I don't know that it would be harder to do 3/4" mixed with 1/2". 3/4" just means heavier panels, a bit more bracing needed during assembly, more $$ if you majorly screw up, but as a whole, it's not terribly more complex to work with IMO.actually doing the bottom and top in 1/2" and sides in 3/4" makes it harder to work with than doing just 1/2" sides..

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic Fabrication Q & A

- Thread starter Turbo's Aquatics

- Start date

-

- Tags

- acrylic diy fabrication

- Tagged users None

- Joined

- Nov 27, 2017

- Messages

- 17

- Reaction score

- 16

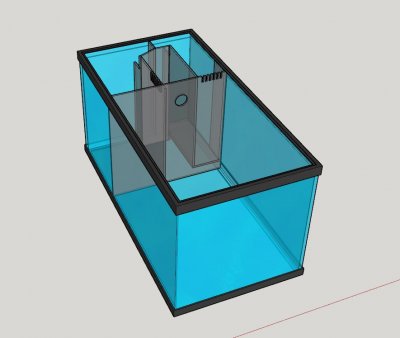

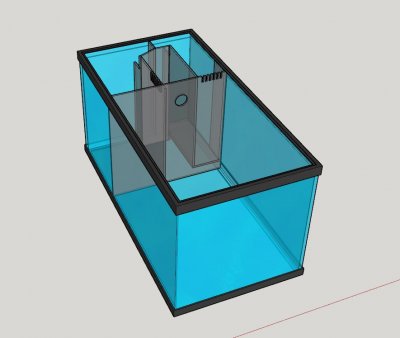

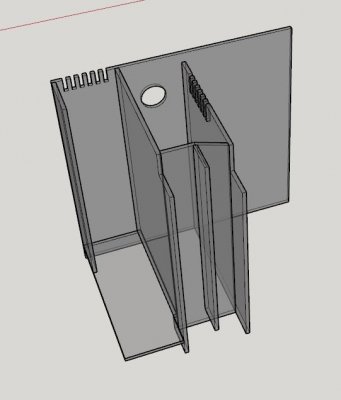

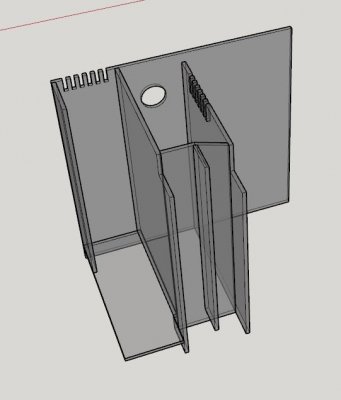

about 5" on the brace, but I'd rather have a 3" perimeter flange with a cross-brace than a 5" flange to have to reach around, but this is preference driven thingI saw this photo and I think instead of a center brace doing a wide brace like in this picture.:

I hope this person does not mind me stealing the pic.

This would allow me to drill holes for plumbing in the bracing and would be easier to light.

See any issues? Any suggestion in width of bracing?

1/2" is plenty..structurally. But what you're wanting is not *just* to hold water as many think, but rather to not bow so much that scraping coralline becomes a problem. So you have to either use thicker material (3/4") or use 1/2" with a wider perimeter flange or a cross-brace. You can certainly build the tank completely out of 1/2" with a 3" flange, at it'll certainly hold - but it'll bow ~1/4" which is more than I personally want to see and it is a direct cause of scratches.Also still debating on the side thickness... so many say 1/2" is plenty all the way around and actually doing the bottom and top in 1/2" and sides in 3/4" makes it harder to work with than doing just 1/2" sides..

My last tank was 60 x 24" (~21" of water) made completely from 1" acrylic with 3" perimeter flange and it bowed just under 1/4" on each side, just to give an idea.. and the top flange is what bowed.

Other that a little more weight, not much difference in the amount of work. In fact, the 3/4" is easier when you're flipping it over as it doesn't flex so much so it doesn't get so "wishy washy"

James

- Joined

- Nov 27, 2017

- Messages

- 17

- Reaction score

- 16

I'm not a fan. Though it's cheap and easy enough to glue, it crazes easier than most cell cast acrylics and ... there was a company using this material a few years ago and their tanks started blowing at the joints. For some reason, the material just doesn't hold up over time. I have theories on this, but they (Plastiglas) won't verify either way.Chemcast GP Acrylic any good?

The top doesn't *really* matter nearly as much as the bottom. I generally make the vertical panes sandwiched between the top and bottom, but there are occasions where this just isn't practical.Also goes the top sit on top the side panels or flush inside or does it matter?

James

- Joined

- Nov 27, 2017

- Messages

- 17

- Reaction score

- 16

Hmm, tough question, actually, if you haven't seen the actual sheets yet. If there are scratches or dings in the material - especially around the perimeter of the sheet, you'd prefer to have some overage to machine off. That said, if the sheets are in good shape and you're routing the edges yourself, I'd say +.125/-0.0 or just bump the size up 1/16" and say +/- 1/16"Thank you ..

Next question I found another place and they are asking me what tolerances I would like it cut too? What do I say?

So if ordering a piece you want to end up at say 24 x 24" - then 24.125 x 24.125" +.125/-0.0".. or 24.18 x 24.18" +/- 1/16"

..or bigger is always better, just means a little more machine time on your part. Nowadays, most distributors can easily cut things +/-.005" but getting a warehouse guys to actually look at the sheets to cut from the best places on the sheet is another story.

Hope this makes sense..

James

To add to this above, keep in mind that they are likely rough-cutting to your requested dimensions using a panel saw. Generally a panel saw will yield relatively square cuts, but you can't bank on it. The parts where the dimensions really matter are the ends, which are welded on all 4 sides. These have to be as square as possible, with finished edges ready to weld. If they are not square, then they at least have to be equally off. So if you double-stick-tape the 2 panels together and square them and finish the edges as a single sandwiched assembly, even if they are off-square by a thousandth of an inch or so, as long as you orient them exactly the same when you assemble the front/sides/back, you will not end up with a "twisted" final product, but rather one with a slight slant. Acrylic is forgiving with respect to this as the solvent dissolves the material, but too far off and you'll end up with some air intrusion (which can be compensated for by using the pins method)

For the front/back, the critical dimension again is the horizontal edge (that is bonded to the top/bottom) but the ends can be left rough cut and that dimension can be 1/4" longer to allow for 1/8" fillet and trim. Or 1/8" for 1/16" fillet/trim. But the vertical dimemsion needs to be the same as the vertical dim of the end, and when you do your squaring run for the ends, you need to pass the front/back through the same pass so these match up. So when you are squaring your ends, remember that whenever you pass to trim the top/bottom edge of that piece, also pass the front/back panels without changing settings. So your last pass for finished edges should be ends, front, back, then rotate all 90 degrees and repeat and then you have 4 panels with the exact same vertical dimension.

with regards to the top and bottom, since these have overage all around, asking for cuts 1/4" larger than your finished needs will mean you have 1/8" of excess to use for the fillet and trim, so that's not as important

For the front/back, the critical dimension again is the horizontal edge (that is bonded to the top/bottom) but the ends can be left rough cut and that dimension can be 1/4" longer to allow for 1/8" fillet and trim. Or 1/8" for 1/16" fillet/trim. But the vertical dimemsion needs to be the same as the vertical dim of the end, and when you do your squaring run for the ends, you need to pass the front/back through the same pass so these match up. So when you are squaring your ends, remember that whenever you pass to trim the top/bottom edge of that piece, also pass the front/back panels without changing settings. So your last pass for finished edges should be ends, front, back, then rotate all 90 degrees and repeat and then you have 4 panels with the exact same vertical dimension.

with regards to the top and bottom, since these have overage all around, asking for cuts 1/4" larger than your finished needs will mean you have 1/8" of excess to use for the fillet and trim, so that's not as important

One place quoted me : We can cut sheets and charge $42.00 per hour and tolerance is +/- .060.

I wish one of the two or both make a video on making a large acrylic reef tank.. It is need some of those on YouTube are horrible. Just seeing a person doing the steps instead of pictures really helps.

I was watching some videos on creating sumps, stands, equipment panels etc and some people have no idea, why video yourself if you do not know what you are doing. I was laughing at some and the tools they use.

At least a thread on doing one beginning to end. I know James did one a real long time ago, I read the whole thing the last few nights.

This thread is great and answers about 95 percent of the questions.

I wish one of the two or both make a video on making a large acrylic reef tank.. It is need some of those on YouTube are horrible. Just seeing a person doing the steps instead of pictures really helps.

I was watching some videos on creating sumps, stands, equipment panels etc and some people have no idea, why video yourself if you do not know what you are doing. I was laughing at some and the tools they use.

At least a thread on doing one beginning to end. I know James did one a real long time ago, I read the whole thing the last few nights.

This thread is great and answers about 95 percent of the questions.

Last edited:

- Joined

- Nov 27, 2017

- Messages

- 17

- Reaction score

- 16

Cheap for NC time.. tolerances are fine. Really shouldn't take long to cut the pieces for a single tank - longest part is just shuffling material around. For a tank and sump - maybe an hour or so tops, depending on how many sheets they have to cut.

James

James

My local Regal Plastics (Dallas area) charged me $22.50 for a cut and handling to hack off a 2’ x 4’ piece of 1/4” cast acrylic. That did not include the cost of the acrylic itself.

Mind if I cross link to my thread for simplicity's sake? This will be my first jump into building anything more than about 2 pieces (still in planning, so I'm open to ideas!):

https://www.reef2reef.com/threads/diy-aio-nano-design.348559

Converting a 15g into AIO Nano:

I've planned it all with 3/16 acrylic because I figured there's no significant pressure issues and it might save me a little real estate in a tight space, plus a little $$ on the material. But would 1/4" be so much easier to work with as to negate those perceived gains? I'd rather change the drawings now than regret it later if so.

Also, for this low stress application, capillary welds OK I assume?

Thanks!

https://www.reef2reef.com/threads/diy-aio-nano-design.348559

Converting a 15g into AIO Nano:

I've planned it all with 3/16 acrylic because I figured there's no significant pressure issues and it might save me a little real estate in a tight space, plus a little $$ on the material. But would 1/4" be so much easier to work with as to negate those perceived gains? I'd rather change the drawings now than regret it later if so.

Also, for this low stress application, capillary welds OK I assume?

Thanks!

For rough cuts I use a tenryu America pro series plastic blade. It’s $150 but worth it. Final cuts are performed by a cnc router.

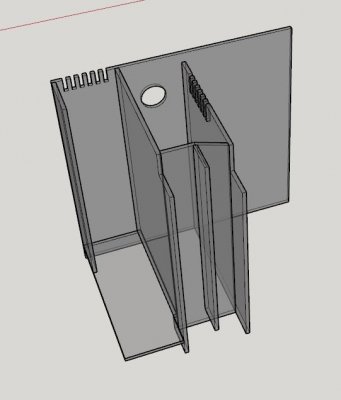

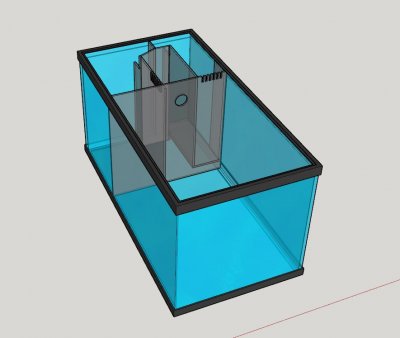

That's a sweet looking designMind if I cross link to my thread for simplicity's sake? This will be my first jump into building anything more than about 2 pieces (still in planning, so I'm open to ideas!):

https://www.reef2reef.com/threads/diy-aio-nano-design.348559

Converting a 15g into AIO Nano:

I've planned it all with 3/16 acrylic because I figured there's no significant pressure issues and it might save me a little real estate in a tight space, plus a little $$ on the material. But would 1/4" be so much easier to work with as to negate those perceived gains? I'd rather change the drawings now than regret it later if so.

Also, for this low stress application, capillary welds OK I assume?

Thanks!

