Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Stand.. Do I need to worry about this?

- Thread starter cpark645

- Start date

- Tagged users None

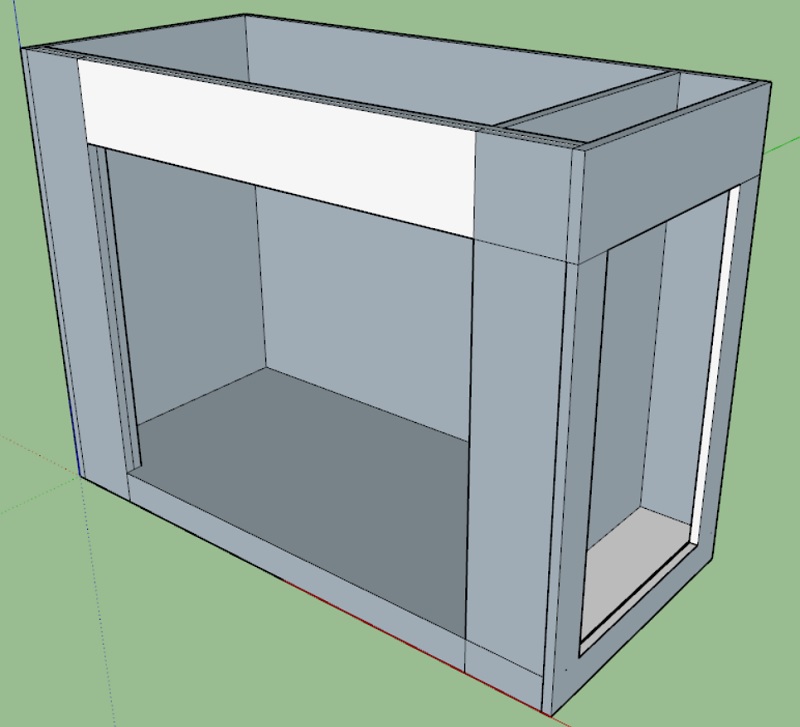

Last couple diagrams look good.

Plywood itself is incredibly strong w/ good design(MDF I'm not a fan of)

As long as you have vertical supports directly under horizontal rails you're good to go pretty much, that and make sure it wont rack however that is achieved, just never rely on screws or fasteners alone on carrying a load.

Plywood itself is incredibly strong w/ good design(MDF I'm not a fan of)

As long as you have vertical supports directly under horizontal rails you're good to go pretty much, that and make sure it wont rack however that is achieved, just never rely on screws or fasteners alone on carrying a load.

You can certainly integrate a side section for electrical into this sort of thing... and if it were me, I'd get the bottom shelf an inch or two off the ground.

As for plywood, go to a woodworking supply, instead of a home depot or lowes, and ask for cabinet grade hardwood ply. If you're going to paint it, poplar works well... for stain, depends on what you want it to look like. My current stand is all done in oak ply.

For paint, I really like Rustoleum's TopSide marine paint. Drys HARD, waterproof, easily available, price isn't stupid high... Bright white inside helps you see better! If you like stain, pick your color, and go over it with a couple of coats of clear poly.

Something like this? You said you have a krieg jig... pocket screws anywhere that you've got an end to end butt joint would be good.

Mind if I ask why you would get the bottom shelf an inch or two off the ground?

Not at all. A flat shelf, sitting right on the ground, doesn't allow the flooring under it to dry, should a spill occur.Mind if I ask why you would get the bottom shelf an inch or two off the ground?

If you really need every last inch of vertical space under your stand, I would suggest not putting a bottom shelf in it at all, perhaps putting a removable plastic sheet or some such directly on the floor.

Like most treads there is a mixture of misinformed information and some really good information. Been building cabinets and stands for 30+ years. First started with making rack mount cabinets that had to survive air flights as well as hold 100lb of electrical equipment and survive a drop from 3 meters. Plywood is incredibly strong. 2x4 in most cases are over kill. Pine and white wood is subject to warping due to the fact it's not dried properly.it also can warp after it's been used. Really a hardwood like oak should be used.

