Ok lid off, Float Switch should be cancelling co2 power but its not. Co2 is a bit away from acr so i have lid resting (that simulates an air pocket- float switch dropped as if excess gas pocket). Carbon doser still powered. Float switch not triggering gas powerHmm, I am not an Apex guy, so I don't know. I know the Apex can monitor power usage, but I am not sure if it logs it passively. If it does, that would be a handy feature and would apply here for monitoring the float switch activity.

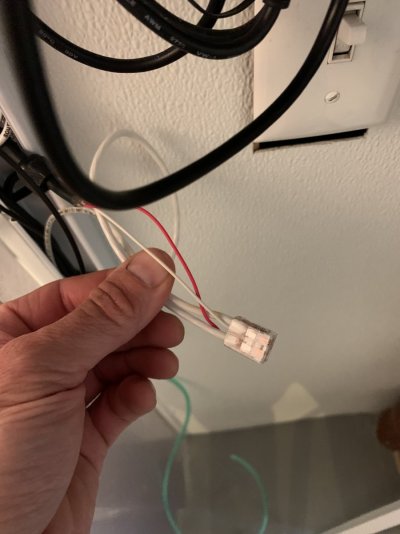

for wiring i have two patch wires connected to float switch , one patch wire to each of the two wires from float switch

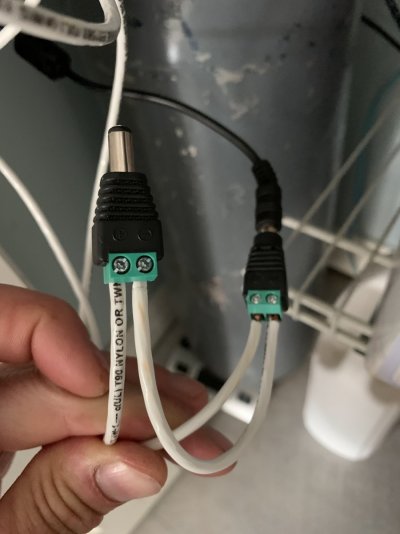

patch wires from float to each of the (+terminals of the adapter

jumper wire to both (-) terminals of adapter

power outlet for doser plugged to female adapter

male adapter plugged to