Introduction

My name is Brad Urbanek, I've been reef keeping just over 8 years. Like many, I've went through the progression of going bigger and bigger only now to go smaller, smaller and smaller. One thing that I learned through my last aquarium, a 250 gallon reef, is that what I love most about the hobby is just having a playground to experiment with. Having a large aquarium didn't provide me any more satisfaction than I got with my 28g Nano or my 110g Rimless. I learned that moving with a large aquarium adds an infinite amount of work and stress. Having to rely on others just to lift the aquarium is something I wanted to avoid moving forward. As I pondered these lessons, I knew that my next adventure would be with tanks that I could lift and carry on my own.

My Vision

If you've followed my last build you know that I enjoy woodworking as much as I do reef keeping. I want to use this build as an opportunity to test new skills and ultimately create a gorgeous display that is free of visible wires and plumbing. I want the system to be as clean and simple as possible while matching the flow of our new home. My options for aquarium locations are limited and when I say limited I mean I have one possible location. In this location, we already has an existing cabinet that matches our kitchen cabinets. Having this cabinet is both a blessing and a curse. A blessing in that it's there, it matches and it's one less thing to pay for. A curse in that getting it ready to support the system while keeping the doors and drawers functional will be a test.

The Plan

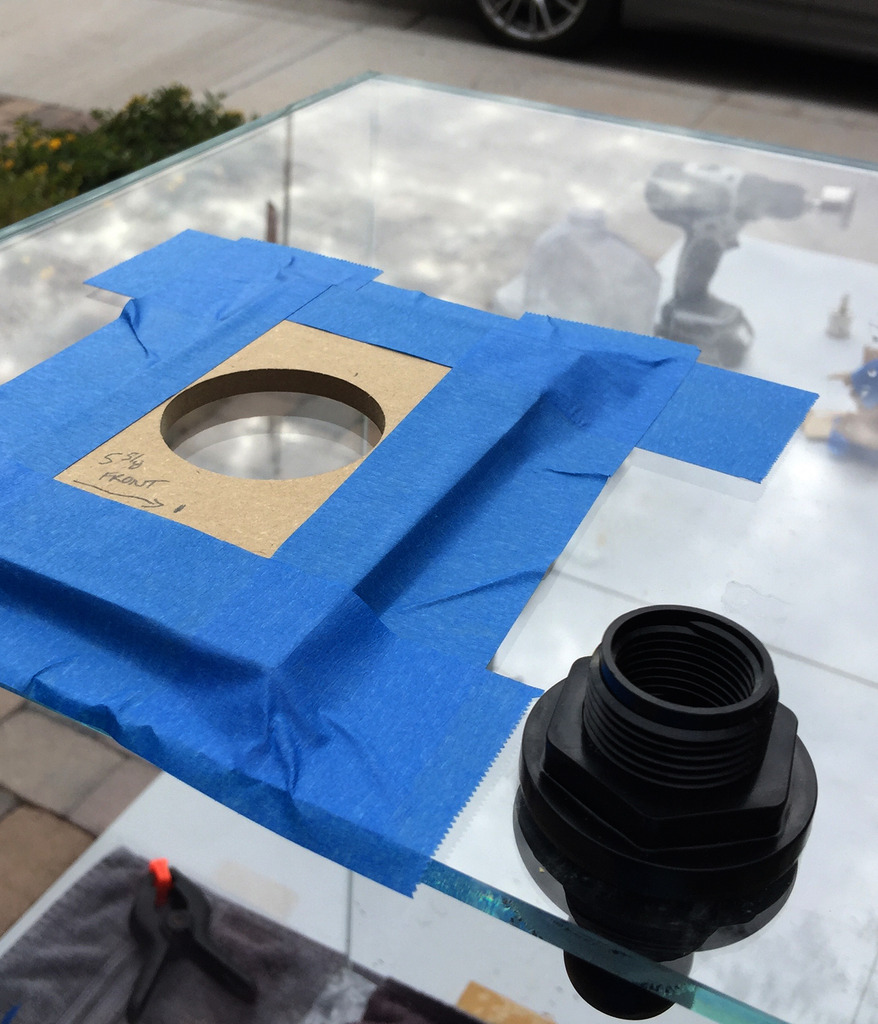

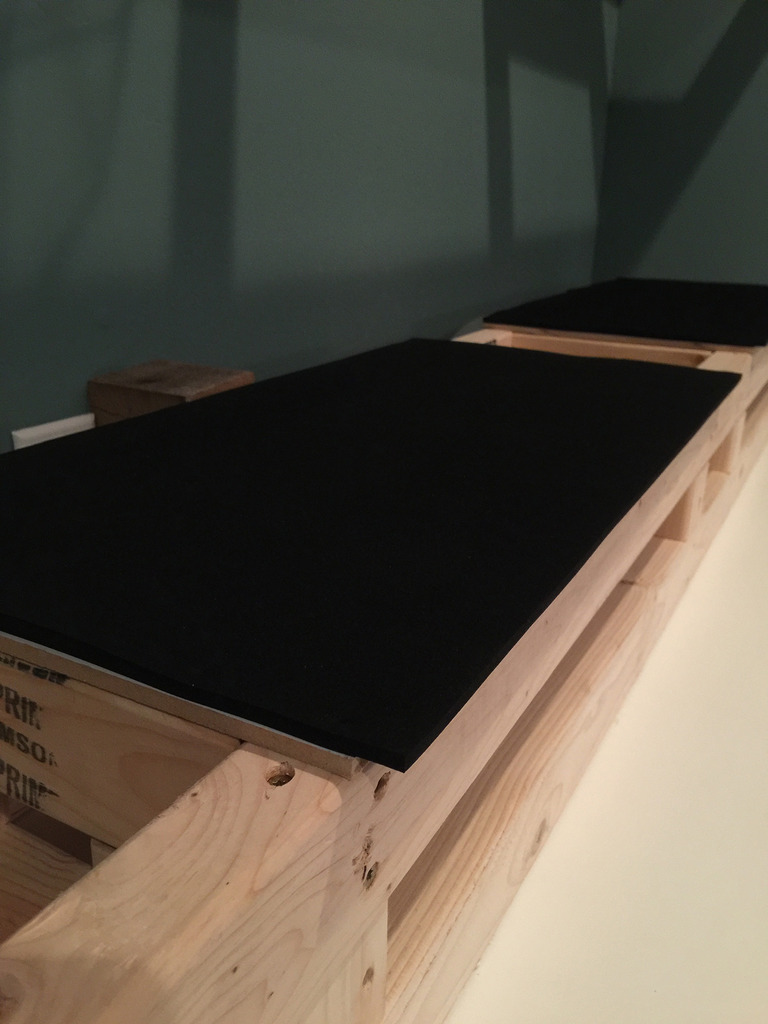

My plan is to install 3 smaller aquariums onto a supplemental cabinet directly on top of the existing cabinet. All three aquariums will be plumbed to a single sump giving me 3 unique ecosystems while having the benefit of an overall larger water volume. I anticipate the overall water volume will be about 60 gallons. The lighting will be concealed in a floating shelf with wires running through a conduit behind the drywall. I hope you will join me through the build process as I attempt to make my vision and plan a reality.

Preliminary Sketch of the Project

My name is Brad Urbanek, I've been reef keeping just over 8 years. Like many, I've went through the progression of going bigger and bigger only now to go smaller, smaller and smaller. One thing that I learned through my last aquarium, a 250 gallon reef, is that what I love most about the hobby is just having a playground to experiment with. Having a large aquarium didn't provide me any more satisfaction than I got with my 28g Nano or my 110g Rimless. I learned that moving with a large aquarium adds an infinite amount of work and stress. Having to rely on others just to lift the aquarium is something I wanted to avoid moving forward. As I pondered these lessons, I knew that my next adventure would be with tanks that I could lift and carry on my own.

My Vision

If you've followed my last build you know that I enjoy woodworking as much as I do reef keeping. I want to use this build as an opportunity to test new skills and ultimately create a gorgeous display that is free of visible wires and plumbing. I want the system to be as clean and simple as possible while matching the flow of our new home. My options for aquarium locations are limited and when I say limited I mean I have one possible location. In this location, we already has an existing cabinet that matches our kitchen cabinets. Having this cabinet is both a blessing and a curse. A blessing in that it's there, it matches and it's one less thing to pay for. A curse in that getting it ready to support the system while keeping the doors and drawers functional will be a test.

The Plan

My plan is to install 3 smaller aquariums onto a supplemental cabinet directly on top of the existing cabinet. All three aquariums will be plumbed to a single sump giving me 3 unique ecosystems while having the benefit of an overall larger water volume. I anticipate the overall water volume will be about 60 gallons. The lighting will be concealed in a floating shelf with wires running through a conduit behind the drywall. I hope you will join me through the build process as I attempt to make my vision and plan a reality.

Preliminary Sketch of the Project