I have no idea what I'm doing tbh

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Under-sizing your return plumbing can have a negative effect! Do you have good return flow?

- QUESTION OF THE DAY

- Thread starter revhtree

- Start date

- Tagged users None

Not at all. I don't think that much return flow is needed to have a successful tank. 10x hour is enough in my opinion. Now actual display flow through the use of powerheads is another story... (never enough!  )

)

I agree with the Posts above.....Return flow doesn't have to be much these days since we have plenty of choices for In-Tank powerheads. A slower return flow can be better due to longer contact time in Sump/Skimmer.

My sump is in basement and Tank is on 1st floor. Lots of height and my plumbing runs thru walls, ceiling, and nd needs to turn a few times.

I don't like hard-plumbling since it can be noisy (buzz, rattle), and hard to get perfect runs with elbows and gluing process. 90 degree turns reduce flow somewhat so better to have gentle angles.

This isn't as pretty as the GLUE PVC pipe/elblow, etc.....but works better for me. Equally Kink free.

For the Pump to Tank plumbing, I used similar type of hose by not as big of a diameter.

https://www.halfoffponds.com/Half-Off-Ponds-Kink-Free-Vinyl-Hose-1-x-100-p/kf1x100.htm

This is the type of hose I used for return-drain out of tank. Smooth on inside for better flow and quieter too. Works like a charm.

BOTH hoses are easily removable for a cleaning if needed to remove (years of calcification on inner walls)

My sump is in basement and Tank is on 1st floor. Lots of height and my plumbing runs thru walls, ceiling, and nd needs to turn a few times.

I don't like hard-plumbling since it can be noisy (buzz, rattle), and hard to get perfect runs with elbows and gluing process. 90 degree turns reduce flow somewhat so better to have gentle angles.

This isn't as pretty as the GLUE PVC pipe/elblow, etc.....but works better for me. Equally Kink free.

For the Pump to Tank plumbing, I used similar type of hose by not as big of a diameter.

https://www.halfoffponds.com/Half-Off-Ponds-Kink-Free-Vinyl-Hose-1-x-100-p/kf1x100.htm

This is the type of hose I used for return-drain out of tank. Smooth on inside for better flow and quieter too. Works like a charm.

BOTH hoses are easily removable for a cleaning if needed to remove (years of calcification on inner walls)

Last edited:

10x …. I’m more in the 3x range. But tank is 400 gallons so ….

Quite remarkable how much flow you can gain by upsizing the return line. Years ago I went from 1” to 1 1/2” and picked up almost 200 gph.

Quite remarkable how much flow you can gain by upsizing the return line. Years ago I went from 1” to 1 1/2” and picked up almost 200 gph.

- Joined

- Jun 6, 2017

- Messages

- 14

- Reaction score

- 17

I know everybody is now saying 3-5x is "enough" or that's a good target or whatever.

But my question is this:

Is there a downside to having a higher return flow? Other than the cost/size of a stronger pump of course.

IMHO: Isn't a higher return flow = more aeration for the livestock, more stable heat/cooling for the livestock, and overall better particulate filtration?

Because we can agree that 1.) more aeration is better (assuming you dont have high CO2 room 2.) Stability is better.

So a quicker turn over will mean quicker distribution of dosing additives and more stable temperature (maybe slightly) if your heaters are down in the sump.

Also regarding the longer contact time with skimmer, I mean, isn't that dependent on your skimmer setup? Although yes, maybe there is longer contact time with the DT water, more water from the DT <> SUMP is flowing through, so if the fish took a poo, the faster the poo will be processed down in the sump.

For someone who likes to feed heavy and export heavy, I think the faster particulate filtration is beneficial on keeping nutrients in check. But i dont know, that's the way I see it.

But my question is this:

Is there a downside to having a higher return flow? Other than the cost/size of a stronger pump of course.

IMHO: Isn't a higher return flow = more aeration for the livestock, more stable heat/cooling for the livestock, and overall better particulate filtration?

Because we can agree that 1.) more aeration is better (assuming you dont have high CO2 room 2.) Stability is better.

So a quicker turn over will mean quicker distribution of dosing additives and more stable temperature (maybe slightly) if your heaters are down in the sump.

Also regarding the longer contact time with skimmer, I mean, isn't that dependent on your skimmer setup? Although yes, maybe there is longer contact time with the DT water, more water from the DT <> SUMP is flowing through, so if the fish took a poo, the faster the poo will be processed down in the sump.

