Really helpful thread

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A stand plan and a tricky little corner

- Thread starter SallyWho

- Start date

- Tagged users None

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

I stood my stand up on its end and only used one. Made it easier to roll around that way. But, I had the plywood on the sides so it made it easy. Otherwise my stand was too long to make some of the turns. Rolled in my 300 pound tank the same way. Made it very easy.Ahhhh, I see what you mean, now. Thanks!

Oh, $20 ain't bad! Think I'll need one for each corner, or will two suffice for the stand? I'll 100% be getting help from a few strong friends to move the actual tank- I don't trust myself to move it solo.

One placed right in the center is enough.Ahhhh, I see what you mean, now. Thanks!

Oh, $20 ain't bad! Think I'll need one for each corner, or will two suffice for the stand? I'll 100% be getting help from a few strong friends to move the actual tank- I don't trust myself to move it solo.

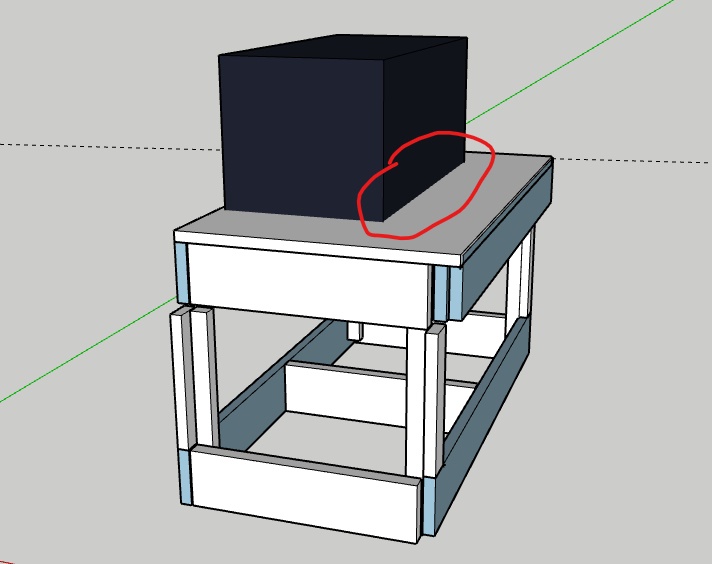

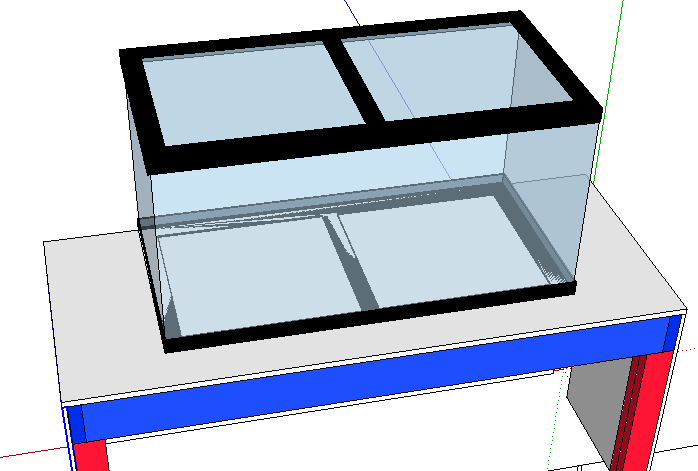

You want a 6' long, 30" wide stand for the extra space inside, so don't sacrifice that space with unnecessary posts & beams. Build it as if the tank was 6' long, 30" wide. The front beam made out of sistered 2x6s, 2x4 'joists' between front & back beams, 3/4" plywood top. 1 2x4 post at back corners, doubled at front corners just to give the sistered beam a place to land. Basically a longer, wider version of mine:

I'd make sure the ends of the tank land on joists - so place them accordingly. Plywood on sides and back makes it plenty strong - even making the 2x4 posts almost redundant.

I'd make sure the ends of the tank land on joists - so place them accordingly. Plywood on sides and back makes it plenty strong - even making the 2x4 posts almost redundant.

You want a 6' long, 30" wide stand for the extra space inside, so don't sacrifice that space with unnecessary posts & beams. Build it as if the tank was 6' long, 30" wide. The front beam made out of sistered 2x6s, 2x4 'joists' between front & back beams, 3/4" plywood top. 1 2x4 post at back corners, doubled at front corners just to give the sistered beam a place to land. Basically a longer, wider version of mine:

I'd make sure the ends of the tank land on joists - so place them accordingly. Plywood on sides and back makes it plenty strong - even making the 2x4 posts almost redundant.

