- Joined

- Feb 19, 2017

- Messages

- 111

- Reaction score

- 220

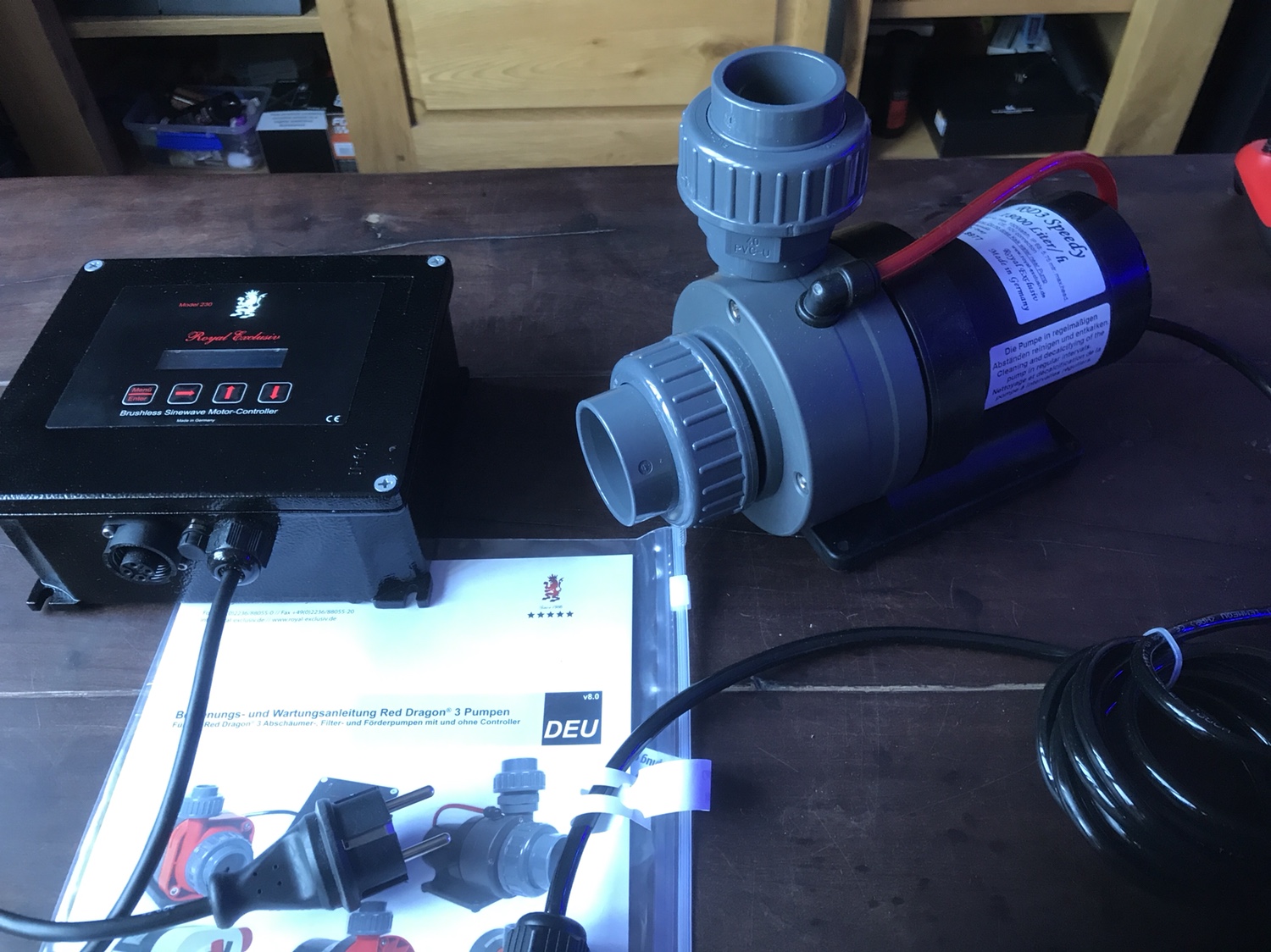

