I have a fixture that I retro'ed the 3watt diodes pictured below. Simple process of unsoldering the Mfgr diode and resolderiing my choice of diode in whatever nm color

PROBLEM: Fixture doesn't seem to have good enough ventilation to keep my 420nm diodes operating temp cool.

I know 420nm run SUPER hot.

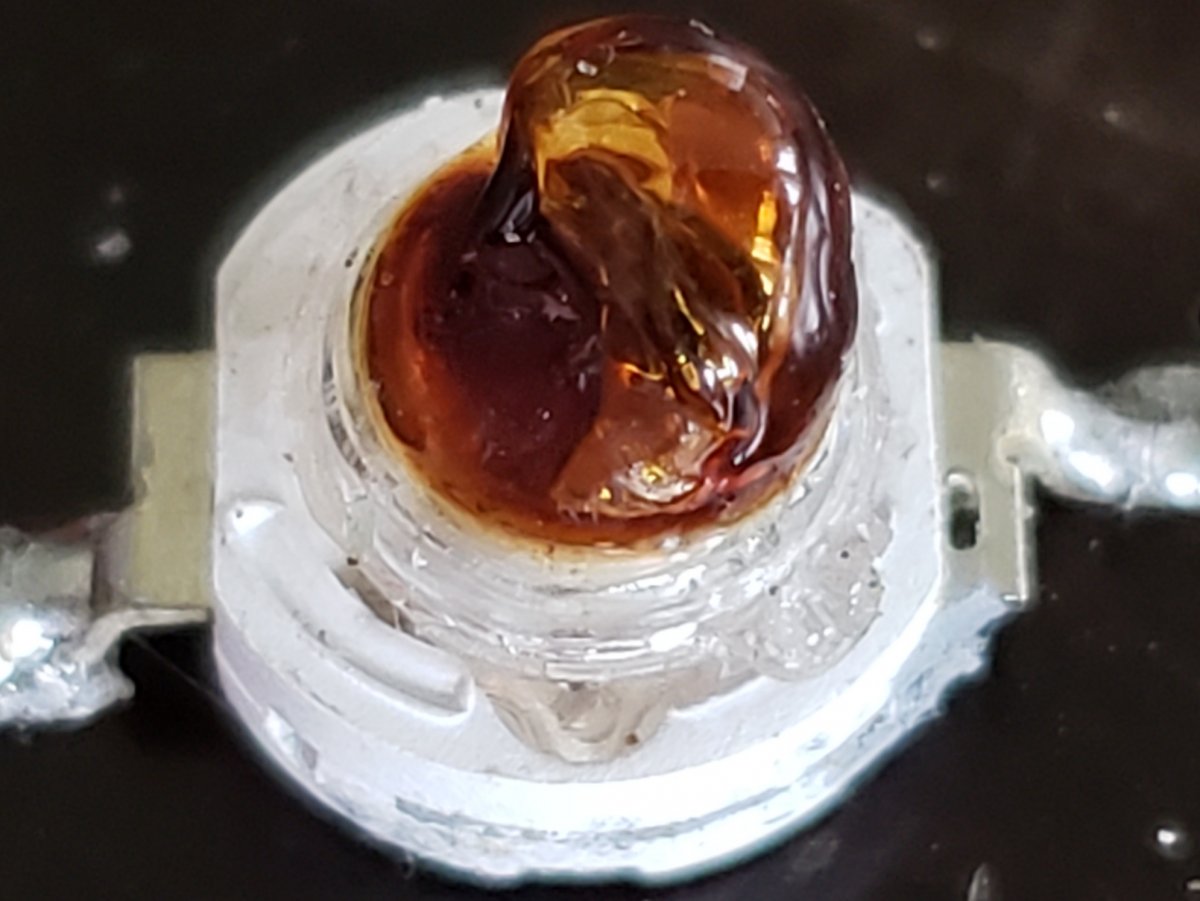

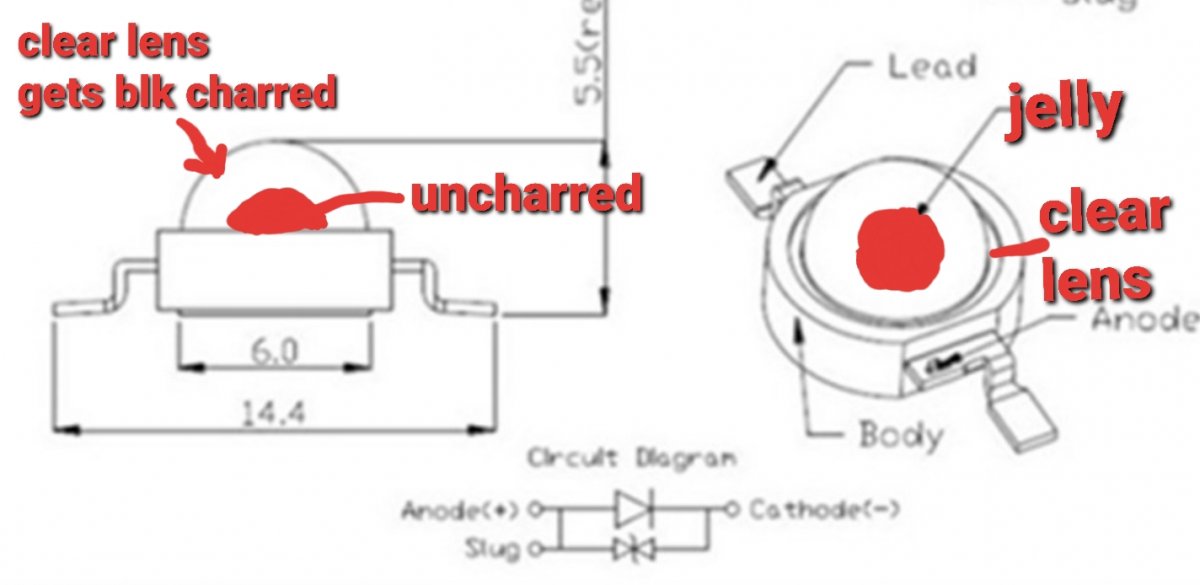

After about 60-90 days the tiny CLEAR LENS that caps the diode onto thediode, get Black and charred from overheating