So you think the sistered 2x6s on the front beam will make up for the fact that the front edge of the tank won't be sitting on anything but plywood? I like your plan because it looks simple enough for me to build on my own and doesn't compromise my sump space, but I've got to admit it makes me a bit nervous! Even with 3/4" plywood, I'd worry about the tank's weight only being directly supported on three sides (back edge, and both sides). Am I worrying needlessly? Do you really think this will adequately support my tank? I'm not trying to be snarky- I'm genuinely asking. Thanks!

Sallywho - The plywood is not holding any weight its the 4 edges.

I really like don_chuwish's idea of sistering the beams and the load bearing edges. That will really secure the weight and eliminate the need for a center support for the front that is usually intrusive.

I really like don_chuwish's idea of sistering the beams and the load bearing edges. That will really secure the weight and eliminate the need for a center support for the front that is usually intrusive.

The 3/4" plywood is supported by the 2x4 joists. Just for extra warm fuzzies you could have one under each 'end' of the tank and then another two in between those (at 16" and 32" relative to tank). Plenty strong. Use the joist hangers, they're cheap insurance.

Funiture sliders work well for moving it around

Sorry it's taken me so long to respond. I don't think I'm fully understanding you yet. Please forgive the atrocious design here (I'm still learning to use this 3d modeling crap, and I'm short on time). I think I've roughly mocked up what you're describing: sistered 2x6s across the front on the top frame, sitting on 2x4 posts. I will have joists underneath the sides of the tank, and the back edge of the tank will be supported by the back edge of the frame. What worries me is what's circled in red. Yes, it'll be sitting on plywood, but there's nothing under the plywood to support the otherwise floating front edge of the tank. Does plywood really do that good a job at weight distribution that I could get away with that? The weight will transfer to those sistered front 2x6s? Am I worrying too much? I know there'll be front-to-back joists under the sides of the tank, but all I can imagine is the plywood bowing and then snapping under the weight of a 4' long unsupported front tank edge. It's totally possible that I simply don't understand the physics of weight distribution, though (I got a D in physics in college...).The 3/4" plywood is supported by the 2x4 joists. Just for extra warm fuzzies you could have one under each 'end' of the tank and then another two in between those (at 16" and 32" relative to tank). Plenty strong. Use the joist hangers, they're cheap insurance.

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

Nope, you are correct. You want the sistered joist under the edge of the tank. A single joist would work fine on the outside edge.Sorry it's taken me so long to respond. I don't think I'm fully understanding you yet. Please forgive the atrocious design here (I'm still learning to use this 3d modeling crap, and I'm short on time). I think I've roughly mocked up what you're describing: sistered 2x6s across the front on the top frame, sitting on 2x4 posts. I will have joists underneath the sides of the tank, and the back edge of the tank will be supported by the back edge of the frame. What worries me is what's circled in red. Yes, it'll be sitting on plywood, but there's nothing under the plywood to support the otherwise floating front edge of the tank. Does plywood really do that good a job at weight distribution that I could get away with that? The weight will transfer to those sistered front 2x6s? Am I worrying too much? I know there'll be front-to-back joists under the sides of the tank, but all I can imagine is the plywood bowing and then snapping under the weight of a 4' long unsupported front tank edge. It's totally possible that I simply don't understand the physics of weight distribution, though (I got a D in physics in college...).

This would probably work because of the supports running parallel to the edge but I wouldn't trust putting my tank on it.

This is why SketchUp is so wonderful. Drawing it out accurately really helps get a 'feel' for weak points.

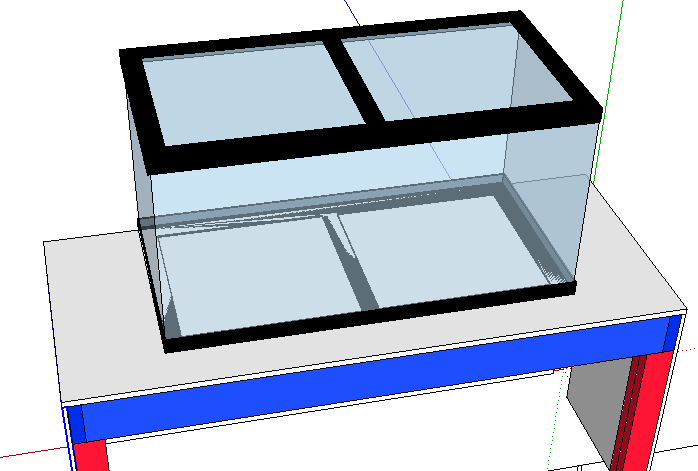

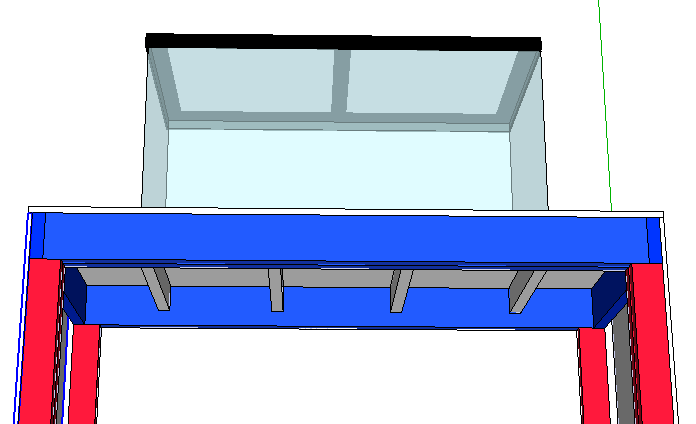

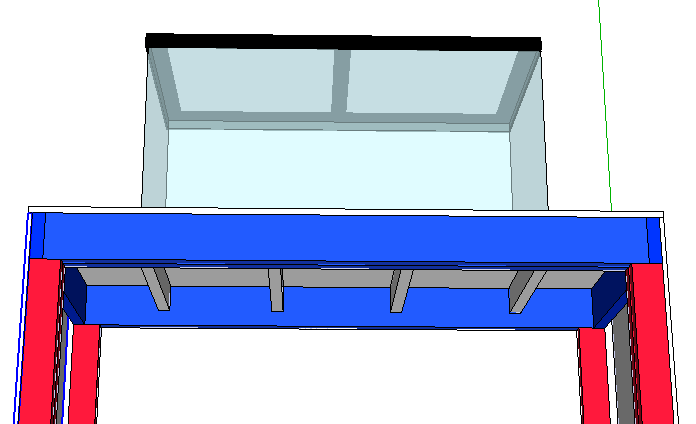

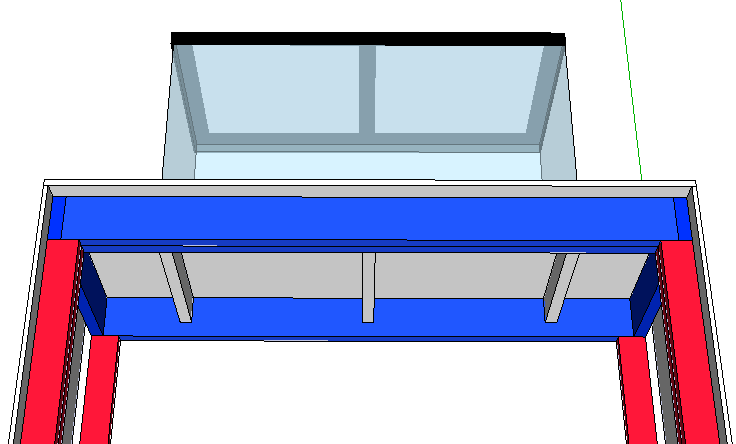

A 30" wide top surface, and a 24" wide tank. The sistered front beam is 3" thick. The distance from the inside edge of the beam to the front edge of the tank is then 3". Not that huge span your diagram shows. Now, consider as well my other suggestion, that you have joists running from front to back under where each end of the tank will rest, and two more at 16" and 32" from either end. That's 4 cross braces running perpendicular under the tank. The plywood is never spanning more than 16" unsupported. The tank itself is not made of rubber, it won't sag down between those 16" spans that are also supported by the beam just 3" away.

I've done a quick hack up of my own drawing to show:

A 30" wide top surface, and a 24" wide tank. The sistered front beam is 3" thick. The distance from the inside edge of the beam to the front edge of the tank is then 3". Not that huge span your diagram shows. Now, consider as well my other suggestion, that you have joists running from front to back under where each end of the tank will rest, and two more at 16" and 32" from either end. That's 4 cross braces running perpendicular under the tank. The plywood is never spanning more than 16" unsupported. The tank itself is not made of rubber, it won't sag down between those 16" spans that are also supported by the beam just 3" away.

I've done a quick hack up of my own drawing to show:

One thing I just thought of that is unrelated to the stand structure - reachability. Having the tank 6" back from the front of the stand is going to make it difficult to reach inside for a lot of things. Just something to keep in mind!

You're a LOT better at SketchUp than I am! How in god's green earth did you do that?! Is there a preprogrammed form for lumber, because I've been trying to draw out my dimensional lumber using the rectangle feature, and it's a pain and a half, and then I can't get them to line up nicely in the right planes. @Brew12 his diagram is infinitely more accurate than mine is- does your opinion change based on his correct dimensions?This is why SketchUp is so wonderful. Drawing it out accurately really helps get a 'feel' for weak points.

A 30" wide top surface, and a 24" wide tank. The sistered front beam is 3" thick. The distance from the inside edge of the beam to the front edge of the tank is then 3". Not that huge span your diagram shows. Now, consider as well my other suggestion, that you have joists running from front to back under where each end of the tank will rest, and two more at 16" and 32" from either end. That's 4 cross braces running perpendicular under the tank. The plywood is never spanning more than 16" unsupported. The tank itself is not made of rubber, it won't sag down between those 16" spans that are also supported by the beam just 3" away.

I've done a quick hack up of my own drawing to show:

I know a 30" deep stand might cause a headache or two with maintenance, but I'd planned to use a step ladder anyway. And a 6" ledge out front is enough for me to stand or brace a foot on as I kneel on the 1' sections on the sides, or to put things down on (like a food container, or a net, or dosing cup or something). Really, I just wanted to maximize space underneath, and perhaps if I get rich and can someday upgrade, I'll have a ready-made stand for a tank with a 6' x 30" footprint!

I really appreciate everyone's input on this! Thanks for helping me get this right.

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

It does not change my thoughts. I would still want my main supports under the tank rims, especially if it isn't rimless.You're a LOT better at SketchUp than I am! How in god's green earth did you do that?! Is there a preprogrammed form for lumber, because I've been trying to draw out my dimensional lumber using the rectangle feature, and it's a pain and a half, and then I can't get them to line up nicely in the right planes. @Brew12 his diagram is infinitely more accurate than mine is- does your opinion change based on his correct dimensions?

I know a 30" deep stand might cause a headache or two with maintenance, but I'd planned to use a step ladder anyway. And a 6" ledge out front is enough for me to stand or brace a foot on as I kneel on the 1' sections on the sides, or to put things down on (like a food container, or a net, or dosing cup or something). Really, I just wanted to maximize space underneath, and perhaps if I get rich and can someday upgrade, I'll have a ready-made stand for a tank with a 6' x 30" footprint!

I really appreciate everyone's input on this! Thanks for helping me get this right.

But again, that is my preference. It will likely be fine if you build it to those plans. Most home build aquarium stands are built way stronger than they need to be. It is just my personal preference to have the rim of the tank over a support beam that is directly supported by uprights 2x4's.

Getting better at SketchUp is just a matter of doing the hours and watching lots of tutorials. I’m still very rudimentary with it and always think I must be doing things the hard way.

In the end we’re not structural engineers who can actually model this stuff - it’s a matter of “feel” and experience. @Brew12 and I “feel” a little different on this one but we’re actually pretty close. Lots of ways you can tackle this design in the end.

In the end we’re not structural engineers who can actually model this stuff - it’s a matter of “feel” and experience. @Brew12 and I “feel” a little different on this one but we’re actually pretty close. Lots of ways you can tackle this design in the end.

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

Yup. I don't doubt it would work. The 2x4 joists will transfer the weight to the edge beams. It just isn't how "I" would do it. This is a much easier build than I would make so that is a plus.Getting better at SketchUp is just a matter of doing the hours and watching lots of tutorials. I’m still very rudimentary with it and always think I must be doing things the hard way.

In the end we’re not structural engineers who can actually model this stuff - it’s a matter of “feel” and experience. @Brew12 and I “feel” a little different on this one but we’re actually pretty close. Lots of ways you can tackle this design in the end.

@don_chuwish said the braces are a good idea. I would consider them mandatory if you go this route. Otherwise the weight of the 2x4's (and therefore the tank) will only be supported by the screws on each end, making it a weak point.

- Joined

- Jul 13, 2017

- Messages

- 396

- Reaction score

- 471

I would not use any kind of "hanger" product for those joists. In the environment they will be put in I promise you they will corrode, and likely very quickly. It may not ever end up contaminating your tank but its a chance I wouldn't want to take. Use a quality screw on the ends and you won't have a problem. If you're still uncomfortable with it you can get a "Timberscrew" for those joists just make sure you predrill.

Admittedly I haven't really thought about doors for this idea but hinges for recessed Euro style cabinets would work. This puts the beam straight under the tank without a whole lot of extra lumber cluttering up the corners. Still get your shelf and extra 6" of floor space front to back in the bottom.

Aren't joist hangers like that designed for outdoor use though, and would therefore be somewhat hardy? Would it make a difference to coat it with clear coat or something similar to protect it from all the moisture? Redundant to set the joist in the hanger, and then add a few screws to really hold it in place in case the hanger gives out?

Guys, I really appreciate all your advice! Thank you!

Guys, I really appreciate all your advice! Thank you!

I would not use any kind of "hanger" product for those joists. In the environment they will be put in I promise you they will corrode, and likely very quickly. It may not ever end up contaminating your tank but its a chance I wouldn't want to take. Use a quality screw on the ends and you won't have a problem. If you're still uncomfortable with it you can get a "Timberscrew" for those joists just make sure you predrill.

Honestly I hadn't really worried myself about the hangers, they are covered in several coats of paint as well as being galvanized, so we'll see. Good quality LONG screws really should be enough given that the plywood transfers so much of the load directly to the beams anyway.

Similar threads

- Replies

- 24

- Views

- 735