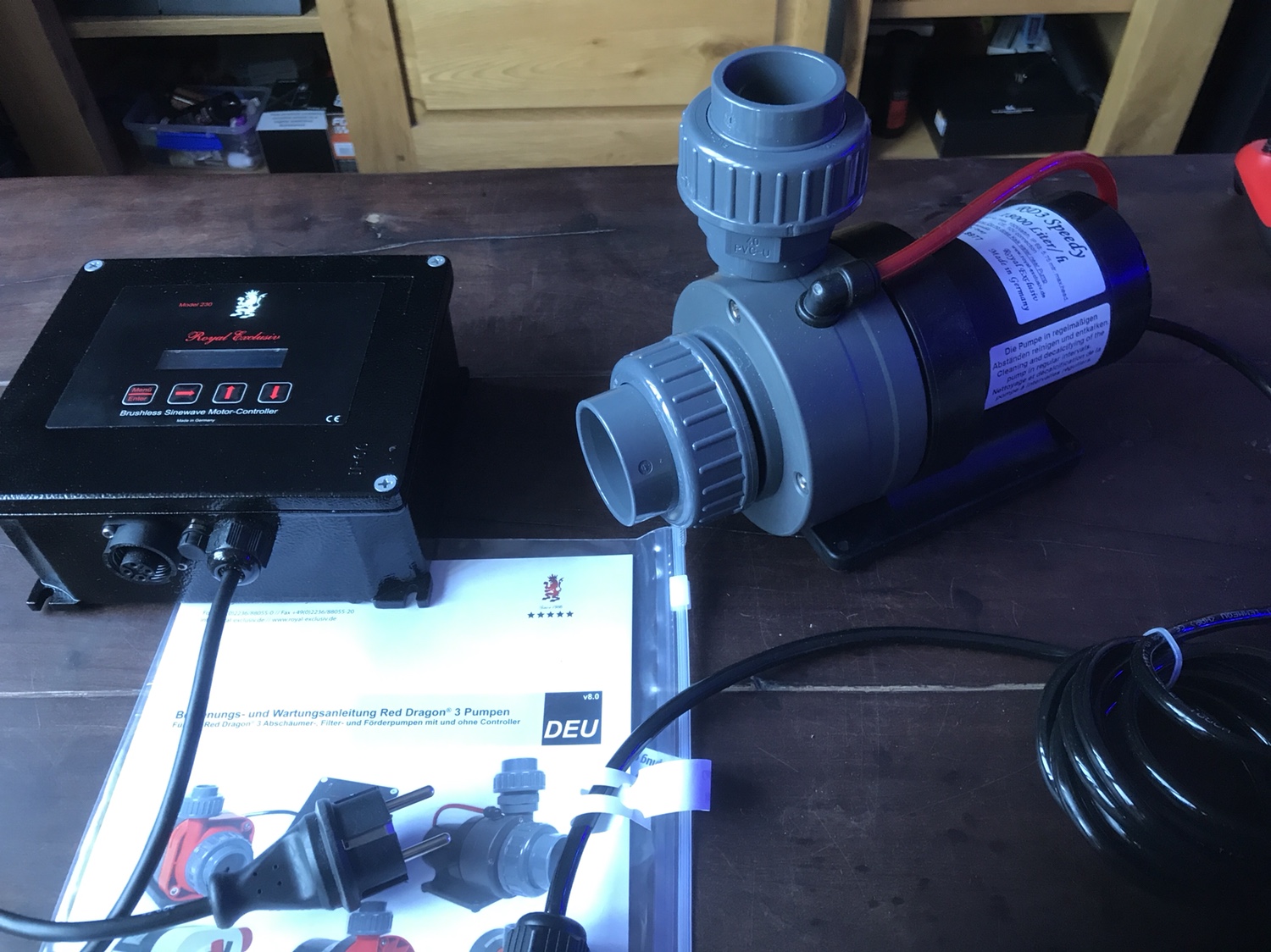

The best place for the vectra is the trash!!!

