Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

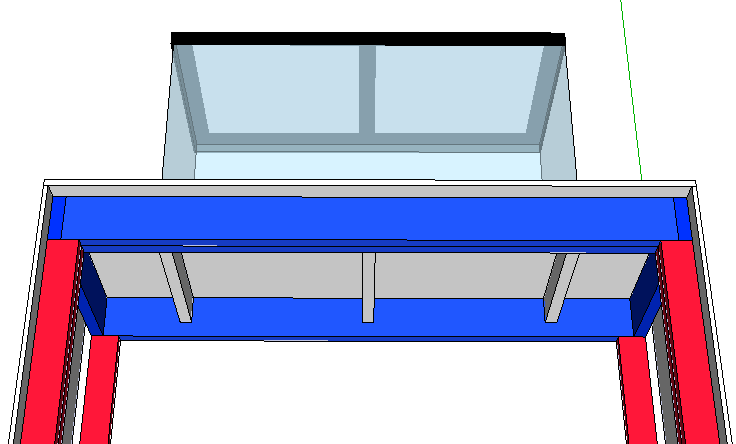

I'm loving this idea. Much better.Admittedly I haven't really thought about doors for this idea but hinges for recessed Euro style cabinets would work. This puts the beam straight under the tank without a whole lot of extra lumber cluttering up the corners. Still get your shelf and extra 6" of floor space front to back in the bottom.

Aren't joist hangers like that designed for outdoor use though, and would therefore be somewhat hardy? Would it make a difference to coat it with clear coat or something similar to protect it from all the moisture? Redundant to set the joist in the hanger, and then add a few screws to really hold it in place in case the hanger gives out?

Guys, I really appreciate all your advice! Thank you!

They are for outdoor use, but not for the salt spray environment that can exist in our sumps. I used Flex Seal (rubberized paint) to coat everything inside my stand. This includes the fasteners. Otherwise, it will rust out eventually.