@ravi197699

I noticed that blue robotics suggests a few seconds of servo.writemicroseconds(1500) in void setup to initialize the thruster ESC. Did you find that unnecessary?

Also, I think 1100-1500 microseconds is reverse and 1500-1900 microseconds corresponds with forward right? Working on a program for it this weekend hopefully with some smooth transitions, I'll let you know if I find any worthwhile departures from yours. - that is correct sir

Also, having a buddy machine a housing from plastic, if it comes out nice, I am sure he would be happy to make a few more. - I would love to see the design on plastic housing and how are you planning to secure to glass with magnet?

was looking at titanium tubes (4"ID thin wall Ti tubing is like $125 for 4 feet, only need about 6 to 8" per thruster, so could make several Abyzz style housings, but they laser cut theirs and i think machining it would stink, so thats why I'll start with plastic.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Using Thrusters as wave makers in aquariums

- Thread starter ravi197699

- Start date

- Tagged users None

Ok, played with it some last night. Initial thoughts on a T200:

1. Not much louder than an ECM63, but with more power (sheesh Ravi you are using T500s!?!).

2. Massive thrust difference at 12V and 20V.

3. Almost concerning levels of thrust. Like you better have a VERY well built fishtank to run one of these at any significant thrust level. I would never fix one of these to a rimless non-eurobraced tank, you'd blow a seam in short order (my subjective assessment)

4. I need to re-think the mounting method, and the code has to be very air-tight to prevent the PWM signal from getting too high. Startup and running torque is significant as is the moment from supporting the thruster only on one side. My biggest thought is you do NOT want one of these coming loose in the tank, it will go through your glass. I'll share what method I land on.

5. Simple lesson, the power supply has to be on before the arduino so that the ESC can get through its initialization steps at PWM 1500 signal. It will emit 5 tones if happy. For some reason I cant get my potentiometer control to work, have been using serial input and ramping code instead. Going to tinker more.

They claim that the unit deadband is PWM signal 1500 +/- 25, but mine is 1500 +/ 100. Like I don't start turning until 1600, which might explain the large initial torque. My initial goal is a smooth ramp up from 1600 to 1750 and back down repeatedly to minimize wear and tear.

Super cool tool, just need to be careful. "with great power comes great responsibility..."

1. Not much louder than an ECM63, but with more power (sheesh Ravi you are using T500s!?!).

2. Massive thrust difference at 12V and 20V.

3. Almost concerning levels of thrust. Like you better have a VERY well built fishtank to run one of these at any significant thrust level. I would never fix one of these to a rimless non-eurobraced tank, you'd blow a seam in short order (my subjective assessment)

4. I need to re-think the mounting method, and the code has to be very air-tight to prevent the PWM signal from getting too high. Startup and running torque is significant as is the moment from supporting the thruster only on one side. My biggest thought is you do NOT want one of these coming loose in the tank, it will go through your glass. I'll share what method I land on.

5. Simple lesson, the power supply has to be on before the arduino so that the ESC can get through its initialization steps at PWM 1500 signal. It will emit 5 tones if happy. For some reason I cant get my potentiometer control to work, have been using serial input and ramping code instead. Going to tinker more.

They claim that the unit deadband is PWM signal 1500 +/- 25, but mine is 1500 +/ 100. Like I don't start turning until 1600, which might explain the large initial torque. My initial goal is a smooth ramp up from 1600 to 1750 and back down repeatedly to minimize wear and tear.

Super cool tool, just need to be careful. "with great power comes great responsibility..."

Thank you for sharing your initial thoughts, I am using T500 but at 8volts and it does not take much to move water, I have never tried above 10 volts, it will push water out on other side of the tank, I agree that if someone wants to use this thruster their tank will have to be built strong or it will break the seam, your potentiometer meter will have to stay at " 0 " and arduino will take up from there, if you move your potentiometer to ramp up then arduino code does not have reference value = 0 to star with and code will not work, please do share your mounting options, I have secured mine on the glass with strong magnets that are sealed in clear 2 part epoxy, there water is getting in that epxy and outside is in clear acrylic box from amazon, works well with 3/4" thick glass,Ok, played with it some last night. Initial thoughts on a T200:

1. Not much louder than an ECM63, but with more power (sheesh Ravi you are using T500s!?!).

2. Massive thrust difference at 12V and 20V.

3. Almost concerning levels of thrust. Like you better have a VERY well built fishtank to run one of these at any significant thrust level. I would never fix one of these to a rimless non-eurobraced tank, you'd blow a seam in short order (my subjective assessment)

4. I need to re-think the mounting method, and the code has to be very air-tight to prevent the PWM signal from getting too high. Startup and running torque is significant as is the moment from supporting the thruster only on one side. My biggest thought is you do NOT want one of these coming loose in the tank, it will go through your glass. I'll share what method I land on.

5. Simple lesson, the power supply has to be on before the arduino so that the ESC can get through its initialization steps at PWM 1500 signal. It will emit 5 tones if happy. For some reason I cant get my potentiometer control to work, have been using serial input and ramping code instead. Going to tinker more.

They claim that the unit deadband is PWM signal 1500 +/- 25, but mine is 1500 +/ 100. Like I don't start turning until 1600, which might explain the large initial torque. My initial goal is a smooth ramp up from 1600 to 1750 and back down repeatedly to minimize wear and tear.

Super cool tool, just need to be careful. "with great power comes great responsibility..."

@Reef-Engineer - this is new sketch that I have not tried, give it a try, this code should ramp up and down randomly, let me know how you like it, I have modified it to run 4 thrusters, I will add small ones on opposite side.Thank you for sharing your initial thoughts, I am using T500 but at 8volts and it does not take much to move water, I have never tried above 10 volts, it will push water out on other side of the tank, I agree that if someone wants to use this thruster their tank will have to be built strong or it will break the seam, your potentiometer meter will have to stay at " 0 " and arduino will take up from there, if you move your potentiometer to ramp up then arduino code does not have reference value = 0 to star with and code will not work, please do share your mounting options, I have secured mine on the glass with strong magnets that are sealed in clear 2 part epoxy, there water is getting in that epxy and outside is in clear acrylic box from amazon, works well with 3/4" thick glass,

#include <Servo.h>

const int servoPins[] = {9, 10, 11, 12}; // Pins for the four servo motors

Servo servos[4]; // Array of Servo objects

void setup() {

// Attach servos to their respective pins

for (int i = 0; i < 4; i++) {

servos.attach(servoPins);

}

}

void loop() {

// Randomly generate target positions for each servo

int targetPos[4];

for (int i = 0; i < 4; i++) {

targetPos = random(0, 180); // Adjust the range based on your servo's limits

}

// Randomly generate ramp duration

int rampDuration = random(500, 2000); // Adjust the range for ramp duration

// Randomly generate ramp speed for each servo

int rampSpeeds[4];

for (int i = 0; i < 4; i++) {

rampSpeeds = random(1, 10); // Adjust the range for ramp speed

}

// Ramp up all servos

for (int point of sale = 0; point of sale <= 180; point of sale++) {

for (int i = 0; i < 4; i++) {

servos.write(point of sale * rampSpeeds);

}

delay(rampDuration / 180);

}

// Random delay before ramping down

delay(random(1000, 3000)); // Adjust the range for delay

// Ramp down all servos

for (int point of sale = 180; point of sale >= 0; point of sale--) {

for (int i = 0; i < 4; i++) {

servos.write(point of sale * rampSpeeds);

}

delay(rampDuration / 180);

}

// Random delay before next iteration

delay(random(1000, 3000)); // Adjust the range for delay

}

@ravi197699 I will give it a shot. Right now I have a good program with my PWM signal ramping from 1600 to 1800 and back down again smoothly, and it is printing out the live PWM signal to the serial window so that I can monitor it.

The weird thing is, the RPM of the T200 is only changing at 1600, 1700, and 1800. No values in between. So while the PWM signal is ramping smoothly, the rpm of the thruster is slow at 1600, medium at 1700, and high at 1800, with no change in-between. Any ideas?

It is doing this at 8V, 12V and 16V so I don't think it is a power supply issue. Could it be the ESC only changes frequency at PWM intervals of 100uS?

The weird thing is, the RPM of the T200 is only changing at 1600, 1700, and 1800. No values in between. So while the PWM signal is ramping smoothly, the rpm of the thruster is slow at 1600, medium at 1700, and high at 1800, with no change in-between. Any ideas?

It is doing this at 8V, 12V and 16V so I don't think it is a power supply issue. Could it be the ESC only changes frequency at PWM intervals of 100uS?

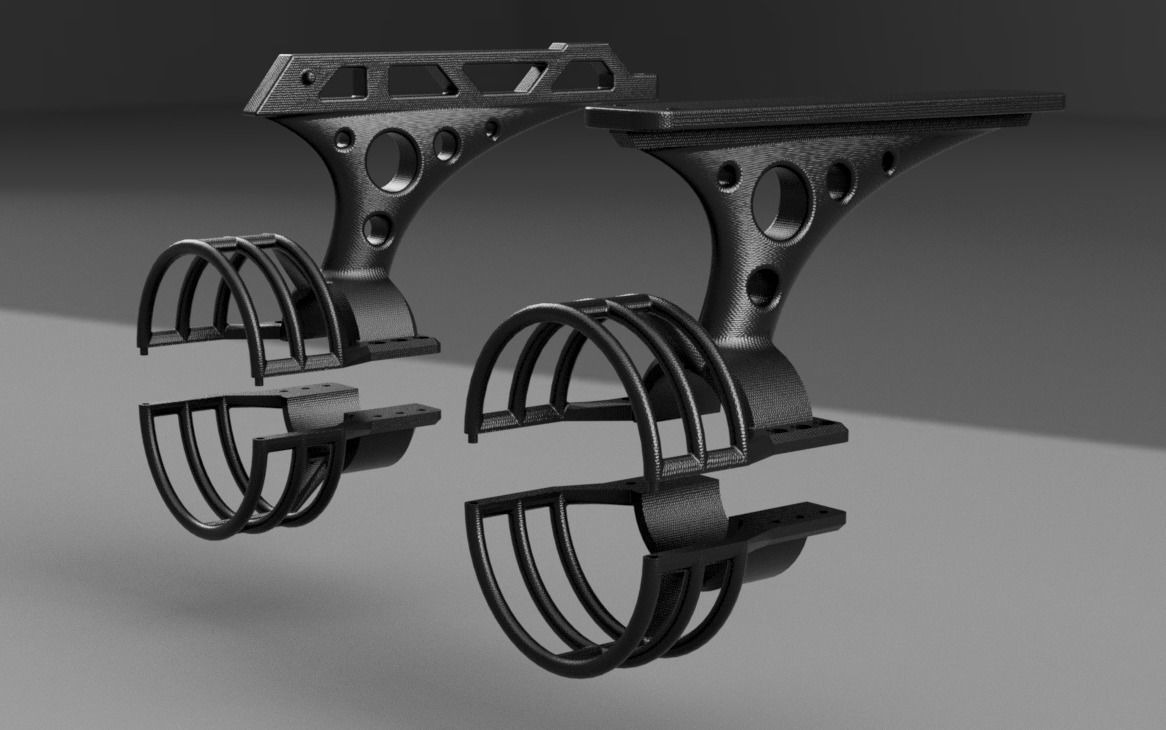

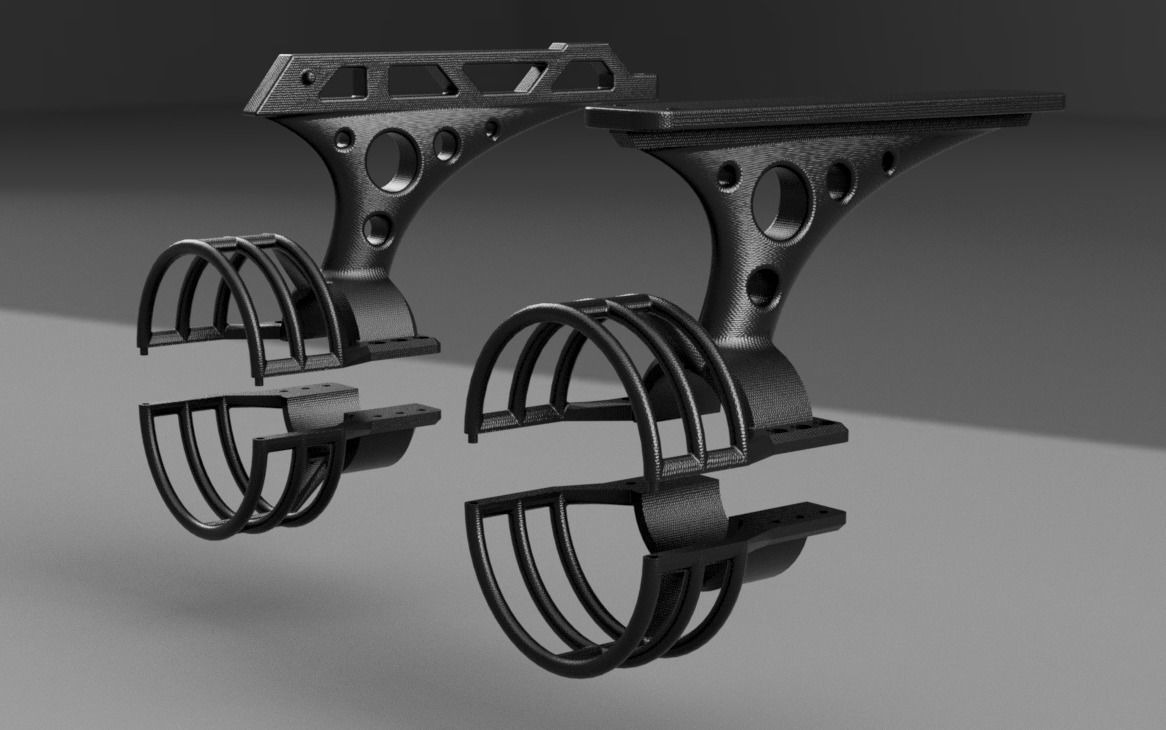

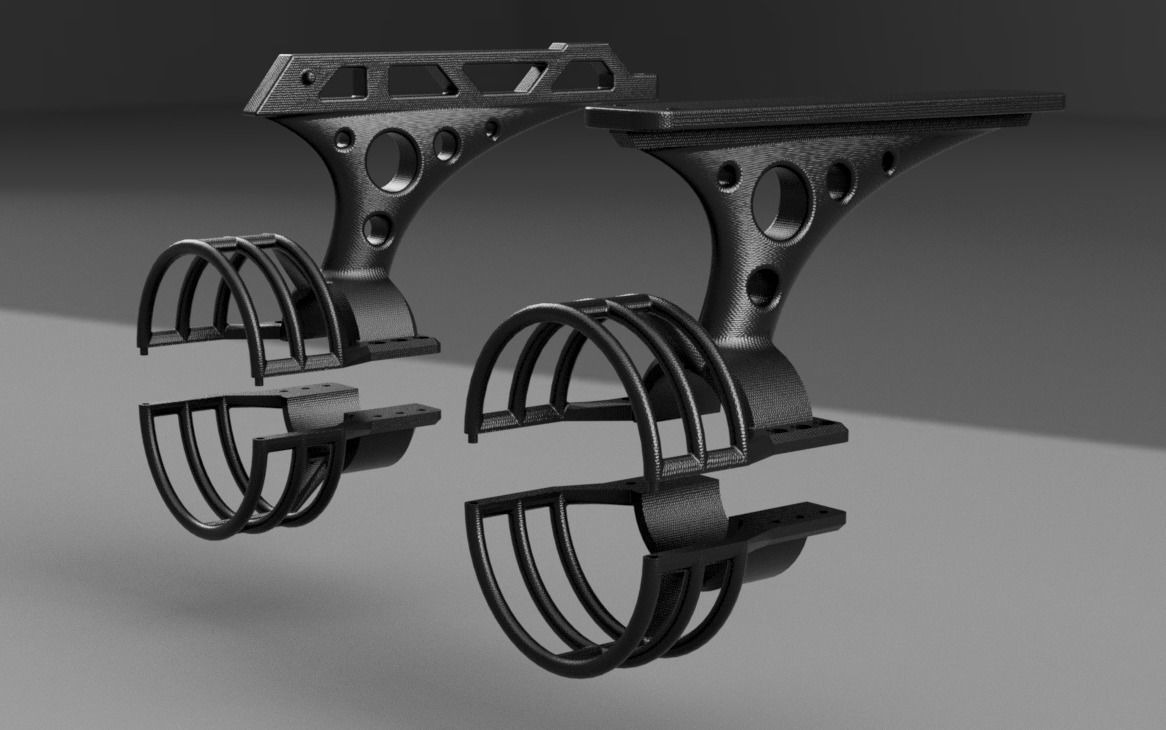

One interesting mount idea (these are paddleboard mounts).

I just bought some magnets and am going to try to sketch up a axial mount (like standard panta rhei) to attach to the back of the motor, receive three magnets, and mount to your glass. I just need to dust off some CAD skills to make the .slt file so someone can print it.

No more progress last night on programming the thruster. Mine is just jumping RPM at every 100uS PWM change (so 1600, 1700, 1800, 1900) which does not make for a smooth ramp. I am chatting with blue robotics about it. The right PWM signal is going out, the ESC is just not changing its output except for at those numbers above. hrm.

I just bought some magnets and am going to try to sketch up a axial mount (like standard panta rhei) to attach to the back of the motor, receive three magnets, and mount to your glass. I just need to dust off some CAD skills to make the .slt file so someone can print it.

No more progress last night on programming the thruster. Mine is just jumping RPM at every 100uS PWM change (so 1600, 1700, 1800, 1900) which does not make for a smooth ramp. I am chatting with blue robotics about it. The right PWM signal is going out, the ESC is just not changing its output except for at those numbers above. hrm.

One interesting mount idea (these are paddleboard mounts).

I just bought some magnets and am going to try to sketch up a axial mount (like standard panta rhei) to attach to the back of the motor, receive three magnets, and mount to your glass. I just need to dust off some CAD skills to make the .slt file so someone can print it.

No more progress last night on programming the thruster. Mine is just jumping RPM at every 100uS PWM change (so 1600, 1700, 1800, 1900) which does not make for a smooth ramp. I am chatting with blue robotics about it. The right PWM signal is going out, the ESC is just not changing its output except for at those numbers above. hrm.

I too have been playing around with mine. I cannot get the potentiometer sketch on the Blue Robotics site to work, but I have @ravi197699 sketch from a few days ago working. The changes between random power levels are a bit too jerky for my liking.

I agree with @Reef-Engineer on the power. Cranking the volts REALLY makes this thing push water!

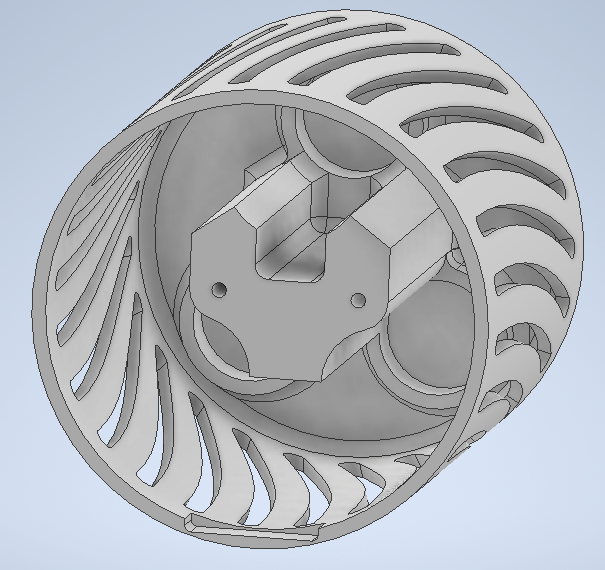

I was a bit upset with how loud it was when I tested it because it whined pretty loudly when spinning quickly or with startup torque. Then I realized that the shroud I have it in isn’t letting it pull enough water so it was stressing the motor. It was also pulling so hard that even a a low power, a fish could get stuck to it. A few hundred drill holes later and this issue should be fixed. This is shroud is just temporary.

But yeah, we need a sketch that really smoothes out the power changes. Unfortunately this part is beyond my skill set.

this is nice design and I like the 2-piece design if you can change the design to accommodate magnet that will be awesome, I have shared few sketches that I have tried and my thrusters ramp up and down smoothly, But I will keep changing the sketch until I find the sweet spot.;One interesting mount idea (these are paddleboard mounts).

I just bought some magnets and am going to try to sketch up a axial mount (like standard panta rhei) to attach to the back of the motor, receive three magnets, and mount to your glass. I just need to dust off some CAD skills to make the .slt file so someone can print it.

No more progress last night on programming the thruster. Mine is just jumping RPM at every 100uS PWM change (so 1600, 1700, 1800, 1900) which does not make for a smooth ramp. I am chatting with blue robotics about it. The right PWM signal is going out, the ESC is just not changing its output except for at those numbers above. hrm.

@ravi197699 I tried the sketch that you sent yesterday and my system was not smoothly ramping (jumping RPM), so I am troubleshooting that now. you were sending 0-180 servo orders as opposed the 1100-1900 uS signals and maybe that is where the magic is. I'll share what I find and when I have a sketch for a mount.

you can modify the sketchI too have been playing around with mine. I cannot get the potentiometer sketch on the Blue Robotics site to work, but I have @ravi197699 sketch from a few days ago working. The changes between random power levels are a bit too jerky for my liking.

I agree with @Reef-Engineer on the power. Cranking the volts REALLY makes this thing push water!

I was a bit upset with how loud it was when I tested it because it whined pretty loudly when spinning quickly or with startup torque. Then I realized that the shroud I have it in isn’t letting it pull enough water so it was stressing the motor. It was also pulling so hard that even a a low power, a fish could get stuck to it. A few hundred drill holes later and this issue should be fixed. This is shroud is just temporary.

But yeah, we need a sketch that really smoothes out the power changes. Unfortunately this part is beyond my skill set.

ok see the sketches below and try, I know I have modified the code, please see my working document link below - https://docs.google.com/document/d/...ouid=107534192004657059569&rtpof=true&sd=true@ravi197699 I tried the sketch that you sent yesterday and my system was not smoothly ramping (jumping RPM), so I am troubleshooting that now. you were sending 0-180 servo orders as opposed the 1100-1900 uS signals and maybe that is where the magic is. I'll share what I find and when I have a sketch for a mount.

that linked doc is locked, I requested access. I'll work it more tonight.you can modify the sketch

ok see the sketches below and try, I know I have modified the code, please see my working document link below - https://docs.google.com/document/d/...ouid=107534192004657059569&rtpof=true&sd=true

granted sirthat linked doc is locked, I requested access. I'll work it more tonight.

something is definitely up with my Arduino. I controlled the T200 via the thruster commander and get smooth RPM transitions from stopped to full FWD and full reverse. I have tried a dozen codes of mine and Ravi's and I get super jerky motion because the RPM of the motor is only changing every hundred microseconds of signal change (like 1600, 1700, 1800, 1900). so 4 discreet RPMs forward and 4 backward. Makes for VERY rough ramping. I am still trying to work out why this is. The Arduino is calculating the correct PWM signals in uS and then claims to be sending them, and actually must be because the motor notices when it hits one of those round numbers and changes speed, it just doesnt change for anything less than a round hundred. so weird. I might take a break if I get stuck on that and draw up an axial mount, I ordered some nice potted magnets to mount it to the glass like a panta rhei.

did you try to change the number that will delay the speed of ramp and it will ramp up gradually? are you changing the code, I shared the document above where I have multiple sketches that does different things, try one of the sketch and make sure potentiometer is in the center "0" , let me know if any of the sketch is working based on your liking and tinker with it?something is definitely up with my Arduino. I controlled the T200 via the thruster commander and get smooth RPM transitions from stopped to full FWD and full reverse. I have tried a dozen codes of mine and Ravi's and I get super jerky motion because the RPM of the motor is only changing every hundred microseconds of signal change (like 1600, 1700, 1800, 1900). so 4 discreet RPMs forward and 4 backward. Makes for VERY rough ramping. I am still trying to work out why this is. The Arduino is calculating the correct PWM signals in uS and then claims to be sending them, and actually must be because the motor notices when it hits one of those round numbers and changes speed, it just doesnt change for anything less than a round hundred. so weird. I might take a break if I get stuck on that and draw up an axial mount, I ordered some nice potted magnets to mount it to the glass like a panta rhei.

Yeah i have run a few of the codes and made some modifications but my motor is just running at 4 fwd and 4 reverse rpms so the programs perform poorly. I set it all up with their thruster controller and it worked perfectly. So something with my arduino uno r4 wifi is updid you try to change the number that will delay the speed of ramp and it will ramp up gradually? are you changing the code, I shared the document above where I have multiple sketches that does different things, try one of the sketch and make sure potentiometer is in the center "0" , let me know if any of the sketch is working based on your liking and tinker with it?

Arduino Uno R4 wifi pwm problem

Well, there you go. Its a known issue on this new arduino, and not fixed yet i dont think.

So for all others out there using arduino uno r4 wifi, its not you, its not your code, its your arduino.

Well, there you go. Its a known issue on this new arduino, and not fixed yet i dont think.

So for all others out there using arduino uno r4 wifi, its not you, its not your code, its your arduino.

I followed the link to github, some fantastic souls made code modifications and i uploaded a new servo library to the IDE and fixed the issue. Back in business!

how are thrusters working on modified code? please if you can share the code as well so that I can try with my arduino and thrusters,I followed the link to github, some fantastic souls made code modifications and i uploaded a new servo library to the IDE and fixed the issue. Back in business!

Well, this is likely part of my problem. Look forward to seeing your new sketch if you don’t mind sharing.Arduino Uno R4 wifi pwm problem

Well, there you go. Its a known issue on this new arduino, and not fixed yet i dont think.

So for all others out there using arduino uno r4 wifi, its not you, its not your code, its your arduino.

@sawdonkey which Arduino are you using? If it is an Uno R4 with a Renesas microcontroller then it has this issue and you have to update the servo library. I can walk you through that if needed.

Here is a teaser of the thruster housing. So it attaches to the two machine screws where the current nosecone attaches, passes the power cable out, holds three coated magnets inside, and those interface with three coated magnets outside in the outer component.

Buddy is going to help me machine one and I will likely print one as well and see what turns out better. This part, the outboard magnet holder, plus the required long M3 screws, and the 6 magnets, will be what is needed to transform a T200 into a mount-to-glass powerhead.

Here is a teaser of the thruster housing. So it attaches to the two machine screws where the current nosecone attaches, passes the power cable out, holds three coated magnets inside, and those interface with three coated magnets outside in the outer component.

Buddy is going to help me machine one and I will likely print one as well and see what turns out better. This part, the outboard magnet holder, plus the required long M3 screws, and the 6 magnets, will be what is needed to transform a T200 into a mount-to-glass powerhead.

Similar threads

- Replies

- 5

- Views

- 228

- Replies

- 6

- Views

- 154