The only thing I see is if you get evap your center chamber is going to drain way down to the pump, 3/16 is likely OK but maybe 1/4 for the main panel?

You have a sort of "false bottom" on the first chamber, any reason? Seems unnecessary. I would just drop that panel and continue that first wall to the bottom.

You have a side panel on the right of the main overflow that looks like it's there to form a bonding plane to silicone, if that's what you intended then that's good. But what I would do instead is make that a separate piece and just bond that to the tank wall, do the same on the opposite tank wall, and then use that as the point to place the whole assembly. The idea here is that acrylic doesn't strongly bond to acrylic but with a flat gusset, that gives you a lot more area so it works OK. Then you use that gusset as a brace point. and just seal around it. This also allows you to cut the front panel of the overflow about 1/16" short of touching, as acrylic expands and can crack the glass over time if you try to make it tight and then seal it.

Make sense?

That's a sweet looking design

The only thing I see is if you get evap your center chamber is going to drain way down to the pump, 3/16 is likely OK but maybe 1/4 for the main panel?

You have a sort of "false bottom" on the first chamber, any reason? Seems unnecessary. I would just drop that panel and continue that first wall to the bottom.

You have a side panel on the right of the main overflow that looks like it's there to form a bonding plane to silicone, if that's what you intended then that's good. But what I would do instead is make that a separate piece and just bond that to the tank wall, do the same on the opposite tank wall, and then use that as the point to place the whole assembly. The idea here is that acrylic doesn't strongly bond to acrylic but with a flat gusset, that gives you a lot more area so it works OK. Then you use that gusset as a brace point. and just seal around it. This also allows you to cut the front panel of the overflow about 1/16" short of touching, as acrylic expands and can crack the glass over time if you try to make it tight and then seal it.

Make sense?

Thanks! Let me try to explain around some of your points. The input is greatly appreciated!

Evap & Return chamber: certainly a concern but I'll set up an ATO. It's probably going in my office on a desk, so I should be able to keep an eye on it.

False bottom: inspiration came from the IM Nuvo AIO Nanos - it's at the right height for their skimmer and media caddy. But also adds a little extra volume to the return chamber.

Side panel: It's a spacer to bring the media caddy out from under the tank trim lip and hold it snug. Hadn't meant it as a brace since pressure will be mostly equal on either side of that overflow panel. I like your idea of sticking it to the tank wall separately though, it'll make assembly easier. The main panel is already spec'd 1/8" shy of the tank inside dimension for a 1/16" gap each side.

I will be adding some small bits not yet in the drawing to hold the media caddy snugly in place against the flow. Wedge shaped scraps that'll let it slide in easily but push it back tight to the overflow panel.

The aquarium will go in a corner, filtration to the left. So viewing is long side and right short side. The little refugium will be part of the display. So no brace on that side for sure - and I have to make it a nice clean silicone job!

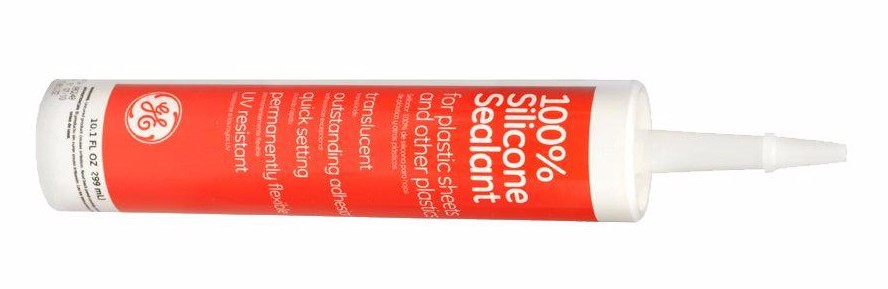

@redfishbluefish suggested the GE silicone for plastic and I found one YouTube video demonstrating how well it does bond to acrylic compared to regular silicone. Looks promising. Also, after watching one of melev's videos I think I will use the pin wicking method to weld it all.

Whole thing started out as an idea I wanted to explore, but the more I think about it, the more it seems like I'll actually do it. ;-)

Silicone is silicone. It does not structurally bond to acrylic. What this means is that you can't build an acrylic tank in the same manner as a glass tank, but that doesn't mean silicone won't hold acrylic together in certain situations, it absolutely will, especially in the manner I described with gussets flat against glass. But if you silicone in a baffle with a water level difference between two sides, it will hold initially and may hold for a while, but it will eventually give way.

There is nothing special about the GE stuff (the non-bath/kitchen stuff, that is - you want the windows/doors stuff without mildew inhibitors) or the silicone you buy in the fish stores or Momentive RTV-100 series (which is what you should use, you can get it in many places, it's what the tank builders use).

The more important thing here is to remember that you need a full 2 week cure time for the silicone before putting any inhabitants in it. This is typically the source of the "you used the wrong silicone" line - cure time is needed or it leeches chemicals into the water that some (not all) inhabitants won't react well to, so you'll hear anecdotal stories of what "worked for me" and the same thing didn't work for someone else and their tank crashed or corals RTNd etc, because person A had inhabitants that didn't get bothered for some reason, and person B did.

There is nothing special about the GE stuff (the non-bath/kitchen stuff, that is - you want the windows/doors stuff without mildew inhibitors) or the silicone you buy in the fish stores or Momentive RTV-100 series (which is what you should use, you can get it in many places, it's what the tank builders use).

The more important thing here is to remember that you need a full 2 week cure time for the silicone before putting any inhabitants in it. This is typically the source of the "you used the wrong silicone" line - cure time is needed or it leeches chemicals into the water that some (not all) inhabitants won't react well to, so you'll hear anecdotal stories of what "worked for me" and the same thing didn't work for someone else and their tank crashed or corals RTNd etc, because person A had inhabitants that didn't get bothered for some reason, and person B did.

Thanks, yes I've used acrylic baffles from TaylorPilot and silicone in my 40B sump before, so I'm familiar with the limitations. Fortunately the two front to back panels that make up the walls of the return chamber make for a lot of support.

But looking at the product mentioned, and the video I found, it does look promising:

Skip to 5:15 for the interesting part:

But looking at the product mentioned, and the video I found, it does look promising:

Skip to 5:15 for the interesting part:

That is interesting, thank you for sharing!!

I would like to see that one put up against the Momentive RTV-100 series silicone. I'm interested to see which one wins. Might have to do this one myself

I would like to see that one put up against the Momentive RTV-100 series silicone. I'm interested to see which one wins. Might have to do this one myself

Wow new to this forum, a ton of useful information in here. I've been watching a ton of DIY king acrylic aquarium builds and was under the impression that was the best method of assembly. Nearly jumped into making a tank. So, there have been several posts within this thread that state DIY king's aquarium acrylic calculator is inaccurate and then several posts later individuals link an Excel spreadsheet that is allegedly more accurate. However, it seems that both calculators are based upon a formula made by a company named CYRO. Seems to be a bit of conflicting information, can anyone clear this up for me? Anyways, by using this calculator it appears that a tank 72 inches long x 16 inches high would require less 1/2 inch acrylic ( 0.430 inches). I am dubious of this calculation.

A local company provides a sheet of cell cast acrylic 1/2 inch at 5 feet x 8 feet for $494 Canadian Rupees, I would like to optimize these dimensions of course. My ideal dimensions would be 72 x 16 x 20 with additional acrylic to be purchased for the bracing. Would this be an unwise thing to do? Should I just go with a 3/4 inch acrylic at 600~ ish Canadian Rupees just to be safe?

Thanks

A local company provides a sheet of cell cast acrylic 1/2 inch at 5 feet x 8 feet for $494 Canadian Rupees, I would like to optimize these dimensions of course. My ideal dimensions would be 72 x 16 x 20 with additional acrylic to be purchased for the bracing. Would this be an unwise thing to do? Should I just go with a 3/4 inch acrylic at 600~ ish Canadian Rupees just to be safe?

Thanks

That is interesting, thank you for sharing!!

I would like to see that one put up against the Momentive RTV-100 series silicone. I'm interested to see which one wins. Might have to do this one myself

I'd love to see your test results!

Similar threads

- Replies

- 17

- Views

- 402