I put the deposit down yesterday on the tank, and the room officially becomes mine on Monday, so it's time to start the build thread!

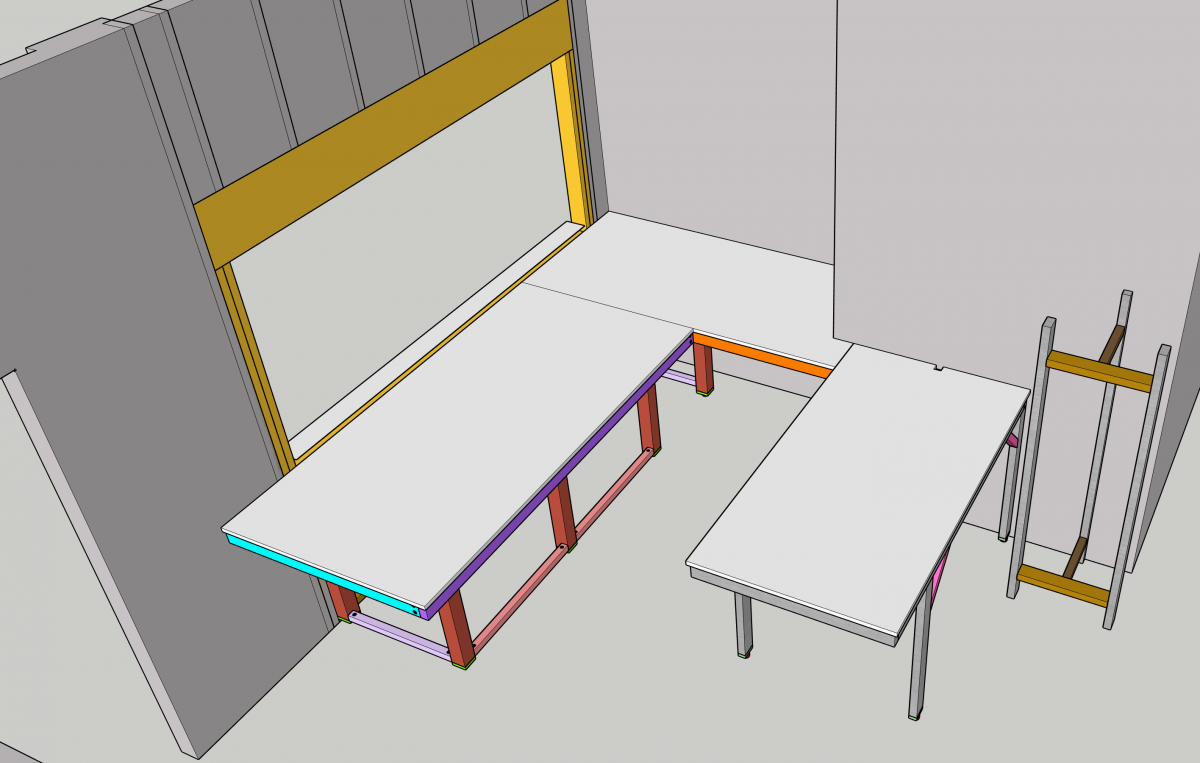

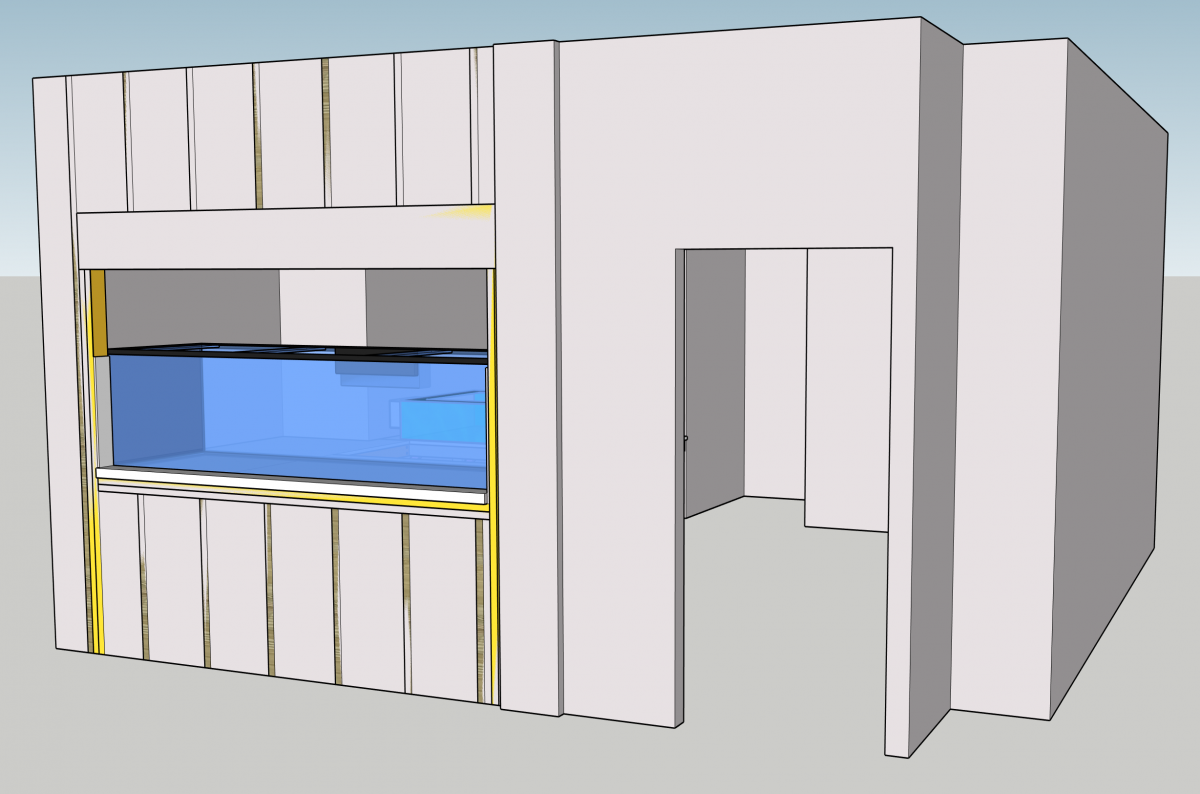

The room will officially be multi-use, as it was intended to be a mother-in-law suite. 1/2 will be the fish room, and 1/2 will be setup for an exercise room. It also has an attached full bathroom and separate entrance from the exterior of the house. The wall behind the frag tank is the sink and toilet in the bathroom, so I will have easy access to a drain and water supply.

Here are the plans for equipment:

