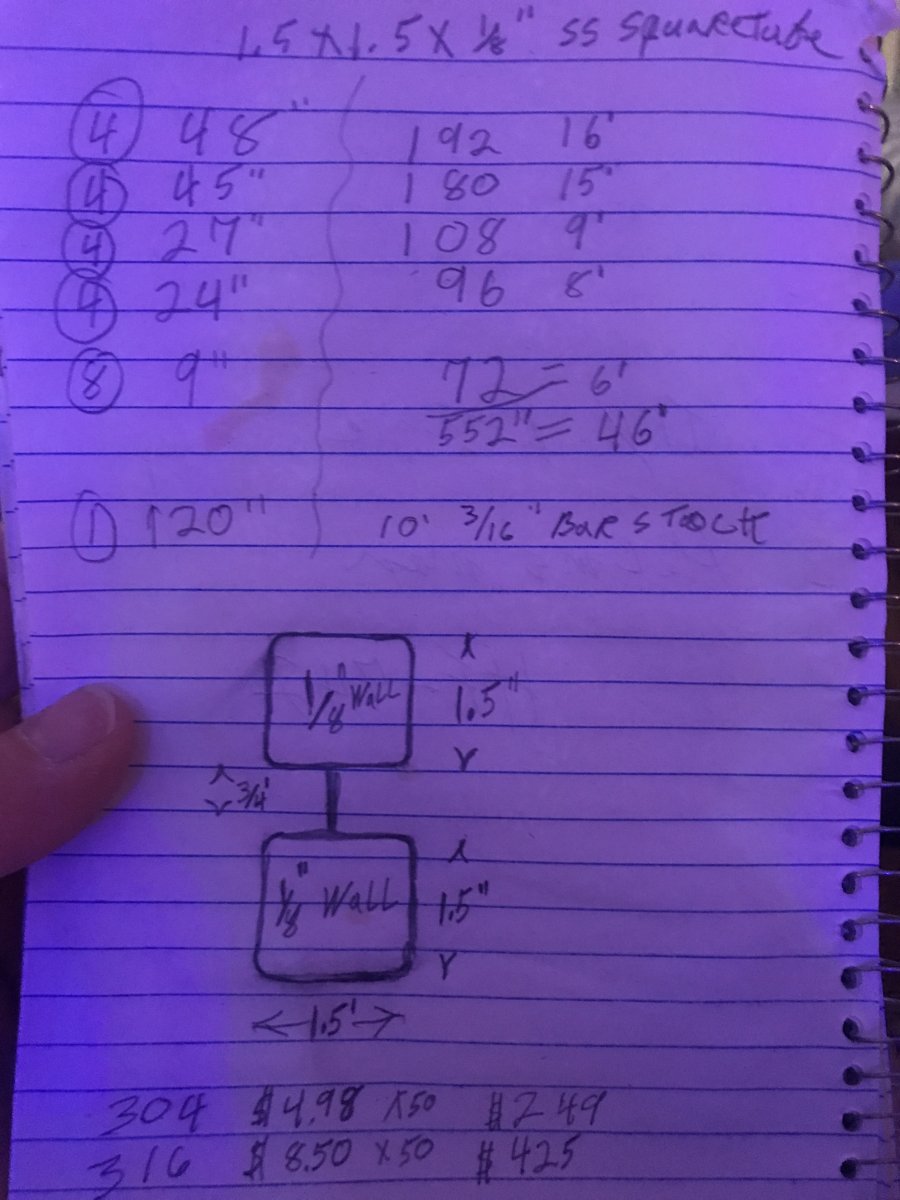

This is where I’m at. I’d like to fasten plumbing hangers, light davitts, panel magnets, controller boxes ect which I’d use stainless Fasteners for so aluminum’s out. Here in Gloucester the commercial fishermen are having good luck with 304 stainless finished with rinoguard which is an additional expense (not sure how much yet). My international paint rep recommended interprotect which is a marine barrier coat for bellow the waterline. If I go with 316 I’d need to hire a welder but would need no finishing. And finally I’m still not sure if my design is strong enough. The photo is pricing and top 48” beams profile

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stainless steel stand?

- Thread starter zirky

- Start date

- Tagged users None

what's the purpose of the flat bar between the tubes? I don't think a 3/4" wide bar is going to add much stiffness.

Might I suggest just putting the two tubes flush on top of each other and then put a 3" bar on the outside face of the tubes. Would cover the seam and make it look like a single 3" tube from the outside, and the 3" depth would add more stiffness than the 3/4" bar. You could put a second 3" bar on the inside too if you wanted. Or just use a 3" x 1-1/2" tube for that front pc. Way less welding.

Might I suggest just putting the two tubes flush on top of each other and then put a 3" bar on the outside face of the tubes. Would cover the seam and make it look like a single 3" tube from the outside, and the 3" depth would add more stiffness than the 3/4" bar. You could put a second 3" bar on the inside too if you wanted. Or just use a 3" x 1-1/2" tube for that front pc. Way less welding.

As swell as giving me more rigidly The flat Bar will also allow me to To through bolt my light brackets and recess my panel magnets Ect. At least that’s my thought.what's the purpose of the flat bar between the tubes? I don't think a 3/4" wide bar is going to add much stiffness.

Might I suggest just putting the two tubes flush on top of each other and then put a 3" bar on the outside face of the tubes. Would cover the seam and make it look like a single 3" tube from the outside, and the 3" depth would add more stiffness than the 3/4" bar. You could put a second 3" bar on the inside too if you wanted. Or just use a 3" x 1-1/2" tube for that front pc. Way less welding.

thanks I’ll check it out.Just do steel and use pur 15 frame paint the stuff drys like a rock

I concur with the 3/4" webbing adding minimal rigidity at the expense of a lot of extra welding. I-beams are strong structural elements, but only because they are solid formed. You could add some 6" wide x 1/8" webs at intervals across the span and achieve the same strength, but I would highly recommend wider/deeper than 3/4" because that's a very difficult space to weld into.

You could stick with 1.5" tubing for the webs. Concept below (apologies for the crude sketch, PhotoShop was faster than CAD).

You could stick with 1.5" tubing for the webs. Concept below (apologies for the crude sketch, PhotoShop was faster than CAD).

Last edited:

Here is my 120 4x2x2 open steel stand.

2" box for side bottom and cross bars top only.

2"x3" on the top.

Mild steel, por15 topcoat added for complete rust protection.

2" box for side bottom and cross bars top only.

2"x3" on the top.

Mild steel, por15 topcoat added for complete rust protection.

The sketch is awsome. This is exactly the kind of input I was hoping for thank you.I concur with the 3/4" webbing adding minimal rigidity at the expense of a lot of extra welding. I-beams are strong structural elements, but only because they are solid formed. You could add some 6" wide x 1/8" webs at intervals across the span and achieve the same strength, but I would highly recommend wider/deeper than 3/4" because that's a very difficult space to weld into.

You could stick with 1.5" tubing for the webs. Concept below (apologies for the crude sketch, PhotoShop was faster than CAD).

That looks great. What gauge steel is it?Here is my 120 4x2x2 open steel stand.

2" box for side bottom and cross bars top only.

2"x3" on the top.

Mild steel, por15 topcoat added for complete rust protection.

1

1/4"That looks great. What gauge steel is it?

Your gusset sizing and placement looks dead-on. Excellent engineering.I doubled up the long tubes on my stand build.

I can't tell exactly what spacing you have between the upper horizontal members, if any?

The only suggestion I have for your next stand would be to stagger the inner and outer welds between the doubled members so that they are not directly across from each other. That will give you some added strength and spread the loading of those members.

Similar threads

- Replies

- 24

- Views

- 677