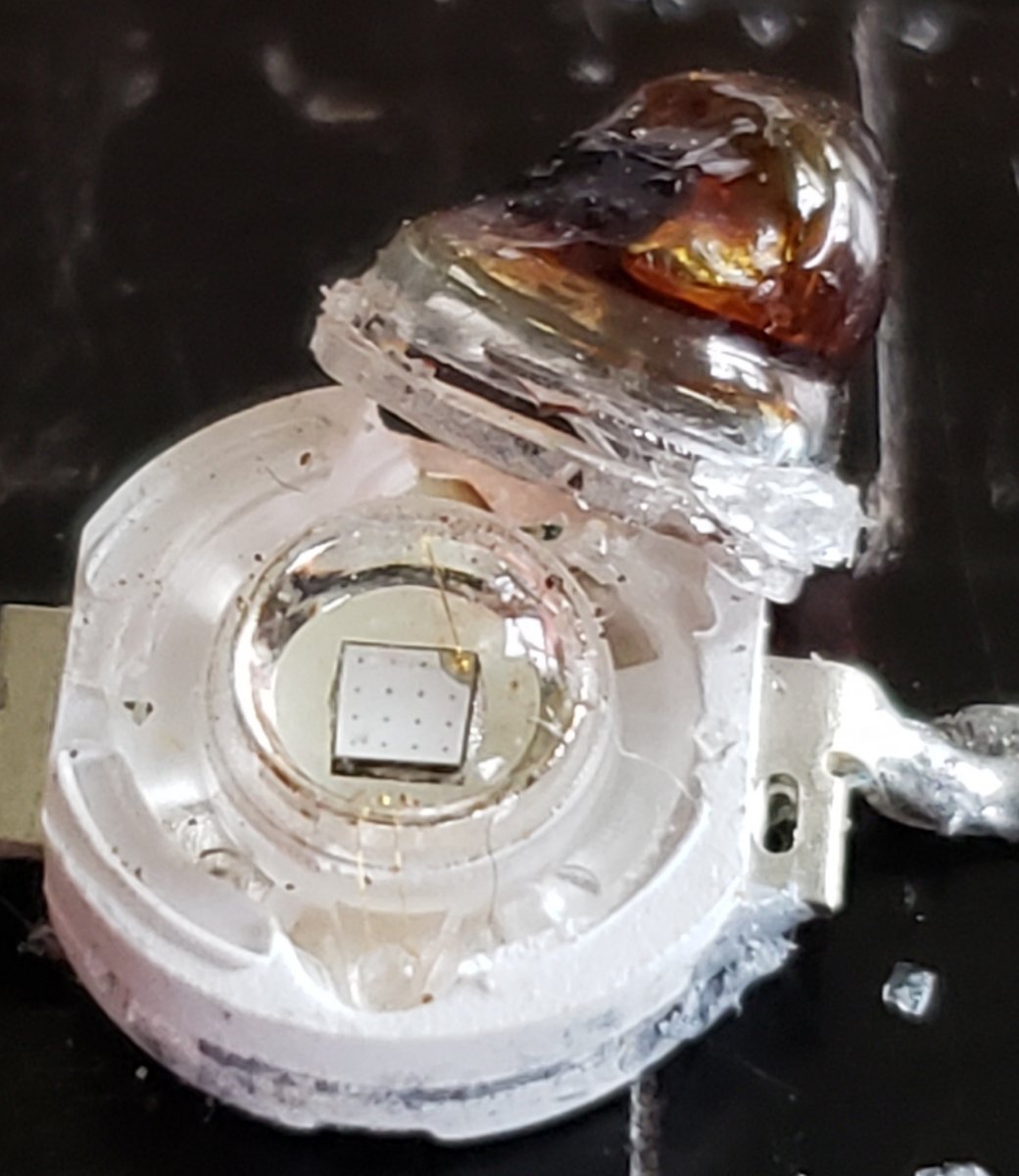

BUT! I'm noticing if I pry off the CLEAR LENSE the diode still has a JELLY-like substance surrounding the diode chip. That's represented as the RED BLOB I put in the diagram below

QUESTIONs:

If I removed the charred clear lens and left the diode with the Jelly bubble and just silicone sealed the LENS CAP back on (picturedbelow)...what am I to expect?

Diode goes on being a diode for a long time?

Diode overheats and burns out?

The Jelly gets contaminated and destroys the diode chip?

Ideas?

PROBLEM: Fixture doesn't seem to have good enough ventilation to keep my 420nm diodes operating temp cool.

I know 420nm run SUPER hot.

After about 60-90 days the tiny CLEAR LENS that caps the diode onto thediode, get Black and charred from overheating

BUT! I'm noticing if I pry off the CLEAR LENSE the diode still has a JELLY-like substance surrounding the diode chip. That's represented as the RED BLOB I put in the diagram below

QUESTIONs:

If I removed the charred clear lens and left the diode with the Jelly bubble and just silicone sealed the LENS CAP back on (picturedbelow)...what am I to expect?

Diode goes on being a diode for a long time?

Diode overheats and burns out?

The Jelly gets contaminated and destroys the diode chip?

Ideas?

Last edited: