Maybe they live by the ol “If it’s yellow let it mellow if it’s brown flush it down “You need to drink more water if you are only flushing twice a day.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cryptic problem: RO membranes clog up. Please help

If 4 people went 4 times a day it’s still only 40 gallons . Also most people do get out and use public restrooms during the day especially if they work .You need to drink more water if you are only flushing twice a day.

I like that !!!Maybe they live by the ol “If it’s yellow let it mellow if it’s brown flush it down “

That’s funny

ok here is an update:

I just talked to Russ from Buckey Hydro, was pleasantly surprised to get hold of him right away

Very nice guy, by the way. He listened patiently and gave me a a few suggestions:

Remove the fouled membrane and smell the ends

If it stinks, it is bio-fouled, meaning bacteria growing on the membrane

Then put a few drops of acid on the membrane

If it fizzes, it is fouled with calcium

Put a new membrane in, increase waste to product ratio to 4:1

If it works fine for a few months, then it is the hardness in the water.

Then I could choose to stay with the 4:1 ratio, or put a water softener.

If it fouls again, something else is in the water.

Do a water test.

Sounds reasonable to me. So I am going to order a membrane. When it comes, I will do some dissection on the fouled membrane

Also going to order that adjustable valve. That will allow me to change the waste water flow much easily.

I just talked to Russ from Buckey Hydro, was pleasantly surprised to get hold of him right away

Very nice guy, by the way. He listened patiently and gave me a a few suggestions:

Remove the fouled membrane and smell the ends

If it stinks, it is bio-fouled, meaning bacteria growing on the membrane

Then put a few drops of acid on the membrane

If it fizzes, it is fouled with calcium

Put a new membrane in, increase waste to product ratio to 4:1

If it works fine for a few months, then it is the hardness in the water.

Then I could choose to stay with the 4:1 ratio, or put a water softener.

If it fouls again, something else is in the water.

Do a water test.

Sounds reasonable to me. So I am going to order a membrane. When it comes, I will do some dissection on the fouled membrane

Also going to order that adjustable valve. That will allow me to change the waste water flow much easily.

- Joined

- Aug 13, 2019

- Messages

- 1,778

- Reaction score

- 2,385

Post your findings in case it may help someone else down the road. So many people leave the internet hanging, in suspense, patiently waiting for season two……only to find out a year later that it was cancelledok here is an update:

I just talked to Russ from Buckey Hydro, was pleasantly surprised to get hold of him right away

Very nice guy, by the way. He listened patiently and gave me a a few suggestions:

Remove the fouled membrane and smell the ends

If it stinks, it is bio-fouled, meaning bacteria growing on the membrane

Then put a few drops of acid on the membrane

If it fizzes, it is fouled with calcium

Put a new membrane in, increase waste to product ratio to 4:1

If it works fine for a few months, then it is the hardness in the water.

Then I could choose to stay with the 4:1 ratio, or put a water softener.

If it fouls again, something else is in the water.

Do a water test.

Sounds reasonable to me. So I am going to order a membrane. When it comes, I will do some dissection on the fouled membrane

Also going to order that adjustable valve. That will allow me to change the waste water flow much easily.

absolutely! Will doPost your findings in case it may help someone else down the road. So many people leave the internet hanging, in suspense, patiently waiting for season two……only to find out a year later that it was cancelled

Sorry I didn't read all, but what is the order of your entire filter system,?Uh oh.....getting sucked into buying a lot of stuff now

He even has this! Yahoo!

Mine goes water in to 1micron sediment filter to two chlorimine carbon filters to one 5micron sediment filter to two 75gpd r.o filters (150gpd) out to first stage of 3 stage pro series resin (purple, blue mixed sorry forgot the names)then to my 4th stage d.i wich is a silicate removal resin.

Basically do you have good pre filtration before your r.o membrane? And another big one with new carbon blocks flush them separately not into the membrane.

And on the water softener part I can't remember but I want to say that it will use up resin quicker because the salt gets past the membrane, but I could be wrong on that but for some reason I remember there being a different aspect when going after a water softener.

Sorry I saw this and these were my thoughts.

Sorry I didn't read all, but what is the order of your entire filter system,?

Mine goes water in to 1micron sediment filter to two chlorimine carbon filters to one 5micron sediment filter to two 75gpd r.o filters (150gpd) out to first stage of 3 stage pro series resin (purple, blue mixed sorry forgot the names)then to my 4th stage d.i wich is a silicate removal resin.

Basically do you have good pre filtration before your r.o membrane? And another big one with new carbon blocks flush them separately not into the membrane.

And on the water softener part I can't remember but I want to say that it will use up resin quicker because the salt gets past the membrane, but I could be wrong on that but for some reason I remember there being a different aspect when going after a water softener.

Sorry I saw this and these were my thoughts.

no worries, it is on the first page

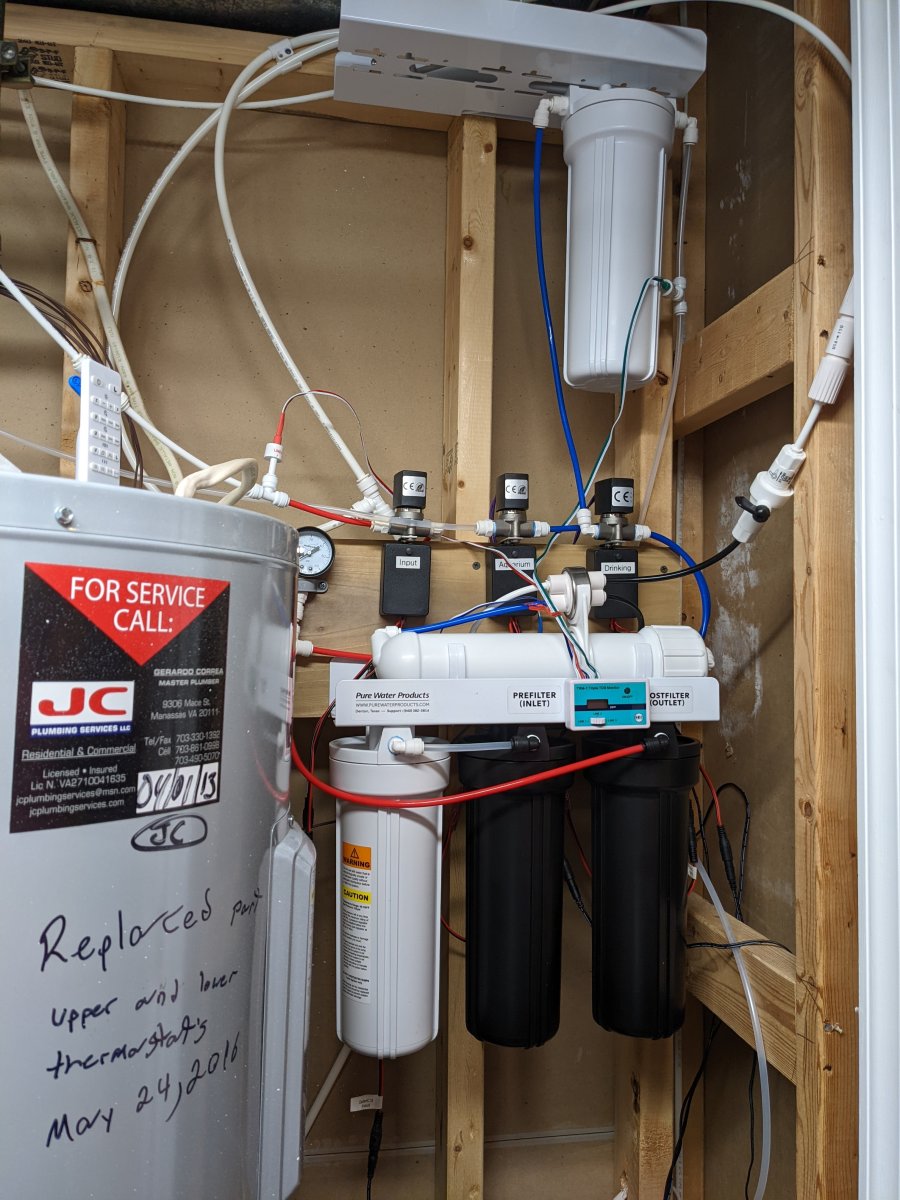

System setup:

inlet> Tee to TDS sensor > 1 micron sediment> 1 micron carbon> 1 micron carbon>Tee to pressure gauge> membrane 1 (and sometimes, membrane 2), Tee to TDS sensor > Tee split to >

one way valve > DI canister > Tee to TDS sensor > drum > pump to aquarium

one way valve > remineralization block for drinking water > drum > pump to kitchen water faucet + fridge

I do have a ASO valve

I am removing DI stage today. Do not really need it.

DT is 75g high-tech freshwater + 20 g sump with Discus in it.

Have you tried a second r.o membrane with a booster pump up to 80 psi, I use the dow membranes with 80 psi and 190-200+tds incoming it will be exactly 3tds post membrane for a couple of months then exactly at 4tds for a couple of months then at 5tds I change it but it will go 10 months or more and I make allot of water easily 330 Gallons a monthHello everyone,

I have a very interesting problem related to my RO filter. It has been going on for almost a year. Lots of troubleshooting has already gone into it last year. Talked to multiple vendors, tried different proposed solutions. But the problem keeps coming back.

Problem:

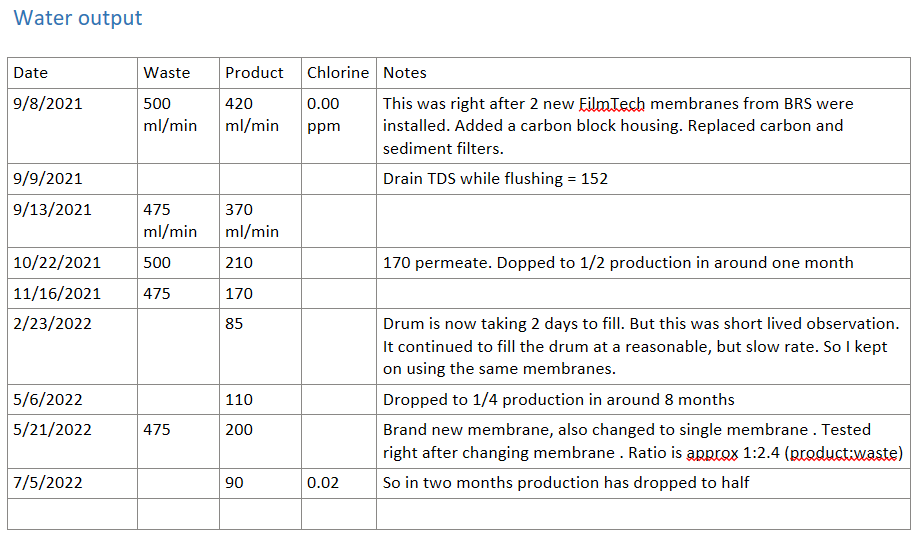

Any new membrane I install drops its water production to half after a month. After a few months the production drops to a trickle. I have measured water production carefully.

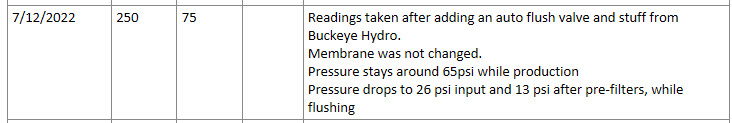

Screenshot below:

Proposed solutions that I have tried:

- Changing RO membrane to a different brand (started with Pentair GRO 1:1, now using DOW Filmtech)

- Adding a second RO membrane (BRS kit)

- Adding a second carbon block canister

- Replacing carbon and sediment block filters

Observations / notes / details:

System setup:inlet> Tee to TDS sensor > sediment> carbon> carbon>Tee to pressure gauge> membrane 1 (and membrane 2), Tee to TDS sensor > Tee split to >one way valve > DI canister > Tee to TDS sensor > drum > pump to aquariumone way valve > remineralization block for drinking water > drum > pump to kitchen water faucet + fridgeI do have a ASO valveInlet TDS 175post membrane TDS around 4-7post DI 0 TDSChlorine after the carbon blocks stays very low. Right now it is at 0.02, measured by a Hanna. Carbon blocks were replaced 10 months ago.Our city uses Chloramines in summerSummer or winter, does not matter, same problem happens – membrane clogs up.Water pressure as measured on a gauge installed after carbon blocks = 55 to 70 psi, and that stays pretty much the same, unless someone else us in the house opens water faucet (drops 10 psi)Adding dual membrane kit does nothing. Almost same rate of clogging happens.I do not have an auto-flush system. I do flush manually.I make around 30 gallons of RO water every 2 days. (split into fish tank water changes and drinking water also)55 gallon brute drum for fish water10 gallon brute drum for drinking water

What do you think I should try next?

Thanks for your time and advice

BTW I also posted some stuff in another thread here, but time has passed, so I thought it is probably best to start a new thread of my own...

https://www.reef2reef.com/threads/eating-up-ro-membranes.843152/post-9319924

I have tried two, but not with a booster pump.Have you tried a second r.o membrane with a booster pump up to 80 psi, I use the dow membranes with 80 psi and 190-200+tds incoming it will be exactly 3tds post membrane for a couple of months then exactly at 4tds for a couple of months then at 5tds I change it but it will go 10 months or more and I make allot of water easily 330 Gallons a month

May I ask what waste to product ratio you are running in your system?

Other than the incoming tds and post membrane tds and the pressure Guage before the membrane I don't have any way to measure it other than it takes about 15 min to fill a 5 gallon bucket but is definitely under 20 min.I have tried two, but not with a booster pump.

May I ask what waste to product ratio you are running in your system?

Put a bypass ball valve inline with your drain and this needle valve to manually flush. Should look like this:Uh oh.....getting sucked into buying a lot of stuff now

He even has this! Yahoo!

___________ball valve_______

<___________needle valve____>—

when ball valve closed, reverts all water through needle valve. When open, all water will be drained through ball valve!

Uh oh.....getting sucked into buying a lot of stuff now

He even has this! Yahoo!

I wish I would have purchased one. I have used the long capillary tubes then cut to length to fine tune what I wanted.

Ok so the stuff from Buckeye Hydro is going to arrive today. Membrane surgery should happen soon after that.

I am going to reconfigure my connections, add an auto flush system, quick and dirty style! The build of a raspberry pi based RO controller is also under way. Gotta start a build thread about that soon.

By the way, this is what my RO system looks like today (took out the DI stage canister which was hanging at the top left, besides the re-mineralizing canister for drinking water)...

I am going to reconfigure my connections, add an auto flush system, quick and dirty style! The build of a raspberry pi based RO controller is also under way. Gotta start a build thread about that soon.

By the way, this is what my RO system looks like today (took out the DI stage canister which was hanging at the top left, besides the re-mineralizing canister for drinking water)...

Ooooh! stuff is here

Let the surgery begin!

Ha ha! Good cinema, yeah?

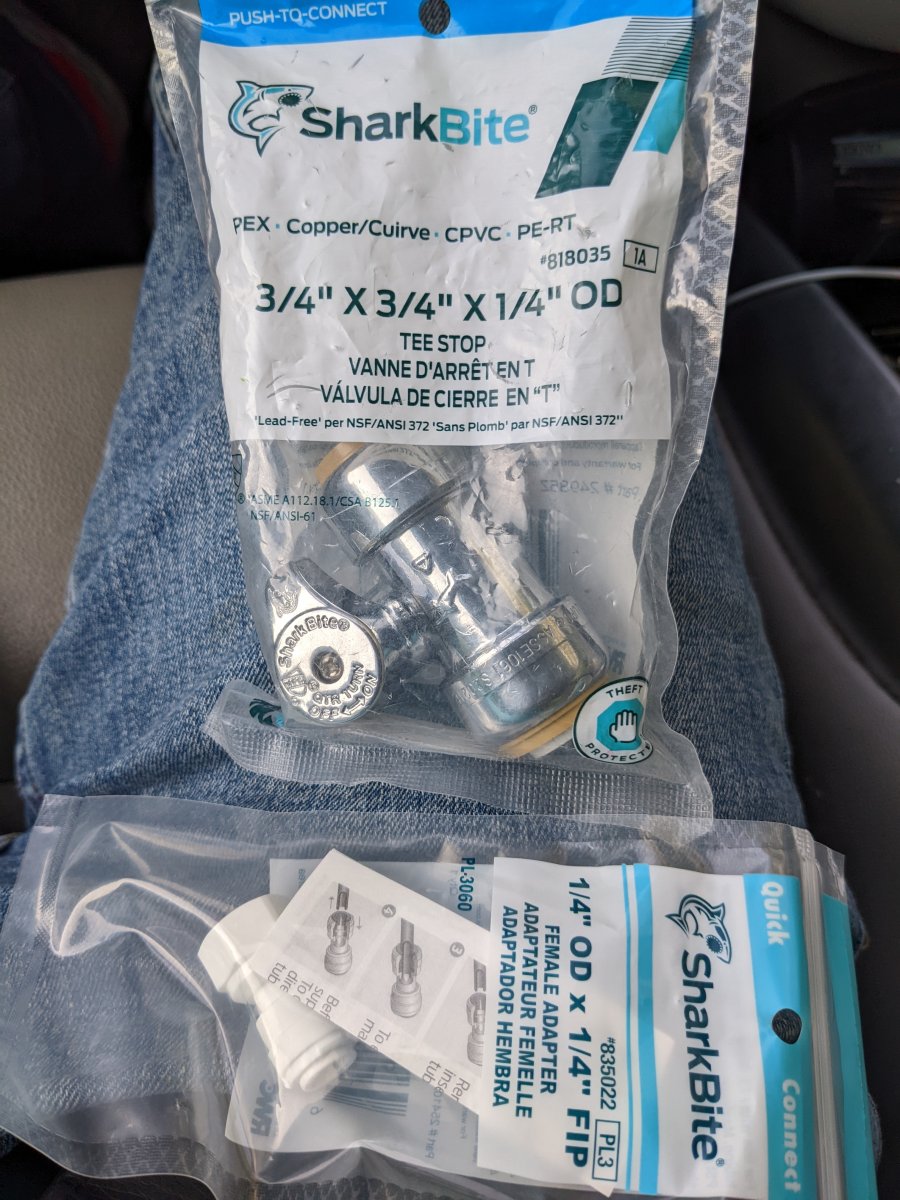

I ran to Lowe's to pick up this... Didn't know that they made this, complete with a stop valve!

I also suspect that needle piercing type valve is reducing the flow. But will make one change at a time to figure out what's really wrong.

First thing to hook up is the auto flush valve.

Pretty simple idea, a solenoid valve bypassing the needle valve, controlled by 12 volt wall wart, plugged into a phone app controlled electrical outlet capable of on-off every hour for a couple of minutes.

The idea is to try to flush out any calcium/ hardness.

I'm going to repurpose one of the already 3 solenoids I have.

Also ordered some motorized ball valves for long cycle use. Found out that these solenoid valves are not supposed to be left on for hours.... that's why they get super hot!

I ran to Lowe's to pick up this... Didn't know that they made this, complete with a stop valve!

I also suspect that needle piercing type valve is reducing the flow. But will make one change at a time to figure out what's really wrong.

First thing to hook up is the auto flush valve.

Pretty simple idea, a solenoid valve bypassing the needle valve, controlled by 12 volt wall wart, plugged into a phone app controlled electrical outlet capable of on-off every hour for a couple of minutes.

The idea is to try to flush out any calcium/ hardness.

I'm going to repurpose one of the already 3 solenoids I have.

Also ordered some motorized ball valves for long cycle use. Found out that these solenoid valves are not supposed to be left on for hours.... that's why they get super hot!

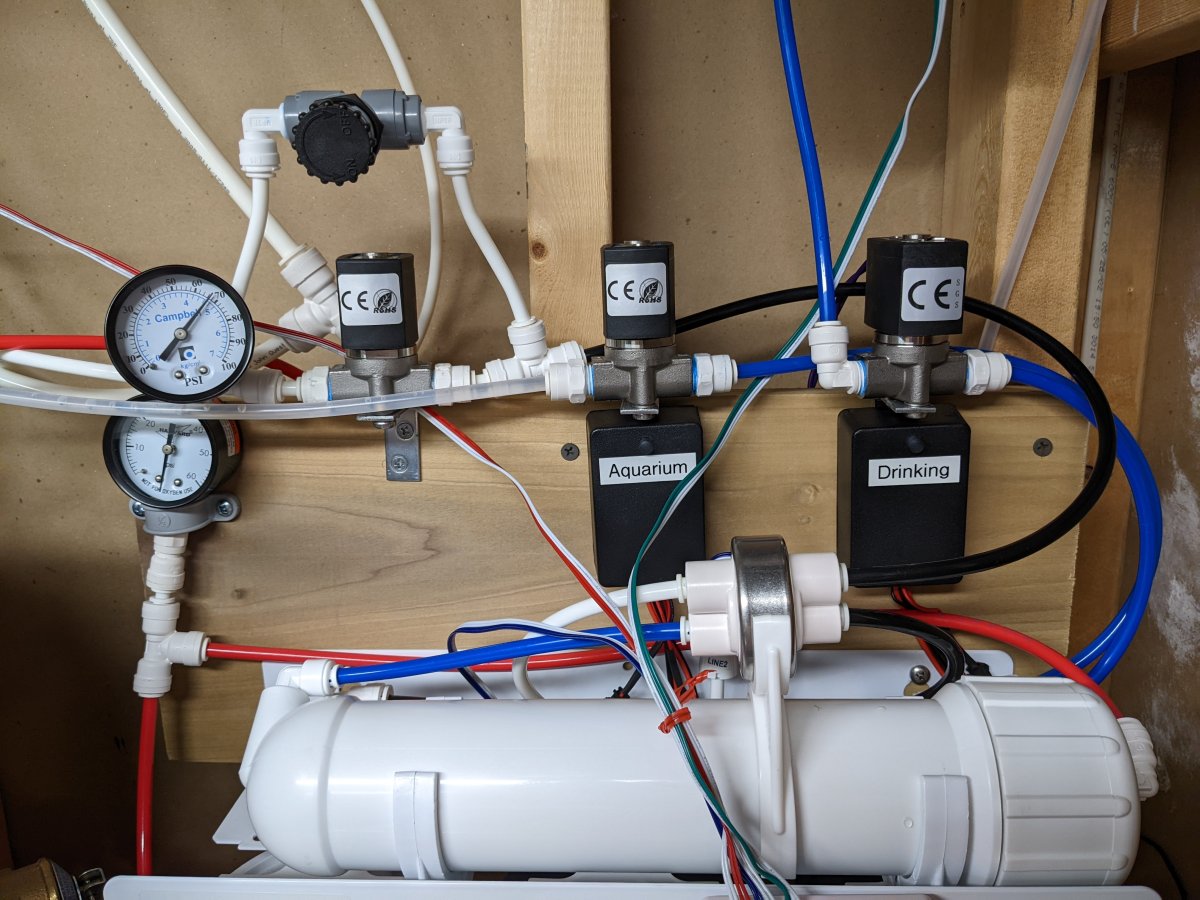

Good morning! Here is an update:

I worked on the RO system a bit:

Added these things:

Hoping to control the waste roduct ratio precisely, I bought this valve:

roduct ratio precisely, I bought this valve:

www.buckeyehydro.com

I found the the valve I got does not live up to its description on that page, which says:

www.buckeyehydro.com

I found the the valve I got does not live up to its description on that page, which says:

Auto flush valve

I rigged up an solenoid which bypasses the needle valve. Setup can be seen in the first photo, its the first one from the left. To flush, this solenoid is energized by a 12v power supply (wall wart). I plugged the wall wart into a app controlled power outlet (photo below). I should be able to program the controlled outlet to do a 2 minute on-off cycle every hour.

Second gauge

I added this for sanity check, I did not trust the gauge I already have, which is connected to the output of the filter canisters. Also it reads only to 60 psi full scale and many times its needle goes above 60.

I added the new gauge to the water input line. Seems both gauges read very similar. With the system's output solenoids shut off and the auto shut off valve also shut off, it reads around 70 psi on both.

(although a more accurate way to do this would be to take out all the media inside the three canisters and THEN do the same test)

Here are stats after adjusting the needle valve:

drain: product in ml/minute

Next up, surgery of the membrane!

I worked on the RO system a bit:

Added these things:

- Needle valve for adjusting drain flow rate

- Auto flush valve

- Second gauge

My notes:

Precision needle valveHoping to control the waste

Precision Needle Valve

At Buckeye Hydro we specialize in providing the highest quality water filtration systems and accessories for every potential need.

Mine takes less than quarter turn to open fully. It is very hard to precisely control the water flow because of this. I will talk to Russ about it, maybe I got a faulty valve.These needle valves are specially configured to allow very precise flow control - even down to several drops per minute! Six turns on the knob take the valve from fully open to fully closed.

Auto flush valve

I rigged up an solenoid which bypasses the needle valve. Setup can be seen in the first photo, its the first one from the left. To flush, this solenoid is energized by a 12v power supply (wall wart). I plugged the wall wart into a app controlled power outlet (photo below). I should be able to program the controlled outlet to do a 2 minute on-off cycle every hour.

Second gauge

I added this for sanity check, I did not trust the gauge I already have, which is connected to the output of the filter canisters. Also it reads only to 60 psi full scale and many times its needle goes above 60.

I added the new gauge to the water input line. Seems both gauges read very similar. With the system's output solenoids shut off and the auto shut off valve also shut off, it reads around 70 psi on both.

(although a more accurate way to do this would be to take out all the media inside the three canisters and THEN do the same test)

Here are stats after adjusting the needle valve:

drain: product in ml/minute

Next up, surgery of the membrane!

Last edited:

I also suspect that needle piercing type valve is reducing the flow. But will make one change at a time to figure out what's really wrong.

Easy way to get water but not a very good long term solution especially with your hard water. I worked for an appliance store when I was in high school a number of times I would get sent out to look at someones ice maker and my repair would be shutting off the piercing valve and turning it back on to clean the build up off the pierce. I do not think that is your problem since I do not remember a low pressure when making RO for you.

Similar threads

- Replies

- 1

- Views

- 47

- Replies

- 7

- Views

- 345

- Replies

- 25

- Views

- 626

New Posts

-

-

Working on Automatic Tester, need help with preparing reagents

- Latest: WillpoleReefers

-

Massachusetts Lighting SOLD 2 radion xr 15 blue g5 SOLD

- Latest: Will_WhatIsThis