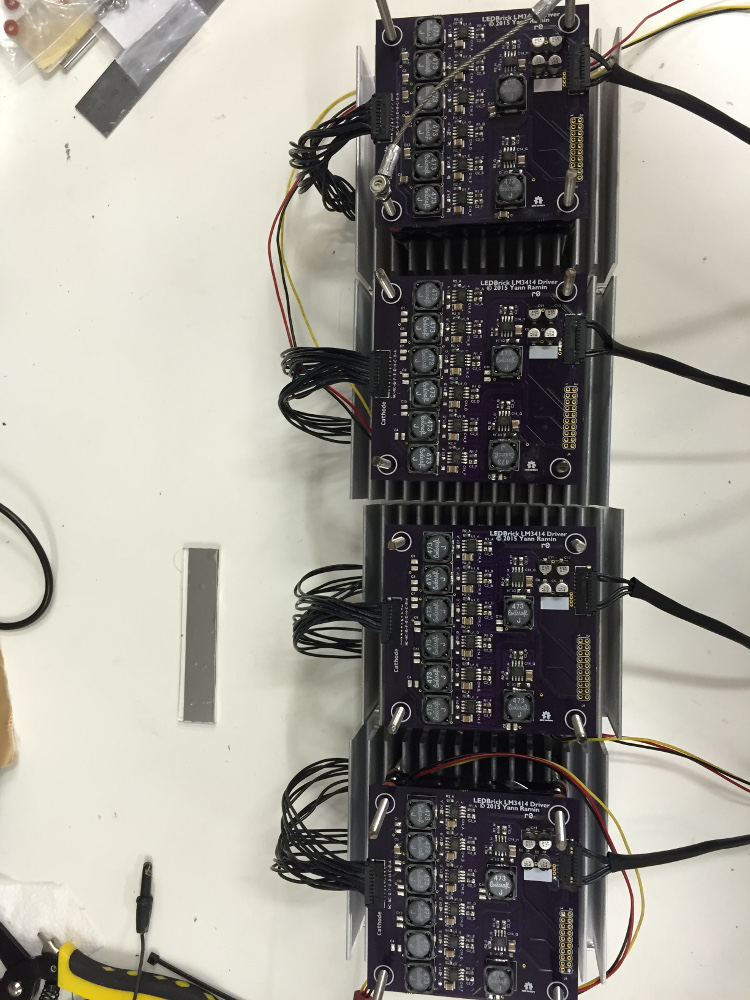

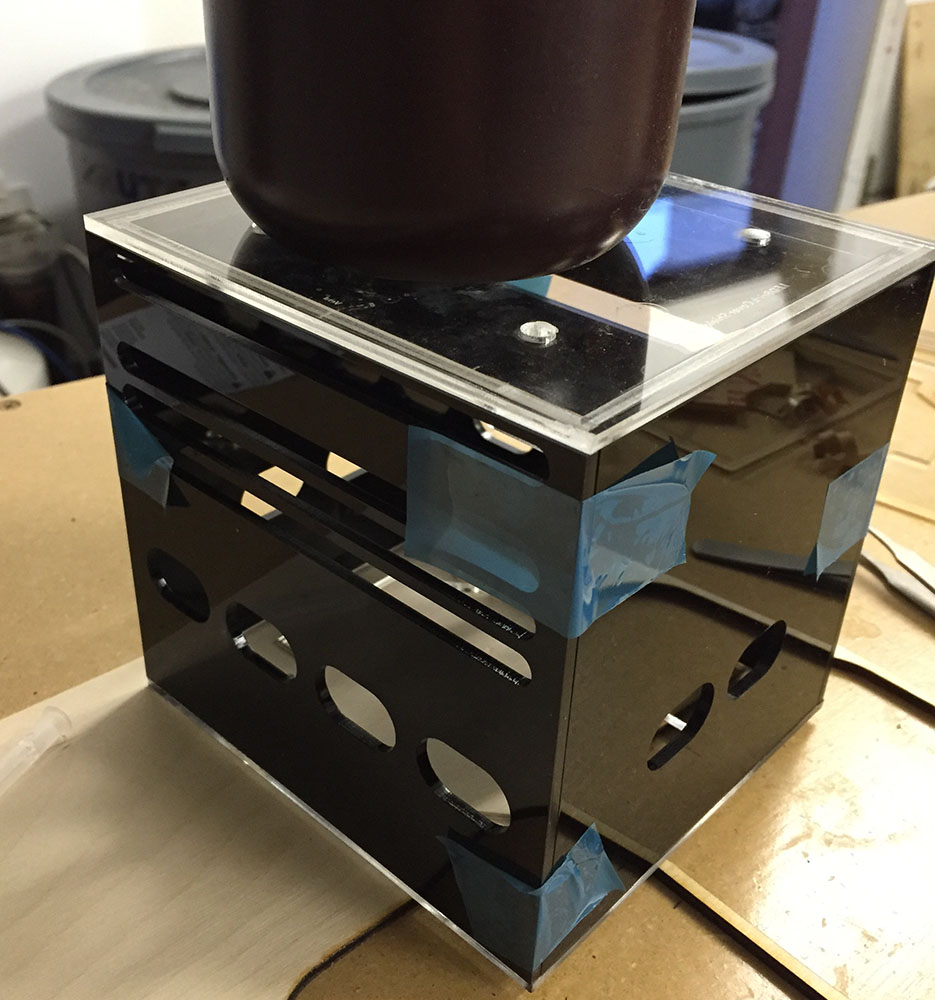

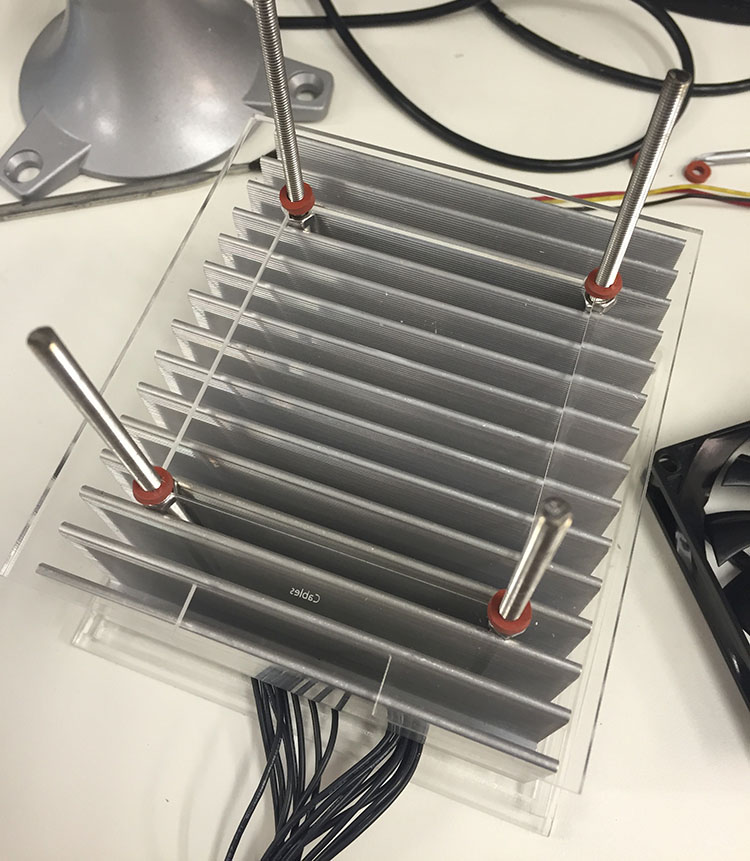

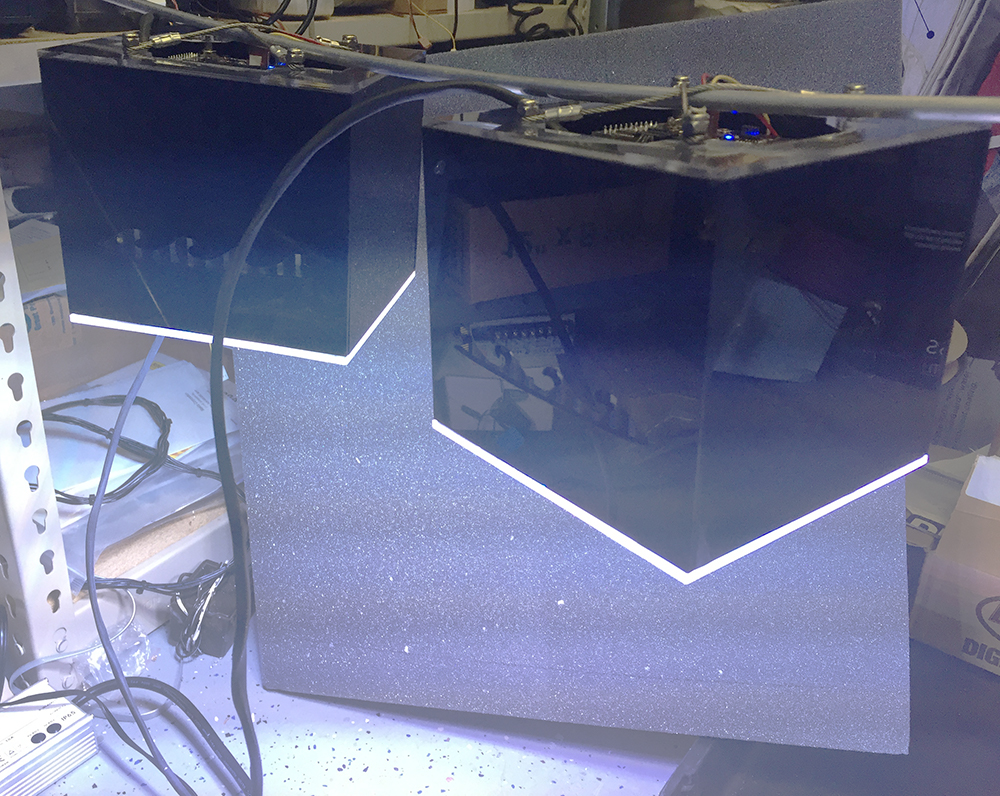

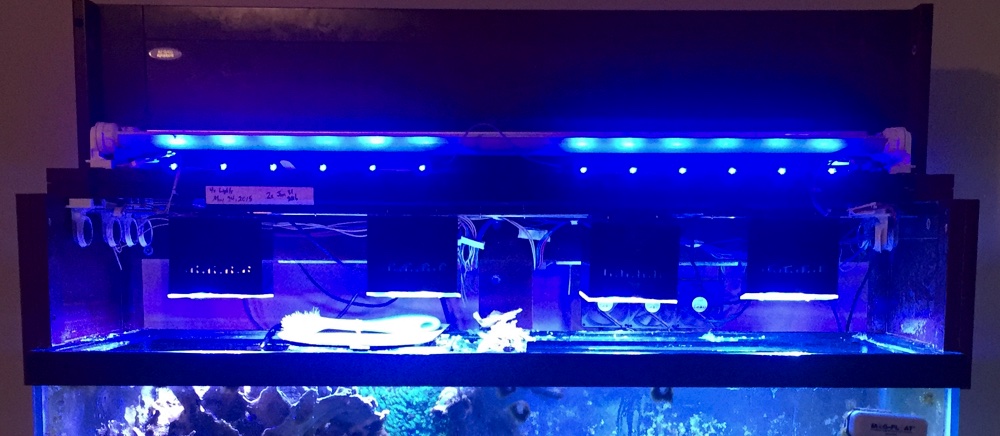

It all started with this concept - a squareish shaped LED "brick" in a pendant form. The mechanics were based around a 4.6in HeatsinkUSA serrated stock, and an 80mm fan.

