Glasscages.com sells black frame acrylic tanks.If you're planning on putting the frame on the bottom of the tank, this is a big no from me. Acrylic tanks need to sit directly on a flat and fully supported surface. You would never put any kind of trim like this on the bottom of an acrylic tank, let alone assemble the tank using the trim piece. Just from a perspective of order of assembly, that would be completely incorrect if I'm interpreting what you're wanting to do

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic Fabrication Q & A

- Thread starter Turbo's Aquatics

- Start date

-

- Tags

- acrylic diy fabrication

- Tagged users None

If you're planning on putting the frame on the bottom of the tank, this is a big no from me. Acrylic tanks need to sit directly on a flat and fully supported surface. You would never put any kind of trim like this on the bottom of an acrylic tank, let alone assemble the tank using the trim piece. Just from a perspective of order of assembly, that would be completely incorrect if I'm interpreting what you're wanting to do

Here is a divided one from glasscages.

Attachments

It doesn't mean it's a good idea. Basics are basics. Acrylic aquariums need to be placed on a flat surface and fully supported.

You might be able to get away with a brace on a smaller tank, as long as you overbuild the bottom panel. It will bow to some extent no matter how thick the bottom is if it is hovering like that.

Also, I will bet good money that the brace is installed after the tank is built, rather than it being built into the brace.

Going back to your original question, it sounds like you were asking if you could place the bottom panel in the brace, then build the walls on top of that one panel at a time - was that what you were asking? I guess it might be one of those things that is hard to describe in words or something, but after reading it several times I'm still having trouble figuring out what assembly steps you were describing. However it has been a very long day....

You might be able to get away with a brace on a smaller tank, as long as you overbuild the bottom panel. It will bow to some extent no matter how thick the bottom is if it is hovering like that.

Also, I will bet good money that the brace is installed after the tank is built, rather than it being built into the brace.

Going back to your original question, it sounds like you were asking if you could place the bottom panel in the brace, then build the walls on top of that one panel at a time - was that what you were asking? I guess it might be one of those things that is hard to describe in words or something, but after reading it several times I'm still having trouble figuring out what assembly steps you were describing. However it has been a very long day....

It doesn't mean it's a good idea. Basics are basics. Acrylic aquariums need to be placed on a flat surface and fully supported.

You might be able to get away with a brace on a smaller tank, as long as you overbuild the bottom panel. It will bow to some extent no matter how thick the bottom is if it is hovering like that.

Also, I will bet good money that the brace is installed after the tank is built, rather than it being built into the brace.

Going back to your original question, it sounds like you were asking if you could place the bottom panel in the brace, then build the walls on top of that one panel at a time - was that what you were asking? I guess it might be one of those things that is hard to describe in words or something, but after reading it several times I'm still having trouble figuring out what assembly steps you were describing. However it has been a very long day....

Yes. I plan on following your steps but inside the bottom frame. Remove masking in the areas to be welded and assemble the whole thing dry. Use IPS 16 or 43 to attach the frame to the bottom pane. Let set for a day. Then weld the short sides to the bottom etc.It doesn't mean it's a good idea. Basics are basics. Acrylic aquariums need to be placed on a flat surface and fully supported.

You might be able to get away with a brace on a smaller tank, as long as you overbuild the bottom panel. It will bow to some extent no matter how thick the bottom is if it is hovering like that.

Also, I will bet good money that the brace is installed after the tank is built, rather than it being built into the brace.

Going back to your original question, it sounds like you were asking if you could place the bottom panel in the brace, then build the walls on top of that one panel at a time - was that what you were asking? I guess it might be one of those things that is hard to describe in words or something, but after reading it several times I'm still having trouble figuring out what assembly steps you were describing. However it has been a very long day....

Thank you so much for making this thread!!!

I think @Joe Glass Cages might have been trying to give you a simple answer rather than a technical one. If you look at their tanks, they are rounded and polished. The only way you can do that is by having the front/back/sides assembled, flush trimmed, rounded, and polished (you need to have overage on the front/back panels along the vertical edges to prevent air from sucking into the joint).

Then, there might be a method where you attach the bottom to the frame, or set it in the frame, place the "wall assembly" on top of it, rig up some spacers, fill the gap with weld-on 40/42 which does a double duty by filling the gap and (very permanently) attaching the frame to the bottom and sides (FYI 3/4/16 is not a gap filler). Also this technique would elminate

I don't know that you would want to do this with 3/4/16 because the entire joint really needs to be pinned and shimmed, tight, weights on top to ensure no air creeps in or seams peel apart as the solvent evaporates, etc.

The bonuses of doing it this way is you don't really care what the bottom joint looks like because you'll never see it. You only "really" have to make the front & back roughly square, and the end panels just have to be dead on parallel on the 2 vertical edges (because the bottom edges of the wall assembly don't actually touch the bottom panel when using 40/42, and the top frame covers up any misalignment).

The downside is you have to work with 40/42, which is really strong, and you kind of have to know what you're doing.

Back to your original post though, you said you were having trouble finding a flat sheet of MDF...I don't know why I didn't answer that one right away but MDF isn't totally rigid, so if you place it on a warped table and place a tank on it, it will bend. Try taking 2 sheets of 3/4", placing one on a flat floor, wood glue, place the other on top, then weights. Let sit for a day. This will be more rigid. But if your work table sucks, you will want to use wood slats and shims under the MDF to make it flat.

You can do this with one sheet also (slats/shims). You should be able to make an MDF surface that is flat and workable without issue...

Then, there might be a method where you attach the bottom to the frame, or set it in the frame, place the "wall assembly" on top of it, rig up some spacers, fill the gap with weld-on 40/42 which does a double duty by filling the gap and (very permanently) attaching the frame to the bottom and sides (FYI 3/4/16 is not a gap filler). Also this technique would elminate

I don't know that you would want to do this with 3/4/16 because the entire joint really needs to be pinned and shimmed, tight, weights on top to ensure no air creeps in or seams peel apart as the solvent evaporates, etc.

The bonuses of doing it this way is you don't really care what the bottom joint looks like because you'll never see it. You only "really" have to make the front & back roughly square, and the end panels just have to be dead on parallel on the 2 vertical edges (because the bottom edges of the wall assembly don't actually touch the bottom panel when using 40/42, and the top frame covers up any misalignment).

The downside is you have to work with 40/42, which is really strong, and you kind of have to know what you're doing.

Back to your original post though, you said you were having trouble finding a flat sheet of MDF...I don't know why I didn't answer that one right away but MDF isn't totally rigid, so if you place it on a warped table and place a tank on it, it will bend. Try taking 2 sheets of 3/4", placing one on a flat floor, wood glue, place the other on top, then weights. Let sit for a day. This will be more rigid. But if your work table sucks, you will want to use wood slats and shims under the MDF to make it flat.

You can do this with one sheet also (slats/shims). You should be able to make an MDF surface that is flat and workable without issue...

Thanks @Turbo's Aquatics, that is spot on!I think @Joe Glass Cages might have been trying to give you a simple answer rather than a technical one. If you look at their tanks, they are rounded and polished. The only way you can do that is by having the front/back/sides assembled, flush trimmed, rounded, and polished (you need to have overage on the front/back panels along the vertical edges to prevent air from sucking into the joint).

Then, there might be a method where you attach the bottom to the frame, or set it in the frame, place the "wall assembly" on top of it, rig up some spacers, fill the gap with weld-on 40/42 which does a double duty by filling the gap and (very permanently) attaching the frame to the bottom and sides (FYI 3/4/16 is not a gap filler). Also this technique would elminate

I don't know that you would want to do this with 3/4/16 because the entire joint really needs to be pinned and shimmed, tight, weights on top to ensure no air creeps in or seams peel apart as the solvent evaporates, etc.