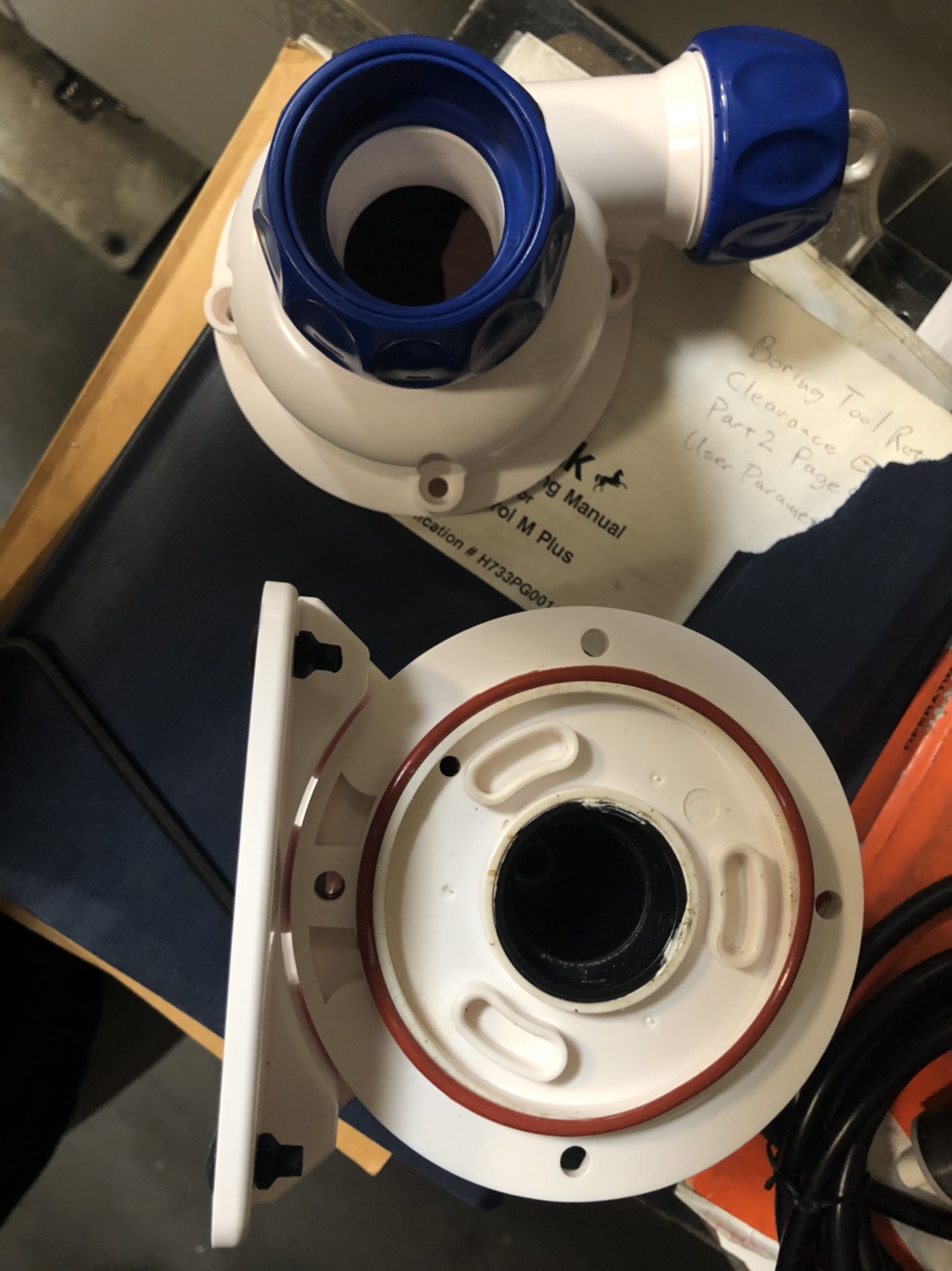

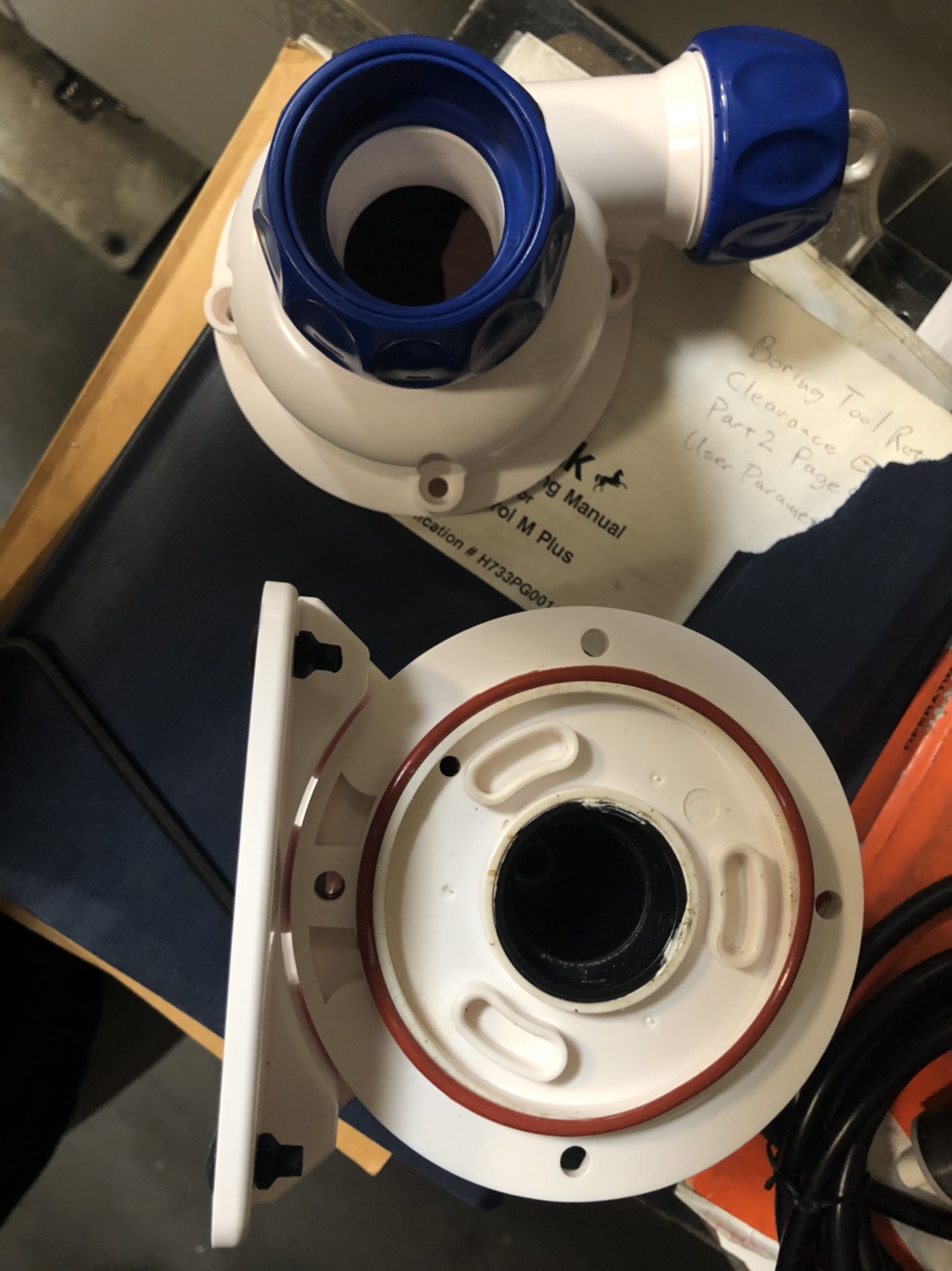

Then replace with this [emoji12]

Then replace with this [emoji12]

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

The best place for the vectra is the trash!!!

Then replace with this [emoji12]

Yep

Down the trash where its belong, newer buy this **** again!

