- Joined

- Aug 13, 2019

- Messages

- 1,794

- Reaction score

- 2,403

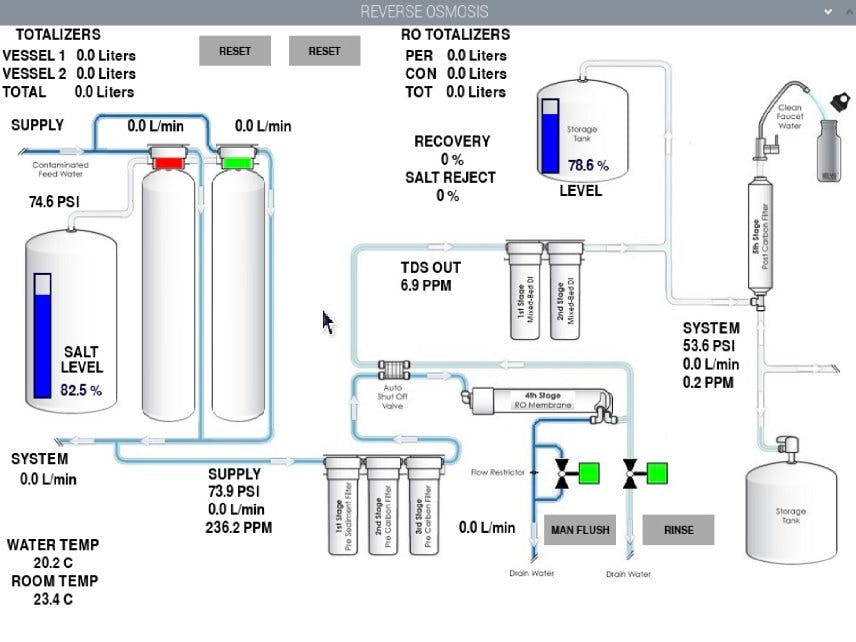

I’m not understanding how when you previously took the unit outside and connected it to a garden hose, eliminating the piercing valve, there was no improvement in flow. Yet when you replaced the piercing valve with a tee the flow is astronomically better? Something doesn’t make senseGood morning all! I got a bunch of stuff done yesterday night.

Time for updates:

Check your water flow (in addition to the pressure)!

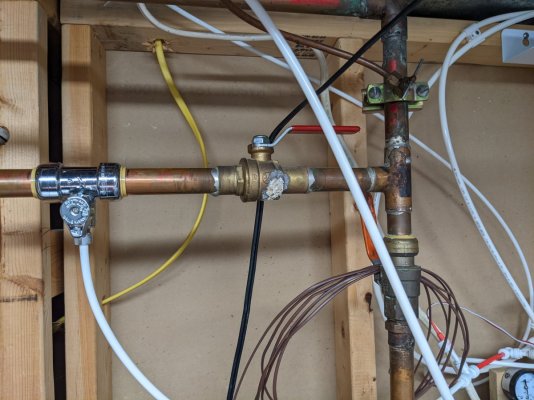

So I installed the sharkbite tee and shut-off valve combo. Here is what it looks like:

I compared the water flow between the saddle valve and this new tee based shut-off valve. WOW

The difference is night and day!

Just like I posted earlier, the measured pressure is exactly the same...around 70 PSI. However the flow of water shooting out is much, much faster from the shut-off valve. Why? Clearly it is the orifice size difference.

Why does it matter to us?

Well, when we flush the membrane, it is the flow of water which will flush away the sediments and impurities from the RO membrane. In my case, the flow was too low. So even if I flushed, the membrane was probably not getting cleaned/flushed.

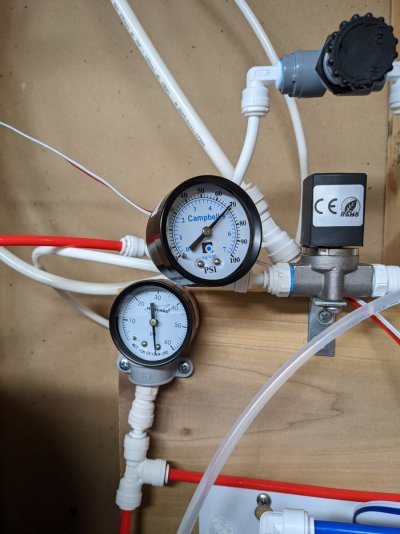

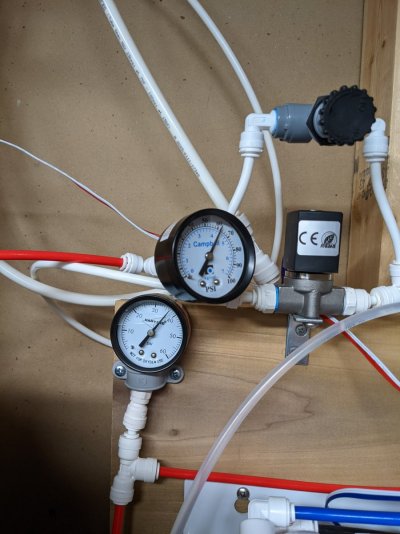

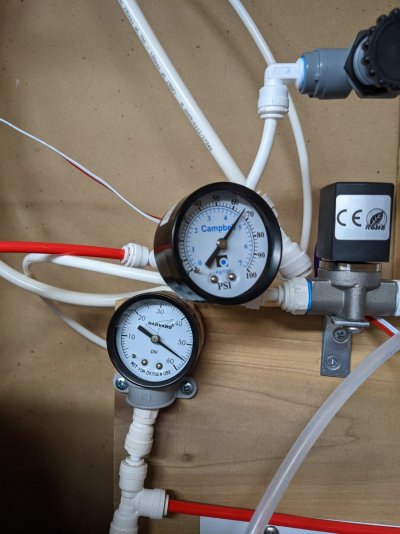

Showing pressure when the outlet is shut off. Notice both gauges show almost the same 70 psi:

Another thing I observed:

Check out the water pressure difference while flushing:

Water intake from piercing saddle valve:

Input gauge: 26 PSI

post-filters gauge: 13 PSI

Water intake from piercing saddle valve:

Input gauge: 62 PSI

post-filters gauge: 37 PSI

Which one will do a better job flushing the membrane?

Showing pressures while flushing:

But wait there is more!

So I have changed the membrane to the new one. The needle valve was useful while dialing down the target 4:1 wasteroduct water ratio Russ recommended for my hard water. It took a few back-and-forth adjustments but I was able to dial it to

- 250 ml/min product

- 1000 ml/min waste

PS: Talked to Russ about the precision on the flow adjustment valve being not so "precise". I observe that a tiny rotation makes a huge difference in water flow. I was expecting more precision. He said it is what it is and could be user error also. Well, it works for now. I guess I will try to find another flow adjustment valve which could do better.

Hey I just remembered this: I have a very precise flow adjustment valve for my CO2 injection system. I think I will look into getting one of those valves.

Anyway, I noticed that a tiny adjustment in the waste water flow adjustment also affects the product flow. Kinda makes sense, but also points out to the fact that input pressure matters a lot for reverse osmosis product. Here are the pressures while producing at the rate shown above:

Notice the 10 PSI drop over the filter blocks. Is that normal? Or does that mean my pre-filters are clogged?

Note that once the output solenoid closes, both pressure gauges show 70 PSI ...guessing that does not matter, but sill worth mentioning.

If anyone have two gauges like me, can you post a reading while producing RO water please?

Auto flush

Now I have an auto flush cycle programmed every hour for 2 minutes.

Is that good or I need to change this schedule?

Well, that is all for now!

Again, I will urge anyone with a RO system to check your water flow, just looking at your pressure gauge is NOT enough