- Joined

- Oct 27, 2018

- Messages

- 251

- Reaction score

- 260

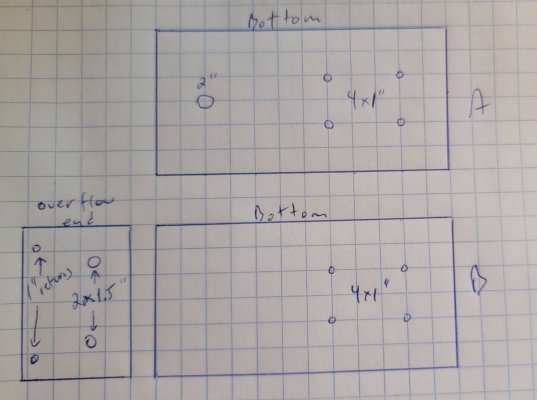

I put down a deposit with CDA for a large peninsula before the new year, current production times about 3-4 months, so I wanted to get my place in line even though I hadn't finalized the design fully. The tank overall will be 72x36x26 peninsula, 24" modular marine overflow (3x1.5" bulkheads) and 1" returns on each side of the overflow. I am planning to put 2-4 MP40s, maybe mp60s on the overflow end, but like most folks, don't want any power heads on the 3 viewable sides. In order to really get more flow at the far (viewable) end of the tank, I really think a closed loop is the way to go.

My thought is to have 4 x 1" outlets, concentrated at end of the tank.

From there I had two thoughts on the intake and pump.

A. Single Abyzz A200 with a 2" intake drilled in the bottom of the tank, maybe 1' from the overflow end, centered in the 36" width. I am going to use an Abyzz A200 as my return pump from a remote sump in the basement. Not that I like the idea of keeping a $2000 pump on the shelf, but I could in theory have a single spare that could replace either should the need arise.

B. Two Vectra L2s, each with their own intake on the overflow end panel, each would feed two returns. A little more total flow than a single A200, much cheaper. Concerned about leaving enough room for vortecs' between the sump returns and 24" overflow, its already a busy panel. I suppose it would be possible to put the 2x1.5" intake on the bottom panel like option A.

Thoughts, 1 pump or 2, intake(s) on bottom or end of the tank?

My thought is to have 4 x 1" outlets, concentrated at end of the tank.

From there I had two thoughts on the intake and pump.

A. Single Abyzz A200 with a 2" intake drilled in the bottom of the tank, maybe 1' from the overflow end, centered in the 36" width. I am going to use an Abyzz A200 as my return pump from a remote sump in the basement. Not that I like the idea of keeping a $2000 pump on the shelf, but I could in theory have a single spare that could replace either should the need arise.

B. Two Vectra L2s, each with their own intake on the overflow end panel, each would feed two returns. A little more total flow than a single A200, much cheaper. Concerned about leaving enough room for vortecs' between the sump returns and 24" overflow, its already a busy panel. I suppose it would be possible to put the 2x1.5" intake on the bottom panel like option A.

Thoughts, 1 pump or 2, intake(s) on bottom or end of the tank?