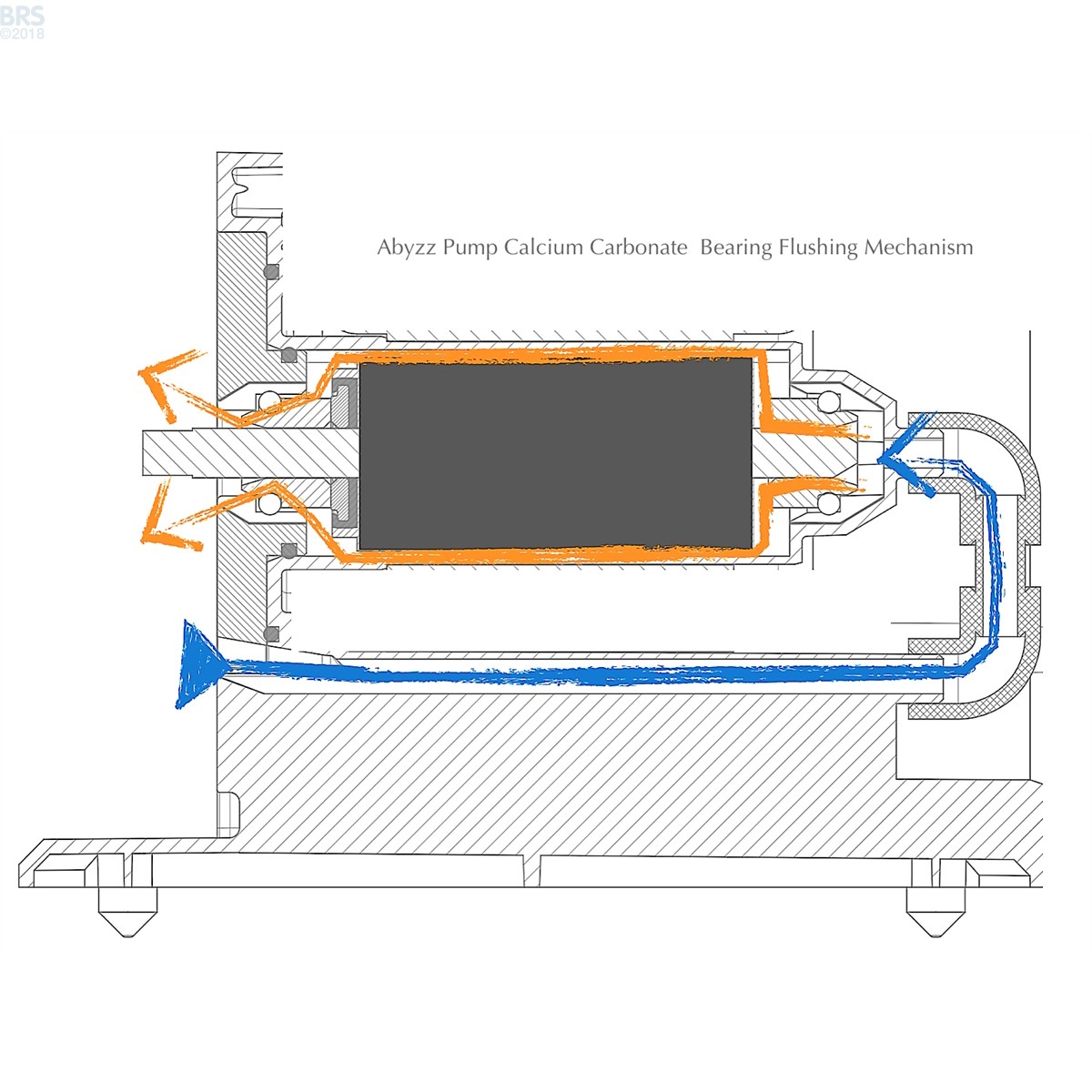

I think it is a heat and impeller flushing issue so far from what I read from users running it externally have more issues and second are the submerged ones running 90-100 percent. It’s sad I wanted one to go with my Radions but instead got an abyzz a100. I will later get a reef octopus as a backup. In caseHas everyone who had the problem run their pumps external?? Wonder if that’s the common issue.

