Thank You and the repair/rebuild process has started.Sorry for the leak but look forward to the progress from here on

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mehaffy's 1100+ gallon Plywood display in North Alabama

- Monster Build

- Thread starter mehaffydr

- Start date

- Tagged users None

I took a few days off of working on the tank for a couple reasons one obvious was just the disappointment in the whole situation. and I just needed to be really sure I had a good goforward plan. So tonight when I got home it was go time. I first removed the rock and then the sand. It took 6 buckets to hold the sand and boy are those heavy! I then removed the plastic I had protecting the bottom and worked to get all of the water out. First with a plastic scoop and then finally just using a towel soaking it up and wringing into a bucket. Hopefully its nice and dry by morning so I can start sanding, removing glass and building the wood structure that will reinforce the front.

Thank youI’m so sorry about the leak, I know it’s got to be extremely frustrating. Wishing you all the best and sending good vibes your way - this project is absolutely amazing and really shows a ton of talent.

- Joined

- Aug 23, 2015

- Messages

- 268

- Reaction score

- 365

Tough going with the failure, but like everyone else I'm happy to see it not get you down in the long run. This tank is truly an inspiration and I know we'll all be happy to see it all fixed up!

Was the issue that the rabbit for the glass weakened the front panel too much, which in turn allowed the bowing to occur?

Was the issue that the rabbit for the glass weakened the front panel too much, which in turn allowed the bowing to occur?