The bonuses of doing it this way is you don't really care what the bottom joint looks like because you'll never see it. You only "really" have to make the front & back roughly square, and the end panels just have to be dead on parallel on the 2 vertical edges (because the bottom edges of the wall assembly don't actually touch the bottom panel when using 40/42, and the top frame covers up any misalignment).

The downside is you have to work with 40/42, which is really strong, and you kind of have to know what you're doing.

Back to your original post though, you said you were having trouble finding a flat sheet of MDF...I don't know why I didn't answer that one right away but MDF isn't totally rigid, so if you place it on a warped table and place a tank on it, it will bend. Try taking 2 sheets of 3/4", placing one on a flat floor, wood glue, place the other on top, then weights. Let sit for a day. This will be more rigid. But if your work table sucks, you will want to use wood slats and shims under the MDF to make it flat.

You can do this with one sheet also (slats/shims). You should be able to make an MDF surface that is flat and workable without issue...

@Not_Eeyore, my reply to your PM question was spot on as well. However not in the right context for this thread.

Glasscages will build an acrylic framed tank for the following foot prints only, 12 x 6, 16 x 8, 20 x 10, 24 x 12, 30 x 12, 36 x 12, 36 x 18, 48 x 12 and 48 x 18 with a max height of 25". And deviation from those foot prints, the tank will be build without a frame and constructed as @Turbo's Aquatics outlined. In addition, any tank with the foot prints above mention with a requested height above 25" will not be built with a frame.

I am completely synchronized with @Turbo's Aquatics outline and suggestions.

Hope this helps.

Yes, my build is 48 x 18. I turned to DIY when the shipping quote for your tank was $335 to a terminal 100 miles from my place. I wish your company had offered pre-cut/prepped pieces with instructions for DIY assembly.Thanks @Turbo's Aquatics, that is spot on!

@Not_Eeyore, my reply to your PM question was spot on as well. However not in the right context for this thread.

Glasscages will build an acrylic framed tank for the following foot prints only, 12 x 6, 16 x 8, 20 x 10, 24 x 12, 30 x 12, 36 x 12, 36 x 18, 48 x 12 and 48 x 18 with a max height of 25". And deviation from those foot prints, the tank will be build without a frame and constructed as @Turbo's Aquatics outlined. In addition, any tank with the foot prints above mention with a requested height above 25" will not be built with a frame.

I am completely synchronized with @Turbo's Aquatics outline and suggestions.

Hope this helps.

I am also using the 1/4" the quote suggested as an upgrade thickness. As I understand your message, I should assemble dry and attach the bottom to the frame, and then proceed with @Turbo's Aquatics steps.

Typo in bold and italic...should be 1/2". Glasscages standard is 3/8" for black frame acrylic tanks and they offer an upgrade option to 1/2"Yes, my build is 48 x 18. I turned to DIY when the shipping quote for your tank was $335 to a terminal 100 miles from my place. I wish your company had offered pre-cut/prepped pieces with instructions for DIY assembly.

I am also using the 1/4" the quote suggested as an upgrade thickness. As I understand your message, I should assemble dry and attach the bottom to the frame, and then proceed with @Turbo's Aquatics steps.

Turbo's Aquatics Joe Glass Cages any recommendations for remover to make sure all masking glue is off the edges?

Oophf, epic battle with old masking paper! Over then course of 3 weeks I peeled, rubbed, and scraped the stubborn masking paper from the edges of my build. Couple of tips for anyone else dealing with this... If the paper is just old then cold is your best friend. If the sheet has rubbed or been scraped against some thing else; then olive oil, warmth, and a wide acrylic scraper worked well for me. My finger tips worked well for getting the leftover glue balled up. Understand, I am not a pro and this is my first try at this. Probably the ugliest peel ever but I am really proud of my success.

Oophf, epic battle with old masking paper! Over then course of 3 weeks I peeled, rubbed, and scraped the stubborn masking paper from the edges of my build. Couple of tips for anyone else dealing with this... If the paper is just old then cold is your best friend. If the sheet has rubbed or been scraped against some thing else; then olive oil, warmth, and a wide acrylic scraper worked well for me. My finger tips worked well for getting the leftover glue balled up. Understand, I am not a pro and this is my first try at this. Probably the ugliest peel ever but I am really proud of my success.

Attachments

Now... about these edges... sigh. No router so scraper and Dremel it is.

#DIYwizards suggestions?

#DIYwizards suggestions?

Attachments

For old paper, just use a heat gun on a higher setting, keep it moving and watch your fingers

I chickened out on the heat gun after my dad said he caught a porch on fire the first time he tried to use one.For old paper, just use a heat gun on a higher setting, keep it moving and watch your fingers

Would you point me to any info on perfecting the edges to be welded? I do not have a router. They feel smooth, just look odd.

- Joined

- Apr 21, 2020

- Messages

- 118

- Reaction score

- 92

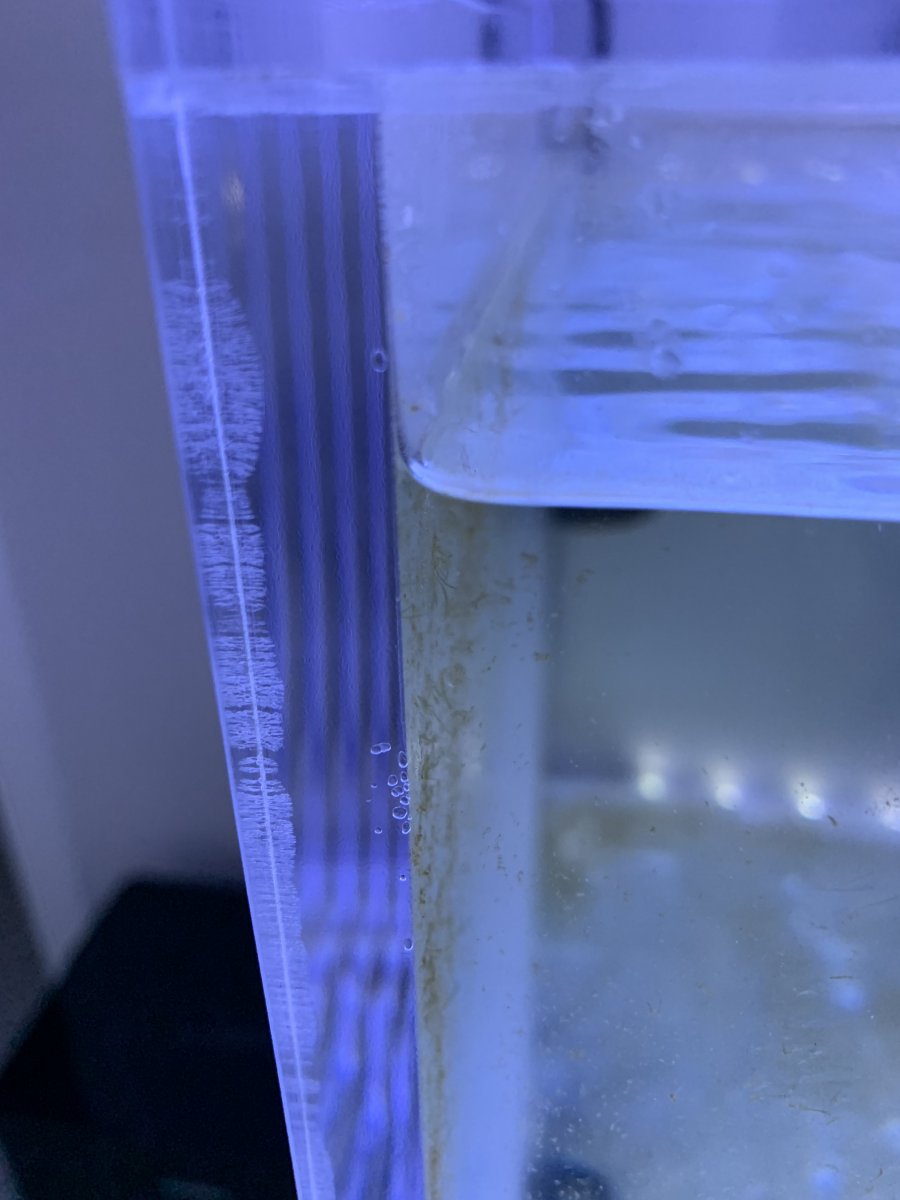

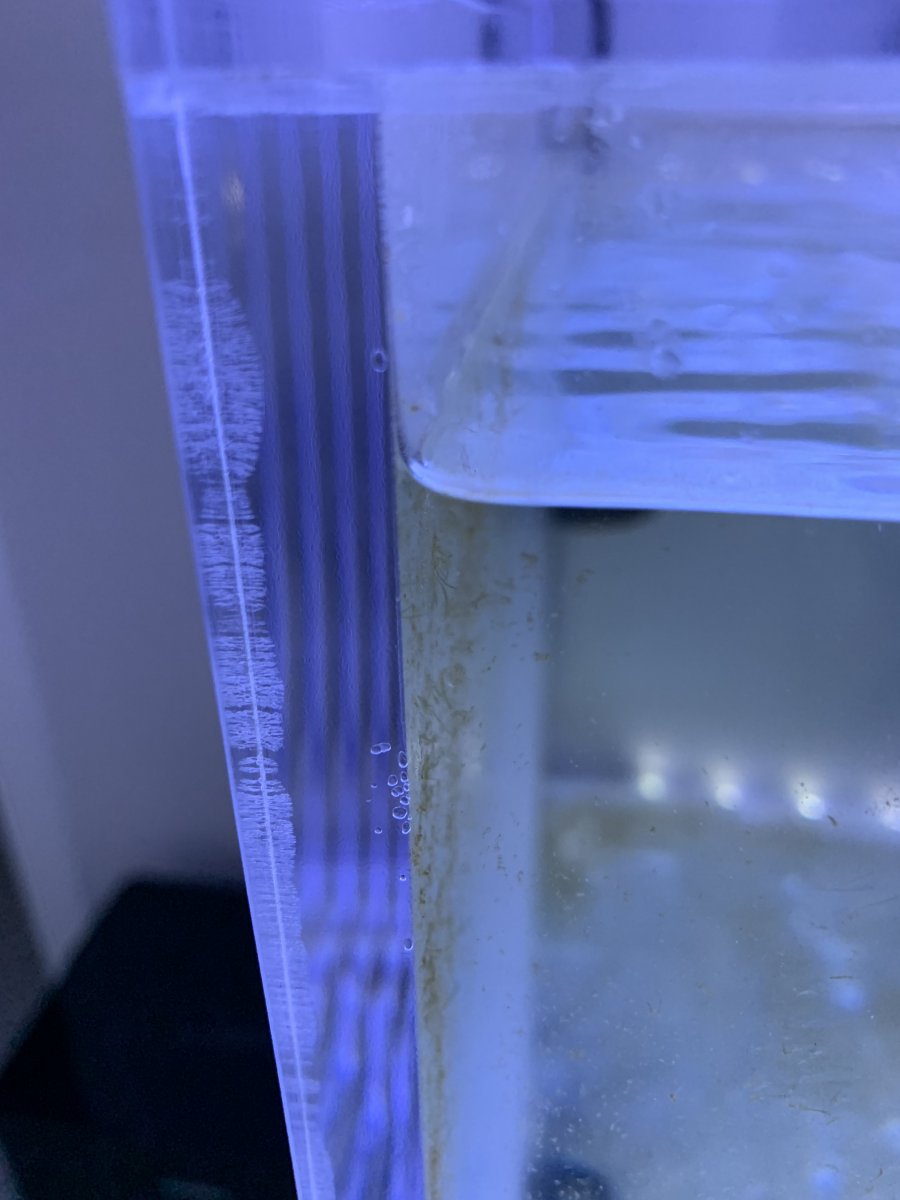

I have had my tank full for about 4 months and today noticed some hazing in the seams. I know I need to worry about this but is there any way to know how much of an immediate concern there is? As in, do I need to drain it right away? I can't say for sure how long it has taken for this to develop but I guess fairly quickly.

I was always upset about the bubbles in this seam as well. The hazing is happening in a few seams but this is the worst.

I was always upset about the bubbles in this seam as well. The hazing is happening in a few seams but this is the worst.

I am not a seasoned builder but have some tanks built by pros with similar issue. It doesn’t look bad to me and I personally wouldn’t stress over it. Maybe the pros will chime in soon. Good luck.I have had my tank full for about 4 months and today noticed some hazing in the seams. I know I need to worry about this but is there any way to know how much of an immediate concern there is? As in, do I need to drain it right away? I can't say for sure how long it has taken for this to develop but I guess fairly quickly.

I was always upset about the bubbles in this seam as well. The hazing is happening in a few seams but this is the worst.

Looks like crazing or the start of a seam seapartion. Could caused by stress or flame polishing. Could be due to edge prep technique and/or welding technique. Lots of possibilities

But I'll tell you, my LFS has a 600g tank with seam separations that you could slide a piece of paper into, 3/4 of the way through the seams on the bottom edge and along one of the side panels too. I've been waiting for that tank to blow for nearly 10 years. It's still there.

New tank?

Used tank? If so, was the same stand used?

How is the tank supported (i.e. what is the stand top frame like, is it on 3/4" plywood, etc)

But I'll tell you, my LFS has a 600g tank with seam separations that you could slide a piece of paper into, 3/4 of the way through the seams on the bottom edge and along one of the side panels too. I've been waiting for that tank to blow for nearly 10 years. It's still there.

New tank?

Used tank? If so, was the same stand used?

How is the tank supported (i.e. what is the stand top frame like, is it on 3/4" plywood, etc)

I find Acrylic tanks tend show stress cracks near the tops in the seams. My guess is because the top swells upward and puts stress on the seams there. Probably nothing to worry about

- Joined

- Apr 21, 2020

- Messages

- 118

- Reaction score

- 92

Tank was bought new and has been filled for 4 months. It's on an aluminum stand with 5/8" plywood. I only have a 6' level and the tank is 7' but with the 6' level, the tank is 100% level in all directions. Concrete floor.Looks like crazing or the start of a seam seapartion. Could caused by stress or flame polishing. Could be due to edge prep technique and/or welding technique. Lots of possibilities

But I'll tell you, my LFS has a 600g tank with seam separations that you could slide a piece of paper into, 3/4 of the way through the seams on the bottom edge and along one of the side panels too. I've been waiting for that tank to blow for nearly 10 years. It's still there.

New tank?

Used tank? If so, was the same stand used?

How is the tank supported (i.e. what is the stand top frame like, is it on 3/4" plywood, etc)

I don't know when this started but I am monitoring it daily. I know there is always some risk but I guess as long as I don't see a progression, I will trust it for now.

I am just hoping that if I need to replace the tank, I can do it in a few months from now when I have a break from work.

Here’s a few spots on my 4 year old 560 gallon I built. These spots apeared in the first 6 months and never changed at all. Hopefully yours does the same. Just do what your doing and keep an eye on it. But I’m guessing it will settle in and that’ll be it.

Attachments

The best way I have found to level a large tank is to put a few inches of water in the tank and then measure each corner from the top of the tank to the waterline and adjust the stand to make all the measurements the same. Hopefully that makes sense lolTank was bought new and has been filled for 4 months. It's on an aluminum stand with 5/8" plywood. I only have a 6' level and the tank is 7' but with the 6' level, the tank is 100% level in all directions. Concrete floor.

I don't know when this started but I am monitoring it daily. I know there is always some risk but I guess as long as I don't see a progression, I will trust it for now.

I am just hoping that if I need to replace the tank, I can do it in a few months from now when I have a break from work.

Similar threads

- Replies

- 17

- Views

- 402