For someone who likes to feed heavy and export heavy, I think the faster particulate filtration is beneficial on keeping nutrients in check. But i dont know, that's the way I see it.

I followed this with a Modular Marine bean animal overflow and boy it was a huge mistake. It was hell getting everything quiet after a water change. I even added a gate valve on my secondary pipe. I finally tore down the tank, took a huge chance, drilled the return hole larger and went with equal size PVC pipe. Problem solved!Well, i always tought that return pipe diameter is related to drain pipe diameter.

And always, i follow guideline that i read (or maybe heard) somewhere, and it says -

1" for drain, and 3/4 for return.

5/4" for drain and 1" for return.

6/4" for drain and 5/4" for return.

2" for drain and 6/4 for return.

So, basicaly, return is one number smaller than drain pipe, of course, main factor for determining diameter is pump flow and lifting height, and do one have splitted outputs, manifolds, etc....

For me, pumps are bit on weak side, two pumps, 4000lph each, and with 3/4" return pipe, two 1" drain lines have no problem, even with stronger pumps, all i need to do is open valve bit more.....

My return is a Vectra L2 on a WB peninsula 7225 which is around 210g. I had to set it lower than 40% or the drain could not keep up - it was also extremely noisy in the sump. I have since calibrated it and I run it at 95% of the calibrated full power (which is probably around 35%). I contacted Waterbox because I reckoned for 10x flow I should be running it around 70% but they told me their tanks/sumps/drains are designed for approx 5x flow which is about where I am (maybe a bit lower). They said they would recommend the M2 for this tank size but I was oversold the L2 by the supplier - not too sad about that since at least I have room to up it if need be but I don't think I ever will. I am trying to run a UV from one of the WB utility outlets but am not happy with the flexibility that gives me (next to none - even at valve full open I get slightly lower than the minimum recommended flow rate for my UV). I think I will be adding a dedicated pump for my UV in the future and want to plumb the return from the UV back into the return to the display (currently it dumps back into the sump).

As someone else mentioned getting water movement at the far (non-weir) end of a peninsula is a challenge and I will agree with them! I use a MaxSpect xf350 mounted on the weir with the dry side magnet in a ziplock bag in the weir (under water). It's currently running the random pattern set to 70% which gives some nice effects. This helps the two MP40s which are mounted on the sides on the weir but it is still far from perfect.

As someone else mentioned getting water movement at the far (non-weir) end of a peninsula is a challenge and I will agree with them! I use a MaxSpect xf350 mounted on the weir with the dry side magnet in a ziplock bag in the weir (under water). It's currently running the random pattern set to 70% which gives some nice effects. This helps the two MP40s which are mounted on the sides on the weir but it is still far from perfect.

I have the same issue. I needed to reduce the power of my Vectra S2 because the drains could not keep up. When I first installed the pump, I nearly had a major flood.I have plenty of return flow capability. My problem lies with the drain flow. If I crank my Varios 8 past 35% the noise from the drain pipe is unbearable.

Awesome I didn’t know that!This can be true. There are different styles of fittings out there. If you get what is called a "full port" fitting it will have the stated diameter all the way through the fitting. So a 1 inch "standard" ball valve vs. a 1 inch "full port" ball valve will have different flow rates. The full port valve will be larger and that will need to be taken into account for the given application.

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

Here are a couple things that have caused that problem for me....

The feed pump. When you manually cycle it, it should run from 1 to 99 very quickly - if it is too slow (clogged filter), or if the one way valve is not working - or if it the valve is too stiff and impeding flow - you can get the same problem. I had to find a different one way valve, the one supplied by Deltec caused too much resistance. You can just try and blow through it to see how stiff the one way valve is. If your ears pop and your eye balls pop out - it's too stiff!

Also, make sure the effluent line is not submerged in the sump.

Faster turnover is better... but it depends on your sump design and returns.I know everybody is now saying 3-5x is "enough" or that's a good target or whatever.

But my question is this:

Is there a downside to having a higher return flow? Other than the cost/size of a stronger pump of course.

IMHO: Isn't a higher return flow = more aeration for the livestock, more stable heat/cooling for the livestock, and overall better particulate filtration?

Because we can agree that 1.) more aeration is better (assuming you dont have high CO2 room 2.) Stability is better.

So a quicker turn over will mean quicker distribution of dosing additives and more stable temperature (maybe slightly) if your heaters are down in the sump.

Also regarding the longer contact time with skimmer, I mean, isn't that dependent on your skimmer setup? Although yes, maybe there is longer contact time with the DT water, more water from the DT <> SUMP is flowing through, so if the fish took a poo, the faster the poo will be processed down in the sump.

For someone who likes to feed heavy and export heavy, I think the faster particulate filtration is beneficial on keeping nutrients in check. But i dont know, that's the way I see it.

It comes down to practical limits. What can your sump handle without microbubbles?.... and if you run mechanical filtration, at some point high flow just overwhelms your socks and rollers. I voted that my flow was "fine" only because I would have to redesign my sump system to handle more.

My concern is keeping stuff in suspension and directing it to the overflows - so I don't have to siphon my bare bottom all the time. Still trying to figure that out!

- Joined

- Apr 1, 2020

- Messages

- 1,172

- Reaction score

- 1,619

Why is faster turnover better? As long as you have strong flow with your powerheads i see no reason why it's necessary to have fast turnover.Faster turnover is better... but it depends on your sump design and returns.

It comes down to practical limits. What can your sump handle without microbubbles?.... and if you run mechanical filtration, at some point high flow just overwhelms your socks and rollers. I voted that my flow was "fine" only because I would have to redesign my sump system to handle more.

My concern is keeping stuff in suspension and directing it to the overflows - so I don't have to siphon my bare bottom all the time. Still trying to figure that out!

This one of those assumptions that could use a challenge.

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

I challenge you back! If you COULD turn your tank over more through your sump with no consequences or any kind.... why would you not?Why is faster turnover better? As long as you have strong flow with your powerheads i see no reason why it's necessary to have fast turnover.

This one of those assumptions that could use a challenge.

Regarding maximal sump turnover - within practical limitations... In a bare-bottom system - better and faster clearance of the suspended detritus to the filter system below would be accomplished by faster turnover to the sump... leaving less to siphon. Perhaps, less need for san bed maintenance in non bare-bottom systems.

Also, less worry about how to plumb your skimmer, UV sterilizer, Ozone system, heater, turf scrubber etc.... once you are sure that the sump has access to everything you are trying to get out of the main tank - you can just let them loop the sump water passing by and not fret about tying in returns directly to certain equipment or rolling consequences to adjusting your return flow.

Less need for in tank power heads, surge devices, complicated closed loops and other equipment in the display.

And of course... I am only talking about realistic parameters - like 2 x per hour versus 10 x per hour.

I admit that going up ridiculous sump turnovers (20 x per hour) would not likely have any benefit at all.

Most of all, I admit and emphasize that reducing the strain on the sump and plumbing and return pump power usage is a huge advantage... which is why 3 or 4 x turnover per hour is good enough for my 1000 gallon display tank. Higher turnover is only an advantage if one ignores that practical hassles that go along with it.

So, basically, I agree with you, when you put it all together - the practical costs of blasting large amounts of water through the sump - is NOT better.

Last edited:

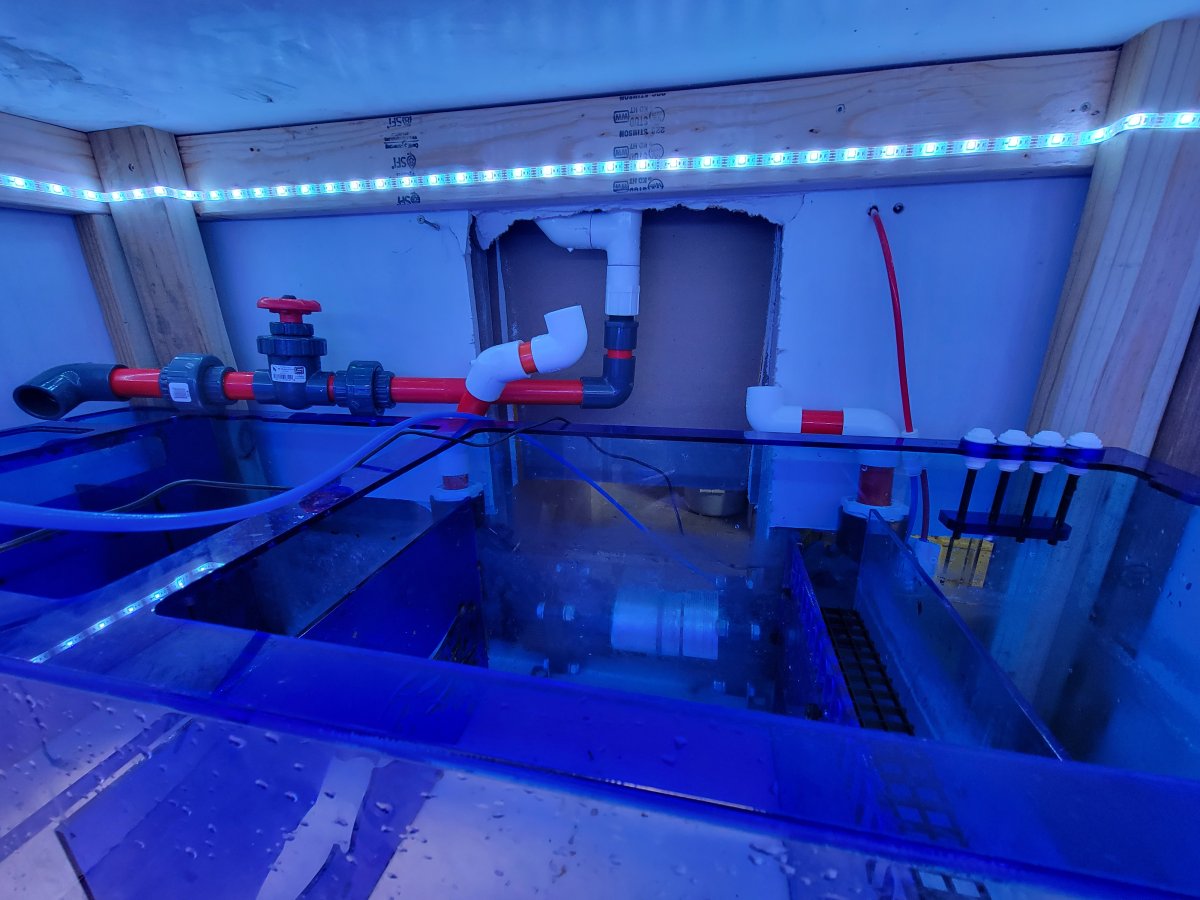

My main goal was to eliminate pumps in the tank. Peninsula tank with no powerheads on the far side to muddy up the end panel.

So for me high flow through the sump was nessacary to push the return water all the way across the tank.

I know that people tend to not use their return as flow in the display but I designed my system with that intent.

I do have one powerhead to help with random flow but it is tucked away on the weir side and not ruining the look by hanging off of the far end of the tank.

Funny enough, my low flow area of the tank is not on the far side of the peninsula, it is on the bottom, below the weir and returns.

So for me high flow through the sump was nessacary to push the return water all the way across the tank.

I know that people tend to not use their return as flow in the display but I designed my system with that intent.

I do have one powerhead to help with random flow but it is tucked away on the weir side and not ruining the look by hanging off of the far end of the tank.

Funny enough, my low flow area of the tank is not on the far side of the peninsula, it is on the bottom, below the weir and returns.

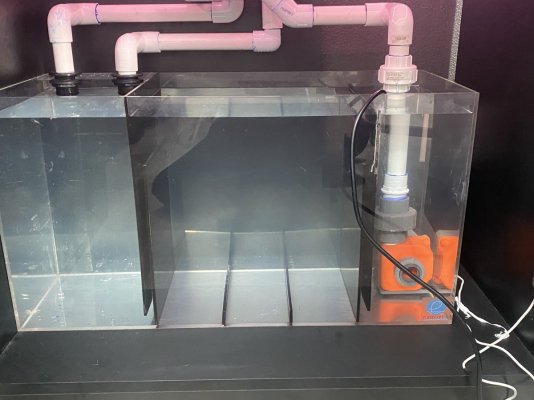

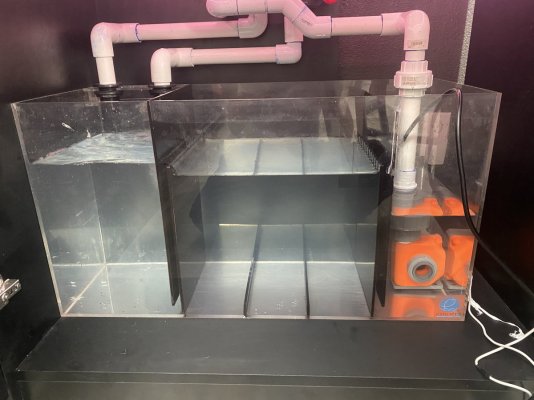

Right now I’m having issues. My drain and my return are both 1”. I can only run my Cor 15 at 5% or return chamber will run dry. I still haven’t installed filter roller. Advice would be greatly appreciated Please. First pic is pump off 2nd is pump on.