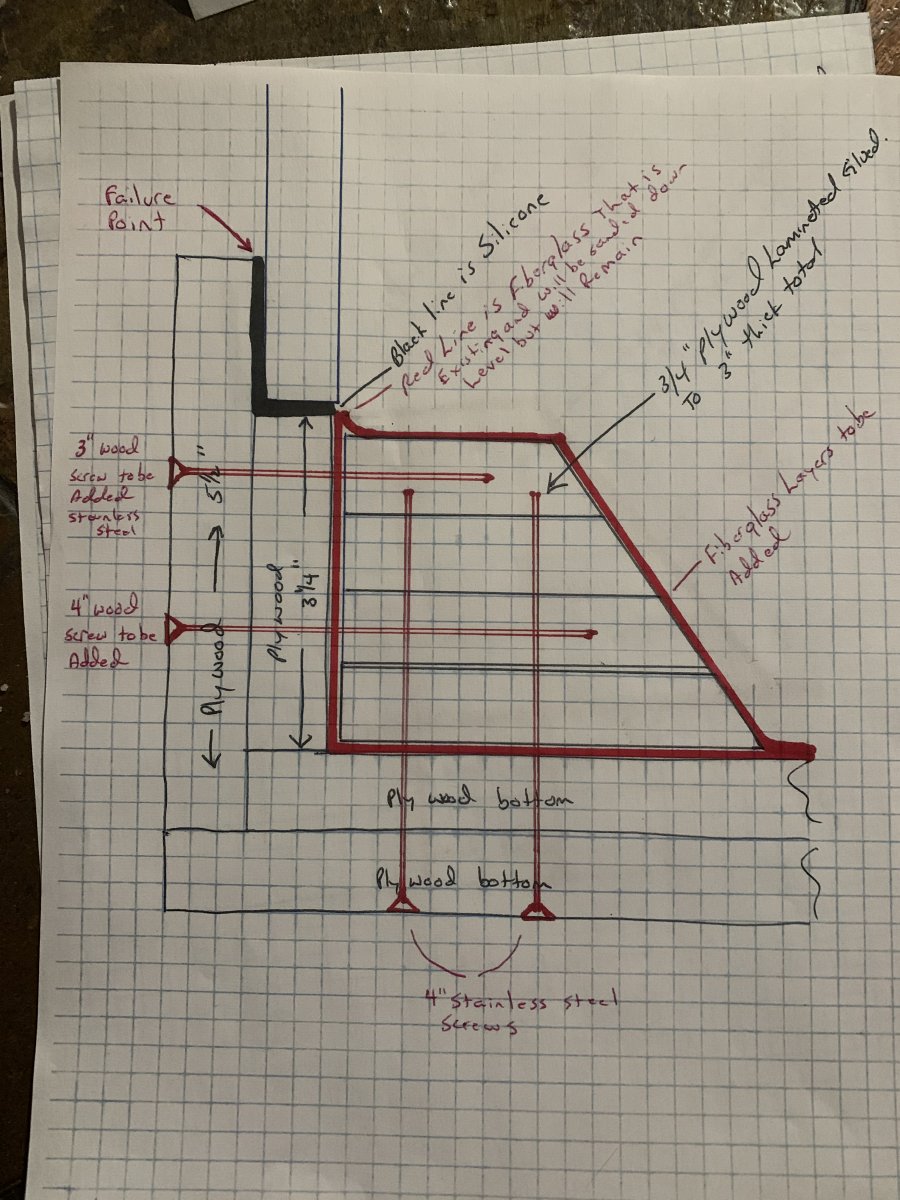

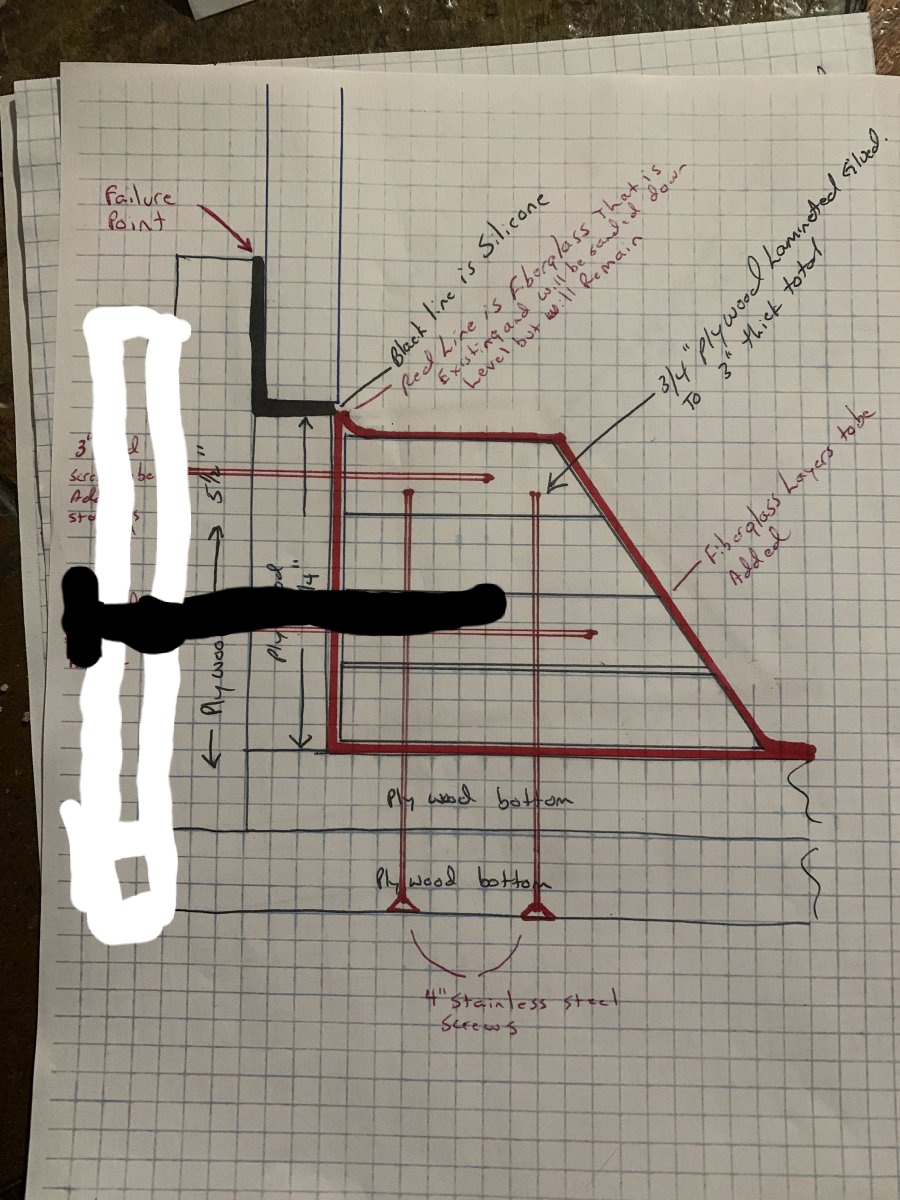

The rabbet could be part of it. But the real issue is the wood between the bottom of the glass and the bottom of the tank. I think if I would not have done the rabbet and just ran the glass all the way to the bottom it would not have failedTough going with the failure, but like everyone else I'm happy to see it not get you down in the long run. This tank is truly an inspiration and I know we'll all be happy to see it all fixed up!

Was the issue that the rabbit for the glass weakened the front panel too much, which in turn allowed the bowing to occur?

Today I started the repair work after removing all of the rock and sand last night. It was slow going and hard work I used a utility knife and slowly cut the silicone out of the inside rabbet. But still have to cut all the way around the front which will be more difficult because I can't get a knife blade in there.

I did get all the pieces of wood cut and glued together for the front support shown in the drawing. I will clean up the edges on the table saw tomorrow.

Tomorrow I will continue to work to get the glass removed. Things should move pretty fast once I get the glass out.

.

I did get all the pieces of wood cut and glued together for the front support shown in the drawing. I will clean up the edges on the table saw tomorrow.

Tomorrow I will continue to work to get the glass removed. Things should move pretty fast once I get the glass out.

.

I am happy with what I was able to get done this weekend. Removing the glass was a lot of work but I anticipated that and it went as well as I could have hoped. I bought a new blade for my Dremel that had some good teeth. The basic one had too fine of teeth and was not getting uch progress so I went to the store and found one with much more aggressive teeth. This was the ticket for getting the outer silicone seal cut. Took about 6 hours to do the whole thing.

The front glass is out. After a long day cutting silicone I was finally able to get the glass out. This was a little tricky getting it out and lowering it down. I was by myself and this piece is close to 300 lbs. I use the boards for support and slowly eased it down a little bit at a time until I had it all the way flat. Now I will start the install of the from reinforcing piece fiberglass and repaint. Then reinstall glass and start over with new water test.

Wow, you had quite the day, that is a truck load of work! Brilliant with the boards. I imagine that pane being both really heavy and awkward. Stinks doing that kind of stuff alone. Also, just want to add that you are an inspiration!

sorry to see what happen to the tank

but now better than later

at less there is no livestock still so that a point for you

hope you get back to it very soon

but now better than later

at less there is no livestock still so that a point for you

hope you get back to it very soon

Thank You and don't worry I'm back at it full force. This tank will hold water just needs a little extra reinforcement.sorry to see what happen to the tank

but now better than later

at less there is no livestock still so that a point for you

hope you get back to it very soon

Tonight after work I started sanding. I am sanding the area that is getting the reinforcing section. I thought it best to sand down the epoxy paint before fiberglassing it in. I will be installing the reinforcing section tomorrow with fiberglass and the lag screws like I have in the drawing.

This Epoxy I used from Sherwin Williams is unbelievably hard. It was very difficult to sand through. I was sanding with a heavy Duty Porter Cable Belt sander and 80 grit belts and I worked on it for at least 2 hours just to sand this section 10' x about 6". Oh and this is what you look like after sanding Black Epoxy for 2 hours.

This Epoxy I used from Sherwin Williams is unbelievably hard. It was very difficult to sand through. I was sanding with a heavy Duty Porter Cable Belt sander and 80 grit belts and I worked on it for at least 2 hours just to sand this section 10' x about 6". Oh and this is what you look like after sanding Black Epoxy for 2 hours.

If that is not a face of hard tank work I am not sure what is. Congrats on your amazing build and sorry for the minor setback

One thing I have realized is that there is really no need for the plastic sheet i put under the rock work as hard as this epoxy was to sand there's no way the rocks will scratch through it. I will go ahead and use it because I have it and a falling rock could possibly do damage but I'm pretty sure it would not.

I was able to make some good progress today getting the reinforcement piece installed. First I laid down a nice thick layer of shredded fiberglass and resin. I then laid the wood in and clamped it in place. I then drill and installed the lag screws. Next I will need to lay 3-4 layers of fiberglass over the top to seal in the wood and then repaint Epoxy and install glass.

That piece of steel clamped on there is just to hold everything straight while the resin cures it will be removed tomorrow when I start laying on the top layers of fiberglass.

That piece of steel clamped on there is just to hold everything straight while the resin cures it will be removed tomorrow when I start laying on the top layers of fiberglass.

Happy to see that this didn't demolish your spirit! It's hard from my screen to even be patient - I can't imagine how much you're wanting to just be able to enjoy the spoils of all this work!

Progress is happening. This evening I was able to lay down 1 layer of fiberglass and resin on the corner reinforcement. I will do at least 4 layer and maybe more before a paint with the epoxy paint. I will do 1 layer of fiberglass per day and them 1 coat of paint per day so about 8-10 days before I will be ready to reinstall the glass. I also received the new pump cover from Reeflo for my Tigershark pump so I installed that on the pump. I will put the pump in place sometime before refilling the tank as I would like the extra flow and I will keep the Hammerhead as a spare.

Tonight I laid down the second layer of fiberglass and resin on the corner brace. I also installed new bulbs in all of my fixtures. SO all new MH 4ea 250watt and 14ea. 39watt T-5. Other than that not a lot to do just lay down fiberglass and wait to dry. Ill be doing that a lot over the next week with finishing the fiberglass and then epoxy paint. I am thinking I may be installing glass next weekend.

Thanks for the input all ideas are always welcome. I'm just not sure if this would add much additional structural strength especially if I use wood. Wood on its side like that does not really offer much stability it will most likely just flex. Not sure about some kind of metal? If metal I think it would need to be some type of angle or it would most likely just flex also. I have actually considered building a wall up the front so that I could have 2x4's or 2x6's perpendicular to the tank face around the opening.I like the idea of the internal brace, i think that will do a lot do eliminate pressure warping. The only other idea i had would be to whaler it out with a brace on the outside. But, that would give you a lip. Forgive my crude rendition. The white would be whatever ridgid material you fancy, maybe 8020 aluminum or a 2x6 that would be lag bolted to your internal brace to sandwich it all together.

Or maybe even carry it the whole width if the frame so its flush with the socket for the glass and the bottom of the frame. So it will look like it belongs.

HTH

I have to admit that this was a very disappointing set back but its going to take a lot worse than this to get me down. It is just disappointing because I expected to have fish swimming in this tank right now. But one thing that this hobby does teach you is patience.Happy to see that this didn't demolish your spirit! It's hard from my screen to even be patient - I can't imagine how much you're wanting to just be able to enjoy the spoils of all this work!

Similar threads

- Replies

- 117

- Views

- 3,246

- Replies

- 9

- Views

- 280

New Posts

-

-

-

I'm preparing to set up a CO2 scrubber, and I have some questions...

- Latest: penguinexdeus