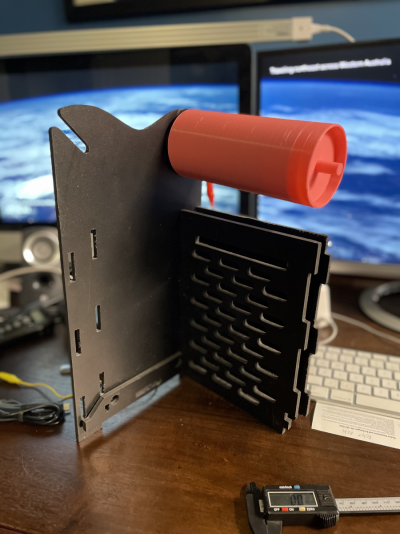

The roller has been working with minimal issues. I have thought about reprinting it and adding more guides for the filter paper. I haven't had to deal with filter socks for over a week, which is sweet. I manually roll the filter every day, and it seems to work. I'm pleased with the outcome when I consider the little effort I put into the design.

@Frank_Aaron, I'm going to check out your design. I look forward to your CNC roller.

@Frank_Aaron, I'm going to check out your design. I look forward to your CNC roller.