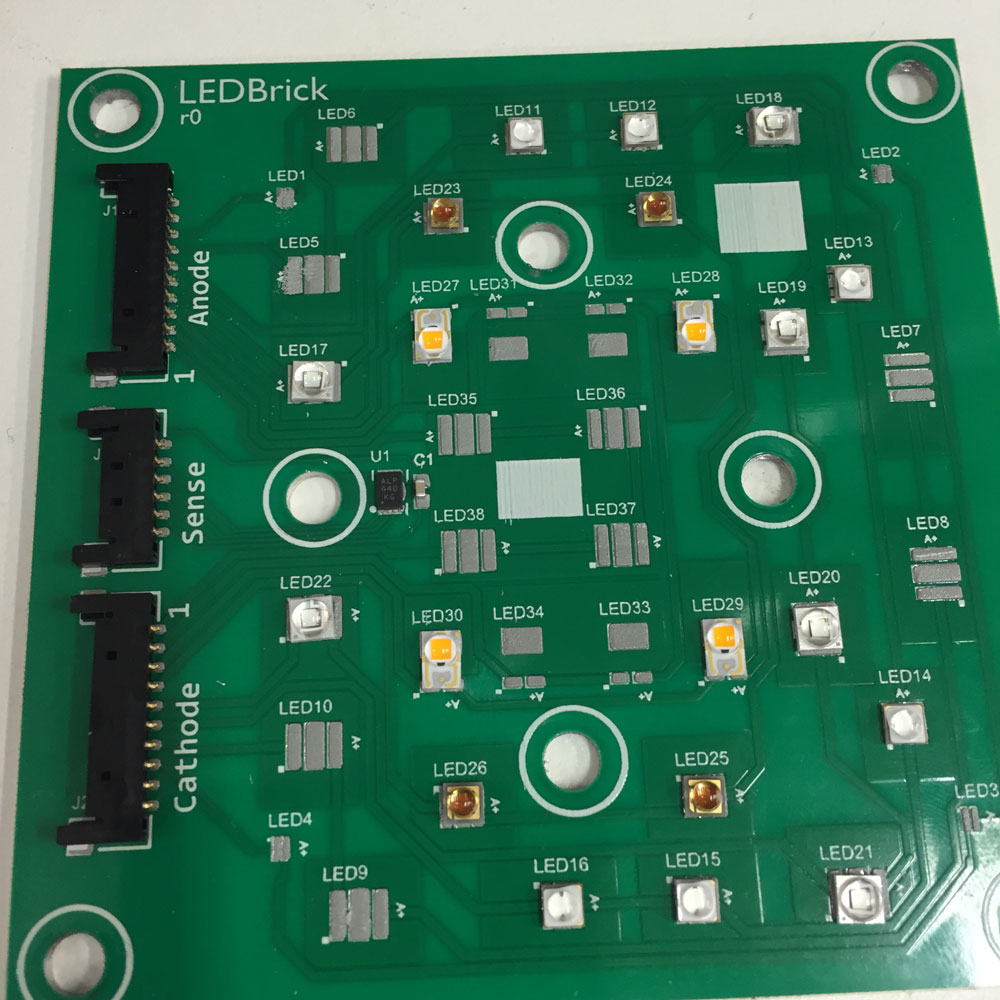

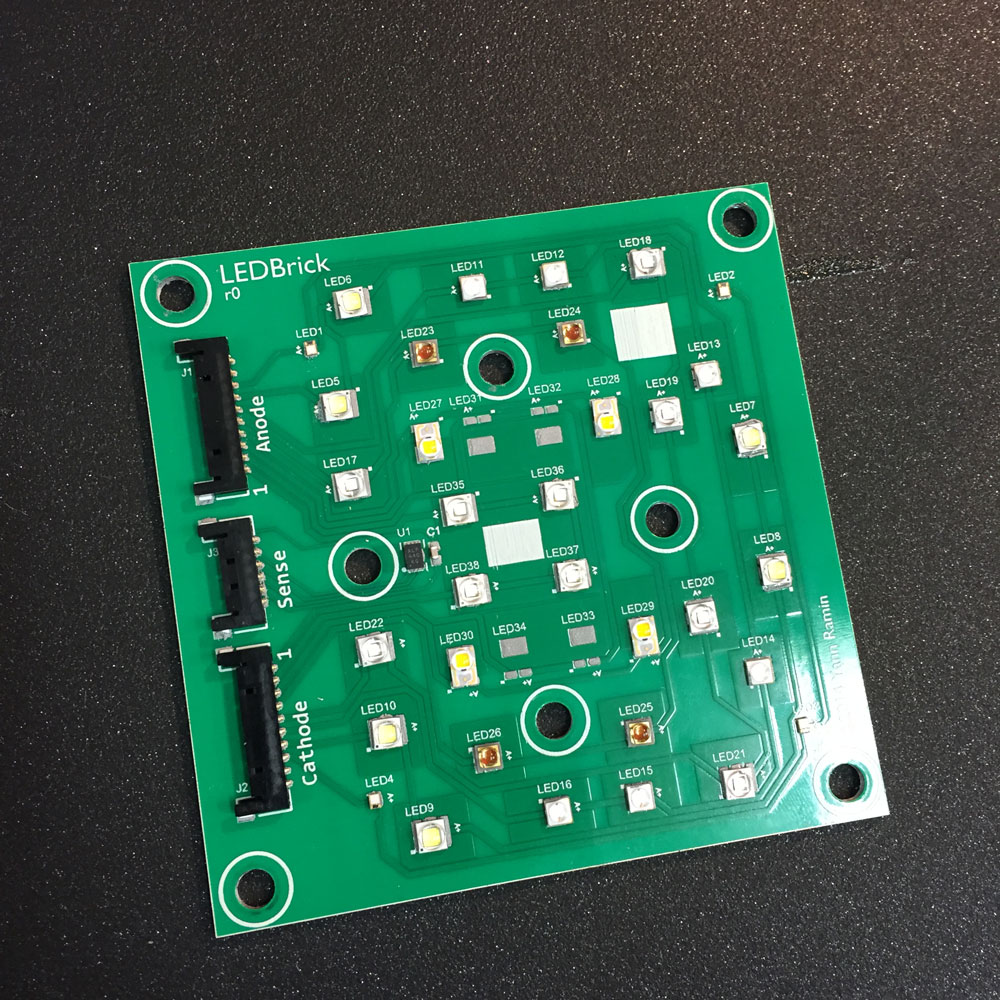

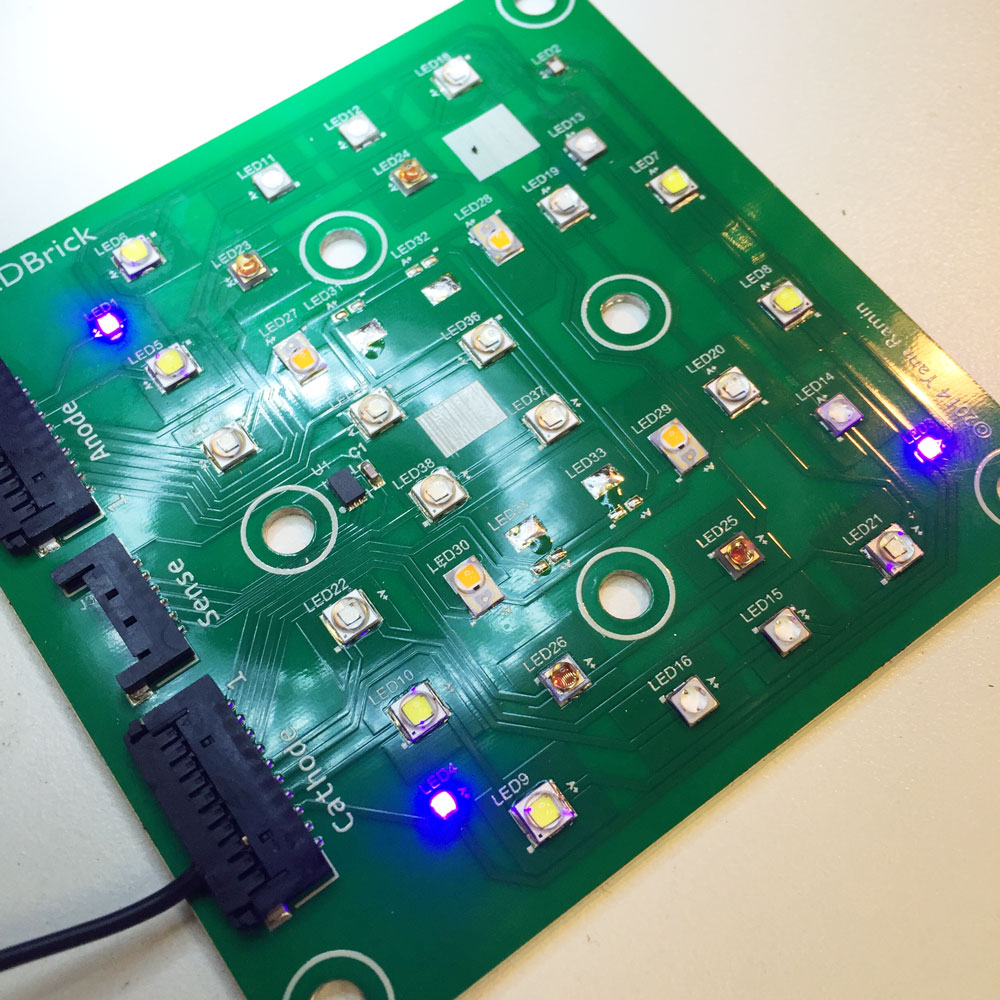

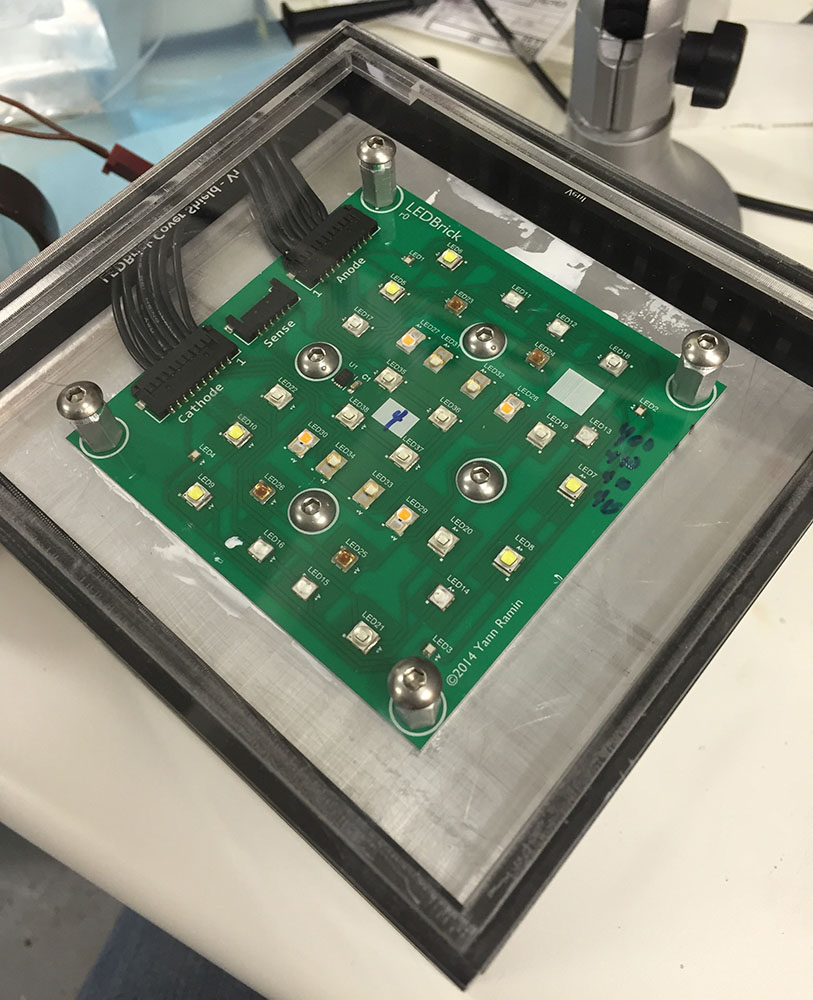

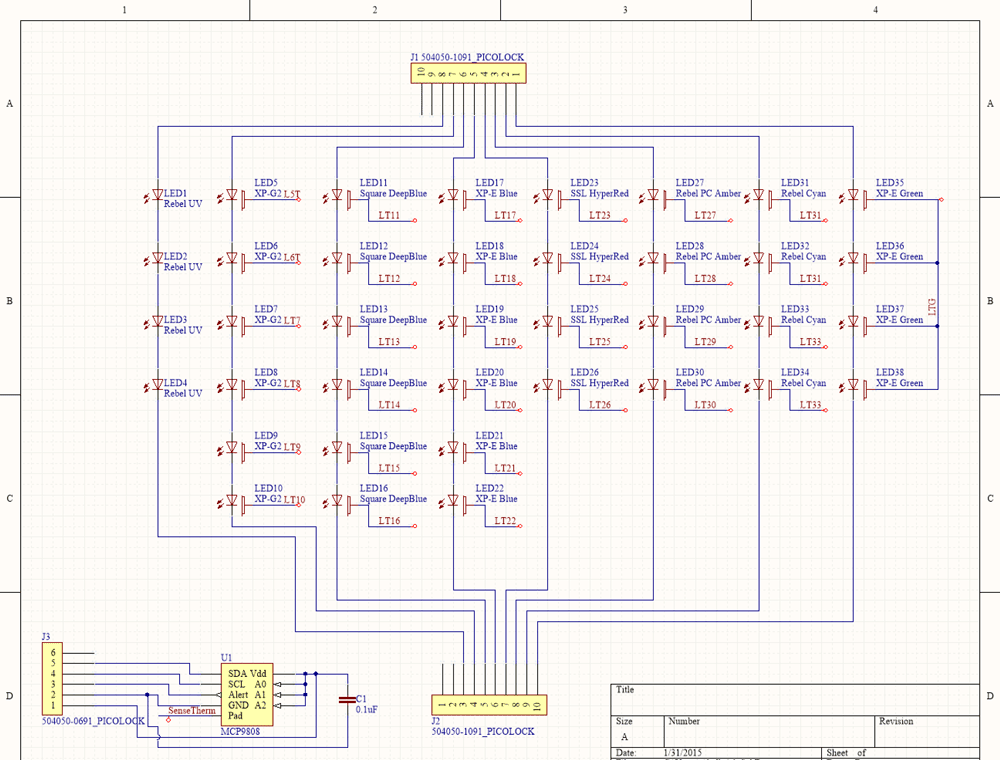

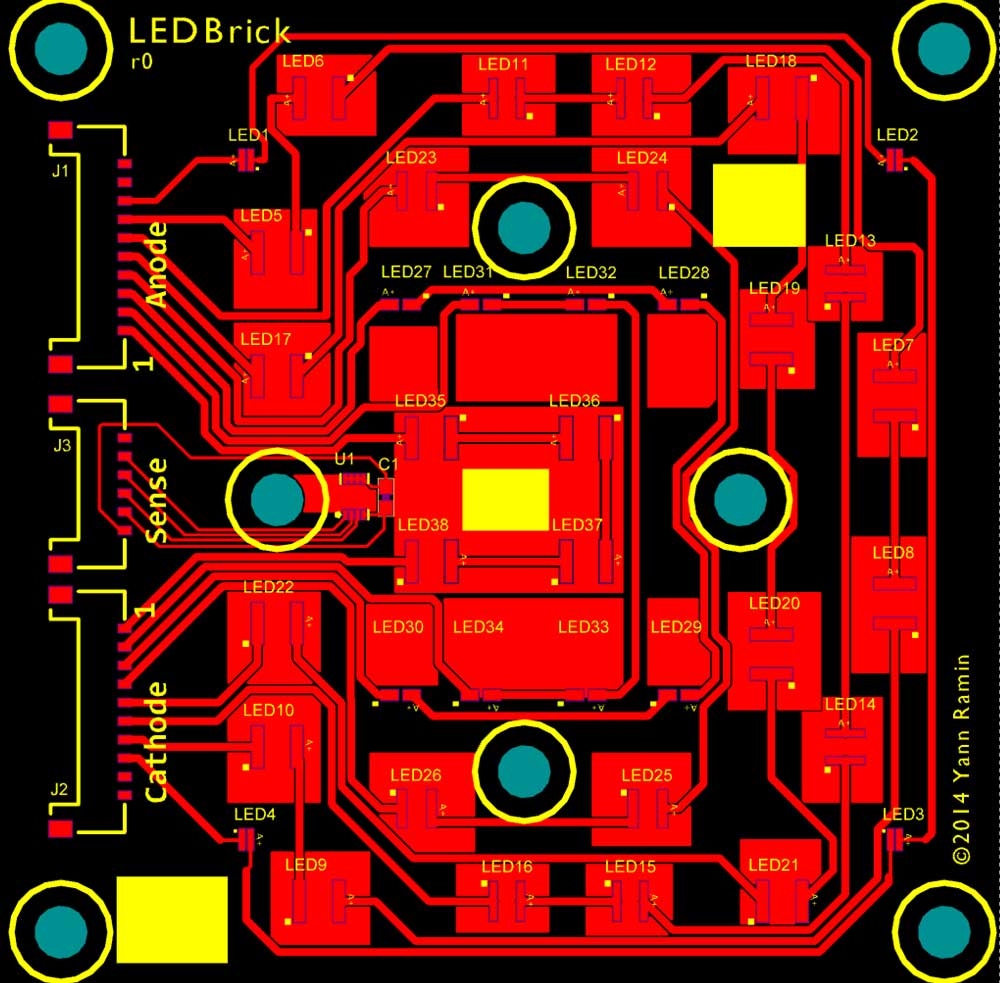

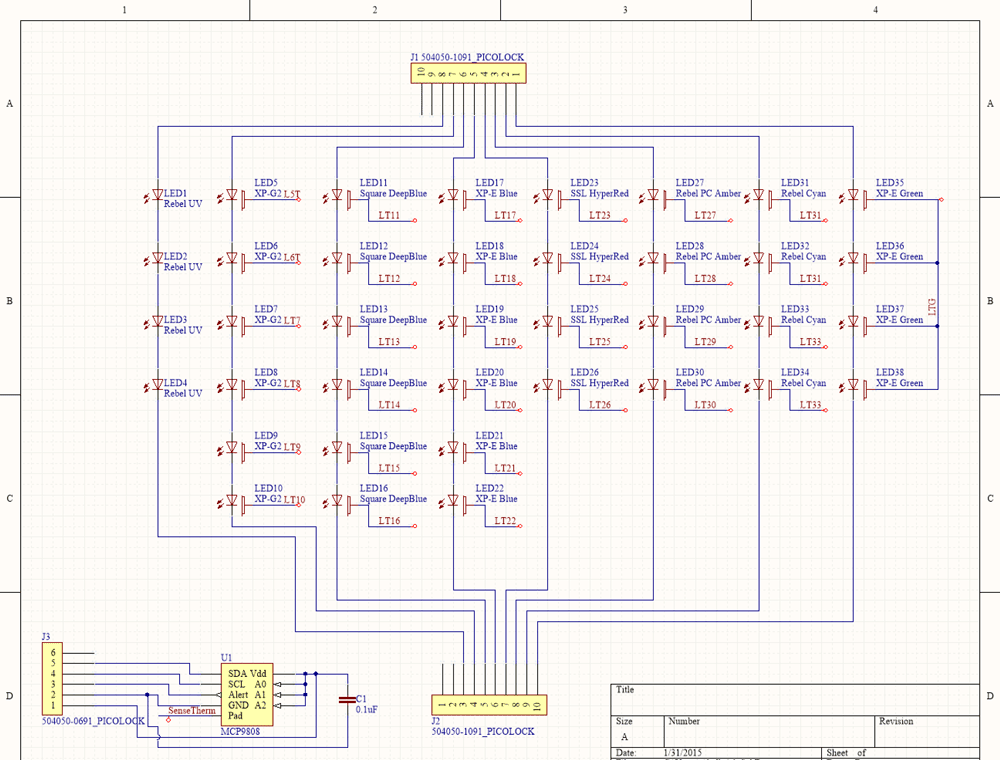

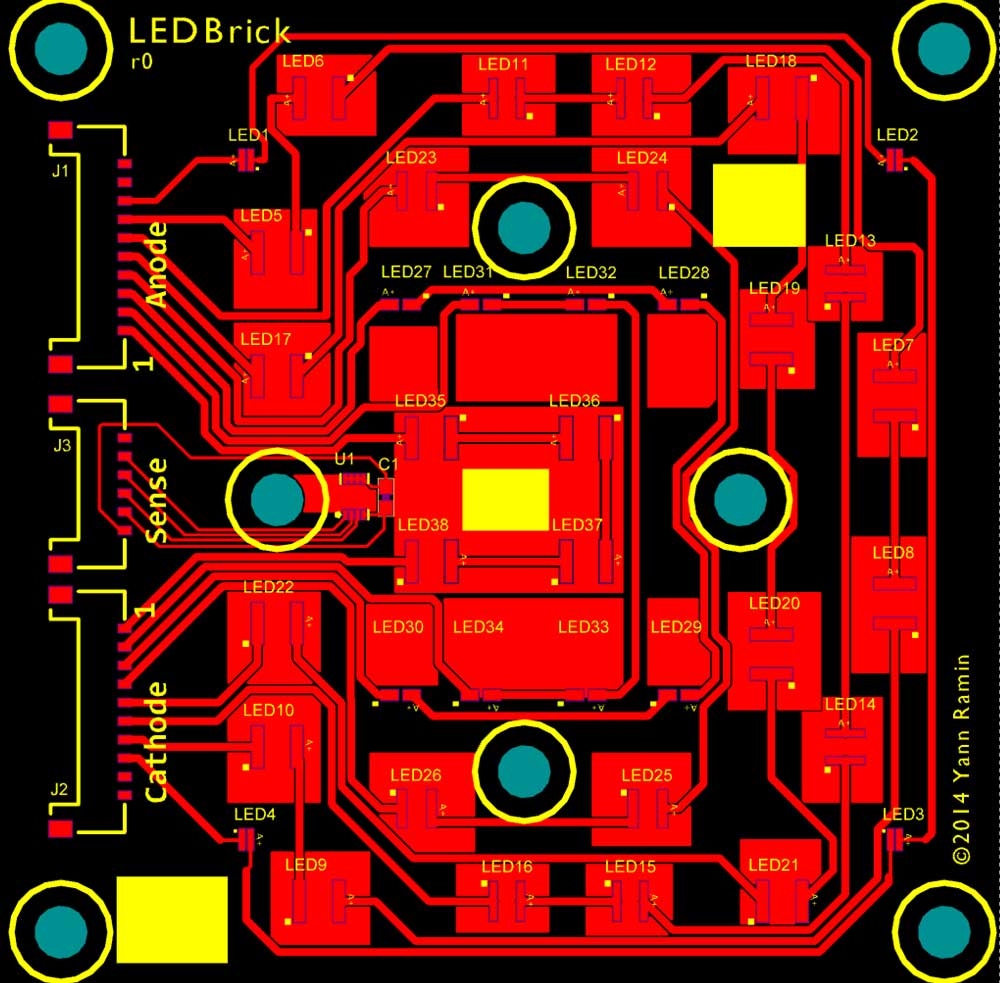

The LED arrangement I started with was this:

The pads and suggested LEDs are:

4 Rebel UV emitters (these are very expensive, but more efficient than the popular Chinese SemiLEDs emitters. They however do not have a primary optic - more on this later)

6 Cree XP-G(2) White emitters (or any Cree XP package)

6 Cree XP-E Blue emitters (or any Cree XP package)

6 Osram Oslon Squre Deep Blue emitters

4 Osram SSL Hyper-Red

4 Phillips Rebel PC-Amber

4 Phillips Rebel Cyan

4 Cree XP-E Green (or any XP)

Why so many LEDs? Lower currents, higher efficiency, and future flexibility. Remember, this is not a build-cost efficient fixture

A downside to the large emitter count is the inability to provide secondary-optics, focusing the light tighter than 120 degrees from the primary optic. The emitters are simply too close together to use most commercially available lenses, which feature large footprints. I intend to run these pendents very close to the water, which would not need the use of an optic. My later designs use a reflector with very dense LED arrangements.

