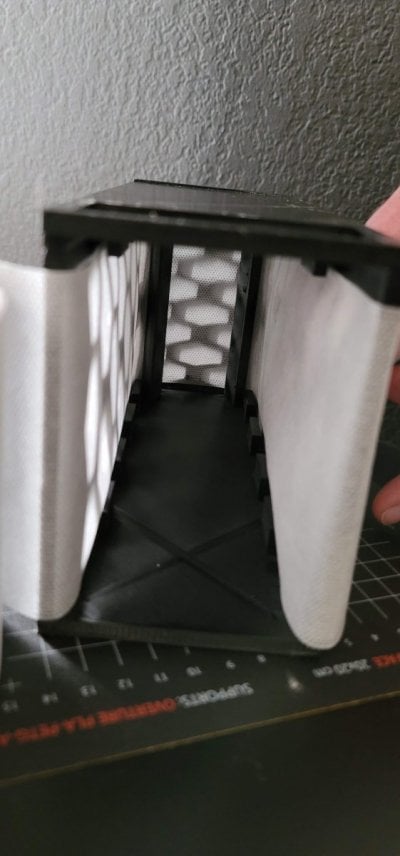

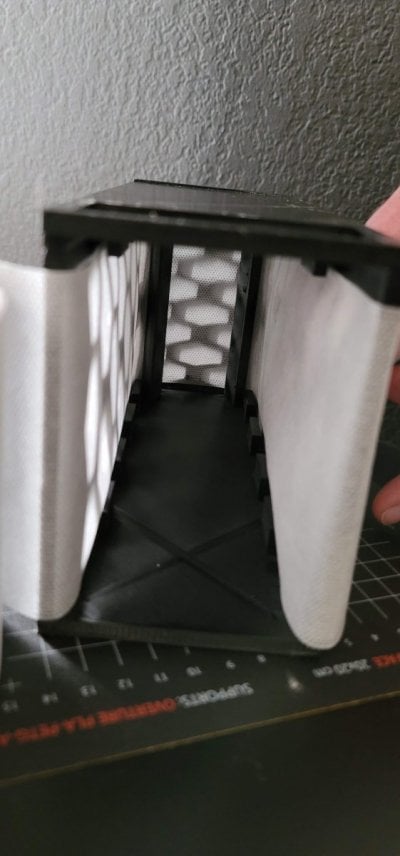

I'm new to 3d printing but wanted to see if I could add a filter roller to my tank. I had limited space and didn't want to change my plumbing, so I spent some time on Tinkercad. The holder for the new fleece and the roller for the used fleece are both separate pieces that I attached to my stand. The return pipe is 1.5" and drains directly into the filter roller cage. I'm not sure what my flow is through my overflow but I'm using a Clarisea SK-3000 roll.