How are you feeding water to the reactor?Thanks for the reply!

Oh that makes sense.

Steady as in removing the needle valve and letting the effluent flow unobstructed?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Calcium reactor control by Neptune Trident

- Thread starter trido

- Start date

- Tagged users None

I'm running a Korallin C-1502 calcium reactor that's being fed water by a RIo Plus 400 aqua pump 144 GPH (which is the recommended pump for this calcium reactor).How are you feeding water to the reactor?

The idea is to have your reactor tuned so the alk levels slowly rise. The throttle program kicks in when it hits the upper alk settings which will then let the levels drop slowly until it stops throttling and lets the alk slowly rise again

You will need to use the needle valve then to control the effluent or you will pump too much water through the reactorI'm running a Korallin C-1502 calcium reactor that's being fed water by a RIo Plus 400 aqua pump 144 GPH (which is the recommended pump for this calcium reactor).

That makes sense.The idea is to have your reactor tuned so the alk levels slowly rise. The throttle program kicks in when it hits the upper alk settings which will then let the levels drop slowly until it stops throttling and lets the alk slowly rise again

What should I set my drip rate to be then?

I use a peristaltic pump set on 27ml/min.That makes sense.

What should I set my drip rate to be then?

your effluent flow and CO2 bubble count will be very different from mine. You want to get your reactor set up so it is adding a little more alkalinity each day than is consumed and occasionally triggering the throttle program. For proper settings of CO2 and effluent rates test the dkh of the effluent and try to keep it around 25. Normal test kit won’t read that high so just dilute a sample 50% with rodi and double the test result

No, keep your drip rate from the the reactor as you normally would for peak efficiency.Thanks for the reply!

Oh that makes sense.

Steady as in removing the needle valve and letting the effluent flow unobstructed?

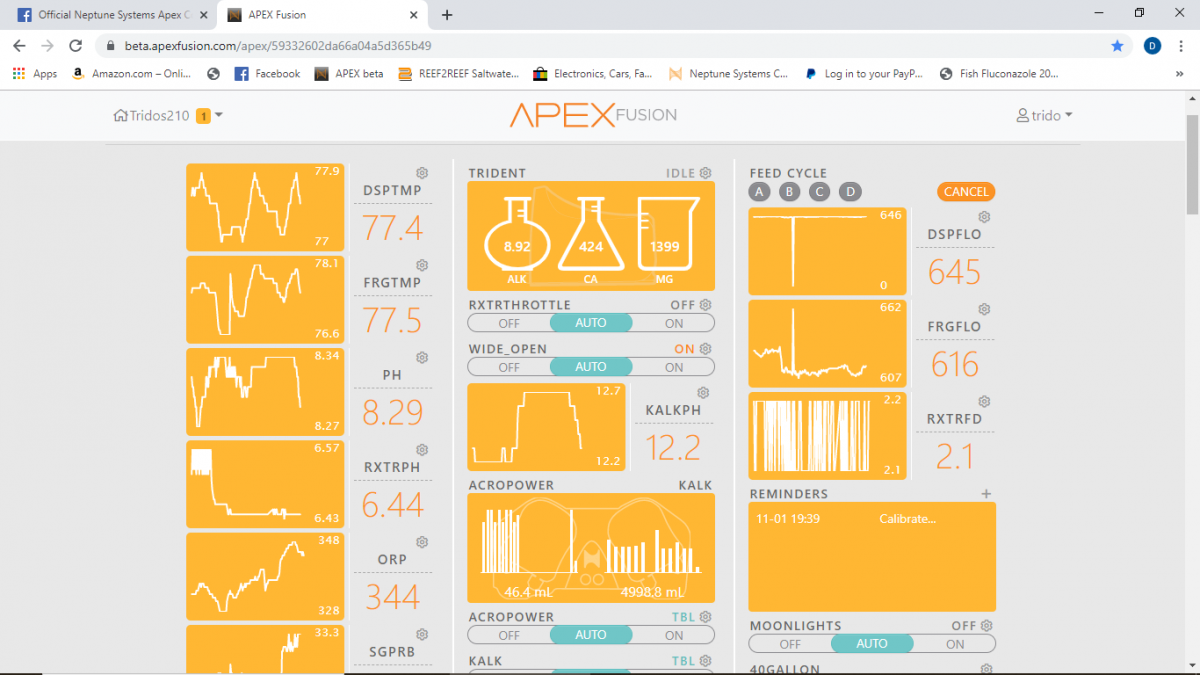

I'm new to apex Programming and I'm somewhat ignorant on this subject matter so my question may sound lame but I want to understand something here. The trident simply shows "Alk" but in your code your have used "Alkx2" . How does it know it is the alkalinity of the trident?Since the beginning of April 2019 I've had my Trident and after a couple weeks when I trusted it, I started experimenting with some programming I thought of well before its release. More people with reactors need to know about this easy to create and use program to help with Alkalinity stability so I'm sharing it on R2R in hopes more reefers see it. A sticky thread would be best.

For 15 years prior to the Neptune Trident, my Alkalinity was always on a slow climb, or slow drop due to my laziness. I learned that as long as changes happened slowly my corals don't really care. Because of that, I never worried about dialing my reactor in perfectly and I would often go several months without testing for Alkalinity. I've had Alkalinity as low as 6 and as high as 16. Those two extremes are when my corals showed visible signs of stress and of course I had to jump to action to correct the problem. A 10% WC and slight correction of the reactor is all that was ever needed. The problem happened slowly so correcting it slowly is always best with SPS. Every number in between is pretty safe in my experience. Of course 7-11 is the target. I have not tested for Calcium in over a decade, and rarely test for Magnesium. In my opinion, with a Calcium reactor, those two numbers are not real important, because with a quality media, they will always be balanced.

Enough back story, on to the good stuff.

This program should work with any CO2 regulator with an electronic selenoid. Its very simple and consists of two virtual outlets. One is the high limit of your choice, and the second is the toggle that slows the melt (raises the pH in the reactor) to slowly lower the Alkalinity in the tank.

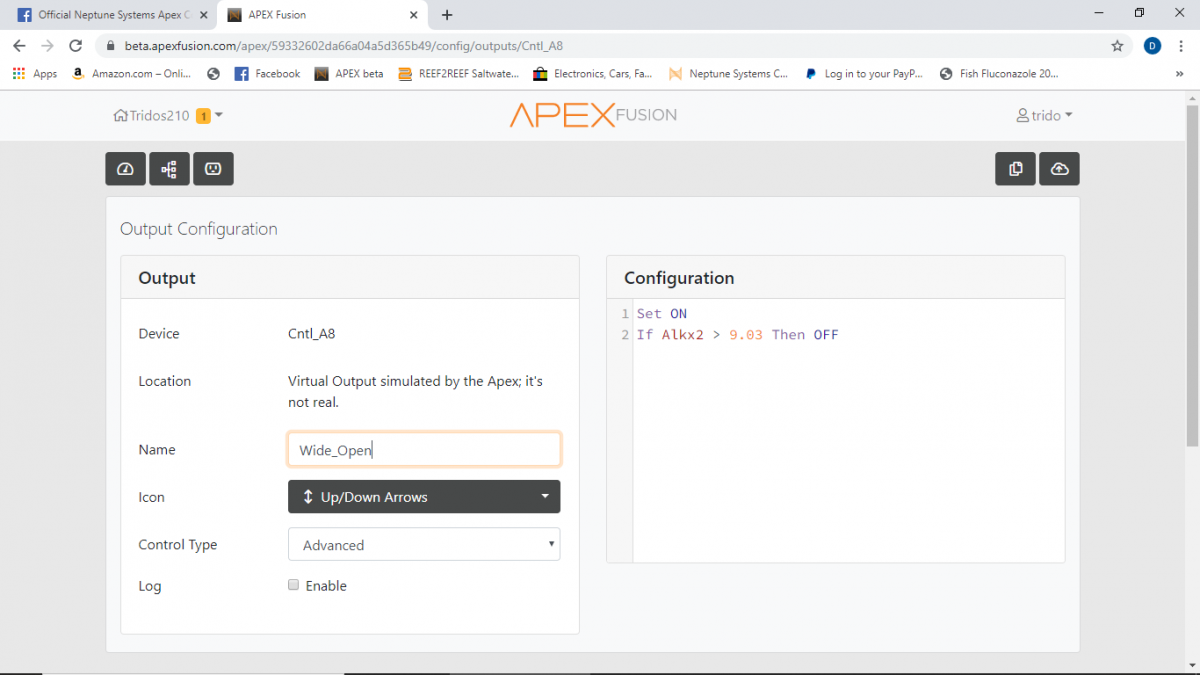

This is the high limit Virtual Outlet. I chose 9.03 as a random number for the initial experiment and never changed it. The Target Alkalinity is 9.00.

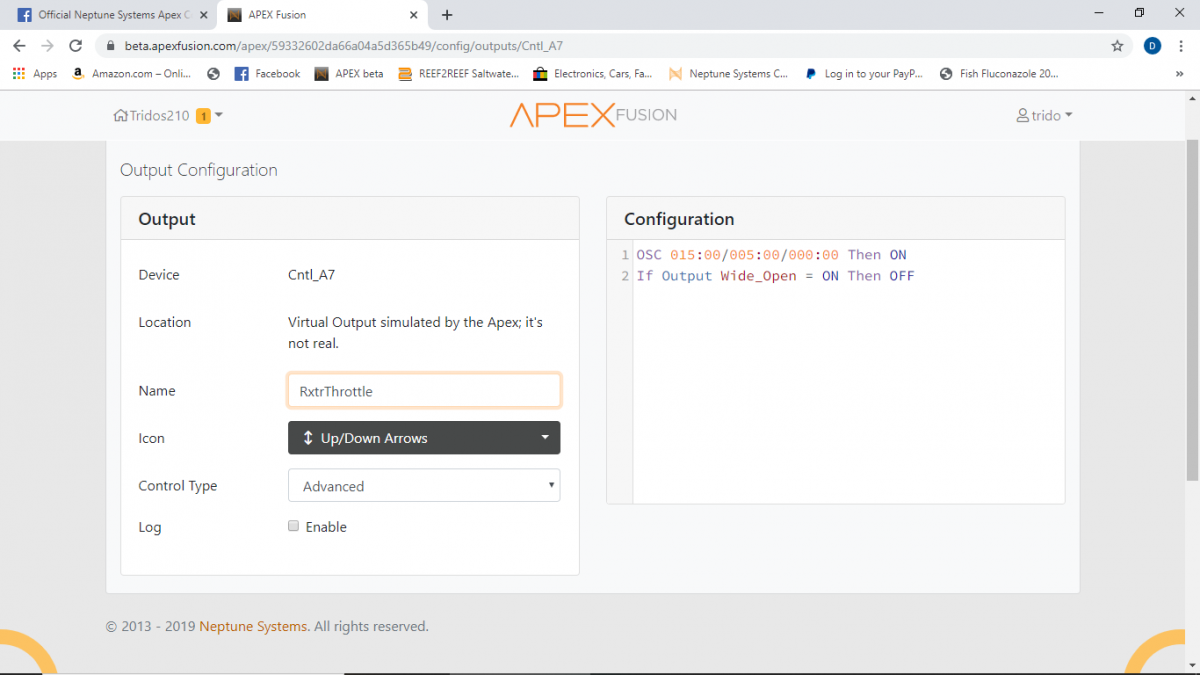

This is my OSC Virtual Outlet. For every twenty minute cycle, the CO2 is turned off which raises the reactor pH up about two tenths

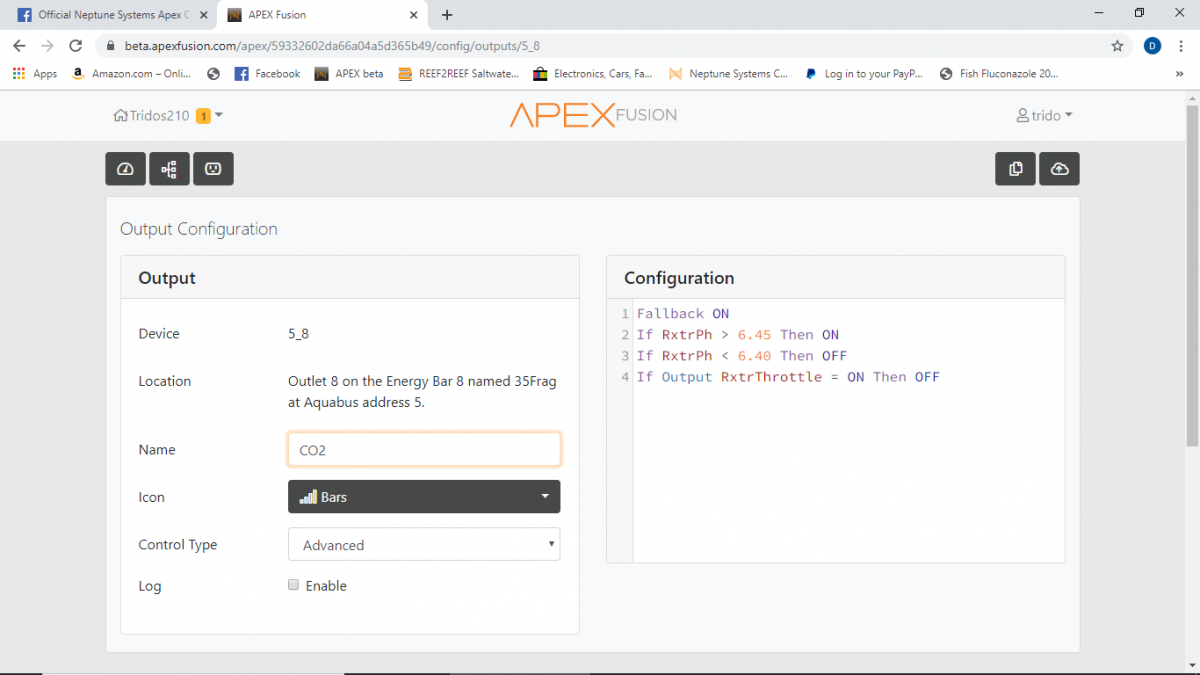

For the reactor CO2, I left my old original programming as a fail safe and simply added the last line. At this point I could remove the second line, but leaving it will make things easier for when I have to take the Trident off line for maintenance.

Thats it! The program requires you to dial in the reactor to work slightly harder than you need it to and as demands increase the toggle will come on less often as a high limit. This has been successfully working for quite a few large SPS tanks including @melev and @Thales as well as my own. I hope it helps you too.

Can anyone answer this please?Great idea. How do I figure out what my Trident ALK is called to program this? I tried the Alkx2 with no luck

Thanks Trido. You said it. It is in the graph. Got it. thanks. I asked even before reading the whole three pages of this discussion. My bad!Can anyone answer this please?

The way it supposed to work-

When your Alk is above your target it will go into the oscillate mode where the CO2 is on for 5 minutes then off for 15 thereby providing a lower nominal level of Alkalinity. If it falls below the target then the Max setting kicks in, keeping it the CO2 on continuously until the next test and drop below the target.

What you need to work out is your nominal levels which its in the throttle mode. This part is like running a CaRX with out Apex...you need to spend a few days adjusting you bubble count and reactor pH for you tanks needs. Once this is set then the Apex control will work well. It will take a few days to reach a fairly steady state.

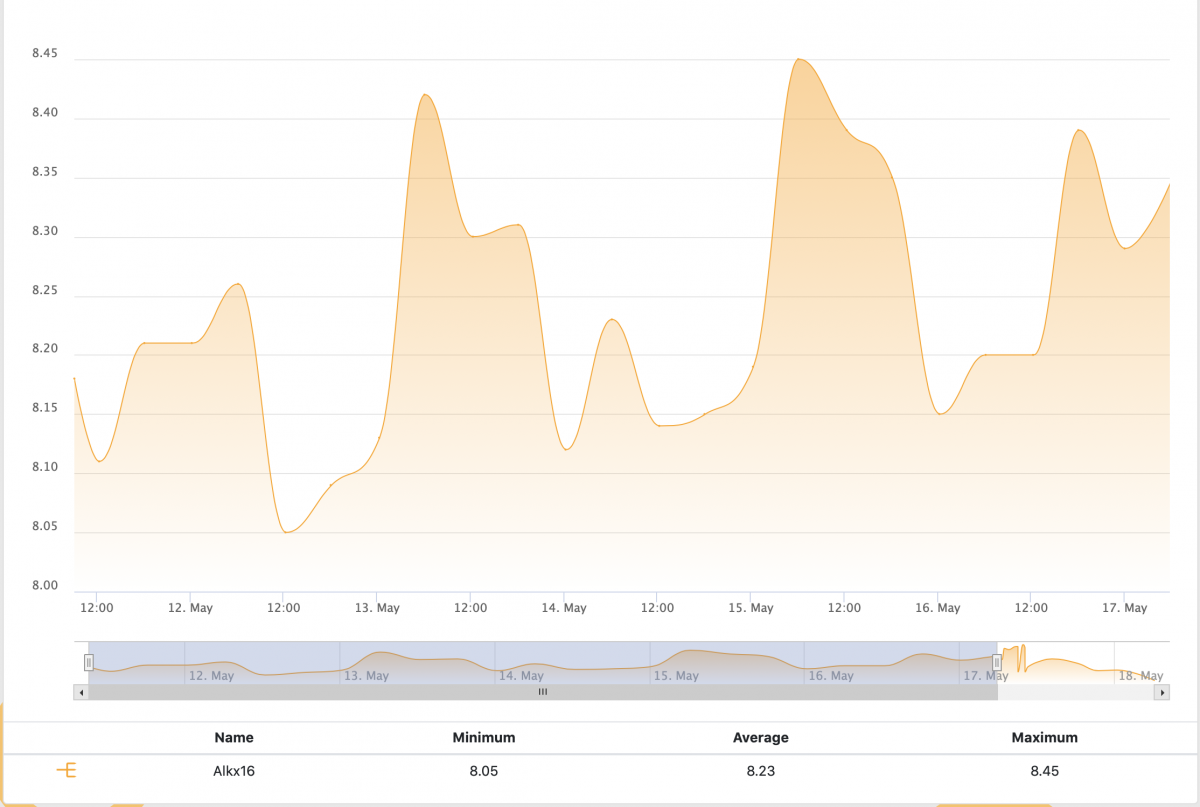

Here is my graph, my tank is under low demand currently and I'm bubbling 4 bubble per minute with a flow from my Kamoer pump at 28 cc. I have my target Alk to 8.2. As you can see mine fluctuates about .4-.5 dKH. I'm only testing 4x per day but if I wanted tighter control I could test more often.

Hope this helps.

I seem to be stuck. Can you help me determine how to find the "nominal levels which its in the throttle mode"?

So far I have successfully maintained my target of 9 dkh perfectly with the following settings:

The Carbon Doser fixed at the bubble rate = 1 bubble every 4 seconds, The Carbon Doser is plugged into the Apex power switch and turning on & off when the reactor's pH probe reach set points at 6.56 OFF and 6.65 ON, and the Effluent Flow fixed at 10ml/min via Kamoer FX-STP2 pump.

So in order to find the nominal levels you speak of, do I simply remove the code for the pH probe and instead add all the code described by Duane in this thread, keeping my Kamoer at 10ml and bubble rate at 1 bubble every 4 secs as a starting point? Really can't understand how to proceed.

I really would appreciate a little further explanation and direction if you can spare the time.

If you have found a good balance at your current effluent rate and bubble count that is a good starting point. I use the throttling codes to target a 8.88-9dkh alk level. I ended up using a couple throttling codes one low one high. So to answer your question, yes you are controlling the Carbon Doser based on tank Alk and not on CaRX pH.I seem to be stuck. Can you help me determine how to find the "nominal levels which its in the throttle mode"?

So far I have successfully maintained my target of 9 dkh perfectly with the following settings:

The Carbon Doser fixed at the bubble rate = 1 bubble every 4 seconds, The Carbon Doser is plugged into the Apex power switch and turning on & off when the reactor's pH probe reach set points at 6.56 OFF and 6.65 ON, and the Effluent Flow fixed at 10ml/min via Kamoer FX-STP2 pump.

So in order to find the nominal levels you speak of, do I simply remove the code for the pH probe and instead add all the code described by Duane in this thread, keeping my Kamoer at 10ml and bubble rate at 1 bubble every 4 secs as a starting point? Really can't understand how to proceed.

I really would appreciate a little further explanation and direction if you can spare the time.