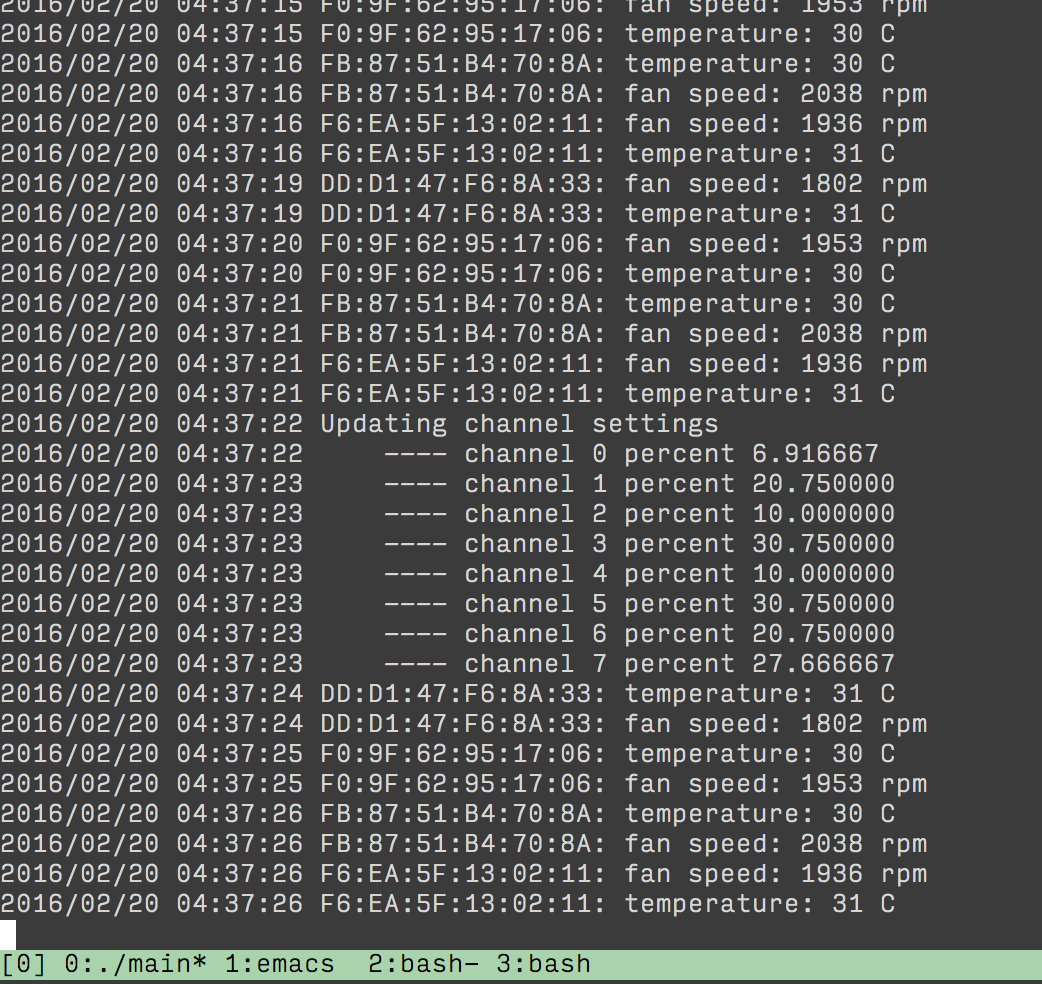

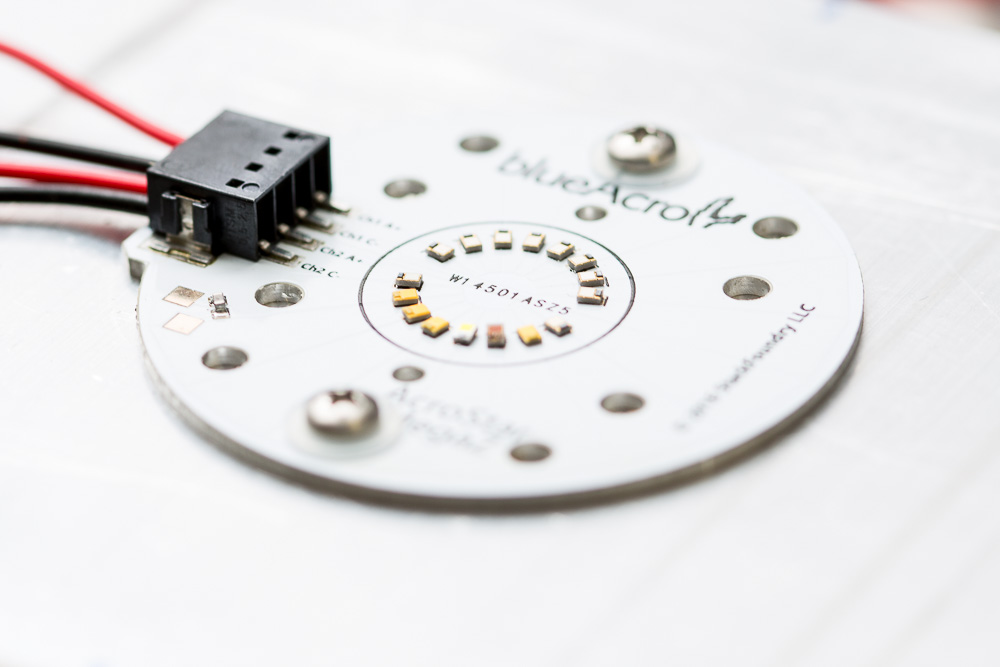

Also integral to the board is a Microchip MCP9808 I2C temperature sensor. The sensors ground pad is brought out to one of the mounting screws, in an effort to get a good thermal path.

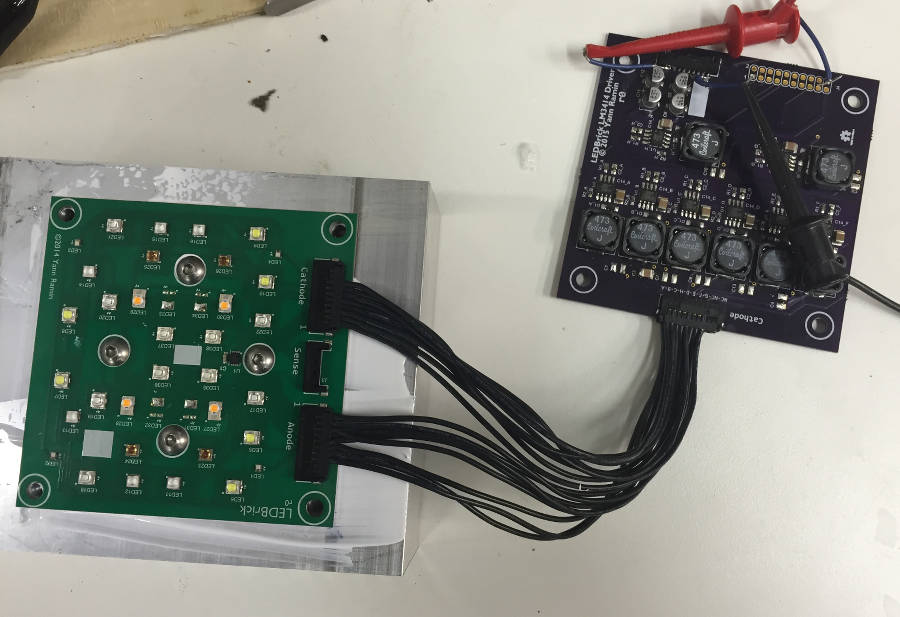

All connectors to the board are a series of Molex PicoLock blade-style high current flat wire-to-board connectors.

New design underway

-------------------------------------------

(This is my summary of a project I did over the past ~ year, in condensed form, for others to be inspired by across the reef forum community. I'm also actively working on new components, LED emitters, and drivers, but the first series of posts is on the original version).

It all started with this concept - a squareish shaped LED "brick" in a pendant form. The mechanics were based around a 4.6in HeatsinkUSA serrated stock, and an 80mm fan.

The LED arrangement I started with was this:

The pads and suggested LEDs are:

4 Rebel UV emitters (these are very expensive, but more efficient than the popular Chinese SemiLEDs emitters. They however do not have a primary optic - more on this later)

6 Cree XP-G(2) White emitters (or any Cree XP package)

6 Cree XP-E Blue emitters (or any Cree XP package)

6 Osram Oslon Squre Deep Blue emitters

4 Osram SSL Hyper-Red

4 Phillips Rebel PC-Amber

4 Phillips Rebel Cyan

4 Cree XP-E Green (or any XP)

Why so many LEDs? Lower currents, higher efficiency, and future flexibility. Remember, this is not a build-cost efficient fixture

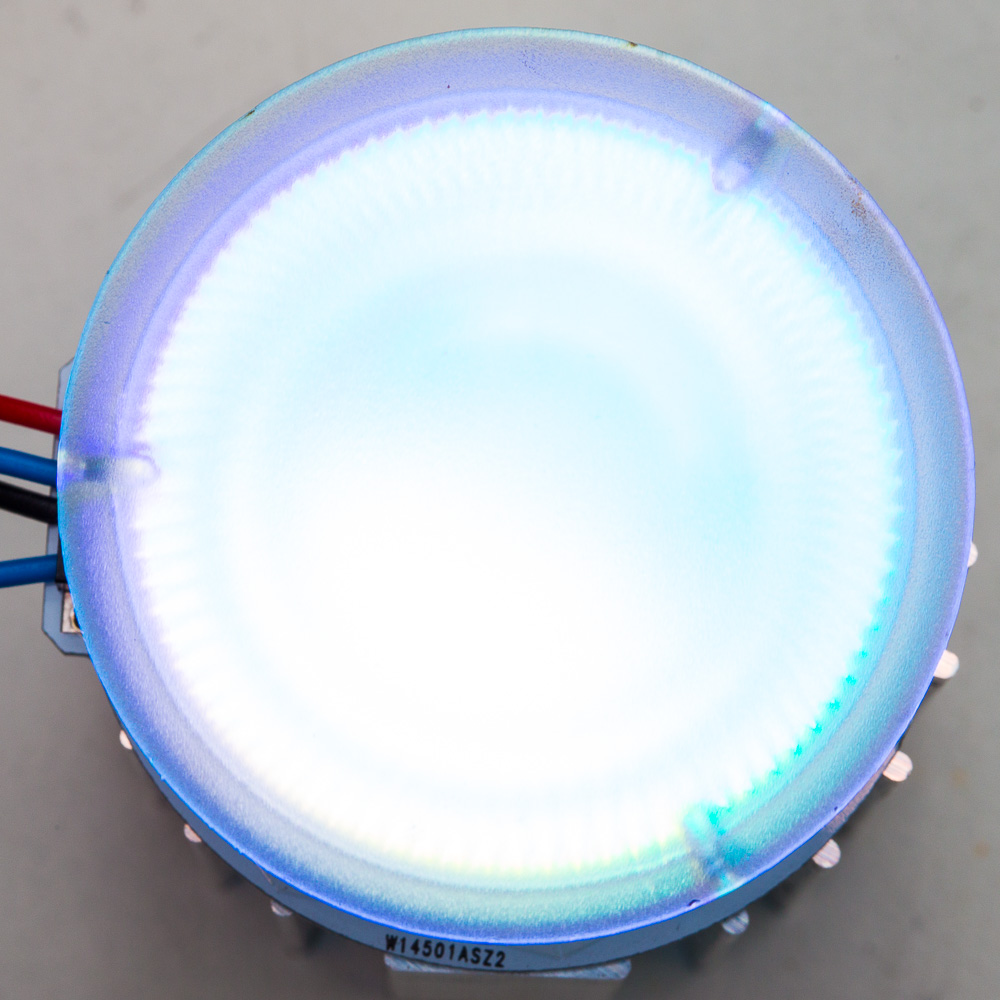

A downside to the large emitter count is the inability to provide secondary-optics, focusing the light tighter than 120 degrees from the primary optic. The emitters are simply too close together to use most commercially available lenses, which feature large footprints. I intend to run these pendents very close to the water, which would not need the use of an optic. My later designs use a reflector with very dense LED arrangements.

Also integral to the board is a Microchip MCP9808 I2C temperature sensor. The sensors ground pad is brought out to one of the mounting screws, in an effort to get a good thermal path.

All connectors to the board are a series of Molex PicoLock blade-style high current flat wire-to-board connectors.

Last edited: