After much thought I've decided to make my own stand to fit a sump and replace particle board store stand. To get wife approval for living room it needs to look clean and match her furniture. So first time project may be a bit challenging and I had questions for you experts.

What saw can I buy to tackle project? Was thinking circular saw

Can I use 2x6's for the top base instead of plywood so it can match furniture top like in picture?

Any pointers on how tall to make it.

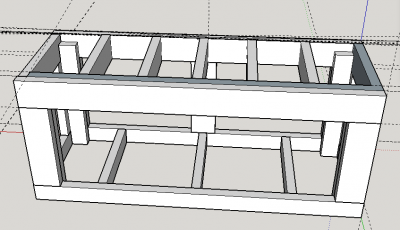

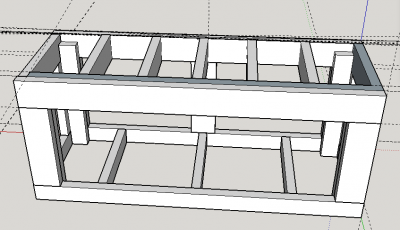

Here are pictures on how I need to match and blueprint im going off

What saw can I buy to tackle project? Was thinking circular saw

Can I use 2x6's for the top base instead of plywood so it can match furniture top like in picture?

Any pointers on how tall to make it.

Here are pictures on how I need to match and blueprint im going off