Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adding removable door panels to a steel frame stand

- Thread starter boudster

- Start date

- Tagged users None

I did not want magnets to fully support my doors. So what I did was to make a channel brace on the bottom out of wood and and magnet with contersunk hole at the top. Door slides down on the bottom and then snaps in place on top. Has been working great for 3 years now. If this idea is anything you would like I can post pictures.

That sounds really intriguing! I would really appreciate if you could post pics as I'm not very savvy when it comes to DIY so I'm having trouble picturing exactly how it would work.I did not want magnets to fully support my doors. So what I did was to make a channel brace on the bottom out of wood and and magnet with contersunk hole at the top. Door slides down on the bottom and then snaps in place on top. Has been working great for 3 years now. If this idea is anything you would like I can post pictures.

Wow. working with Windows 10 is challenging for an old salt! Hope the pictures work.

First picture is front of tank with three panels under the tank.

Second picture is the bottom groove.

Third picture is inside of panel.

Fourth picture is the countersunk magnet.

Last picture is skin on frame without panel.

Hope this helps.

First picture is front of tank with three panels under the tank.

Second picture is the bottom groove.

Third picture is inside of panel.

Fourth picture is the countersunk magnet.

Last picture is skin on frame without panel.

Hope this helps.

Thank you very much! I think with some slight modification this could work for my flush panels.Wow. working with Windows 10 is challenging for an old salt! Hope the pictures work.

First picture is front of tank with three panels under the tank.

Second picture is the bottom groove.

Third picture is inside of panel.

Fourth picture is the countersunk magnet.

Last picture is skin on frame without panel.

Hope this helps.

- Joined

- Oct 24, 2015

- Messages

- 33

- Reaction score

- 13

Not all silicone is compatible with steel, some are corrosive.Just get some regular clear silicone and silicone the holes so the salt creep doesn't get in to the holes and start eating away the steel.

- Joined

- May 5, 2014

- Messages

- 498

- Reaction score

- 253

Im literally at the same exact point in my build. The only difference is I believe your problem is easier than mine seeing you wanna do 3/4 in solid wood pannels (at least it looks this way) I want to do it this way but the wife doesn't like the modern solid smooth panel look. And wants essentially cabinet doors.

Anyway if I were in your situation I would router a few 1/4 in holes/slits in the wood amd use these. http://www.magnet4sale.com/45-lb-holding-power-neodymium-channel-magnet-mcln-200/

They also have stronger ones but are out of stock but I don't think the stronger ones are necessary. If you use a good amount of magnets.

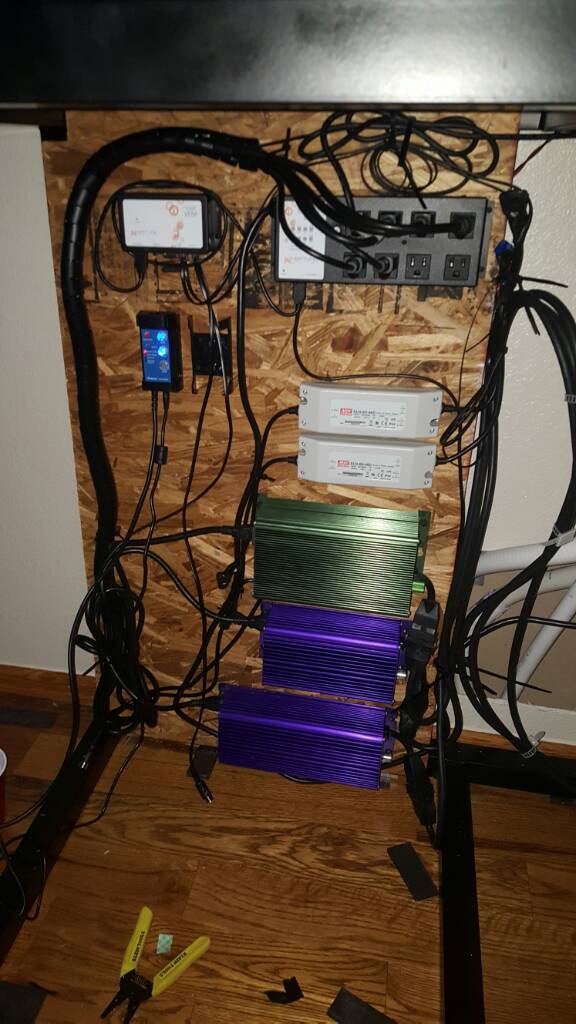

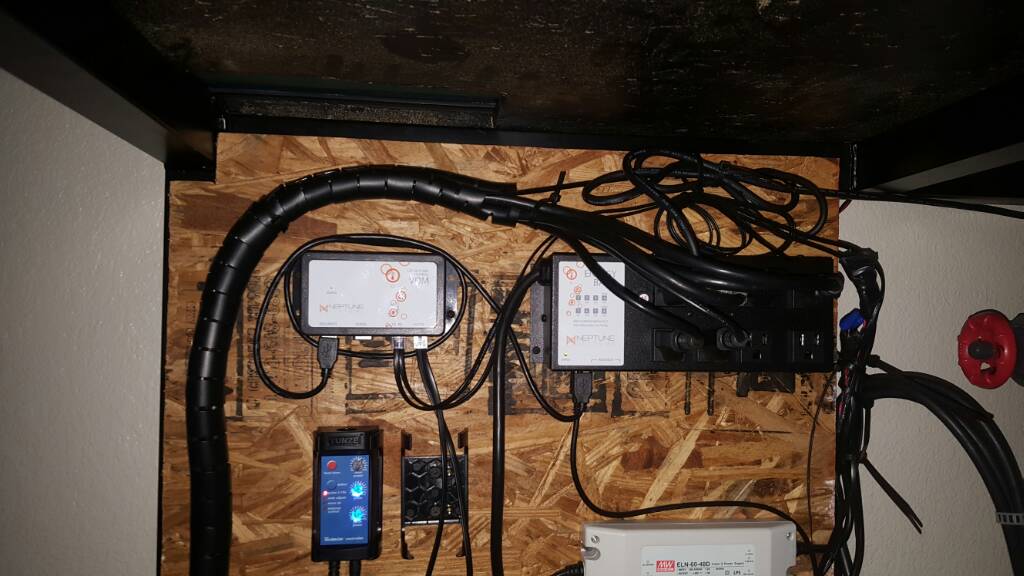

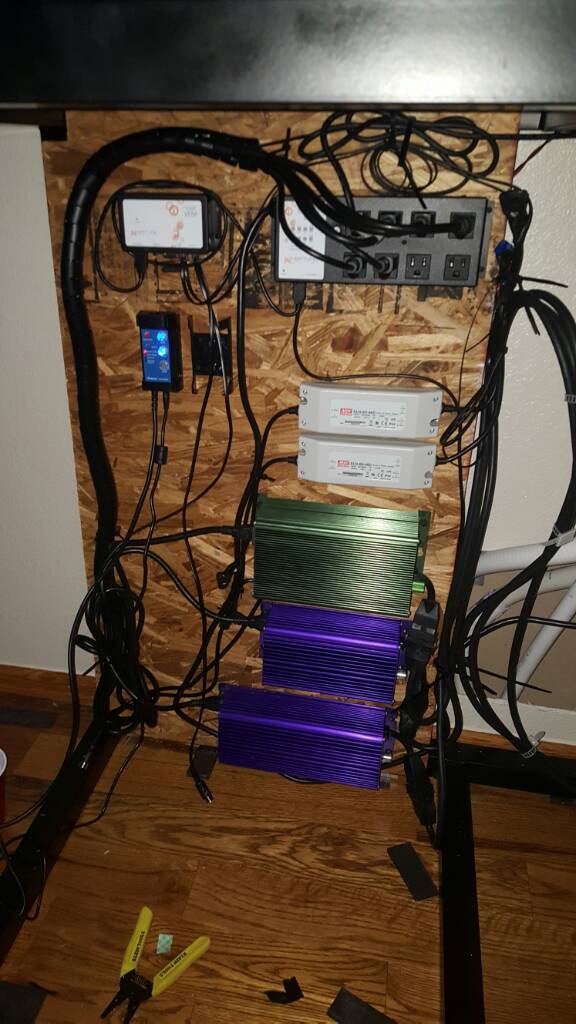

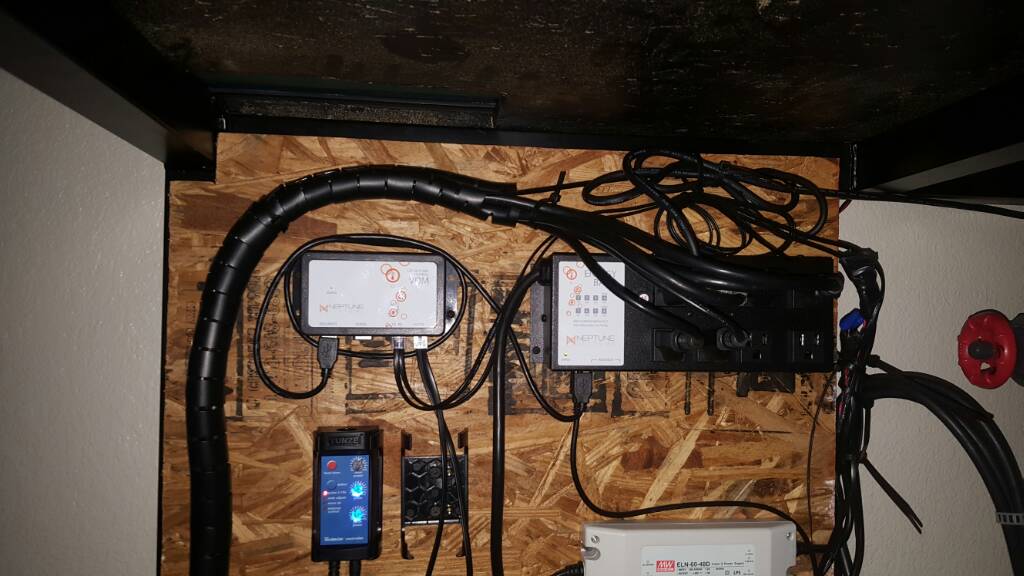

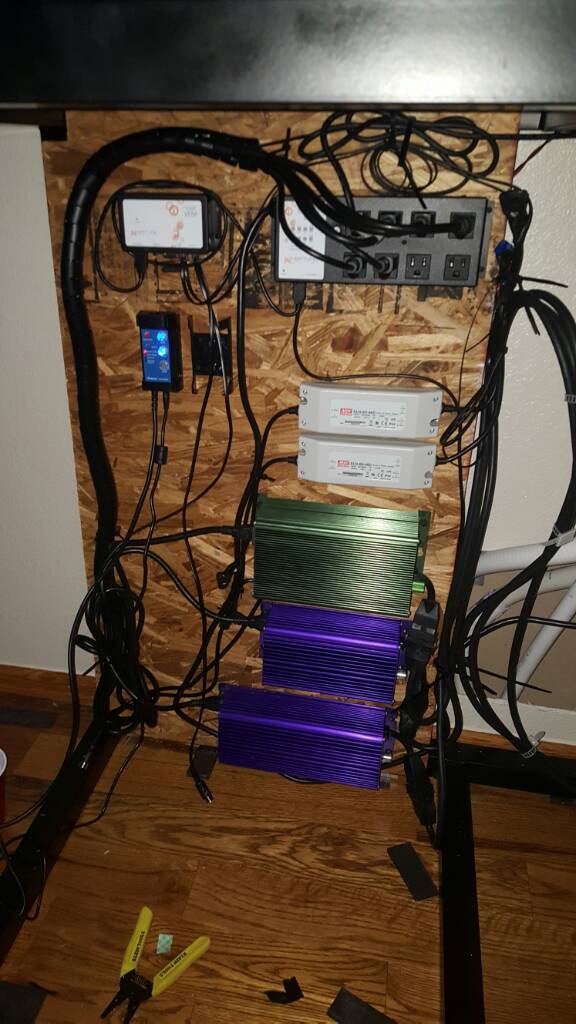

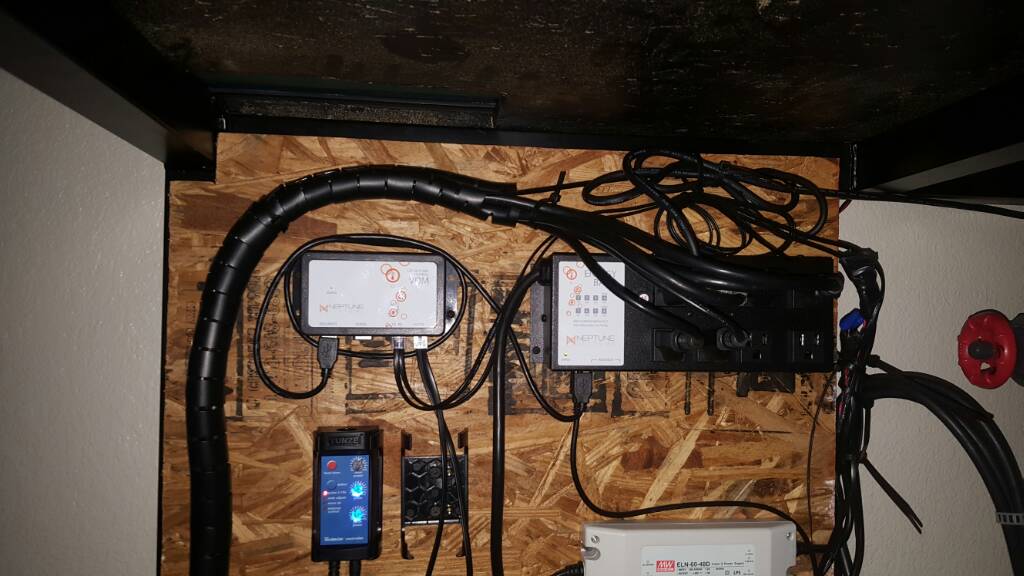

For cord management this is what I did/doing.

As you can see its an osb board. It has 4 of thost magnets I linked. 2 o the upright and one on top towards the middle of the stand and same on bottom if that makes sense.

With the magnets the only problem is it slides up or down. To pull the panel off it takes some good pressure to take the panel off. To solve the problem with sliding I just designed it to rest on the floor. You could just design and install a few bars to hold the door up that rest on inside of the stand.

Hope this makes sense.

Anyway if I were in your situation I would router a few 1/4 in holes/slits in the wood amd use these. http://www.magnet4sale.com/45-lb-holding-power-neodymium-channel-magnet-mcln-200/

They also have stronger ones but are out of stock but I don't think the stronger ones are necessary. If you use a good amount of magnets.

For cord management this is what I did/doing.

As you can see its an osb board. It has 4 of thost magnets I linked. 2 o the upright and one on top towards the middle of the stand and same on bottom if that makes sense.

With the magnets the only problem is it slides up or down. To pull the panel off it takes some good pressure to take the panel off. To solve the problem with sliding I just designed it to rest on the floor. You could just design and install a few bars to hold the door up that rest on inside of the stand.

Hope this makes sense.

Thanks! Yes, that actually makes a lot of sense and I was wondering if that might be a possibility. Since my door panels will essentially be sized to fit snugly inside the frame openings, sliding shouldn't be an issue, so if I were to just install some of those magnets in the top and bottom ends of the panels that might do the trickIm literally at the same exact point in my build. The only difference is I believe your problem is easier than mine seeing you wanna do 3/4 in solid wood pannels (at least it looks this way) I want to do it this way but the wife doesn't like the modern solid smooth panel look. And wants essentially cabinet doors.

Anyway if I were in your situation I would router a few 1/4 in holes/slits in the wood amd use these. http://www.magnet4sale.com/45-lb-holding-power-neodymium-channel-magnet-mcln-200/

They also have stronger ones but are out of stock but I don't think the stronger ones are necessary. If you use a good amount of magnets.

For cord management this is what I did/doing.

As you can see its an osb board. It has 4 of thost magnets I linked. 2 o the upright and one on top towards the middle of the stand and same on bottom if that makes sense.

With the magnets the only problem is it slides up or down. To pull the panel off it takes some good pressure to take the panel off. To solve the problem with sliding I just designed it to rest on the floor. You could just design and install a few bars to hold the door up that rest on inside of the stand.

Hope this makes sense.

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

Go here, magnets find the size you need, forstner drill in the ply on the corners and you are done. As far and not having handles, find a stronger magnet and insert it on the back side of the panel and have a pull that you can use to open the panel with out drilling, do you under stand what I am thinking?

You can get some of these to make gussets out of and then add the panels with magnets.

http://www.homedepot.com/p/Everbilt-2-in-Zinc-Plated-Heavy-Duty-Corner-Brace-2-Pack-15442/202034088

http://www.homedepot.com/p/Everbilt-2-in-Zinc-Plated-Heavy-Duty-Corner-Brace-2-Pack-15442/202034088

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

you will also have to be careful around the controller with the magnets

Go here, magnets find the size you need, forstner drill in the ply on the corners and you are done. As far and not having handles, find a stronger magnet and insert it on the back side of the panel and have a pull that you can use to open the panel with out drilling, do you under stand what I am thinking?

I think I get it. So you're suggesting pulling the panels of using a magnetic "handle" that would not be permanently attached to the door?

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

Yes. The more I think about it, you could attach a piece of metal on the back side of the panel and use a horse shoe magnet and dip in the plastic coating stuff they sell at the big box home supply stores to coat the horse shoe magnet, so that you would not scratch the wood panels.I think I get it. So you're suggesting pulling the panels of using a magnetic "handle" that would not be permanently attached to the door?

Yes. The more I think about it, you could attach a piece of metal on the back side of the panel and use a horse shoe magnet and dip in the plastic coating stuff they sell at the big box home supply stores the coat handles, so that you would not scratch the wood panels.

Very smart idea. That would be really cool to not have handles as I really want the whole look to be very clean. I'm hoping the tank and stand arrive tomorrow, so once I've got everything done plumbing wise I'll install the door panels. I will keep my build thread updated so that anyone interested can see the final results of the panels.

Tank build: https://www.reef2reef.com/threads/boudsters-4x6x18-dream-peninsula.253635/

Another question...i will be painting the panels, so do you all suggest I just use plywood or MDF? Or would you go with "real wood"? Some have even suggested using something other than wood such as ABS. Definitely open to suggestions.

- Joined

- May 5, 2014

- Messages

- 498

- Reaction score

- 253

I think that's totally depending on style. I personally love the look of wood and grains. High quality stain it will last forever. But $$$. You could get a skinned veneer plywood and save some money in the same boat. If you want solid painted color mdf may be a way to go although laminate might be an option.

It will definitely be painted a solid color, light grey (i wanted orange!), as my wife insists it match the decor of the house [emoji6]I think that's totally depending on style. I personally love the look of wood and grains. High quality stain it will last forever. But $$$. You could get a skinned veneer plywood and save some money in the same boat. If you want solid painted color mdf may be a way to go although laminate might be an option.

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

Similar threads

- Replies

- 24

- Views

- 734

- Replies

- 1

- Views

- 147