- Joined

- Oct 3, 2019

- Messages

- 768

- Reaction score

- 1,049

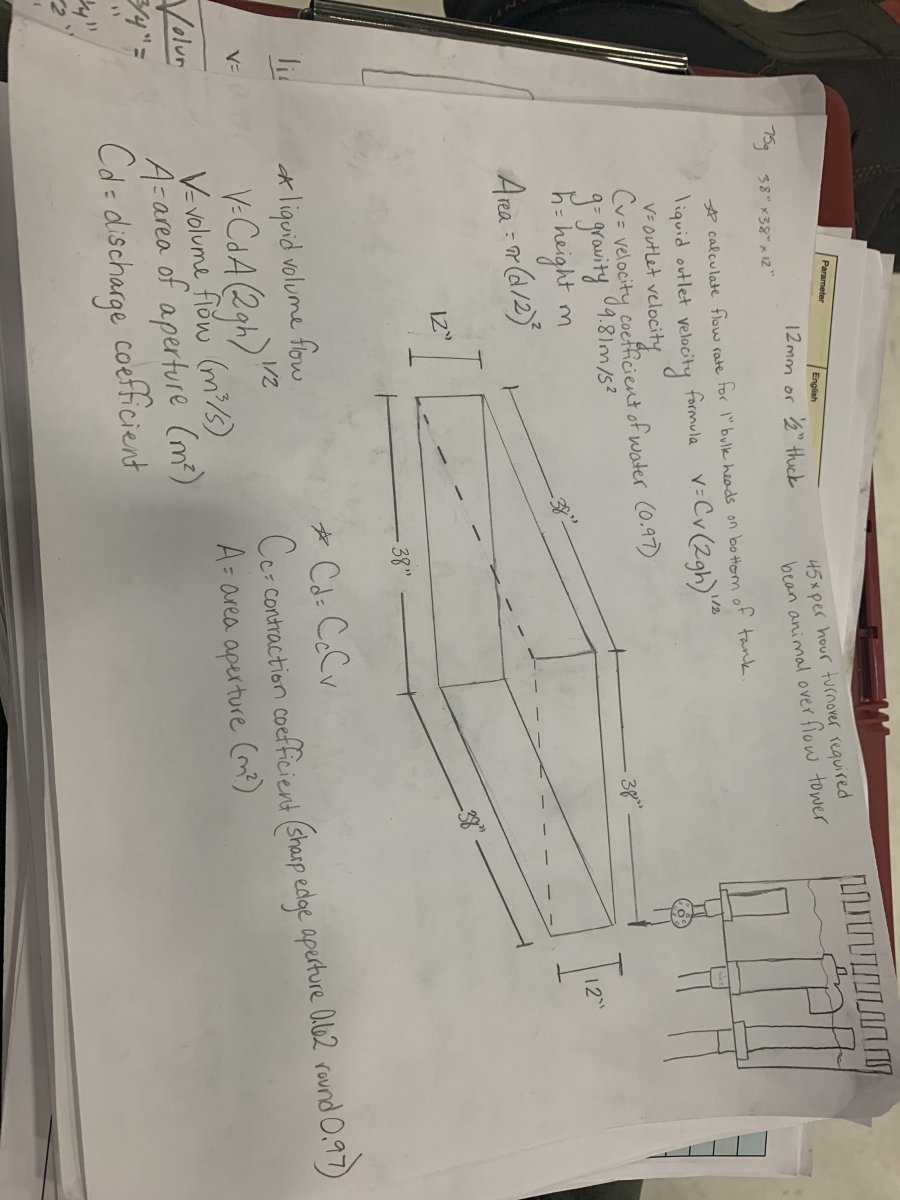

I am currently designing a custom tank build and I have a simple question that requires a good bit of background to explain.

I am aiming for a turnover rate of 30-40 for a 75gal frag tank that I plan to make as my display.

Dimensions: LxWxH 38”x38”x12”

I am going to drill holes in the center of the bottom panel for a true bean-animal overflow tower in the center. (Some call it a tower overflow or a center overflow, but it is basically a square weir in the center)

I want to make this overflow as small as possible so that it does not distract from my display, while leaving enough room to install 3 bulkheads for the bean animal design.

Essentially, I used the inner diameter value of schedule 80 PVC for the following nominal pipe sizes: 3/4”, 1”, 1 1/4”, 1 1/2”, and 2”.

The formula I used to calculate flow rate:

V= CdA(2gh)^.5

where Cd was calculated using (Cc-Cv)

Cc as contraction coefficient over a sharp edge aperture (straight edge) (.62)

Cv as the velocity Coefficient of water (0.97)

These calculations are much easier to do using metric values, so I converted all of the PVC pipe ID square inch areas into square meters.

The result of volumetric flow for a single aperture of each nominal pipe size are as follows, considering I used 11” as my height value (because I want my display tank filled to 1” below the rim)

3/4”= 148.9 gal/h

1”= 241.2 gal/h

1 1/4”= 419.76 gal/h

1 1/2”= 787.32 gal/h

2”= 939.2 gal/h

FINALLY, my question. I am not really sure how the bean animal piping is setup; I know that 1 of them should have a full siphon, so I can assume the full amount of my calculated volumetric flow rate. One pipe must have a partial siphon, right? And the last is an unused emergency drain, right? If anyone can relate my rambling to the bean animal drain setup and explain how much flow rate I can assume from the pipes that are only partially siphoned, I’d really appreciate it.

Thanks for reading this, even if you aren’t a math geek! I have put a lot of time into this because it’s still a ways out of reach, but it’s my dream build and I want to make sure it’s perfect. Happy reefing!

I am aiming for a turnover rate of 30-40 for a 75gal frag tank that I plan to make as my display.

Dimensions: LxWxH 38”x38”x12”

I am going to drill holes in the center of the bottom panel for a true bean-animal overflow tower in the center. (Some call it a tower overflow or a center overflow, but it is basically a square weir in the center)

I want to make this overflow as small as possible so that it does not distract from my display, while leaving enough room to install 3 bulkheads for the bean animal design.

Essentially, I used the inner diameter value of schedule 80 PVC for the following nominal pipe sizes: 3/4”, 1”, 1 1/4”, 1 1/2”, and 2”.

The formula I used to calculate flow rate:

V= CdA(2gh)^.5

where Cd was calculated using (Cc-Cv)

Cc as contraction coefficient over a sharp edge aperture (straight edge) (.62)

Cv as the velocity Coefficient of water (0.97)

These calculations are much easier to do using metric values, so I converted all of the PVC pipe ID square inch areas into square meters.

The result of volumetric flow for a single aperture of each nominal pipe size are as follows, considering I used 11” as my height value (because I want my display tank filled to 1” below the rim)

3/4”= 148.9 gal/h

1”= 241.2 gal/h

1 1/4”= 419.76 gal/h

1 1/2”= 787.32 gal/h

2”= 939.2 gal/h

FINALLY, my question. I am not really sure how the bean animal piping is setup; I know that 1 of them should have a full siphon, so I can assume the full amount of my calculated volumetric flow rate. One pipe must have a partial siphon, right? And the last is an unused emergency drain, right? If anyone can relate my rambling to the bean animal drain setup and explain how much flow rate I can assume from the pipes that are only partially siphoned, I’d really appreciate it.

Thanks for reading this, even if you aren’t a math geek! I have put a lot of time into this because it’s still a ways out of reach, but it’s my dream build and I want to make sure it’s perfect. Happy reefing!