Don’t cut yourself.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

oh boy, 40g breeder build

- Build Thread

- Thread starter count krunk

- Start date

- Tagged users None

waiting on reply from glass shops, I've found a third option.

I have a 7" circular saw and found some glass tile cutting diamond saw blades for $30.

Will probably end up going that route depending on cost from shops.

I have a 7" circular saw and found some glass tile cutting diamond saw blades for $30.

Will probably end up going that route depending on cost from shops.

Well!

Two different glass cutting attempts, two failures. Will go with a shop for $5/cut for the rest of the sump build.

I leveled out the glass on the table where I would be cutting it. I think a problem was getting water to it. I used a water hose with a wand on spray, the saw creates a good amount of wind and was blowing the water away from the blade, so it wasn't getting as wet as I would have liked. It was cutting well for about 2" then I think got too dry and the glass split.

I was wearing nice safety glasses and work gloves, as well as long sleeves so I was well protected. No explosion of shards or anything.

Equipment used

The aftermath

You can also see some chipping in the very beginning. When i go for attempt #3, I will need to employ the use of a tile saw. I considered getting a 10" blade for my miter saw, but don't want to mess that saw up as it is much more valuable than my 7" skill circular saw.

I will go with something like this for # 3, but not sure when that will be.

Two different glass cutting attempts, two failures. Will go with a shop for $5/cut for the rest of the sump build.

I leveled out the glass on the table where I would be cutting it. I think a problem was getting water to it. I used a water hose with a wand on spray, the saw creates a good amount of wind and was blowing the water away from the blade, so it wasn't getting as wet as I would have liked. It was cutting well for about 2" then I think got too dry and the glass split.

I was wearing nice safety glasses and work gloves, as well as long sleeves so I was well protected. No explosion of shards or anything.

Equipment used

The aftermath

You can also see some chipping in the very beginning. When i go for attempt #3, I will need to employ the use of a tile saw. I considered getting a 10" blade for my miter saw, but don't want to mess that saw up as it is much more valuable than my 7" skill circular saw.

I will go with something like this for # 3, but not sure when that will be.

Well!

Two different glass cutting attempts, two failures. Will go with a shop for $5/cut for the rest of the sump build.

I leveled out the glass on the table where I would be cutting it. I think a problem was getting water to it. I used a water hose with a wand on spray, the saw creates a good amount of wind and was blowing the water away from the blade, so it wasn't getting as wet as I would have liked. It was cutting well for about 2" then I think got too dry and the glass split.

I was wearing nice safety glasses and work gloves, as well as long sleeves so I was well protected. No explosion of shards or anything.

Equipment used

The aftermath

You can also see some chipping in the very beginning. When i go for attempt #3, I will need to employ the use of a tile saw. I considered getting a 10" blade for my miter saw, but don't want to mess that saw up as it is much more valuable than my 7" skill circular saw.

I will go with something like this for # 3, but not sure when that will be.

Sorry to see.

I just had this old beat up 55g and wanted to try my hand at cutting sheets of it down. It was much too thick for the cutting tool wheel thing, and i wasn't steady enough with a circular saw. Def need a table saw for glass sheets I am thinking.

I'll check out the glass at HD/Lowes and see how that compares to getting the rest of the 55g glass cut to size by a glass shop.

Just wanted to try something new! Glass worker I am not haha. Drilling is no problem, cutting, different story!

Will hopefully have the sump complete or at least glass cut in 1-2 weeks. Will update again with some good sump news next!

I'll check out the glass at HD/Lowes and see how that compares to getting the rest of the 55g glass cut to size by a glass shop.

Just wanted to try something new! Glass worker I am not haha. Drilling is no problem, cutting, different story!

Will hopefully have the sump complete or at least glass cut in 1-2 weeks. Will update again with some good sump news next!

- Joined

- Jul 5, 2018

- Messages

- 382

- Reaction score

- 185

I tried to cut the glass twice before I found out about them cutting it for me... cracked it both timesI just had this old beat up 55g and wanted to try my hand at cutting sheets of it down. It was much too thick for the cutting tool wheel thing, and i wasn't steady enough with a circular saw. Def need a table saw for glass sheets I am thinking.

I'll check out the glass at HD/Lowes and see how that compares to getting the rest of the 55g glass cut to size by a glass shop.

Just wanted to try something new! Glass worker I am not haha. Drilling is no problem, cutting, different story!

Will hopefully have the sump complete or at least glass cut in 1-2 weeks. Will update again with some good sump news next!

no progress (holidays) but goodies have arrived

Going to also use some Jebao powerheads, will update a year in to see how the Jebao play worked out

- Jebao 4000 1000 GPH at max output (will use for return, will see how it handles manifold, may need another one for that)

- IM Aqua Gadget ATO

- American DJ 8 plug power strip w/individual switches

- Jebao 4 channel doser

- Ozone machine

Going to also use some Jebao powerheads, will update a year in to see how the Jebao play worked out

- Joined

- Jul 5, 2018

- Messages

- 382

- Reaction score

- 185

I’m thinking about a jaebo pp8 for my 40b let me know how it goes! What kind of overflow are you doing? What kind of overflow are you doing?no progress (holidays) but goodies have arrived

Changed mind on next steps, going to build the stand next, install the overflow, then build the sump to ensure it lines up how I want.

- Jebao 4000 1000 GPH at max output (will use for return, will see how it handles manifold, may need another one for that)

- IM Aqua Gadget ATO

- American DJ 8 plug power strip w/individual switches

- Jebao 4 channel doser

- Ozone machine

Going to also use some Jebao powerheads, will update a year in to see how the Jebao play worked out

I will be using this overflow with a bean animal drain setup.

the over flow is in! a door rehab project is all that is standing between me and a stand build. That should be done in 2-3 weeks.

For the sump i decided i would get thin glass from HD and have them cut it, or cut it myself via the scoring snapping method.

Here are some pics of the overflow. It is a fiji cube 1200 GPH 3 hole external overflow and it is SICK. came with all the bulkheads needed (5) and the glass hole bit and the hole drilling template. the template is on some sort of plastic, it is very tough.

The overflow overall has EXCELLENT build quality. Nice think, beveled edges where needed. Very slick. Will leave an official review on their website once I get it up and running.

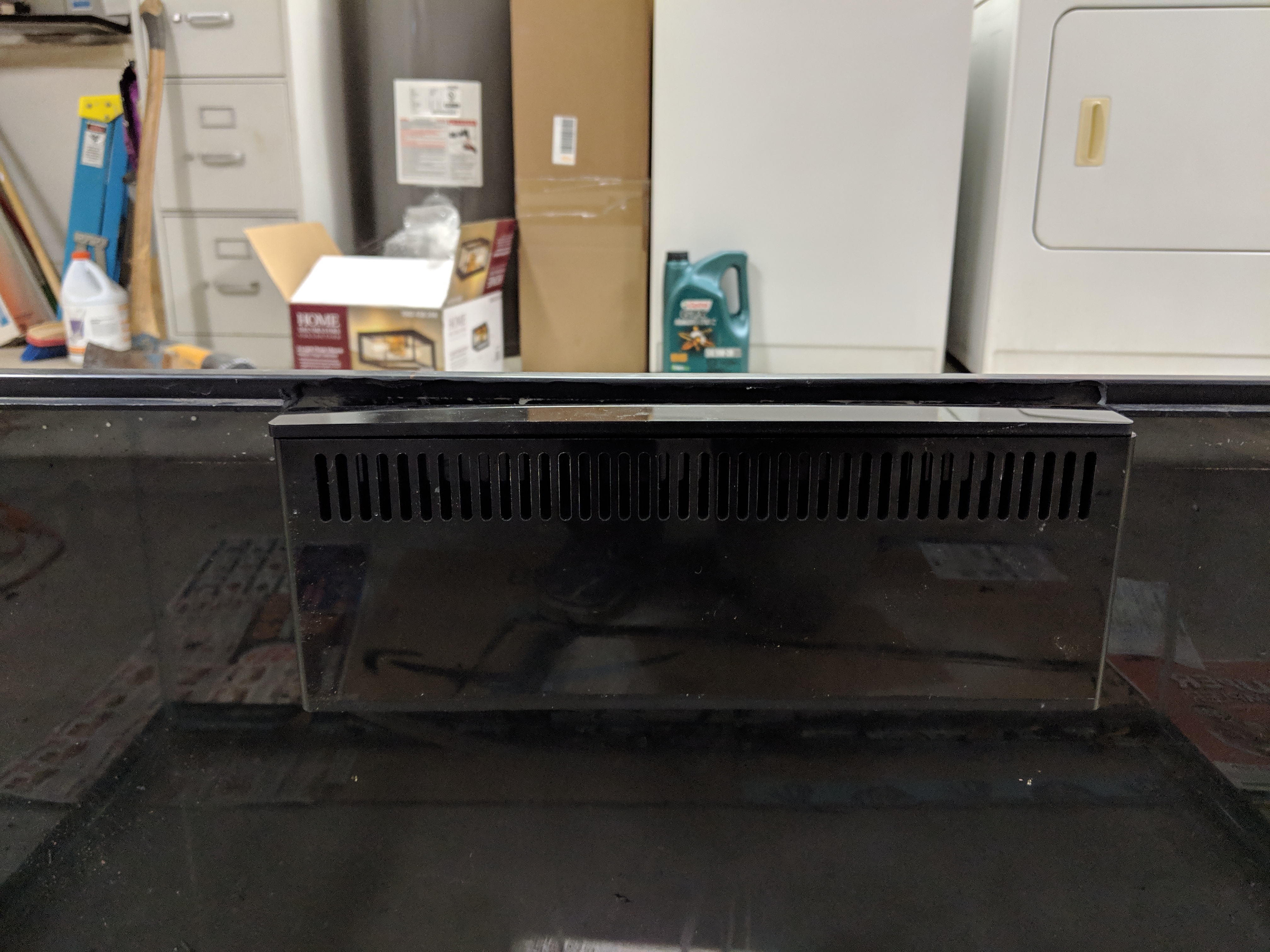

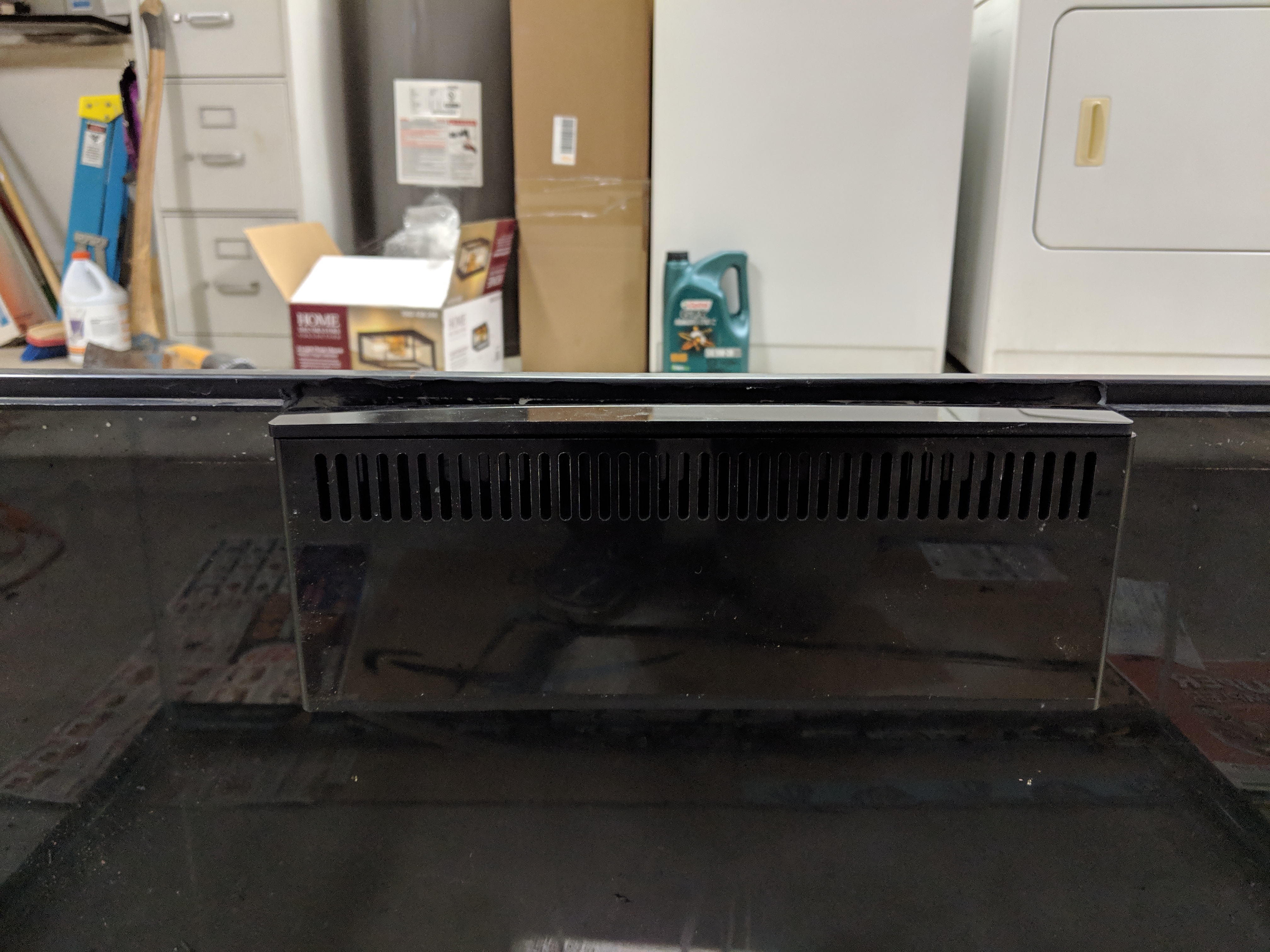

front

side

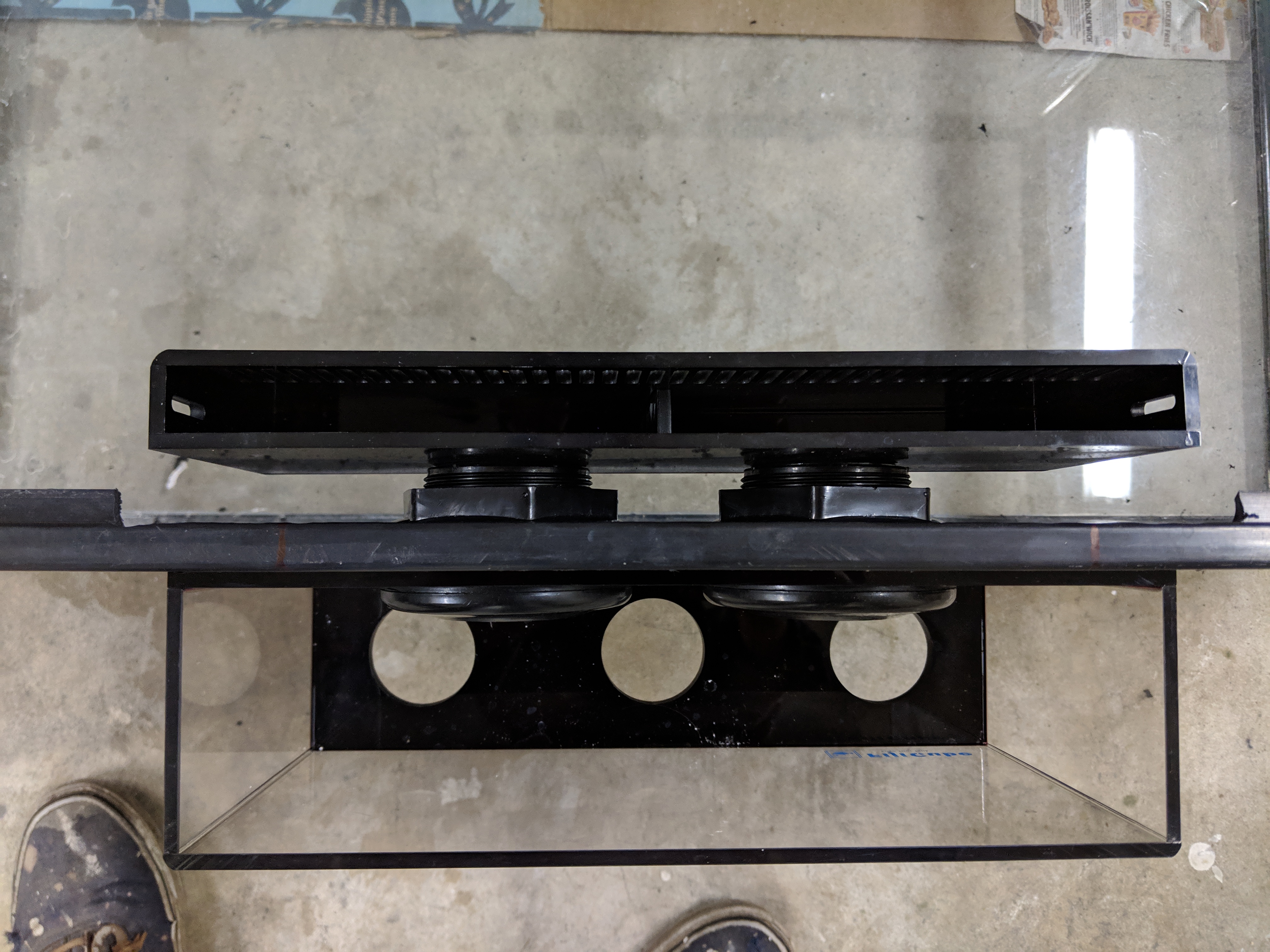

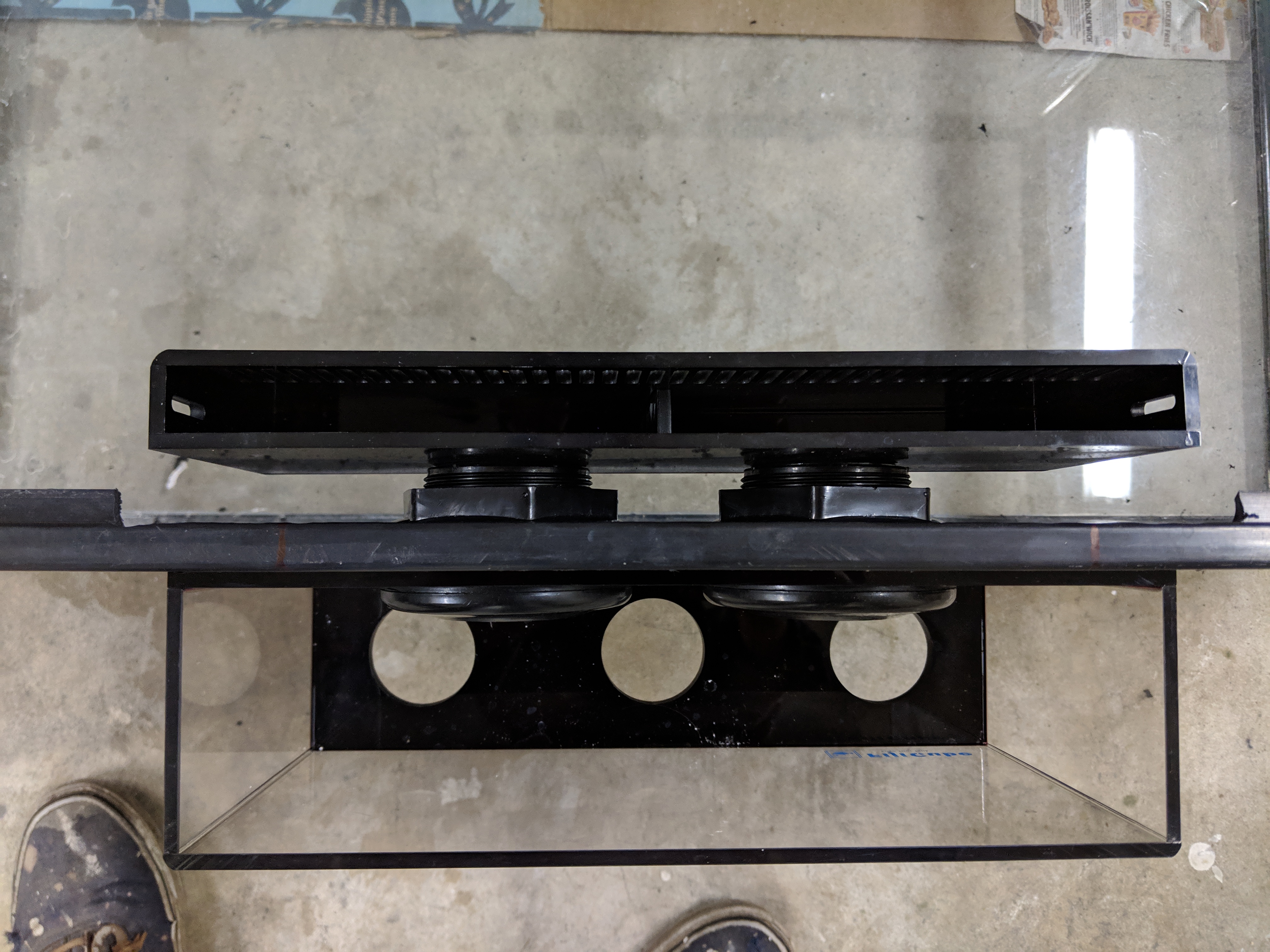

top

lids

the drain overflows plus hole saw

all this for $99, that included shipping as well. AND i would rather have this than a bulkhead less $180 synergy

For the sump i decided i would get thin glass from HD and have them cut it, or cut it myself via the scoring snapping method.

Here are some pics of the overflow. It is a fiji cube 1200 GPH 3 hole external overflow and it is SICK. came with all the bulkheads needed (5) and the glass hole bit and the hole drilling template. the template is on some sort of plastic, it is very tough.

The overflow overall has EXCELLENT build quality. Nice think, beveled edges where needed. Very slick. Will leave an official review on their website once I get it up and running.

front

side

top

lids

the drain overflows plus hole saw

all this for $99, that included shipping as well. AND i would rather have this than a bulkhead less $180 synergy

could it be? progress?? yes!! this build is finally cranking up.

I'm building the stand out of 2x2's, 1/2 ply for top and bottom, and 1/4 ply for sides and front. Going to leave the back open.

I have all the 2x2's cut. Will have to nibble off a bit of the interior frame bits. As you will see in the pictures, I have the two long sides put together, i will then connect them with the 16" 2x2's, then put in an interior frame on each corner to beef it up.

Each 2x2 is connected via kreg hole saw and wood glue.

I also have the tank drilled and overflow attached. I took off more trim than needed on the inside, but oh well haha. I had to take a bite out of the trim so the water level would be above the trim, which is a must-have for me. The template Fiji cube provided was excellent. It also had an approximate water line mark on it. Which made it very easy to plan the placement of my overflow.

I got the overflow mounted 1/16" off center, which is just fine for me

The two bulkheads that connect the external box to the tank come with 3 gaskets. Now I know why. As you will see in the pictures it goes bulkhead >gasket > exterior box >gasket >glass >gasket>bulkhead nut making a perfect watertight seal once the bulkheads are tight. then the interior box slips into those bulkheads, and the interior box has gaskets built into the pipes that are attached to the interior box. All this makes for a very fast and very leak proof setup.

Also got the back of the tank painted with some gloss black spray paint i had on hand. Did the business nicely.

FTS lol

top-down lids on of overflow

close up front view of overflow

top-down lids off of overflow

the long sides of the stand

I'm building the stand out of 2x2's, 1/2 ply for top and bottom, and 1/4 ply for sides and front. Going to leave the back open.

I have all the 2x2's cut. Will have to nibble off a bit of the interior frame bits. As you will see in the pictures, I have the two long sides put together, i will then connect them with the 16" 2x2's, then put in an interior frame on each corner to beef it up.

Each 2x2 is connected via kreg hole saw and wood glue.

I also have the tank drilled and overflow attached. I took off more trim than needed on the inside, but oh well haha. I had to take a bite out of the trim so the water level would be above the trim, which is a must-have for me. The template Fiji cube provided was excellent. It also had an approximate water line mark on it. Which made it very easy to plan the placement of my overflow.

I got the overflow mounted 1/16" off center, which is just fine for me

The two bulkheads that connect the external box to the tank come with 3 gaskets. Now I know why. As you will see in the pictures it goes bulkhead >gasket > exterior box >gasket >glass >gasket>bulkhead nut making a perfect watertight seal once the bulkheads are tight. then the interior box slips into those bulkheads, and the interior box has gaskets built into the pipes that are attached to the interior box. All this makes for a very fast and very leak proof setup.

Also got the back of the tank painted with some gloss black spray paint i had on hand. Did the business nicely.

FTS lol

top-down lids on of overflow

close up front view of overflow

top-down lids off of overflow

the long sides of the stand

the framing is done! Next step, sand, paint it with some primer for a bit of water resistance. Put on the plywood top and bottom, paint the bottom with the kilz primer. Then build the electronics cabinet on the right side of it.

After that, time to build the sump!

the front

side

best part about the 2x2's is that it is nice and light. I can easily pick up this frame with one hand. its about 30 pounds i would guess.

After that, time to build the sump!

the front

side

best part about the 2x2's is that it is nice and light. I can easily pick up this frame with one hand. its about 30 pounds i would guess.

I just had this old beat up 55g and wanted to try my hand at cutting sheets of it down. It was much too thick for the cutting tool wheel thing, and i wasn't steady enough with a circular saw. Def need a table saw for glass sheets I am thinking.

I'll check out the glass at HD/Lowes and see how that compares to getting the rest of the 55g glass cut to size by a glass shop.

Just wanted to try something new! Glass worker I am not haha. Drilling is no problem, cutting, different story!

Will hopefully have the sump complete or at least glass cut in 1-2 weeks. Will update again with some good sump news next!

You were going to cut glass with a circular saw?

With a diamond glass cutting blade.You were going to cut glass with a circular saw?

Couldn't keep it steady enough. A tile saw with this same blade will work very well i imagine

And I did cut glass with a circular saw. Just not very well haha

Well well well. My craigslist prowling has resulted in another good deal. great deal i say this time.

i was able to pick up a (used) Aqua RX 200 GPD 6 stage dual tds dual DI desin RO/DI filter for $150! The nice older man also gave me a separate TDS reader and 1000 TDS solution.

he is a buyer and reseller of lots of equipment, he had loads of all sorts of things in his home. I will buy a used skimmer from him in the future i imagine.

Will update with pictures tomorrow. The beast of a unit is nearly 24" long!

i was able to pick up a (used) Aqua RX 200 GPD 6 stage dual tds dual DI desin RO/DI filter for $150! The nice older man also gave me a separate TDS reader and 1000 TDS solution.

he is a buyer and reseller of lots of equipment, he had loads of all sorts of things in his home. I will buy a used skimmer from him in the future i imagine.

Will update with pictures tomorrow. The beast of a unit is nearly 24" long!

dual ro, not di. well i will make it dual di at some point.

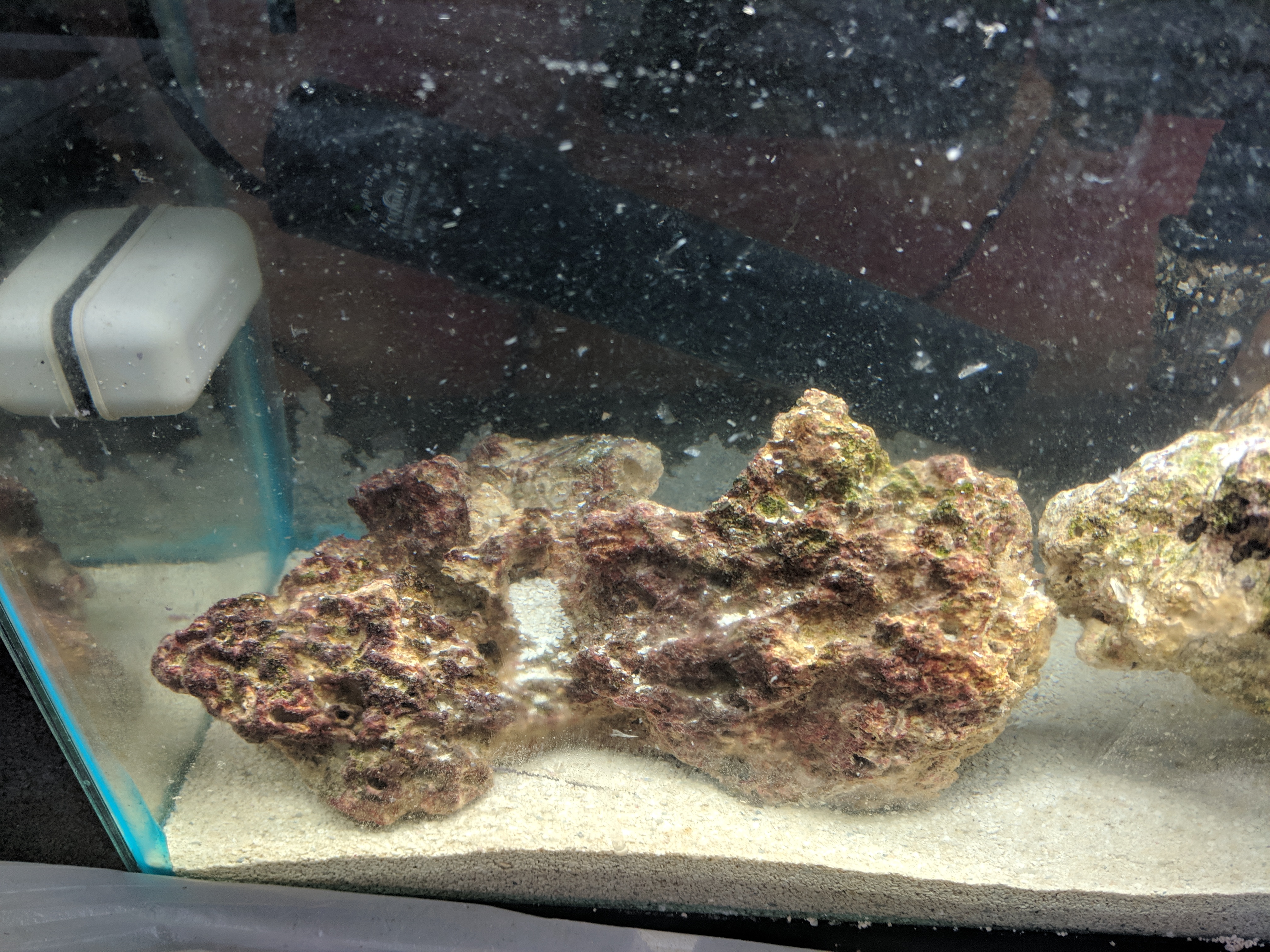

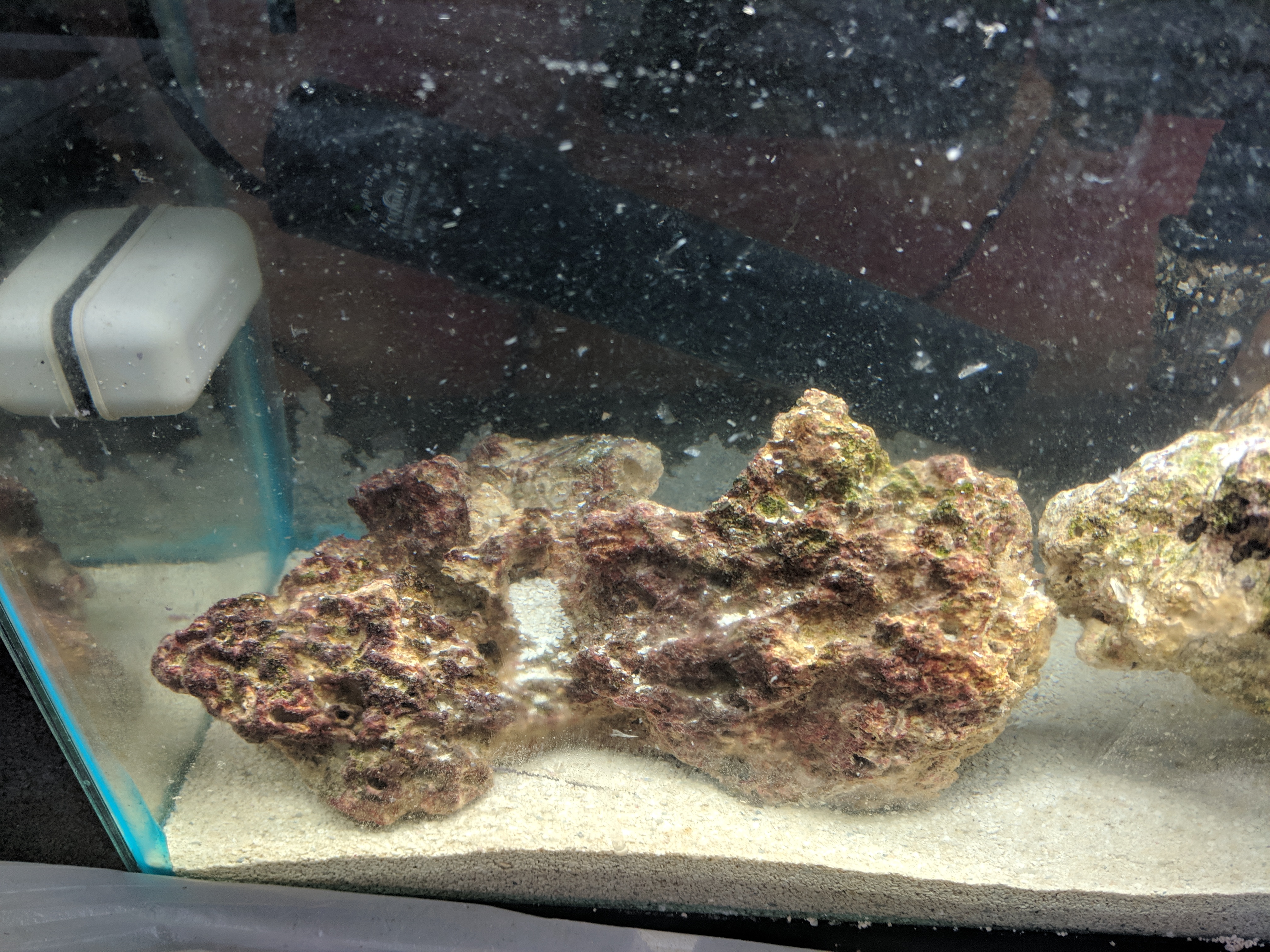

Remember the liverock i posted a ways back?

I moved it to a 10g where it is getting its colors back under a 65w PC and penguin emperor filter that provides plenty of flow.

Here they are now.

other one

I guess the guy really did get them from his uncle who had the rocks for 8+ years in an SPS tank.

I moved it to a 10g where it is getting its colors back under a 65w PC and penguin emperor filter that provides plenty of flow.

Here they are now.

other one

I guess the guy really did get them from his uncle who had the rocks for 8+ years in an SPS tank.

Similar threads

- Replies

- 17

- Views

- 346