It's a little hard to wrap your head around all the codes and what is happening with the on/off but I decided on a second throttling set of code so I could taylor the cycling times between a faster and a slower cycle. Basically I was finding the alk was overshooting my target before the high throttle would kick in. So the low throttle allows my CaRx to continue sending alk to the tank but at a lower dose so it doesn't overshoot my target so much between alk tests by the Trident.

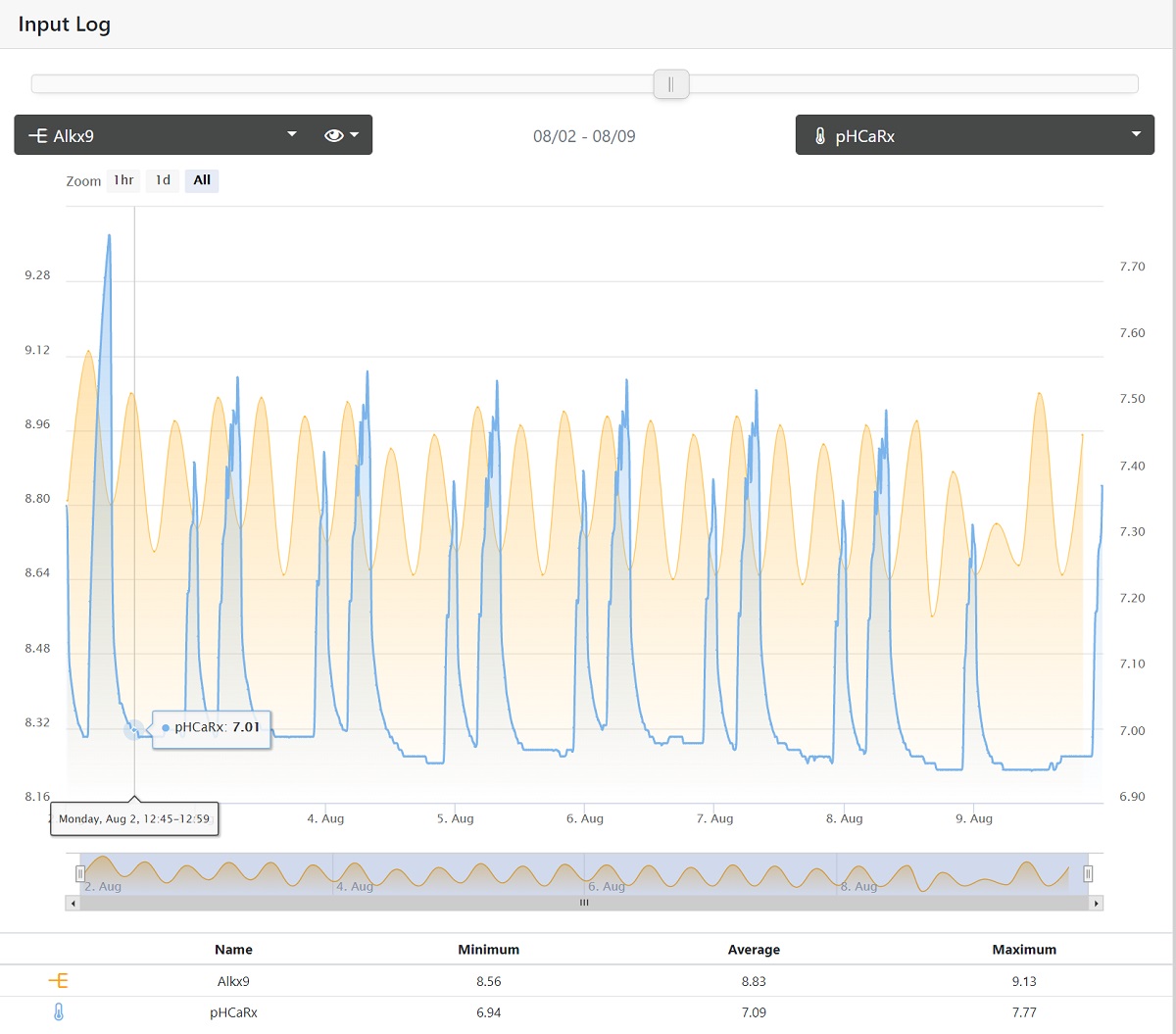

So.. If my alk is below 8.83 which is below my target. The following happens. CdosFlutLow is ON Which Turns CaRxThrotLow OFF. FlutLow and ThrHigh are always in the on/off state unless my alk is over 8.9. So 8.83 or below the carbondoser is running on fully based on the timing set on the CarbonDoser. The Low flutter and Throttle kick in when my alk is between 8.83 and 8.9. This turns the CaRxThrotLow ON which triggers the timing cycle set to the CarbonDoser. Right now it's on for 5minutes and off for 25minutes. If Alk is over 8.9 then FlutLow goes on and turns off the ThrotLow and FlutHigh goes OFF and turns ON ThrHigh timing cycle for Carbon Doser on 5minutes on 35 minutes off. There is a hard cap set on the carbon doser code that if the alk goes over 9.1 it will not turn on at all. I probably should tighten up the 8.9-9.1 range but that is for another day. So why the two sets of code? I like having the flexibility to tweak the lower throttle to a different timing when the Alk is near my target range but still on the low side. I don't want to slow it quite as much as when it is near my target range but slightly over and I would rather dial the CO2 input back but not totally stop it. I have attached a photo of my Alk and CaRx pH levels so you can see how it works. Just a heads up.. back on the 8th I discovered my flow in and out of my reactor was a trickle because of a clogged line which was causing weird alk swings in the tank hence the big spike to over 10 as there was a long delay between the CaRx fluid reaching the tank.. ie it was building up really high DKH and then putting it into the tank in a delayed fashion (note how the CarbonDoser was turned off when alk hit 9.1 but Alk spiked after that to 10.25 as effluent high in alk still continued to flow slowly to the tank). You can see how the throttling codes took over after I fixed the problem and how it's been running the past 5 days. Since then I have been running around a .3dkh swing between high and low. I am still a tad lower than I would like so I am speeding up the bubble count on the carbondoser just a little.

I have the following:

CaRXThrHigh

CDosFlutHigh

CaRXThrotLow

CDosFlutLow

Code for Carbon Doser:

Fallback ON

Set ON

If Output CaRxThrHIGH = ON Then OFF

If Output CaRxThrotLOW = ON Then OFF

If Time 10:30 to 22:00 Then ON

If pHCaRx < 6.44 Then OFF

If Alkx9 > 9.10 Then OFF

Code for CaRXThrHigh:

OSC 005:00/035:00/000:00 Then ON

If Output CDosFlutHIGH = ON Then OFF

Code for CDosFlutHigh:

Set ON

If Alkx9 > 8.90 Then OFF

Code for CaRXThrotLow:

OSC 005:00/025:00/000:00 Then ON

If Output CDosFlutrLOW = ON Then OFF

Code for CDosFlutLow:

Set ON

If Alkx9 > 8.83 Then OFF

If Alkx9 > 8.90 Then ON

Last edited:

I scrolled back to when the CaRx input line was not clogged. Looks like some ups and downs but it is about a .3- .35dkh swing each day. You can see how the low is slowly getting lower each day due to increased consumption. Eventually the CarbonDoser would be running pretty much steady during the day but I like to have it putting out a bit more alk than the tank consumes during the day so that the low point isn't as low as it would go otherwise. You can also see the difference between the CDoser on fully at pH 6.95, low throttle code pH 7.25-7.32ish and high throttle pH 7.55 vs off around 7.9-8.

Thank you for your reply and for your generous sharing of your programming and results. For the time being, I am still learning how the basic changes in my settings (flow & bubble count changes) are affecting the dkh stability of my tank when I set my desired dkh at 9.0.If you have found a good balance at your current effluent rate and bubble count that is a good starting point. I use the throttling codes to target a 8.88-9dkh alk level. I ended up using a couple throttling codes one low one high. So to answer your question, yes you are controlling the Carbon Doser based on tank Alk and not on CaRX pH.

It's a little hard to wrap your head around all the codes and what is happening with the on/off but I decided on a second throttling set of code so I could taylor the cycling times between a faster and a slower cycle. Basically I was finding the alk was overshooting my target before the high throttle would kick in. So the low throttle allows my CaRx to continue sending alk to the tank but at a lower dose so it doesn't overshoot my target so much between alk tests by the Trident.

So.. If my alk is below 8.83 which is below my target. The following happens. CdosFlutLow is ON Which Turns CaRxThrotLow OFF. FlutLow and ThrHigh are always in the on/off state unless my alk is over 8.9. So 8.83 or below the carbondoser is running on fully based on the timing set on the CarbonDoser. The Low flutter and Throttle kick in when my alk is between 8.83 and 8.9. This turns the CaRxThrotLow ON which triggers the timing cycle set to the CarbonDoser. Right now it's on for 5minutes and off for 25minutes. If Alk is over 8.9 then FlutLow goes on and turns off the ThrotLow and FlutHigh goes OFF and turns ON ThrHigh timing cycle for Carbon Doser on 5minutes on 35 minutes off. There is a hard cap set on the carbon doser code that if the alk goes over 9.1 it will not turn on at all. I probably should tighten up the 8.9-9.1 range but that is for another day. So why the two sets of code? I like having the flexibility to tweak the lower throttle to a different timing when the Alk is near my target range but still on the low side. I don't want to slow it quite as much as when it is near my target range but slightly over and I would rather dial the CO2 input back but not totally stop it. I have attached a photo of my Alk and CaRx pH levels so you can see how it works. Just a heads up.. back on the 8th I discovered my flow in and out of my reactor was a trickle because of a clogged line which was causing weird alk swings in the tank hence the big spike to over 10 as there was a long delay between the CaRx fluid reaching the tank.. ie it was building up really high DKH and then putting it into the tank in a delayed fashion (note how the CarbonDoser was turned off when alk hit 9.1 but Alk spiked after that to 10.25 as effluent high in alk still continued to flow slowly to the tank). You can see how the throttling codes took over after I fixed the problem and how it's been running the past 5 days. Since then I have been running around a .3dkh swing between high and low. I am still a tad lower than I would like so I am speeding up the bubble count on the carbondoser just a little.

I have the following:

CaRXThrHigh

CDosFlutHigh

CaRXThrotLow

CDosFlutLow

Code for Carbon Doser:

Fallback ON

Set ON

If Output CaRxThrHIGH = ON Then OFF

If Output CaRxThrotLOW = ON Then OFF

If Time 10:30 to 22:00 Then ON

If pHCaRx < 6.44 Then OFF

If Alkx9 > 9.10 Then OFF

Code for CaRXThrHigh:

OSC 005:00/035:00/000:00 Then ON

If Output CDosFlutHIGH = ON Then OFF

Code for CDosFlutHigh:

Set ON

If Alkx9 > 8.90 Then OFF

Code for CaRXThrotLow:

OSC 005:00/025:00/000:00 Then ON

If Output CDosFlutrLOW = ON Then OFF

Code for CDosFlutLow:

Set ON

If Alkx9 > 8.83 Then OFF

If Alkx9 > 8.90 Then ON

I really like this CaRx control method vs using pH and will continue to use this programming technique with ongoing refinements as time goes by.

No problem. Any questions just hollerThank you for your reply and for your generous sharing of your programming and results. For the time being, I am still learning how the basic changes in my settings (flow & bubble count changes) are affecting the dkh stability of my tank when I set my desired dkh at 9.0.

I really like this CaRx control method vs using pH and will continue to use this programming technique with ongoing refinements as time goes by.

Couple other notes. If I understand correctly the code is executed from top to bottom so the last true line is what happens. So for the CarbonDoser code which has multiple on off scenarios it's important how they are ordered in the program. You will also see I put in a time of day command so that my carbon doser will turn on automatically about 90 minutes before lights on full power. I found the timing of my lights with the trident testing schedule was causing the carbondoser to not turn on or go to a throttle mode just as the trident did it's noon test when my lights were hitting full power. The next test would be late in the day or early evening and the carbondoser was off or in throttle mode the whole time because the noon test indicated alk was at a good level at that time, this would cause a big alk drop at the end of the day. So now the carbondoser will run continuously when the lights are on fully unless for some reason the alk is way high and it triggered the high alk turn off command which is AFTER the on for time of day command.

I am also running 6 tests/day on the Trident. I like to have the extra two alk tests/day to help smooth things out a bit more. The swings were a little bumpier with 4.

Code for Carbon Doser:

Fallback ON

Set ON

If Output CaRxThrHIGH = ON Then OFF

If Output CaRxThrotLOW = ON Then OFF

If Time 10:30 to 22:00 Then ON

If pHCaRx < 6.44 Then OFF

If Alkx9 > 9.10 Then OFF

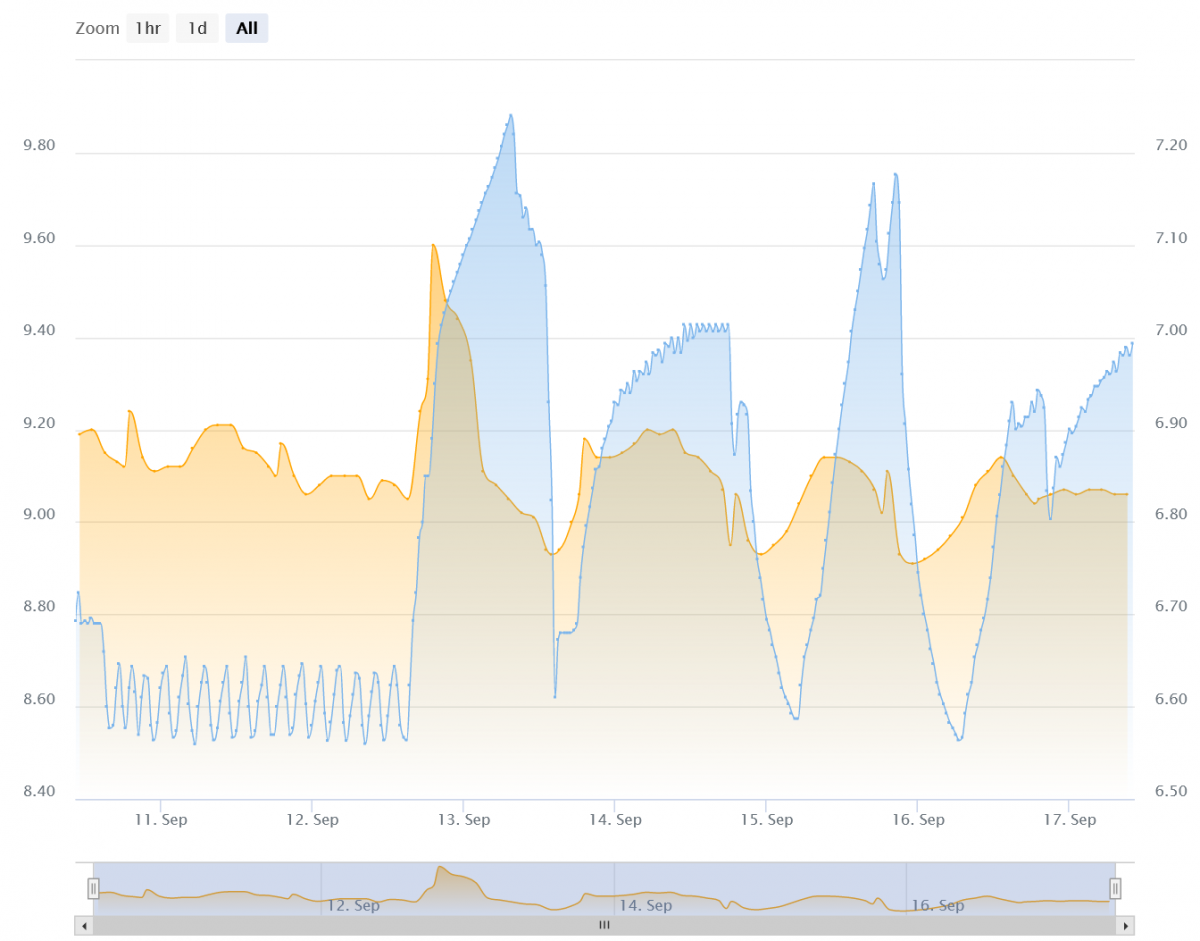

From Sept11-12th: Target dkh=9.0; Flow=10ml/min; 1Bub/4sec; pHcarx > 6.56 ON; pHcarx < 6.65 OFF

From Sept12-16th: Target dkh=9.0; Flow reset at numerous test levels from 10ml to 20ml; 1Bub/4sec; pHcarx code deleted; Carbon Doser sometimes throttled and sometimes FullOn

From Sept16-17th: Target dkh=9.0; Flow=21ml/min; 1Bub/4sec; pHcarx code deleted; during this 12 hour period, by keeping the Flow set to 21ml, Carbon Doser throttling has remained ON throughout and dkh stayed between 9.04-9.07

Hopefully these settings are now balanced correctly and will keep the dkh steady near 9.0

Nice. Yes may take some tweaking in the timing of the on/off throttling. You shouldn't have to mess with the carbon doser much. As uptake increases and the carbon doser is throttled less and less often you can then start to speed up the bubble count a little. Changing flow through the reactor doesn't do much if you leave the carbon doser alone. It will affect pH but you end up with either more effluent at a slightly lower Alk or less effluent that's higher in Alk. As long as the reactor flow isn't so slow that the pH melts the media to mush you are good on flow.

From Sept11-12th: Target dkh=9.0; Flow=10ml/min; 1Bub/4sec; pHcarx > 6.56 ON; pHcarx < 6.65 OFF

From Sept12-16th: Target dkh=9.0; Flow reset at numerous test levels from 10ml to 20ml; 1Bub/4sec; pHcarx code deleted; Carbon Doser sometimes throttled and sometimes FullOn

From Sept16-17th: Target dkh=9.0; Flow=21ml/min; 1Bub/4sec; pHcarx code deleted; during this 12 hour period, by keeping the Flow set to 21ml, Carbon Doser throttling has remained ON throughout and dkh stayed between 9.04-9.07

Hopefully these settings are now balanced correctly and will keep the dkh steady near 9.0

My last settings with target dkh=9.0, 1 bub/4sec and Flow=21ml/min seem (so far) to be balanced. But I do worry that the current flow is too low and over time will clog the tiny 1/4" effluent line. I would prefer to run the effluent line quite a bit faster so that it is NOT just dripping out but instead flows in a very slight stream. I am afraid if I increase the Flow any more, and then adjusting the bubbles slower (1 bub/5sec?) to compensate, it might completely throw out the balance I have now.

I run 30ml/min and have not had any issues with the effluent clogging the 1/4 poly tubing. The end is submerged in the refugium. I have also had it sending the effluent into the skimmer in the past. I think I recall Randy mentioning the amount of alk produced by your CaRx is dependent on the CO2 input. So if you wanted to up the effluent a bit and left the Carbondoser settings alone your overall alk output would be the same. IE your effluent DKH would drop slightly but your putting more into the tank. My skimmer runs around 6.9 pH. I am using Reborn media which supposedly dissolves a bit better at higher pH than some of the other calcium rock on the market.My last settings with target dkh=9.0, 1 bub/4sec and Flow=21ml/min seem (so far) to be balanced. But I do worry that the current flow is too low and over time will clog the tiny 1/4" effluent line. I would prefer to run the effluent line quite a bit faster so that it is NOT just dripping out but instead flows in a very slight stream. I am afraid if I increase the Flow any more, and then adjusting the bubbles slower (1 bub/5sec?) to compensate, it might completely throw out the balance I have now.

With a peristaltic pump the effluent line shouldn't plug at all since there arent any pinch points or a tiny ball valve that will plug with sediment.My last settings with target dkh=9.0, 1 bub/4sec and Flow=21ml/min seem (so far) to be balanced. But I do worry that the current flow is too low and over time will clog the tiny 1/4" effluent line. I would prefer to run the effluent line quite a bit faster so that it is NOT just dripping out but instead flows in a very slight stream. I am afraid if I increase the Flow any more, and then adjusting the bubbles slower (1 bub/5sec?) to compensate, it might completely throw out the balance I have now.

Similar threads

- Replies

- 7

- Views

- 151

New Posts

-

-

Once Cycle is almost done, what order of next items to add?

- Latest: EeyoreIsMySpiritAnimal

-

-

How many corals have you bought and added all at once?

- Latest: Reefing_addiction

-