Attachments

I'm interested in how you are setup - which peninsula do you have - what are the dimensions? What pump and return outlets - i.e. random flow generators? And did you place outlets through the base of your tank before installing or use the stock ones from the return? I personally feel this might be the best way to provide flow at the far end of a peninsula but involves cutting the glass (scary) and scaping around the outflows (probably not too bad but would have to try and ensure they stay free of debris in a sand bottom tank). We have a 6ft and getting decent varied flow at the far end is a challenge.My main goal was to eliminate pumps in the tank. Peninsula tank with no powerheads on the far side to muddy up the end panel.

So for me high flow through the sump was nessacary to push the return water all the way across the tank.

I know that people tend to not use their return as flow in the display but I designed my system with that intent.

I do have one powerhead to help with random flow but it is tucked away on the weir side and not ruining the look by hanging off of the far end of the tank.

Funny enough, my low flow area of the tank is not on the far side of the peninsula, it is on the bottom, below the weir and returns.

We also do not want to 'muddy-up' our far end display panel as it gives a great view through the tank. See my post above - we have 2 MP40s aside the weir about half way up and a XF350 gyre mounted on the weir just under the water surface. I did think about swapping out the MP40s for XF350's mounted vertically but that's a pricy gamble.

In this barmy world, metric pipe size is the OD and imperial pipe size is the ID... so to translate:

32 mm pipe has an ID of 25 mm (~1")

25 mm pipe has an ID of 20 mm (~3/4")

I'm just about to start building a RSR XL 200 which has a 32 mm drain and 25 mm return. Red Sea recommend a 2,000 lph pump.

On the return pump there is a 20 mm spigot (~3/4") and I'm using Eheim 22/16 mm hose.

I'm converting the drain from 32 mm to 25 mm pipe with a Spears valve using this guide: Tutorial on how to change Red sea Reefer downflow valve to a gate valve

I'm aiming for a sump flow of 3x to 5x total water volume per hour. The system holds 200 Litres, so this would be 600 to 1,000 lph.

I chose the TMC Reef-Pump Connect 2500 which according to the flow graph will pump 2,000 lph at the XL 200 head height of approx. 1.5 m (a ~20 % loss).

The pump has 20 settings starting at ~600 lph with 1.5 m head, and at half power ~1,250 lph. I figure the manufacturer's claimed figures might be a bit optimistic, but I expect the pump will still be able to run at less than half power to achieve the desired 3x to 5x flow rate. I've tested the pump and it is almost completely silent at half power.

I've noticed on a few build threads that the Vectra S2 is a popular pump for the XL 200 which is rated at 5,300 lph @ 0 head. This is a much more powerful (and 3x the price) pump than the TMC 2500, so, I'm wondering if I've messed up?

32 mm pipe has an ID of 25 mm (~1")

25 mm pipe has an ID of 20 mm (~3/4")

I'm just about to start building a RSR XL 200 which has a 32 mm drain and 25 mm return. Red Sea recommend a 2,000 lph pump.

On the return pump there is a 20 mm spigot (~3/4") and I'm using Eheim 22/16 mm hose.

I'm converting the drain from 32 mm to 25 mm pipe with a Spears valve using this guide: Tutorial on how to change Red sea Reefer downflow valve to a gate valve

I'm aiming for a sump flow of 3x to 5x total water volume per hour. The system holds 200 Litres, so this would be 600 to 1,000 lph.

I chose the TMC Reef-Pump Connect 2500 which according to the flow graph will pump 2,000 lph at the XL 200 head height of approx. 1.5 m (a ~20 % loss).

The pump has 20 settings starting at ~600 lph with 1.5 m head, and at half power ~1,250 lph. I figure the manufacturer's claimed figures might be a bit optimistic, but I expect the pump will still be able to run at less than half power to achieve the desired 3x to 5x flow rate. I've tested the pump and it is almost completely silent at half power.

I've noticed on a few build threads that the Vectra S2 is a popular pump for the XL 200 which is rated at 5,300 lph @ 0 head. This is a much more powerful (and 3x the price) pump than the TMC 2500, so, I'm wondering if I've messed up?

I have to preface this by saying my first reef tank was converted from a freshwater tank and since I was on the fence as to how it would go I cheaped out and use one of those HOB siphon overflows. It works but the tank is due to be drilled since I’m confident in my ability to build and maintain a reef tank now.

That said, I sized my return to “drive” the overflow. I knew I wanted a DC pump for controllability and knew also that I wanted enough flow for 4x turnover and to drive at minimum a carbon reactor. I ended up using a Jebao DCP-2500 dialed back to 35% which translates to just over 200GPH. Total system volume is 45 gallons so I’m hitting my desired turnover. Drain pipes are 1” with 3/4” return line. Given current setup I have plenty of spare flow to add more rectors and/or crank up the turnover rate.

Now about that HOB overflow………..

That said, I sized my return to “drive” the overflow. I knew I wanted a DC pump for controllability and knew also that I wanted enough flow for 4x turnover and to drive at minimum a carbon reactor. I ended up using a Jebao DCP-2500 dialed back to 35% which translates to just over 200GPH. Total system volume is 45 gallons so I’m hitting my desired turnover. Drain pipes are 1” with 3/4” return line. Given current setup I have plenty of spare flow to add more rectors and/or crank up the turnover rate.

Now about that HOB overflow………..

- Joined

- Jun 7, 2019

- Messages

- 536

- Reaction score

- 523

Notes from an actual plumbing engineer.

Easy answer, Get a pump bigger than you need and you can turn it down.

You want 3-5x turnover for your return. so take your tank size x5, then fine a pump that will do TWICE that amount.

If you are pumping up to another floor you have to look at one more thing. Height. Pumps are sized for head pressure, which is in feet or meters. This is how high the pump can push water straight up. You will need to look at a graph (called a pump curve) and make sure the pump will flow the 5x volume that you want at the height you need.

Best practice for piping, Whatever connection size your have on your pumps go one size up for your plumbing. Got a 3/4" outlet on the pump, use 1". Got a 1.5" inlet, use 2".

After 20 years in the hobby here is what I go by for sizing.

Supply:

1/4" - 0-20 GPH

1/2" - 20-250 GPH

3/4" - 250-750 GPH

1" - 750-1200 GPH

1.25" - 1250-1500 GPH

1.5" - 1500-2000 GPH

2" - 2000-5000 GPH

Drains Open flow:

1/4" - Dont

1/2" - 0-30 GPH

3/4" - 30-250 GPH

1" - 250-750 GPH

1.25" - 750-1200 GPH

1.5" - 1200-1800 GPH

2" - 1800-2400 GPH

Drains Siphon flow:

1/4" - Dont

1/2" - 20-250 GPH

3/4" - 250-750 GPH

1" - 750-1200 GPH

1.25" - 1250-1500 GPH

1.5" - 1500-2000 GPH

2" - 2000-3000 GPH

Easy answer, Get a pump bigger than you need and you can turn it down.

You want 3-5x turnover for your return. so take your tank size x5, then fine a pump that will do TWICE that amount.

If you are pumping up to another floor you have to look at one more thing. Height. Pumps are sized for head pressure, which is in feet or meters. This is how high the pump can push water straight up. You will need to look at a graph (called a pump curve) and make sure the pump will flow the 5x volume that you want at the height you need.

Best practice for piping, Whatever connection size your have on your pumps go one size up for your plumbing. Got a 3/4" outlet on the pump, use 1". Got a 1.5" inlet, use 2".

After 20 years in the hobby here is what I go by for sizing.

Supply:

1/4" - 0-20 GPH

1/2" - 20-250 GPH

3/4" - 250-750 GPH

1" - 750-1200 GPH

1.25" - 1250-1500 GPH

1.5" - 1500-2000 GPH

2" - 2000-5000 GPH

Drains Open flow:

1/4" - Dont

1/2" - 0-30 GPH

3/4" - 30-250 GPH

1" - 250-750 GPH

1.25" - 750-1200 GPH

1.5" - 1200-1800 GPH

2" - 1800-2400 GPH

Drains Siphon flow:

1/4" - Dont

1/2" - 20-250 GPH

3/4" - 250-750 GPH

1" - 750-1200 GPH

1.25" - 1250-1500 GPH

1.5" - 1500-2000 GPH

2" - 2000-3000 GPH

Similar threads

- Replies

- 17

- Views

- 266

- Replies

- 3

- Views

- 238