Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Woodworking, must have tools?

- Thread starter David M.

- Start date

- Tagged users None

Get yourself a combination square. A cheap tool with lots of uses that will last a long time if taken care of correctly. Plus it makes sure your tools and your work are square and not out of whack.

- Joined

- Nov 18, 2015

- Messages

- 404

- Reaction score

- 148

How about this router + table? Sorry for all the questions I just want to make sure my purchases will work for what im trying to do, build stands and canopies.

http://www.harborfreight.com/power-tools/routers/router-table-with-router-95380.html

http://www.harborfreight.com/power-tools/routers/router-table-with-router-95380.html

- Joined

- Nov 18, 2015

- Messages

- 404

- Reaction score

- 148

Circular saw for the actual cutting, looking at a router for joint work.I'd stray away from routers. You're not gonna cut a 2×4 with that

What kind of joint work are you doing? Some stuff from harbor freight isn't bad but you get what you pay for. Just like in this hobby. You don't want to have upgrade to something else cause it wasn't good enough. There are lots of different ways to do joinery. It also takes a lot of practice.

You can certainly jump right into all the tools and watch some videos but you might get a little discouraged that things don't work out as easily as people tell you.

A suggestion: Ask some people near by if they'll help you. You can learn from someone experienced, see if you really need the tool or maybe figure out a better/easier/cheaper way to do it.

You can certainly jump right into all the tools and watch some videos but you might get a little discouraged that things don't work out as easily as people tell you.

A suggestion: Ask some people near by if they'll help you. You can learn from someone experienced, see if you really need the tool or maybe figure out a better/easier/cheaper way to do it.

- Joined

- Oct 25, 2015

- Messages

- 631

- Reaction score

- 473

Ah I see. Where are you located?Circular saw for the actual cutting, looking at a router for joint work.

- Joined

- Nov 18, 2015

- Messages

- 404

- Reaction score

- 148

What kind of joint work are you doing? Some stuff from harbor freight isn't bad but you get what you pay for. Just like in this hobby. You don't want to have upgrade to something else cause it wasn't good enough. There are lots of different ways to do joinery. It also takes a lot of practice.

You can certainly jump right into all the tools and watch some videos but you might get a little discouraged that things don't work out as easily as people tell you.

A suggestion: Ask some people near by if they'll help you. You can learn from someone experienced, see if you really need the tool or maybe figure out a better/easier/cheaper way to do it.

I have a guy in my reef club who has been doing professional wood working for over 20 years, and lots of others with experience that have offered to help when I need it. I'm expecting failure (or close to) for my first couple projects, and thats ok. First project will be a table for my router/saws/tools, which doesnt have to be perfect and will give me some experience with the tools. As for joint work, I dont really know yet. I just want something other than butt joints eventually.

I'm at Fort Gordon, GA.Ah I see. Where are you located?

I have to look for one of those

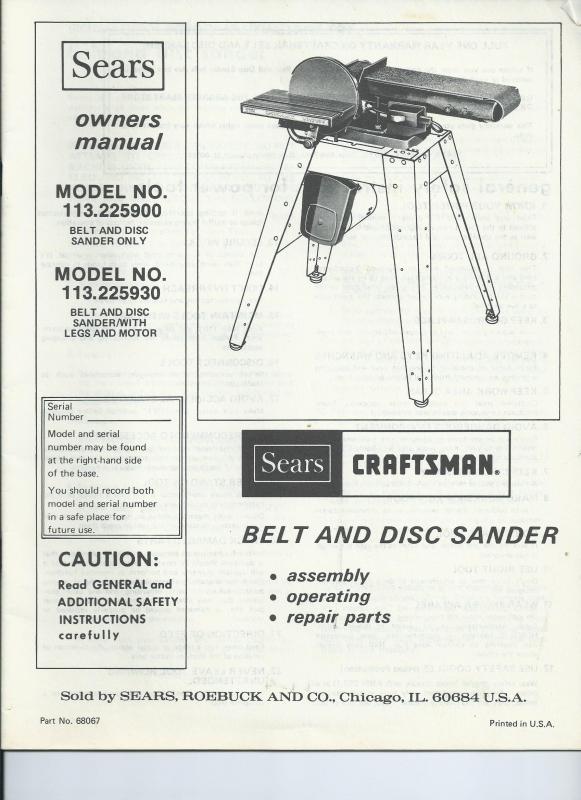

You buy that One New?

Yes I did, over 30 years ago

I have many tools much older than that but someone is coming over tomorrow to buy that table model belt sander as I have two of them.

They actually do have saws that disengage the blade if your finger is close to touching.

I haven't looked at these recently, but back then they threw a sacrificial chunk of metal into the blade to instantly stop it....more or less based on a GFCI circuit. I think an AFCI (arc fault), in this case...if I recall correctly.

Pretty amazing technology....super simple, amazingly effective. Tough on the saw blade though!

[...]Theres even a little 4" table saw for 40 bucks at harbor freight[...]

It is what it is, but here's my $0.02:

All the value in the table saw is in the table. (Hence the name, right??

If you can't afford the price and/or space for at least a full sized "job site" saw (which is arguably crap vs a cabinet saw) I'd stick with the tool list you outlined. (There's also a good chance you don't need one for what you're doing if you can't afford it.)

There are other ways to skin the cat without a mini-table-saw being involved.

- Joined

- Oct 25, 2015

- Messages

- 631

- Reaction score

- 473

I literally brought a square when I went to Lowe's for a table saw. I figured if the display is good then the boxed one should be.It is what it is, but here's my $0.02:

All the value in the table saw is in the table. (Hence the name, right??)

If you can't afford the price and/or space for at least a full sized "job site" saw (which is arguably crap vs a cabinet saw) I'd stick with the tool list you outlined. (There's also a good chance you don't need one for what you're doing if you can't afford it.)

There are other ways to skin the cat without a mini-table-saw being involved.

You could get there with a sliding miter saw, router, pocket hole kit/drill. But I think a table saw makes much of that far easier, and a TS can do so much especially with sheet goods.

A TS can be as expensive or as cheap as you want. I recently picked up an old 80's Craftsman contractor's saw and gave it a quick refurbish: http://blog.woodscrub.info/2014/08/craftsman-table-saw-from-80s.html Less than $150 when I was done, and it was awesome. The upgrades I added later were a mobile base, a Delta T-square fence, and a router table extension wing. For a one car garage shop, having the router table in a small-ish table saw like this and all on a mobile base made the most sense. After all that, probably around $300 into it not counting the router itself and blades for the saw.

Of course, you never use the blades a saw comes with even new. Ugh.

Here's the end product:

A TS can be as expensive or as cheap as you want. I recently picked up an old 80's Craftsman contractor's saw and gave it a quick refurbish: http://blog.woodscrub.info/2014/08/craftsman-table-saw-from-80s.html Less than $150 when I was done, and it was awesome. The upgrades I added later were a mobile base, a Delta T-square fence, and a router table extension wing. For a one car garage shop, having the router table in a small-ish table saw like this and all on a mobile base made the most sense. After all that, probably around $300 into it not counting the router itself and blades for the saw.

Of course, you never use the blades a saw comes with even new. Ugh.

Here's the end product:

- Joined

- Nov 18, 2015

- Messages

- 404

- Reaction score

- 148

That's originally what I was planning to get. But after talking to a buddy of mine I'm a bit confused. He never uses a miter, and said I could do almost everything with a circular saw (and router if I choose). What's y'alls opinion on that? It would definitely save me money up front.

You *can* use a circ saw. But unless you go with a nice track saw, you're going to have a hard time making accurate and straight cuts. And it'll be even more difficult to exactly reproduce dimensions, like legs that MUST all be the same length.

I started out with a jigsaw and a circular saw. Their limitations were quickly apparent so I moved up to a table saw. I have many more tools (miter saw, jointer, planer, etc etc etc) but a tablesaw and router will do so much...

I started out with a jigsaw and a circular saw. Their limitations were quickly apparent so I moved up to a table saw. I have many more tools (miter saw, jointer, planer, etc etc etc) but a tablesaw and router will do so much...

Table Saw (I highly recommend the Sawstop brand)

Track Saw

Miter Saw

Safety glasses and earplugs

Track Saw

Miter Saw

Safety glasses and earplugs

Similar threads

- Replies

- 16

- Views

- 473

- Replies

- 17

- Views

- 317

- Replies

- 48

- Views

- 1,583

New Posts

-

-

What do you look for in a good "marine mix" frozen food?

- Latest: ISpeakForTheSeas

-