1x3 bracing with 1/2 ply or 3/4 is going to be more than strong enough for most applications.

You also don't need alot of tools a good table saw and a cross cut sled. I would use 2 x 6 and cut them down to 1 x 3's. Trim all 4 sides and then use the cross cut sled to get perfect ends. I personally don't like kreg jigs personally I don't think they produce a strong enough join. If you have a router get a trim bit to trim up the ends once you put the top and bottom in.

I've used marine ply. Cabinet ply and lowes ply. There really is not alot of difference to be honest. Alot of it is how much cut out you get when cutting it. Strength wise they are about the same. You should be coating the wood in a very good oil or varnish. All ply will eventually break down if not treated properly.

I'm about to do a new 180 gallon build so might start a thread on it including a new stand.

1x3 bracing with 1/2 ply or 3/4 is going to be more than strong enough for most applications.

You also don't need alot of tools a good table saw and a cross cut sled. I would use 2 x 6 and cut them down to 1 x 3's. Trim all 4 sides and then use the cross cut sled to get perfect ends. I personally don't like kreg jigs personally I don't think they produce a strong enough join. If you have a router get a trim bit to trim up the ends once you put the top and bottom in.

I've used marine ply. Cabinet ply and lowes ply. There really is not alot of difference to be honest. Alot of it is how much cut out you get when cutting it. Strength wise they are about the same. You should be coating the wood in a very good oil or varnish. All ply will eventually break down if not treated properly.

I'm about to do a new 180 gallon build so might start a thread on it including a new stand.

Like most treads there is a mixture of misinformed information and some really good information. Been building cabinets and stands for 30+ years. First started with making rack mount cabinets that had to survive air flights as well as hold 100lb of electrical equipment and survive a drop from 3 meters. Plywood is incredibly strong. 2x4 in most cases are over kill. Pine and white wood is subject to warping due to the fact it's not dried properly.it also can warp after it's been used. Really a hardwood like oak should be used.

1x3 bracing with 1/2 ply or 3/4 is going to be more than strong enough for most applications.

You also don't need alot of tools a good table saw and a cross cut sled. I would use 2 x 6 and cut them down to 1 x 3's. Trim all 4 sides and then use the cross cut sled to get perfect ends. I personally don't like kreg jigs personally I don't think they produce a strong enough join. If you have a router get a trim bit to trim up the ends once you put the top and bottom in.

I've used marine ply. Cabinet ply and lowes ply. There really is not alot of difference to be honest. Alot of it is how much cut out you get when cutting it. Strength wise they are about the same. You should be coating the wood in a very good oil or varnish. All ply will eventually break down if not treated properly.

I'm about to do a new 180 gallon build so might start a thread on it including a new stand.

Thanks for the info. I was actually planning on making all my cuts by making a jig and using a circular saw. Also, I wasn't planning on using any 1x3 bracings, just pure plywood. Do you think this is a bad idea?

Not at all. A flat shelf, sitting right on the ground, doesn't allow the flooring under it to dry, should a spill occur.

If you really need every last inch of vertical space under your stand, I would suggest not putting a bottom shelf in it at all, perhaps putting a removable plastic sheet or some such directly on the floor.

The vertical space is not a concern for me, it's just I don't have the tools to create perfect lumber pieces to use as my bottom frame. Actually even if I built a bottom frame with 2x4's, I'm not sure how that would help me mop up any moisture since I'd be putting a piece of plywood on top of it.

Here's my latest sketchup. Pretty much the same as earlier except I have a single plywood sheet bottom and 3 cross braces for the front. The back 2 braces are the ones holding the majority of the weight for the front, but I designed it like this so I can have the doors sitting flush.

Maybe I can put a bunch of self-leveling feet to raise up the whole stand?

Well, I finally started building the stand... And I messed up the part I was most nervous about, which is cutting the notches on the side panels for the front support strips to fit in. I used a jigsaw and a speed square to try to keep as accurate as possible, but alas... all 3 side panels cut a little bit differently.

I'm wondering what I can do to make sure these are all aligned together? I tried using the jigsaw to cut little thin strips off to shave it down but the blade just bends along the wood. I also tried using a sander but the result is a rather uneven surface. Maybe I need to use a handsaw?

I'm wondering what I can do to make sure these are all aligned together? I tried using the jigsaw to cut little thin strips off to shave it down but the blade just bends along the wood. I also tried using a sander but the result is a rather uneven surface. Maybe I need to use a handsaw?

Yeah, Jig saws are not really precision cutting saws, as you found out. Fortunately, it's not that big of a deal and shouldn't affect the strength of the stand at all. The most important part is that the top of the stand is level, and it appears the bottoms are all flush with each other, so the only part you need to deal with is the backs.

There are a couple ways of dealing with this. If there is one that is accurate, you could take a laminate bit or a pattern cutting bit on a router to match up the other two. That will leave a small area in the corner, but you can clean that up with a chisel.

Another option is to use a chisel to cut a small dado out of the cross piece so it sits flush.

There are a couple ways of dealing with this. If there is one that is accurate, you could take a laminate bit or a pattern cutting bit on a router to match up the other two. That will leave a small area in the corner, but you can clean that up with a chisel.

Another option is to use a chisel to cut a small dado out of the cross piece so it sits flush.

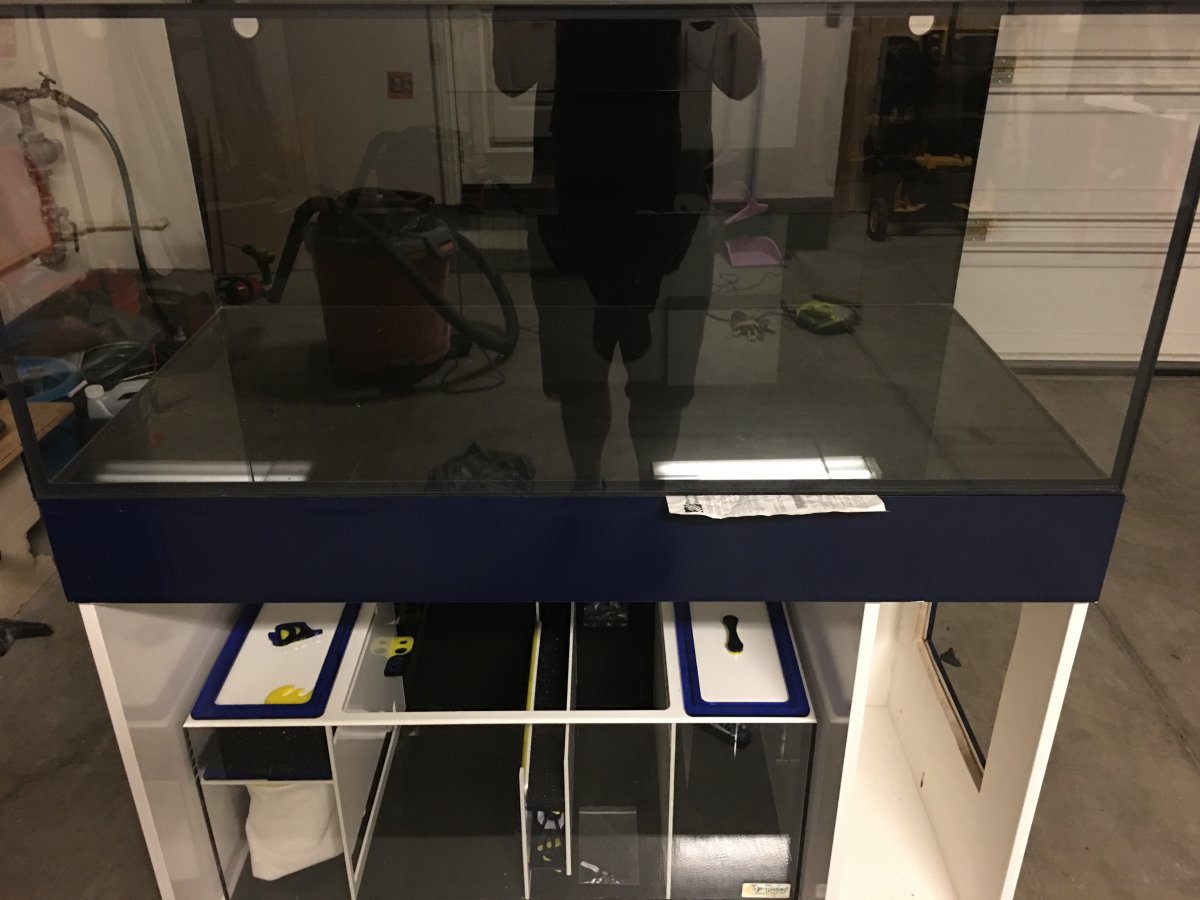

So I finished the stand! Well except the doors. Special thank you to @Greybeard, your suggestions were an inspiration for going through with this all plywood build.

