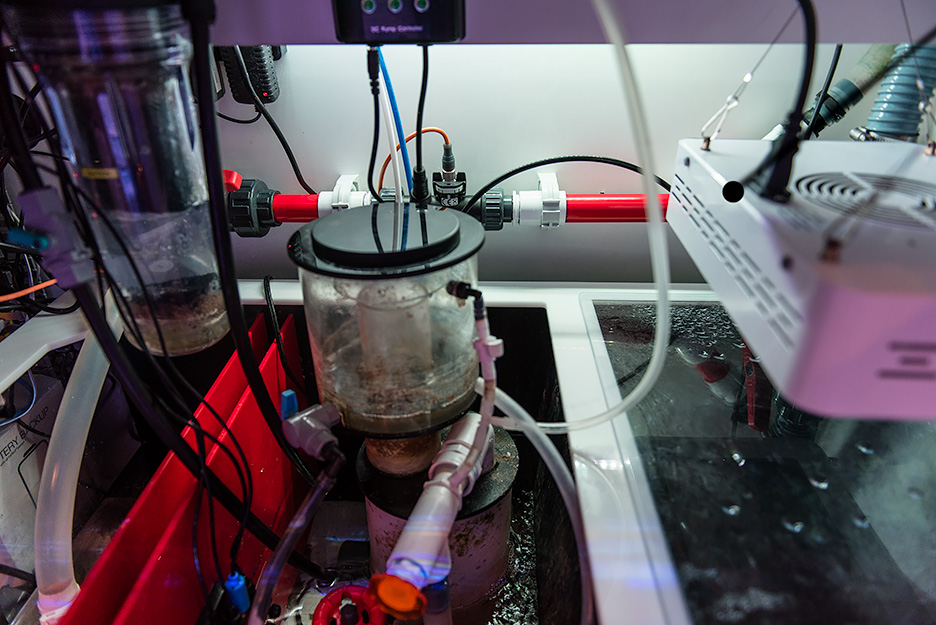

I installed GHL flow meter on my tank this weekend and it confirmed what I was expecting to see... a pretty low flow rate.

I know I have a lot of restriction in my return line, but still seems a bit disappointing.

The pump is a Vectra L1, rated at 3,000 gph max flow with zero head.

It has a 1" outlet, and I have a 1" barb connector coming out of it (barbs are restrictive) so I can use some silicone tubing, which is connected to the second barb connector which is also a 90 degree elbow, into 1" pvc. It then sizes down to 3/4" to get through the flow meter and then back up to 1". Then into the next set of 1" barbs and silicone tubing where it enters the overflow. Within the overflow it splits into two 1/2" returns.

So yes, plenty of restriction and in the end I'm getting only 600 gph running the Vectra L1 at 100%.

Even 1/2" pipe is capable of running around 1200 gph under high pressure, but dc pumps are not high pressure pumps.

This has gotten me curious... can I substantially increase my flow by either moving to a different DC pump, or dumping DC all together and moving back to an AC pump? Either way it would have to be submersible.

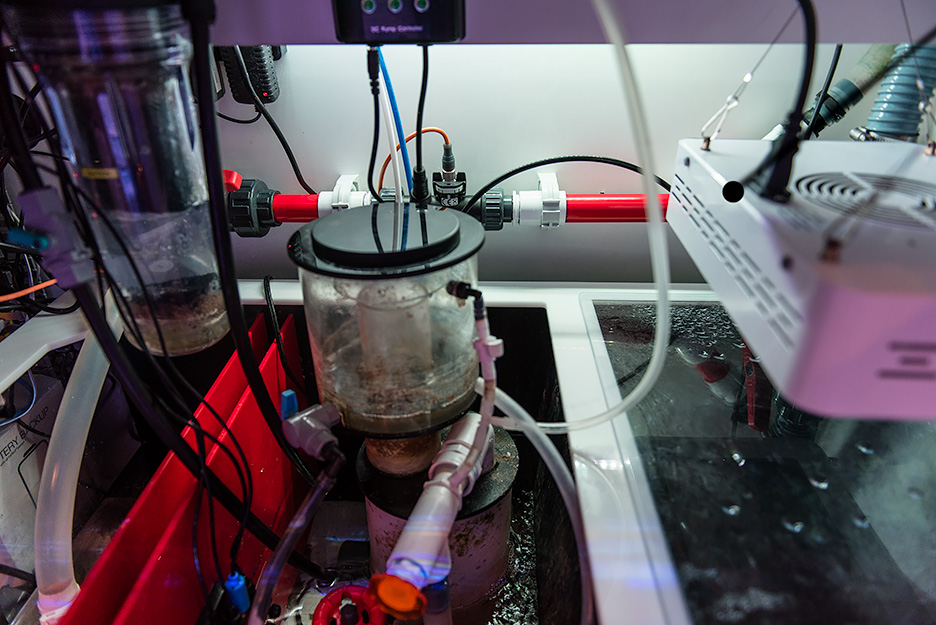

I know I have a lot of restriction in my return line, but still seems a bit disappointing.

The pump is a Vectra L1, rated at 3,000 gph max flow with zero head.

It has a 1" outlet, and I have a 1" barb connector coming out of it (barbs are restrictive) so I can use some silicone tubing, which is connected to the second barb connector which is also a 90 degree elbow, into 1" pvc. It then sizes down to 3/4" to get through the flow meter and then back up to 1". Then into the next set of 1" barbs and silicone tubing where it enters the overflow. Within the overflow it splits into two 1/2" returns.

So yes, plenty of restriction and in the end I'm getting only 600 gph running the Vectra L1 at 100%.

Even 1/2" pipe is capable of running around 1200 gph under high pressure, but dc pumps are not high pressure pumps.

This has gotten me curious... can I substantially increase my flow by either moving to a different DC pump, or dumping DC all together and moving back to an AC pump? Either way it would have to be submersible.