- Joined

- Jan 12, 2020

- Messages

- 33

- Reaction score

- 69

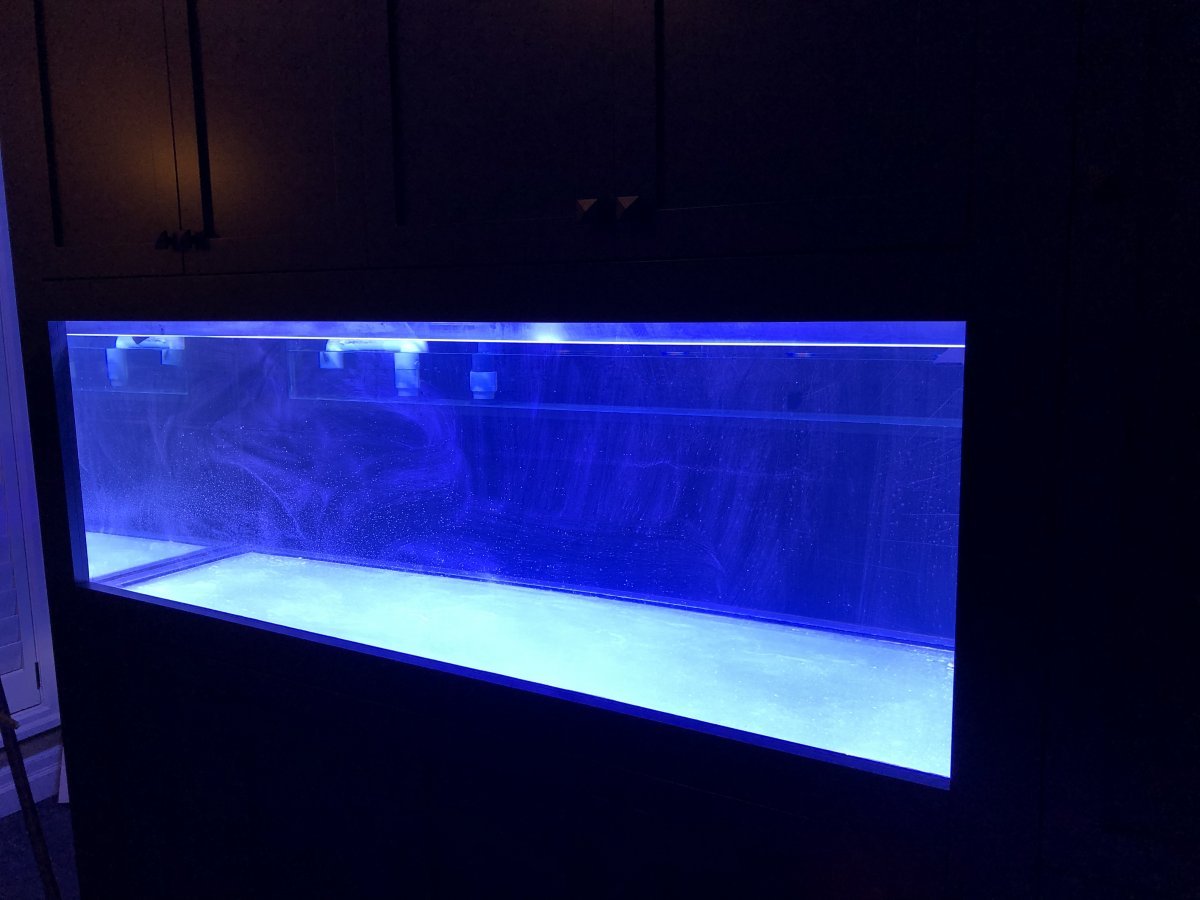

I am going to reserve this first post for the most up to date pictures and stats on my system. At the moment, not a lot of progress ... a tank filled with freshwater, with the glass looking grim. Explanations in the thread to come.