Hi everyone, I'd like to share with you my first post and build thread for my latest reef concept. Something that will set this system apart is that there will be as much (if not more) attention placed on the asthetics outside of the main display as within it.

Focus will be placed on redundancy, proven methods, and a simple approach.

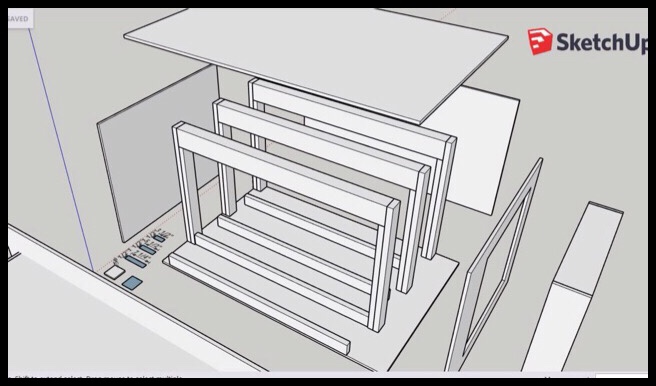

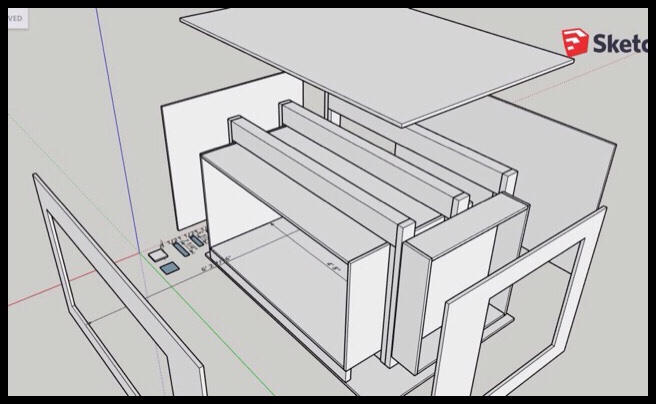

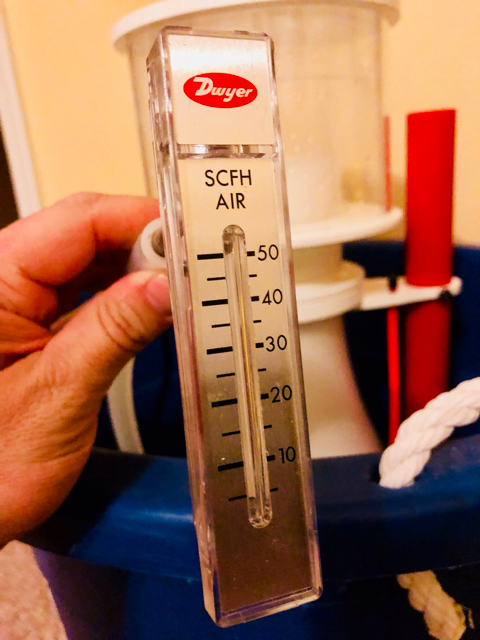

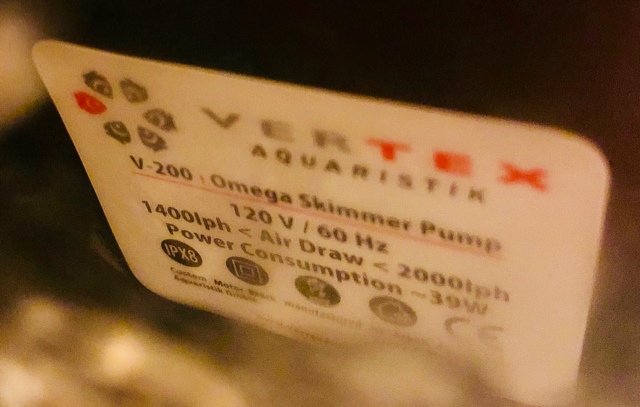

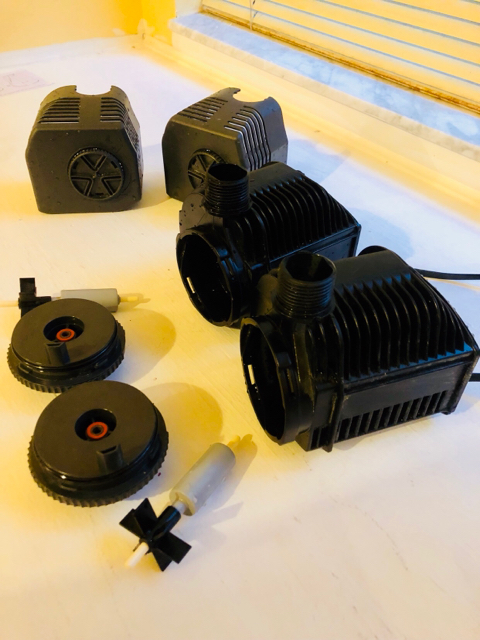

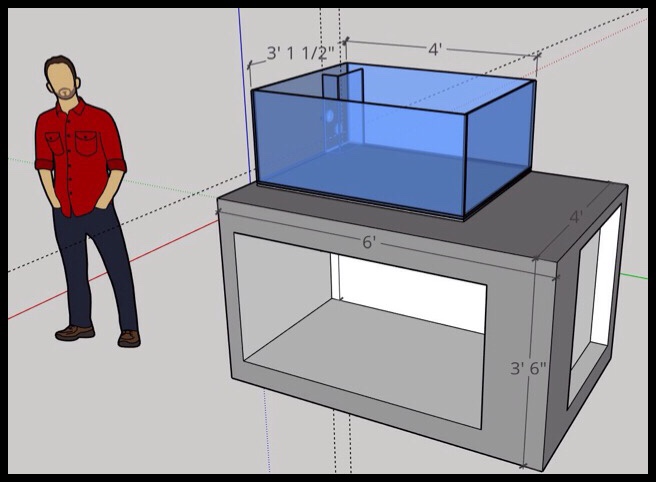

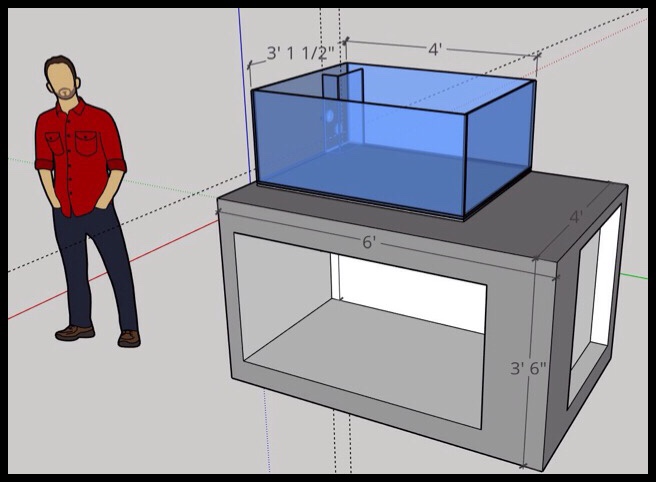

The display will be 48"x38"x20" high, and will boast an oversized open stand, large sump, large skimmer, large refugium, dual AC return pumps, halides, and some really cool plumbing. Didn't think we could make plumbing cool? Stay tuned!!

For inhabitants, the corals will be predominately SPS mixed, with a large bio load of fish to include two shoals,and a centerpiece angelfish.

I hope you will share with me your thoughts and knowledge, and also help keep me from making any mistakes!

This is all for now. I will update with pics and info as I have it. Enjoy, and join in.

Focus will be placed on redundancy, proven methods, and a simple approach.

The display will be 48"x38"x20" high, and will boast an oversized open stand, large sump, large skimmer, large refugium, dual AC return pumps, halides, and some really cool plumbing. Didn't think we could make plumbing cool? Stay tuned!!

For inhabitants, the corals will be predominately SPS mixed, with a large bio load of fish to include two shoals,and a centerpiece angelfish.

I hope you will share with me your thoughts and knowledge, and also help keep me from making any mistakes!

This is all for now. I will update with pics and info as I have it. Enjoy, and join in.

Last edited: