When you say 2/3, what does that mean exactly? Sorry. Also, do you happen to have any links to information on injection? i'm really interested in learning more about it.Yea the most I’d recommend for the bottom is three under the front and back panes and only two on the side panes, I used the injection method and painters tape for cleanup.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

220 Gallon Complete Redo

- Thread starter Phantom7

- Start date

- Tagged users None

So when lining the panes up, I have the front and back (long) glass panes sit on top of three of those beads each, and then the two sides sit on top of two, and then between all the vertical seams I just do two as well. Connect the right angle jigs and you’re good to go. I don’t have any links to injection method but it’s pretty simple. Make sure you have everything set and ready for sealing and make sure all the outside edges are taped. Injection method is when you injection silicon into the seam from the outside of the tank, it will fill the seam as well as making a bead on the inside, which you then do your normal process of scraping that seam up to make the water tight seal. Injection method makes the seam one entire piece instead of two.When you say 2/3, what does that mean exactly? Sorry. Also, do you happen to have any links to information on injection? i'm really interested in learning more about it.

I'm still lost honestly. It sits on top of beads? so like a small dab of silicon? Then you place the panes and inject through the small gap?

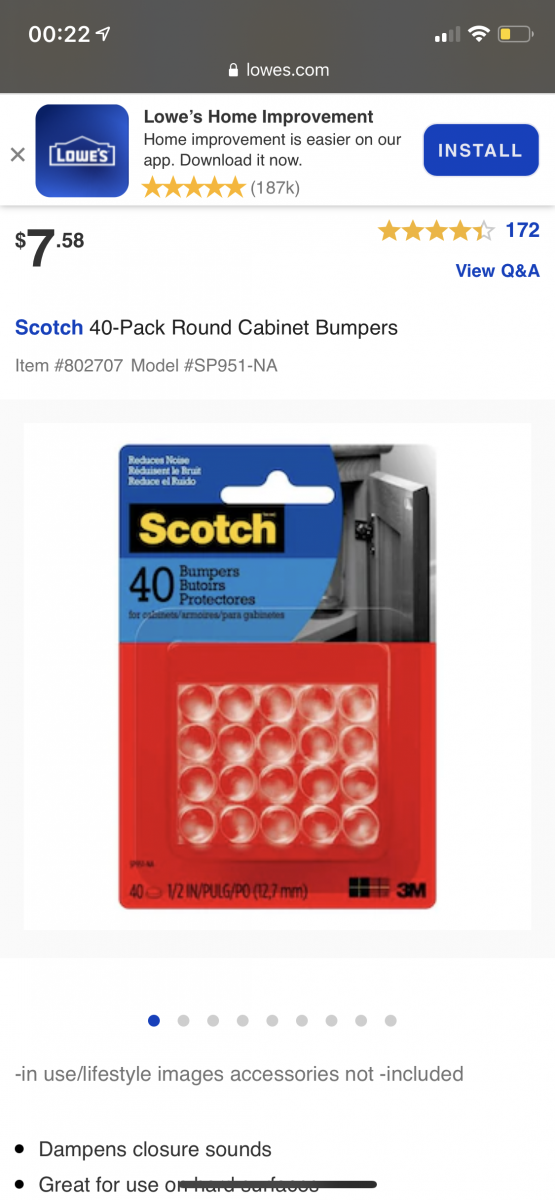

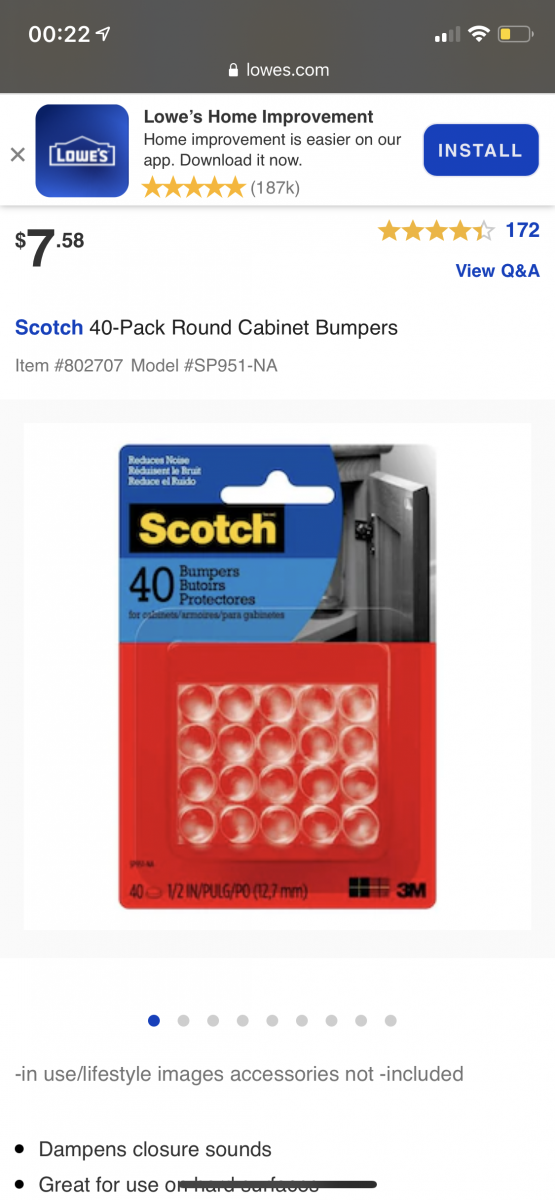

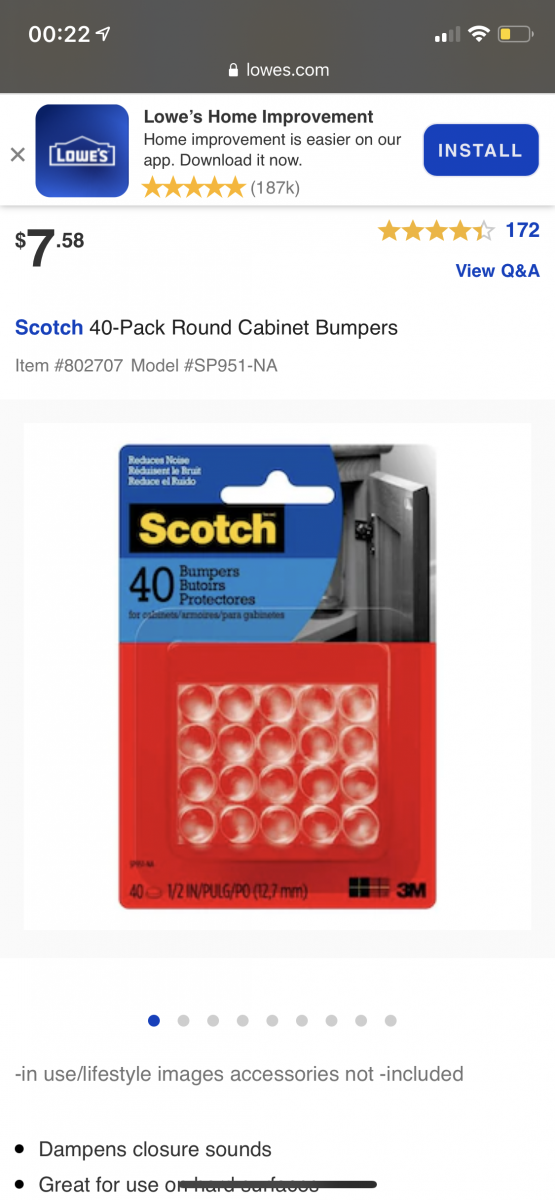

This stuff. It’s like the anti slip bumpers for chairs. Just put those in between the seams links I was describing earlier, and then when you do injection method, the silicone fills in around it and all the seams and you’re good to go. They don’t compress at all and it keeps equal spacing. Just get the smallest ones you can find. Usually the go to measurement is 1/4”

They have a sticky side so when you put them down they won’t move either.

I see, thank you! And those are fine to just leave in the seal? i assume we won't be scraping those back out lol

This stuff. It’s like the anti slip bumpers for chairs. Just put those in between the seams links I was describing earlier, and then when you do injection method, the silicone fills in around it and all the seams and you’re good to go. They don’t compress at all and it keeps equal spacing. Just get the smallest ones you can find. Usually the go to measurement is 1/4”

And use those ones specifically? i see they're 1/2" so i'll try to find one smaller

will this work, or is it too small?

This stuff. It’s like the anti slip bumpers for chairs. Just put those in between the seams links I was describing earlier, and then when you do injection method, the silicone fills in around it and all the seams and you’re good to go. They don’t compress at all and it keeps equal spacing. Just get the smallest ones you can find. Usually the go to measurement is 1/4”

3M Bumpon SJ5012 Bumper/Spacer Pad 18438, Black | RSHughes.com

Yea that should work, I’d get a couple different kinds and just mess with them to see how they fit and what the spacing looks like. They’re pretty cheap and you do t need much anyways. Just make sure that they don’t stick out and will be completely sealed around with silicone. I’ll take a picture tomorrow of my tank to show how they look, but yea the process is much easier with them.will this work, or is it too small?

3M Bumpon SJ5012 Bumper/Spacer Pad 18438, Black | RSHughes.com

www.rshughes.com

I'd really appreciate the photo, and i really appreciate your help! Thank you! i'll try to look for some more of them tomorrow.Yea that should work, I’d get a couple different kinds and just mess with them to see how they fit and what the spacing looks like. They’re pretty cheap and you do t need much anyways. Just make sure that they don’t stick out and will be completely sealed around with silicone. I’ll take a picture tomorrow of my tank to show how they look, but yea the process is much easier with them.

No problem! Always here to helpI'd really appreciate the photo, and i really appreciate your help! Thank you! i'll try to look for some more of them tomorrow.

Thank you. Have a great night, Brad.No problem! Always here to help

- Joined

- Apr 4, 2019

- Messages

- 99

- Reaction score

- 57

Too remove the silicone, I use fine steel wool put some acetone on it and rub the place where the silicone is. It will come off and get stuck in the steel wool. Once you think most of it is off, use a new steel wool and acetone and go over it once again. Once done, use alcohol or acetone on a lint free cloth and clean. Then check it once again with a light source at an angle to see if you missed any spots.

Once all good only use gloves or suction cups to handle the panes especially where the silicone is going.

Get as many buddies as you can while siliconing, the glass is heavy and you have to work fast to make sure you do it all in a single go.

Once all good only use gloves or suction cups to handle the panes especially where the silicone is going.

Get as many buddies as you can while siliconing, the glass is heavy and you have to work fast to make sure you do it all in a single go.

After thinking about it overnight, will these cause issues when going to put on the frames?

This stuff. It’s like the anti slip bumpers for chairs. Just put those in between the seams links I was describing earlier, and then when you do injection method, the silicone fills in around it and all the seams and you’re good to go. They don’t compress at all and it keeps equal spacing. Just get the smallest ones you can find. Usually the go to measurement is 1/4”

Sounds like a good idea. Don’t have many buddies, just family lol. I use both suction cups and gloves, just the suction cups to get my fingers under though. Theoretically if I inject the silicon, I can have it all setup and clamped together before I even start, right?Too remove the silicone, I use fine steel wool put some acetone on it and rub the place where the silicone is. It will come off and get stuck in the steel wool. Once you think most of it is off, use a new steel wool and acetone and go over it once again. Once done, use alcohol or acetone on a lint free cloth and clean. Then check it once again with a light source at an angle to see if you missed any spots.

Once all good only use gloves or suction cups to handle the panes especially where the silicone is going.

Get as many buddies as you can while siliconing, the glass is heavy and you have to work fast to make sure you do it all in a single go.

I also have overflows that I forgot to mention. They’re both missing a piece, should I get new ones? Regardless of new or old, when should I silicon those in? At the same time I’m doing all the seals, or after they’ve dried?

(Bolded for anyone skimming the thread)

I have a various assortment of sandpaper and these cabinet bumper things in hand, but my father is afraid leaving these cabinet bumpers inside the silicon will make a weak spot in the seal. Is this something we should be concerned about?

Hello, I’m having issues getting the tiniest bits of silicon up. It looks like residue at this point. Razor blades work, but only work for a couple swipes before they’re ‘dull’ (for the tiniest of it, not dull by ‘normal’ standards) so I’m going through them by the dozen it seems like.

I’ve tried steel wool and acetone (nothing)

Sanded the absolute edges with I believe 120 then went over with 600 (works a little, but scratches the glass all to hell anywhere that’s visible.)

Letting acetone sit on top of it till it evaporates (nothing)

Steel wire thing (nothing)

I’m not sure what other tricks are up everyone’s sleeves, but I need some.

I’ve tried steel wool and acetone (nothing)

Sanded the absolute edges with I believe 120 then went over with 600 (works a little, but scratches the glass all to hell anywhere that’s visible.)

Letting acetone sit on top of it till it evaporates (nothing)

Steel wire thing (nothing)

I’m not sure what other tricks are up everyone’s sleeves, but I need some.

- Joined

- Apr 4, 2019

- Messages

- 99

- Reaction score

- 57

Is your glass scratched up. With the steel wool I was able to get all of it out except in the scratches which needed a lot more elbow grease. I wet the steel wool with acetone and then started scrubbing, put some pressure while scrubbing.

Another thing I used is a steel scrubber used in the kitchen to remove the larger silicone pieces.

Another thing I used is a steel scrubber used in the kitchen to remove the larger silicone pieces.

There’s just a little residue that you can’t even feel that won’t come up.Is your glass scratched up. With the steel wool I was able to get all of it out except in the scratches which needed a lot more elbow grease. I wet the steel wool with acetone and then started scrubbing, put some pressure while scrubbing.

Another thing I used is a steel scrubber used in the kitchen to remove the larger silicone pieces.

- Joined

- Apr 4, 2019

- Messages

- 99

- Reaction score

- 57

Sent you my number in case you want to talkThere’s just a little residue that you can’t even feel that won’t come up.

we’ve discovered our ‘own’ way of getting the silicon off, which is using ironically, glass cleaner. Spray it on, let it set for 10 minutes, go at it with a razor blade (doesn’t matter if it’s a brand new blade or not) and it’s gone.

I’m going to put the rest of our ‘methods’ below for anyone else who may find theirselves doing a entire tank breakdown.

During the initial process of breaking the tank down, we found ourselves really struggling to get a blade in the exterior seam (and chipped the glass in all 6-7 times in various spots) before we got a method that worked. He liked started in the corners (my dad) but I liked finding a spot where the razor decides to go in easier, and we just work it in a little bit, and (don’t cringe) got a hammer, and ever so lightly tap it in. Once that razor is in, do not take it back out or you will lose the ever so slight gap you created. Get a new razor, and do the same next to the razor you just started. We did this around 4 times before we could (safely) slip a putty knife in, then start reusing the blades we had in. (If they don’t easily pull out, use a different blade, like jenga but more expensive.)

When you get to the end of the specific seam you’re working on, moving the putty knife down (not too much force!) should allow that last inch or so of silicon to go ‘voop’ and let go.

(we turned the tank upside down and did the bottom first. After the bottom was off, we clamped and the side panes together losely, and put cinderblocks with cushions between them and the tank all around it. In hindsight, with two of us was unnecessary, but better safe than sorry. We then took a long pane off because the long panes were resting on the short panes, and it would leave more integrity.)

After we took a pane off, we would set it in our spare room on a moving blanket or towel. and so far, that’s where we’re at. We have completely finished 2 panes of glass (cleaning wise). I shall update when we’re putting it together.

Edit: also, if there’s a piece of glass you chipped or something during this process, 600 grit sand paper has worked for me. (This will scratch the glass where you’re sanding)

I’m going to put the rest of our ‘methods’ below for anyone else who may find theirselves doing a entire tank breakdown.

During the initial process of breaking the tank down, we found ourselves really struggling to get a blade in the exterior seam (and chipped the glass in all 6-7 times in various spots) before we got a method that worked. He liked started in the corners (my dad) but I liked finding a spot where the razor decides to go in easier, and we just work it in a little bit, and (don’t cringe) got a hammer, and ever so lightly tap it in. Once that razor is in, do not take it back out or you will lose the ever so slight gap you created. Get a new razor, and do the same next to the razor you just started. We did this around 4 times before we could (safely) slip a putty knife in, then start reusing the blades we had in. (If they don’t easily pull out, use a different blade, like jenga but more expensive.)

When you get to the end of the specific seam you’re working on, moving the putty knife down (not too much force!) should allow that last inch or so of silicon to go ‘voop’ and let go.

(we turned the tank upside down and did the bottom first. After the bottom was off, we clamped and the side panes together losely, and put cinderblocks with cushions between them and the tank all around it. In hindsight, with two of us was unnecessary, but better safe than sorry. We then took a long pane off because the long panes were resting on the short panes, and it would leave more integrity.)

After we took a pane off, we would set it in our spare room on a moving blanket or towel. and so far, that’s where we’re at. We have completely finished 2 panes of glass (cleaning wise). I shall update when we’re putting it together.

Edit: also, if there’s a piece of glass you chipped or something during this process, 600 grit sand paper has worked for me. (This will scratch the glass where you’re sanding)

- Joined

- Apr 4, 2019

- Messages

- 99

- Reaction score

- 57

Good to know for a future build. Thankswe’ve discovered our ‘own’ way of getting the silicon off, which is using ironically, glass cleaner. Spray it on, let it set for 10 minutes, go at it with a razor blade (doesn’t matter if it’s a brand new blade or not) and it’s gone.

I’m going to put the rest of our ‘methods’ below for anyone else who may find theirselves doing a entire tank breakdown.

During the initial process of breaking the tank down, we found ourselves really struggling to get a blade in the exterior seam (and chipped the glass in all 6-7 times in various spots) before we got a method that worked. He liked started in the corners (my dad) but I liked finding a spot where the razor decides to go in easier, and we just work it in a little bit, and (don’t cringe) got a hammer, and ever so lightly tap it in. Once that razor is in, do not take it back out or you will lose the ever so slight gap you created. Get a new razor, and do the same next to the razor you just started. We did this around 4 times before we could (safely) slip a putty knife in, then start reusing the blades we had in. (If they don’t easily pull out, use a different blade, like jenga but more expensive.)

When you get to the end of the specific seam you’re working on, moving the putty knife down (not too much force!) should allow that last inch or so of silicon to go ‘voop’ and let go.

(we turned the tank upside down and did the bottom first. After the bottom was off, we clamped and the side panes together losely, and put cinderblocks with cushions between them and the tank all around it. In hindsight, with two of us was unnecessary, but better safe than sorry. We then took a long pane off because the long panes were resting on the short panes, and it would leave more integrity.)

After we took a pane off, we would set it in our spare room on a moving blanket or towel. and so far, that’s where we’re at. We have completely finished 2 panes of glass (cleaning wise). I shall update when we’re putting it together.

Edit: also, if there’s a piece of glass you chipped or something during this process, 600 grit sand paper has worked for me. (This will scratch the glass where you’re sanding)

Similar threads

- Price: 1800

- Shipping NOT Available

- Replies

- 1

- Views

- 217

- Replies

- 24

- Views

- 692