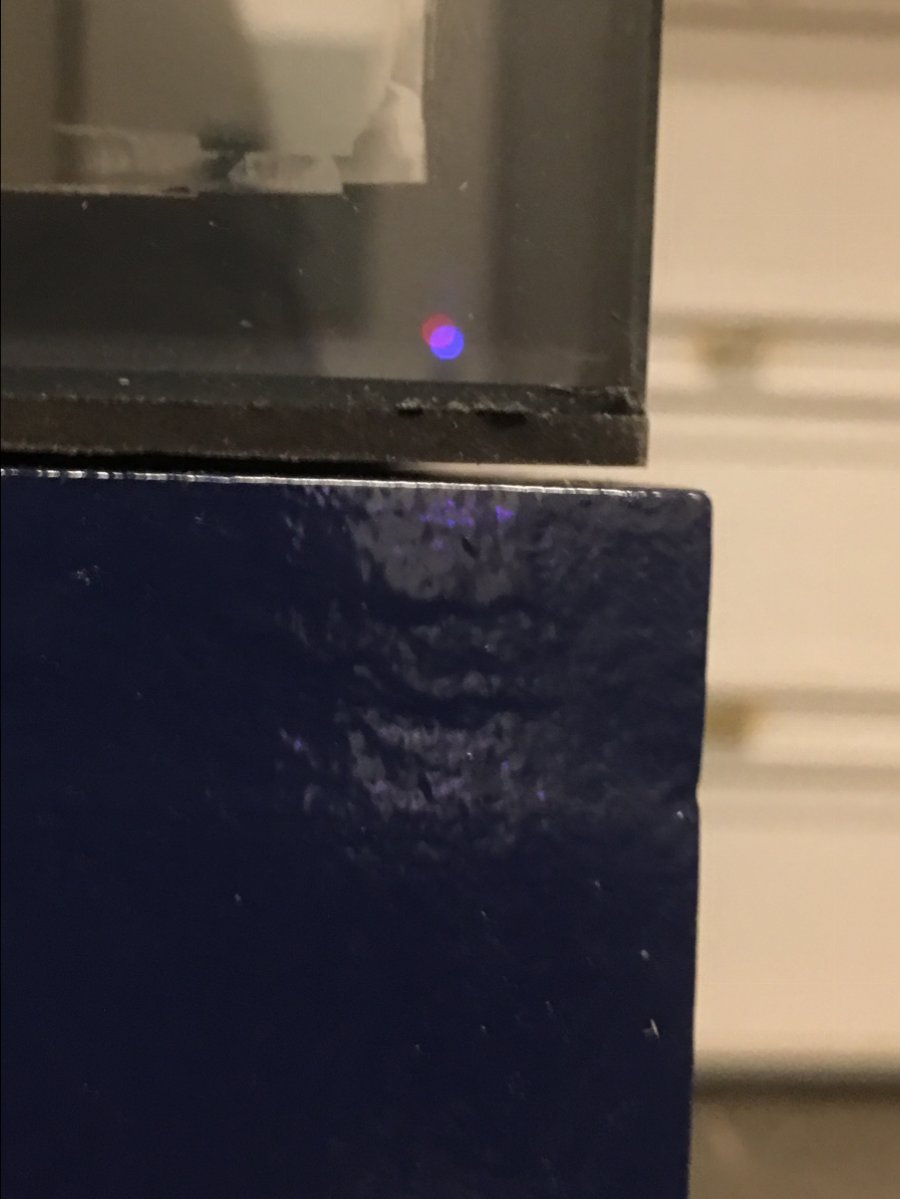

So I thought it looked good, but upon closer inspection... found some bad news.

You can see in the last picture from the receipt that the hairline gap starts almost near the middle of the tank, and widens to the front right corner. At the corner the gap is a little less than 1/16'' of an inch.

I've been reading up on other people with this type of problem and the answers seem to vary between putting a foam pad between the tank/stand, put another piece of plywood on top and shim between that board and the stand, and some say the stand might even out once I fill the tank with water. What should I do?

So I thought it looked good, but upon closer inspection... found some bad news.

You can see in the last picture from the receipt that the hairline gap starts almost near the middle of the tank, and widens to the front right corner. At the corner the gap is a little less than 1/16'' of an inch.

I've been reading up on other people with this type of problem and the answers seem to vary between putting a foam pad between the tank/stand, put another piece of plywood on top and shim between that board and the stand, and some say the stand might even out once I fill the tank with water. What should I do?

You could put a piece of foam board insulation between the tank and plywood.

Nice

The foam isn't a bad idea. Is the top surface smooth and flat? If there are ridges, bumps, that sort of thing, then I'd strongly advise a sheet of foam. If it's flat and smooth, but has a bit of a crown... which is what I'm seeing in the photos... it becomes less important to me. Most rimless, flat bottom glass tanks like yours, the makers recommend the foam sheet anyway. I'd probably put a sheet in there... but I wouldn't panic about it. Water weight is going to settle it down anyway.

The foam isn't a bad idea. Is the top surface smooth and flat? If there are ridges, bumps, that sort of thing, then I'd strongly advise a sheet of foam. If it's flat and smooth, but has a bit of a crown... which is what I'm seeing in the photos... it becomes less important to me. Most rimless, flat bottom glass tanks like yours, the makers recommend the foam sheet anyway. I'd probably put a sheet in there... but I wouldn't panic about it. Water weight is going to settle it down anyway.

Less than a 1/16" I would not be concerned, but would use yoga mat or foam mat, which tank manufacturer probably calls for anyway

As far as I can tell, the top surface is smooth and flat except that one corner. There is a pvcx sheet on the bottom of the tank already which should help with any small bumps and ridges.

I guess I’ll start looking for some insulation foam or a yoga mat. Still a bit nervous about it though..

I guess I’ll start looking for some insulation foam or a yoga mat. Still a bit nervous about it though..

BRS sells neoprene foam. Quite a few manufacturers (Innovative Marine, Mr Aqua and others) sell foam mats with adhesive backing for beneath tanks. Although, a yoga mat would be far less expensive, and may work just as well. I got mine on amazon for $10. I’d check Lowe’s/HD/etc for foam sheets as well.As far as I can tell, the top surface is smooth and flat except that one corner. There is a pvcx sheet on the bottom of the tank already which should help with any small bumps and ridges.

I guess I’ll start looking for some insulation foam or a yoga mat. Still a bit nervous about it though..

No way I’d fill that tank without putting a foam mat under it. Just to be safe.

Beautiful tank and I like the final stand design. But yeah some kind of cushion to fill that gap would be nice. Trick then is to make it look good still.

- Joined

- May 9, 2018

- Messages

- 385

- Reaction score

- 200

For anyone coming across this thread.. if you want a front open span of 48" you need a 2x6 beam (header). It is actually stronger than a double 2x4. Vertical height of a beam is the essential factor. Doubling width..does double strength..but doubling height is strengthens it 3-5 x over. You lose a bit of opening height.. but the internal space is still the same.

Also make sure the back ply is ¾" if the front is open. The sides can be ½" if you have a structural frame inside.

The previous posts are correct with overbuilding & that the real strength comes from skinning with ply and installing and attaching the ply top and ply bottom shelf are very & equally important as they can double the structural strength that prevents racking. (twisting). The sides stop front to back sway.. and the back side to side.

Which is why you want a thick back to compensate for the open front.

If you have or ever come accross a cheap walmart bookshelf.. grab the top and try to move side to side.. then take off the back piece that is laminated to look like wood but is usually CARDBOARD.. And tiny little tacks.. once off you'll notice that the entire shelf wobbles side to side with no effort.

King of DIY has a great oldie but goodie on diy stands & gives some good info on standard lumber strength in this application.

Happy building!

Also make sure the back ply is ¾" if the front is open. The sides can be ½" if you have a structural frame inside.

The previous posts are correct with overbuilding & that the real strength comes from skinning with ply and installing and attaching the ply top and ply bottom shelf are very & equally important as they can double the structural strength that prevents racking. (twisting). The sides stop front to back sway.. and the back side to side.

Which is why you want a thick back to compensate for the open front.

If you have or ever come accross a cheap walmart bookshelf.. grab the top and try to move side to side.. then take off the back piece that is laminated to look like wood but is usually CARDBOARD.. And tiny little tacks.. once off you'll notice that the entire shelf wobbles side to side with no effort.

King of DIY has a great oldie but goodie on diy stands & gives some good info on standard lumber strength in this application.

Happy building!

I'll disagree on the header based on personal experience. I built a stand for my 120 gallon tank (48" wide) out of hickory. I used doubled 1x4's as the header and took pains to make sure everything was perfectly flat. (hickory is much stronger than pine, so you can't make a direct comparison with a 2x4 here.)For anyone coming across this thread.. if you want a front open span of 48" you need a 2x6 beam (header). It is actually stronger than a double 2x4. Vertical height of a beam is the essential factor. Doubling width..does double strength..but doubling height is strengthens it 3-5 x over. You lose a bit of opening height.. but the internal space is still the same.

Also make sure the back ply is ¾" if the front is open. The sides can be ½" if you have a structural frame inside.

The previous posts are correct with overbuilding & that the real strength comes from skinning with ply and installing and attaching the ply top and ply bottom shelf are very & equally important as they can double the structural strength that prevents racking. (twisting). The sides stop front to back sway.. and the back side to side.

Which is why you want a thick back to compensate for the open front.

If you have or ever come accross a cheap walmart bookshelf.. grab the top and try to move side to side.. then take off the back piece that is laminated to look like wood but is usually CARDBOARD.. And tiny little tacks.. once off you'll notice that the entire shelf wobbles side to side with no effort.

King of DIY has a great oldie but goodie on diy stands & gives some good info on standard lumber strength in this application.

Happy building!

After it was finished, I put my tank on the stand and was checking it for level when I noticed a very small gap (1/32") under the middle of the tank. After cursing myself for not keeping the top level I started checking - it turns out the top was level; the tank was not. This tank had already been on another (factory) stand for 3 years without an issue. My conclusion with this is that the weight of my 120 gallon tank is almost exclusively on the edges.

This doesn't necessarily apply to larger/longer tanks and I am not advocating creating stands without center support. I just want to point out that for a 48" tank, the amount of weight in the center is not as much as one would think and a 2x6 header isn't necessary required.

Similar threads

- Replies

- 2

- Views

- 91