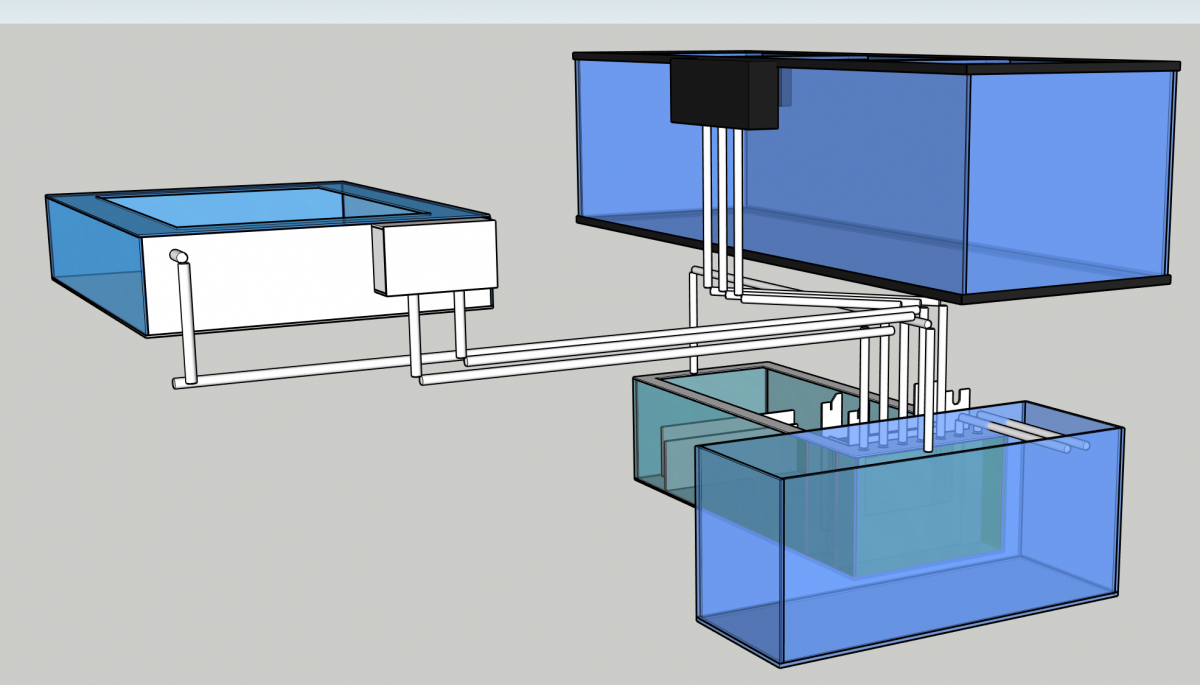

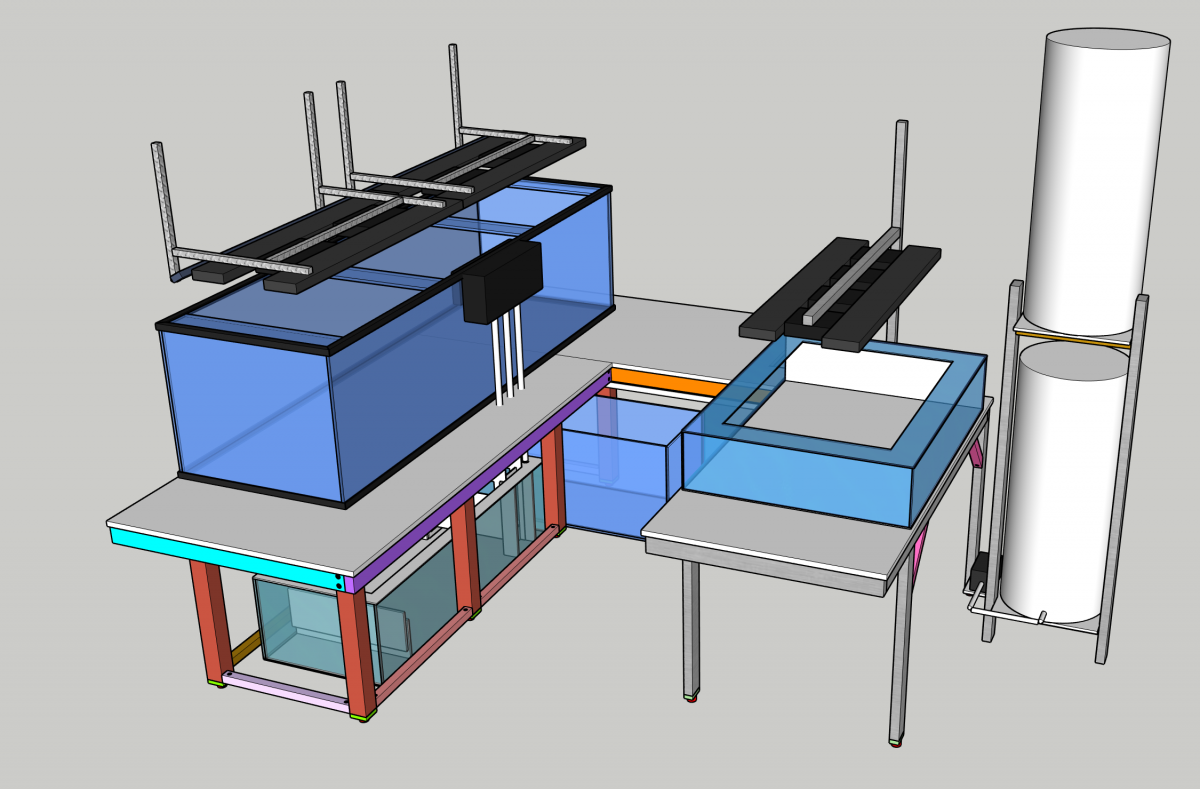

Tank - Planet Aquariums 96x30x25 310g w/ Modular Marine external overflow

Frag Tank - Modular Marine 48x36x10 acrylic

Sump - 75g standard glass tank for rock/fuge and a 60x24x16 Modular Marine Sump with built-in Roller Filter to hold equipment

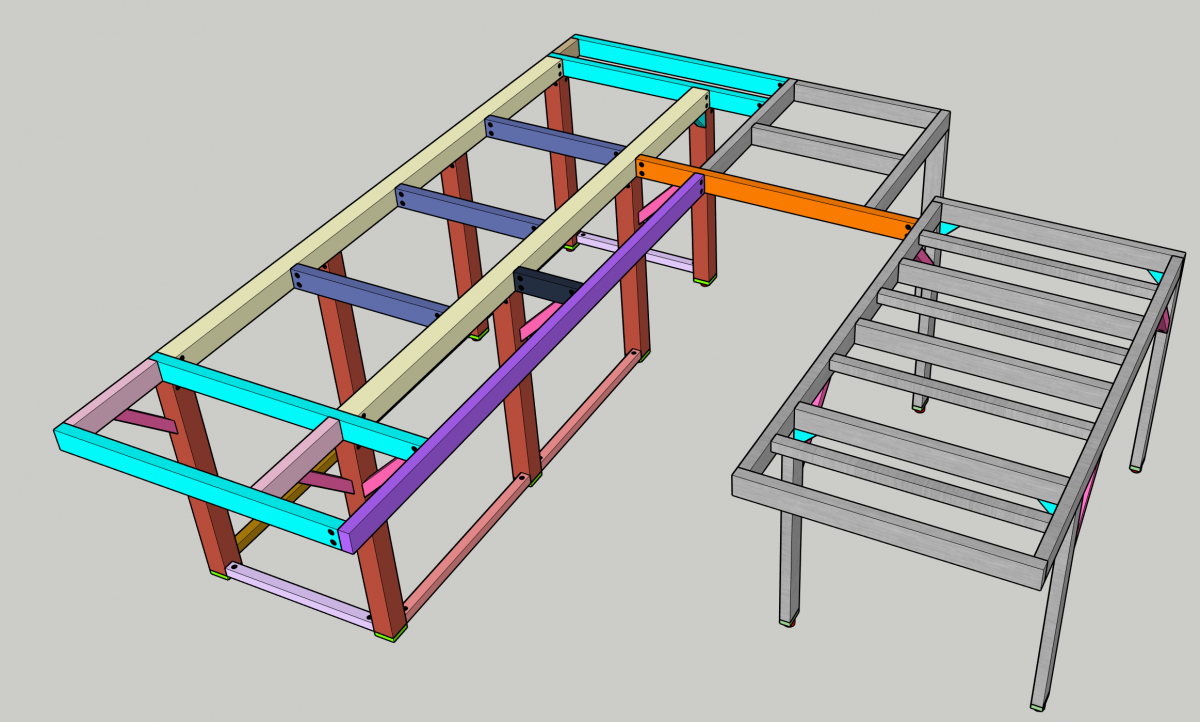

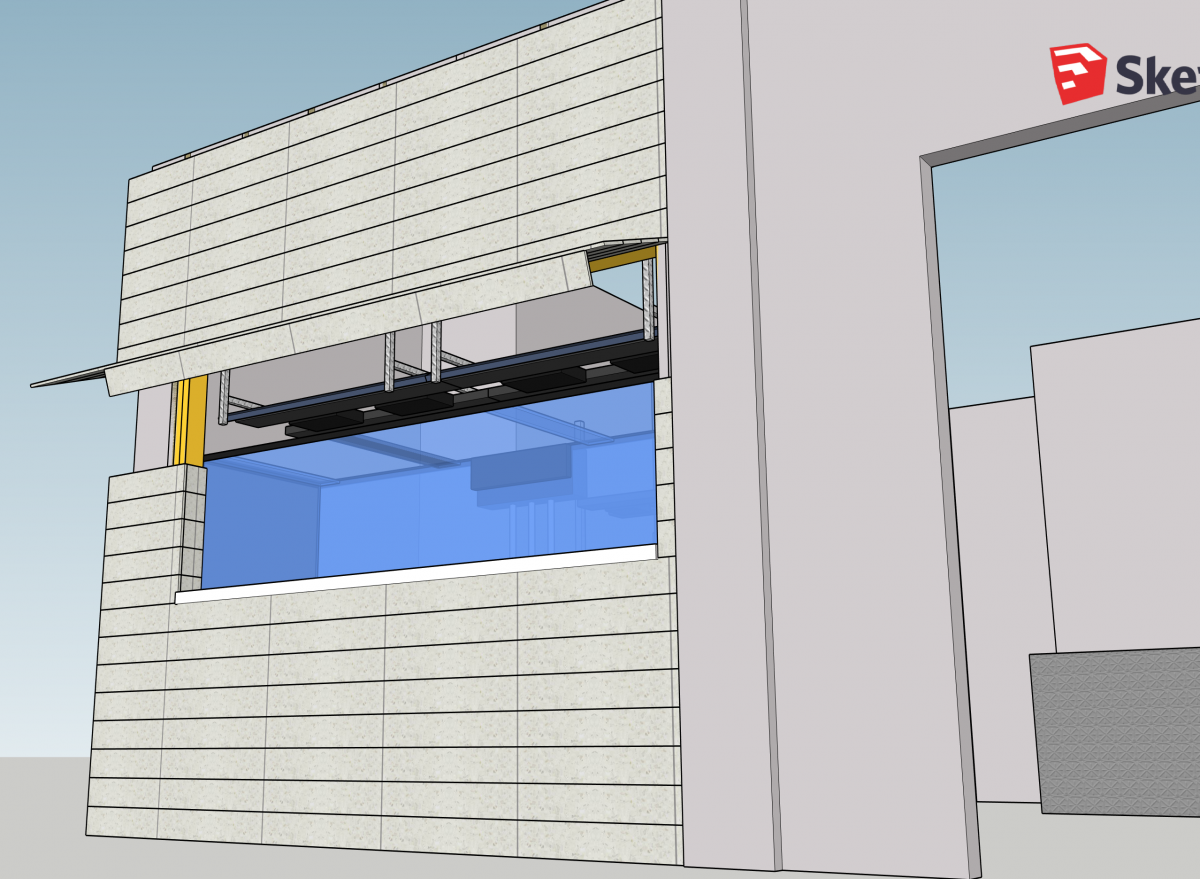

Stand - Custom Designed 15 series 8020. largest beams are 3"x3" and design incorporates additional tables and a full walkboard around the display. Full epoxy coat planned for the top

Display Lights - 4x XR30g4 Pro, 2x 48" Aquaticlife Hybrids, 2x 48" Orphek OR actinic bars

Frag lights - 48" Aquaticlife Hybrid with 4x XR15g4 Pros

Fuge light - 24" Orphek Fuge light

Display Flow - 2x Gyre 350's, 4x MP40QDs

Frag Flow - 2x Gyre 350's

Skimmer - currently a RO Elite INT 220, plan to upgrade to a 300 as it becomes stocked

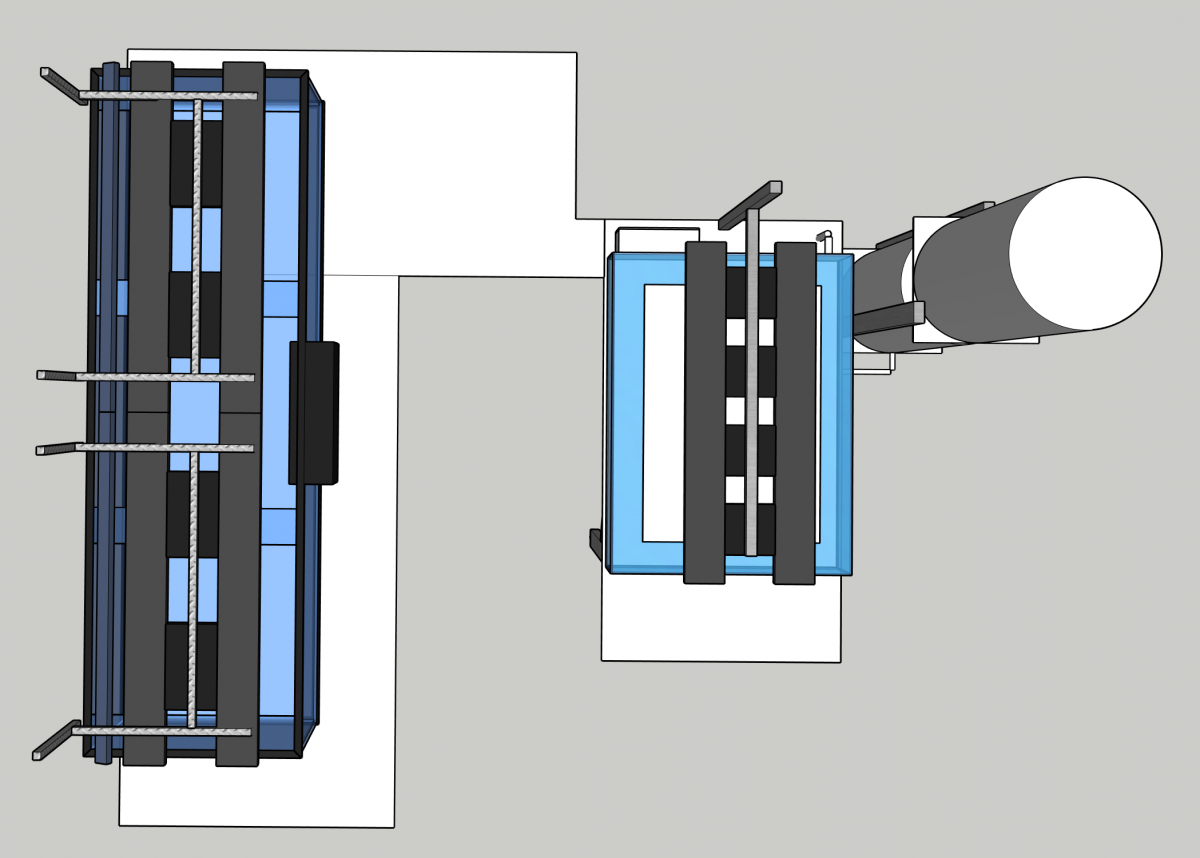

CaRX - custom built 6x18 currently, may upgrade to a 6x24 main body and has a 4x18 second chamber. Kamoer peristaltic pump and Carbon Doser regulator

Kalk - Avast k2 stirrer with Kamoer peristaltic pump

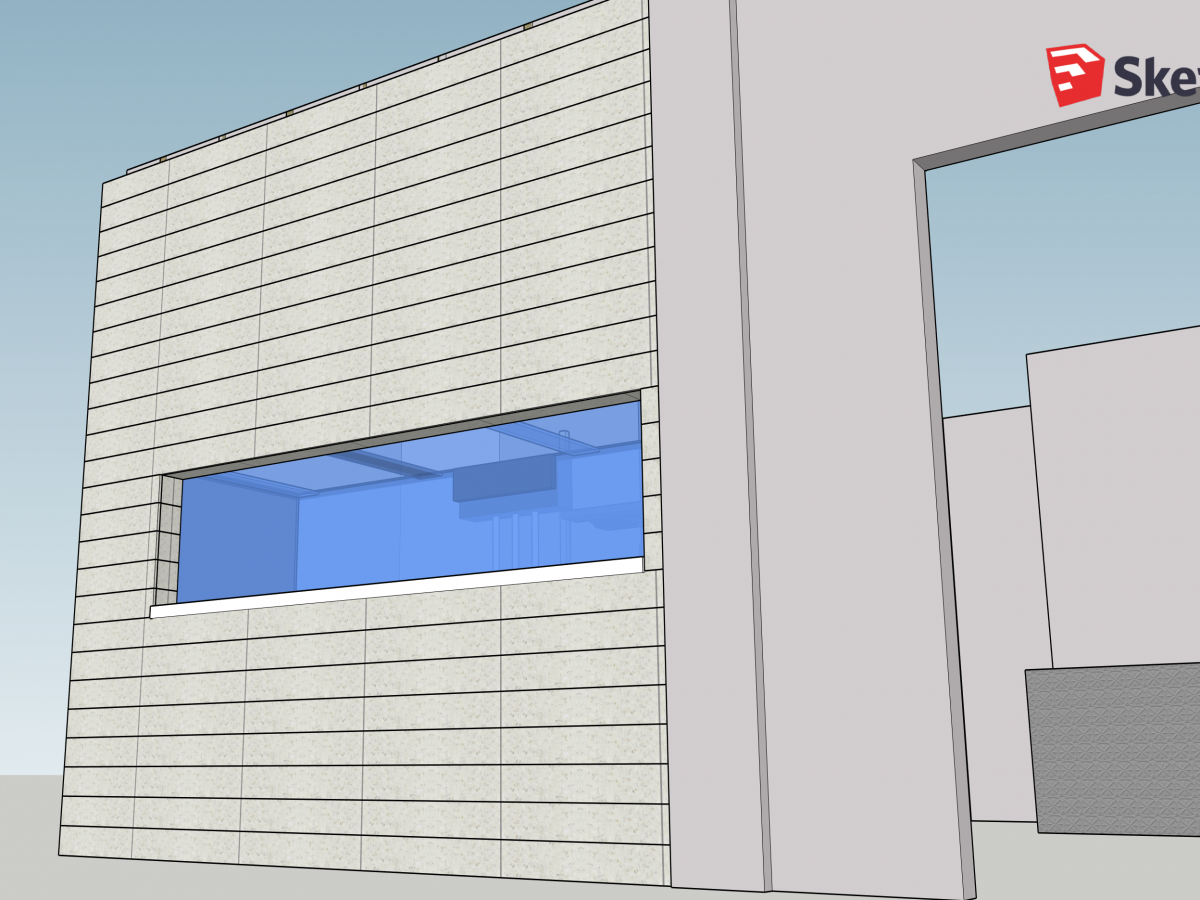

I think that will get this started. Including some design pics below:

The room will officially be multi-use, as it was intended to be a mother-in-law suite. 1/2 will be the fish room, and 1/2 will be setup for an exercise room. It also has an attached full bathroom and separate entrance from the exterior of the house. The wall behind the frag tank is the sink and toilet in the bathroom, so I will have easy access to a drain and water supply.

Here are the plans for equipment:

Tank - Planet Aquariums 96x30x25 310g w/ Modular Marine external overflow

Frag Tank - Modular Marine 48x36x10 acrylic

Sump - 75g standard glass tank for rock/fuge and a 60x24x16 Modular Marine Sump with built-in Roller Filter to hold equipment

Stand - Custom Designed 15 series 8020. largest beams are 3"x3" and design incorporates additional tables and a full walkboard around the display. Full epoxy coat planned for the top

Display Lights - 4x XR30g4 Pro, 2x 48" Aquaticlife Hybrids, 2x 48" Orphek OR actinic bars

Frag lights - 48" Aquaticlife Hybrid with 4x XR15g4 Pros

Fuge light - 24" Orphek Fuge light

Display Flow - 2x Gyre 350's, 4x MP40QDs

Frag Flow - 2x Gyre 350's

Skimmer - currently a RO Elite INT 220, plan to upgrade to a 300 as it becomes stocked

CaRX - custom built 6x18 currently, may upgrade to a 6x24 main body and has a 4x18 second chamber. Kamoer peristaltic pump and Carbon Doser regulator

Kalk - Avast k2 stirrer with Kamoer peristaltic pump

I think that will get this started. Including some design pics below: