Hey guys thanks for stopping by

I purchased a used BRS system 75gpd 6 stage?

Has the 3 pre-filters, 150gpd water saver upgrade, twin DI canisters.

I have well water, albeit clean well water. Just high in iron. No testing to confirm but the pre-filter in my pump house gets really red and loaded with iron sediment/rust.

I run a 10 micron out there and then it feeds the whole house with my water room being last. I have another pre-filter there with a 5 micron sediment filter that feeds the de-gassing barrel. This one stays mostly white for a good period. TDS of feed water fluctuates from 60-100 depending on the time of year from what I can tell. Brand new triple inline TDS monitor from HM Digital. Handheld TDS meter matches results.

I replaced my DI resin and it was rapidly depleted so I did some research and assumed I have high CO2 which was causing my rapid DI consumption.

So I re-did everything and added an offgassing barrel where I pump the water into a holding barrel and let it aerate via Airstone. I also put a heater on there to get the water to optimal RODI temps in the 70s.

I didn't think this through. Given the waste water I am unable to complete filling a 44g brute in a single run and my pump runs dry.

Upon further inspection it seems my waste to product ratio is more around 1:1.

Running a booster through entire RO system at 80psi with a 550ml flow restrictor recommended by BRS.

So now I'm thinking the restrictor is bad?

What else would cause the close to 1:1 ratio?

Using a 250ml graduated cylinder and a stopwatch I got

210ml waste in 20 seconds and

194ml product in the same time.

Tested my rejection rates but something didn't seem right so I will re-test and post the results soon.

Thinking I may be better off dropping a membrane and getting my ratio to 4:1

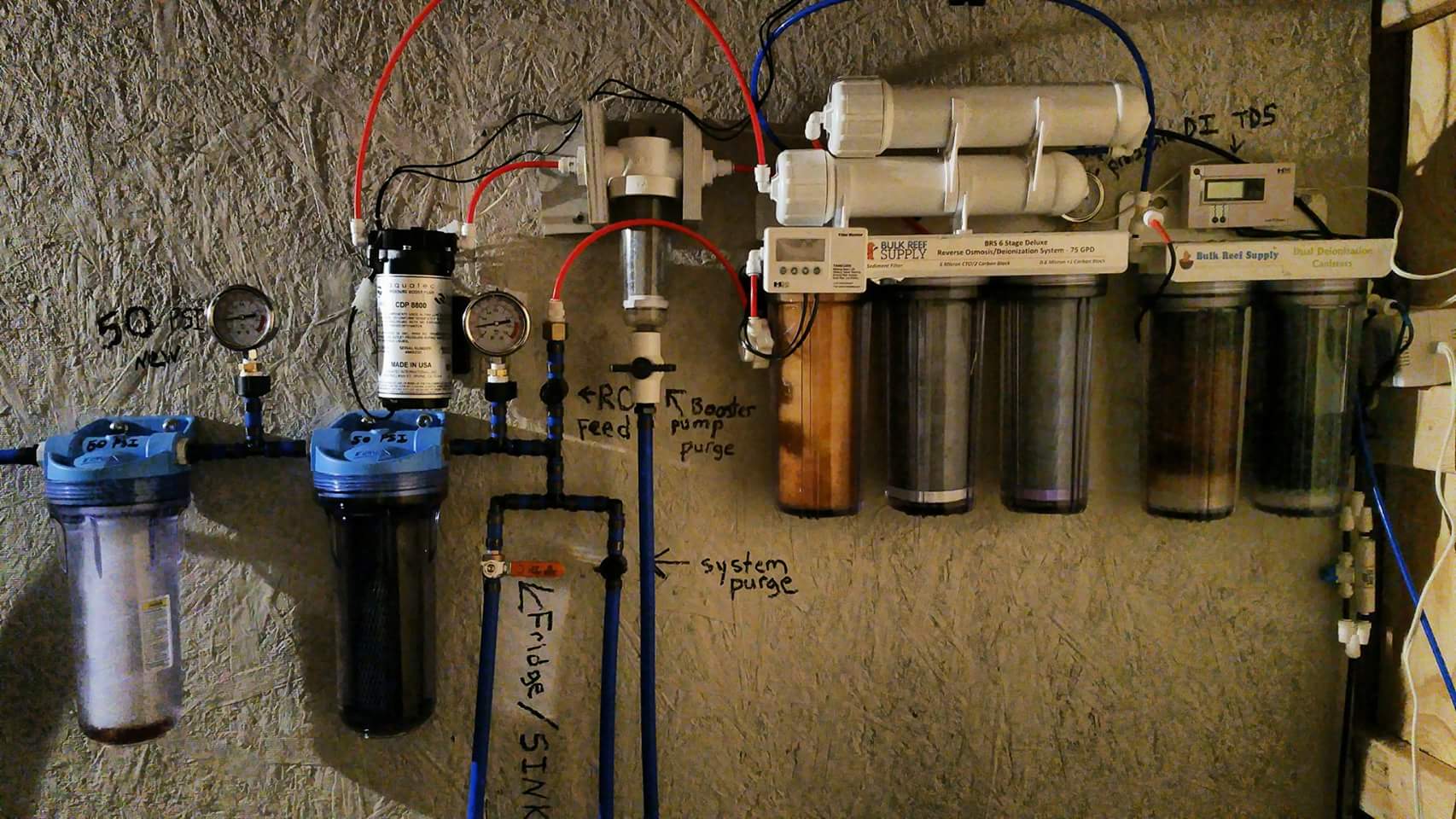

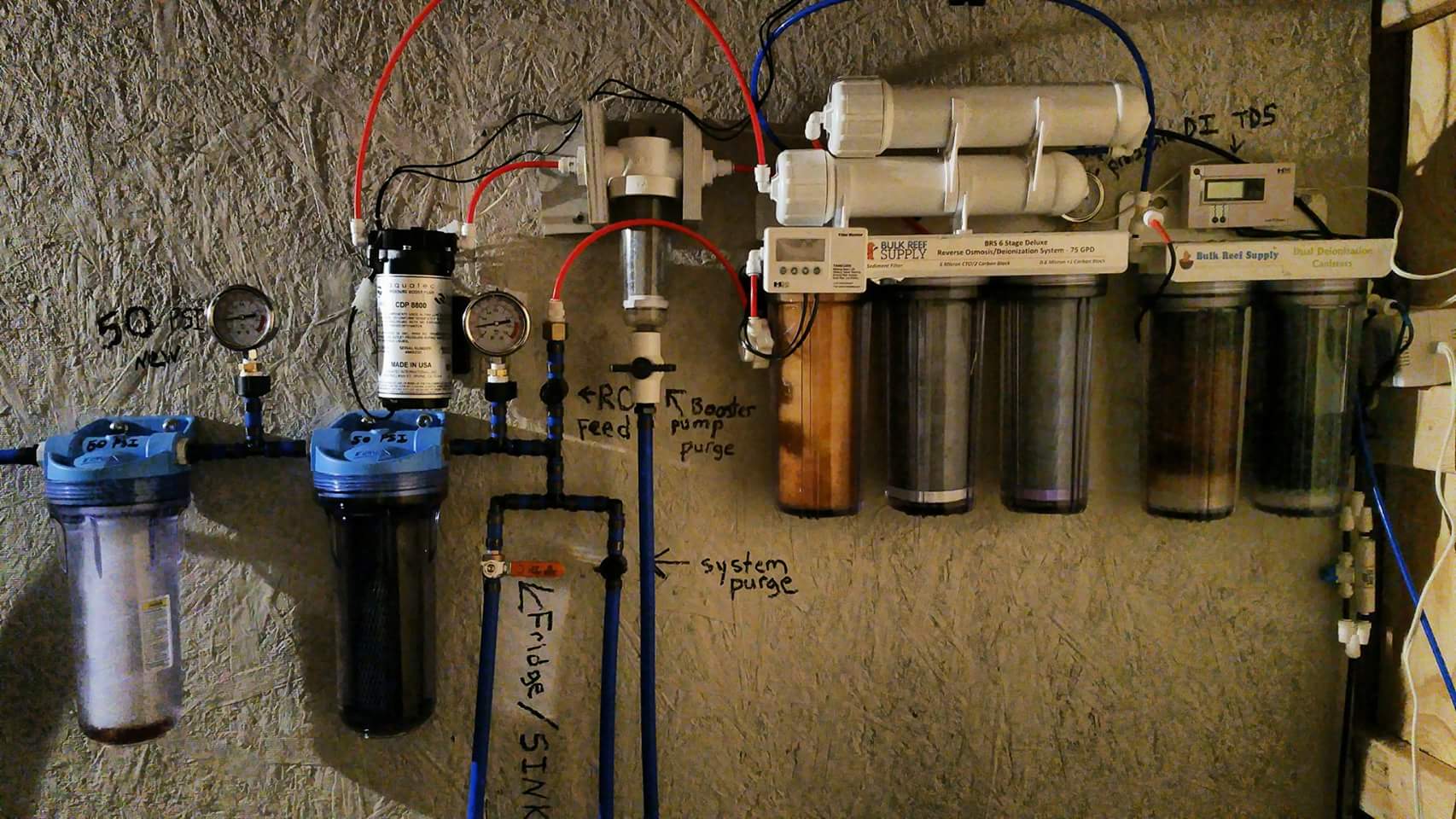

Here's some pics

Original setup

Had to prep for winter while doing this so I added insulation and am working on a door soon.

This is outside on my porch.

Added foam insulation and 1/2" ply floor

Insulation

5 micron pre-filter feeding de-gassing barrel

Via 1/2" pex and 3/8 tubing and float valve.

Gravity fed from barrel into spin-down sediment filter and then another pre-filter with 10 micron sediment filter. Aquatec 8800 with pressure switch

Blue is feed

Red is RO

Clear is RODI

I purchased a used BRS system 75gpd 6 stage?

Has the 3 pre-filters, 150gpd water saver upgrade, twin DI canisters.

I have well water, albeit clean well water. Just high in iron. No testing to confirm but the pre-filter in my pump house gets really red and loaded with iron sediment/rust.

I run a 10 micron out there and then it feeds the whole house with my water room being last. I have another pre-filter there with a 5 micron sediment filter that feeds the de-gassing barrel. This one stays mostly white for a good period. TDS of feed water fluctuates from 60-100 depending on the time of year from what I can tell. Brand new triple inline TDS monitor from HM Digital. Handheld TDS meter matches results.

I replaced my DI resin and it was rapidly depleted so I did some research and assumed I have high CO2 which was causing my rapid DI consumption.

So I re-did everything and added an offgassing barrel where I pump the water into a holding barrel and let it aerate via Airstone. I also put a heater on there to get the water to optimal RODI temps in the 70s.

I didn't think this through. Given the waste water I am unable to complete filling a 44g brute in a single run and my pump runs dry.

Upon further inspection it seems my waste to product ratio is more around 1:1.

Running a booster through entire RO system at 80psi with a 550ml flow restrictor recommended by BRS.

So now I'm thinking the restrictor is bad?

What else would cause the close to 1:1 ratio?

Using a 250ml graduated cylinder and a stopwatch I got

210ml waste in 20 seconds and

194ml product in the same time.

Tested my rejection rates but something didn't seem right so I will re-test and post the results soon.

Thinking I may be better off dropping a membrane and getting my ratio to 4:1

Here's some pics

Original setup

Had to prep for winter while doing this so I added insulation and am working on a door soon.

This is outside on my porch.

Added foam insulation and 1/2" ply floor

Insulation

5 micron pre-filter feeding de-gassing barrel

Via 1/2" pex and 3/8 tubing and float valve.

Gravity fed from barrel into spin-down sediment filter and then another pre-filter with 10 micron sediment filter. Aquatec 8800 with pressure switch

Blue is feed

Red is RO

Clear is RODI