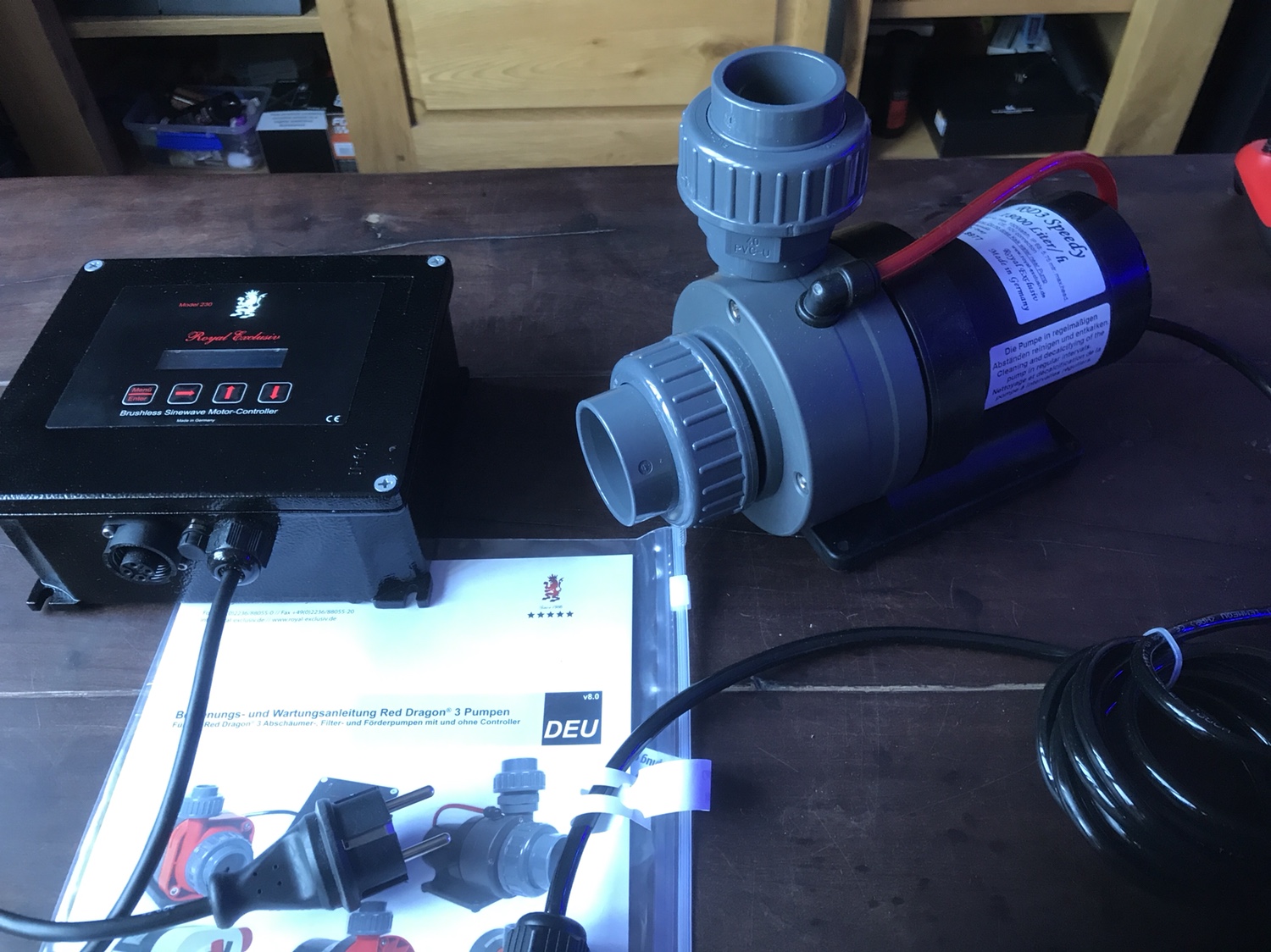

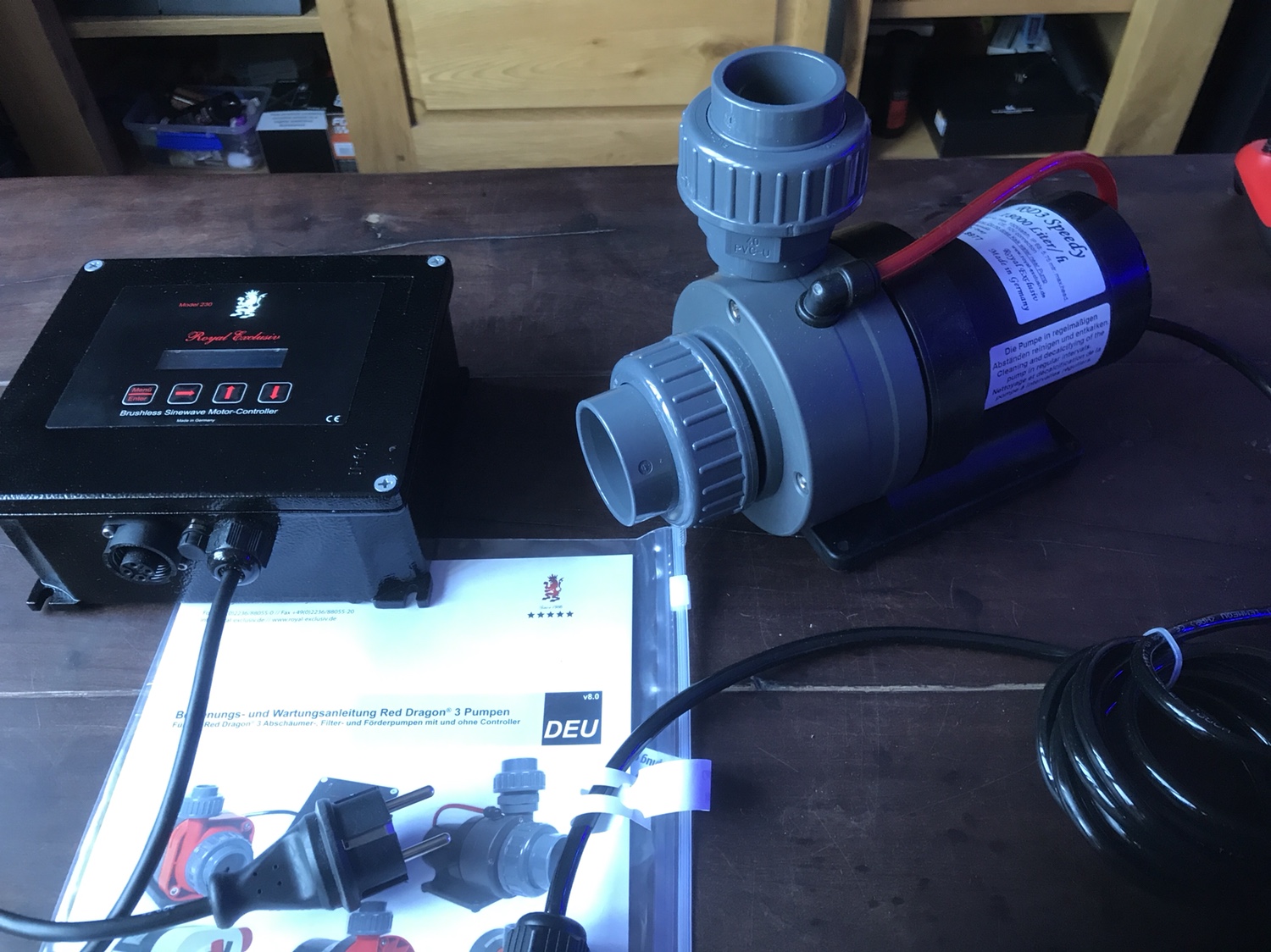

The Red Dragon's use an anti lime bypass loop. It is supposed to pull water from the rear bearing to the pump volute which supposedly the rotor and bearing cool. There are three ways of looking at this feature.A RD3 may be in my future someday, but right now with the kiddos and all, the reef piggybank is not that full! How well does the RD3 flush its impeller, does it also have fouling issues? I'd be interested to see internal pics of one that has been running a while.

new!

So is this the new or old style?

Not saying that the RD3 does not handle cooling properly. I am questioning if there is any added value to the anti lime bypass. Just stating that it may be at the point where there is no added benefit if the pump was properly designed from the beginning. I am pretty sure that it was but since the pump I think it was based on is not available in the US, we will never know.Thanks Greg.

Nothing like a brand new clean pump!

I guess we could really take it to the max and ask how a Abyzz is cooling itself and handling biofouling. Because if the RD3 isnt perfect in that regard, it would be interesting to know if the Abyzz is. Surely if neither of them handle heat/biofouling better, then there is a strong point for sticking with the Vectra.

The only holes that really matter are the one in pic #6 with the goo coming out of it and one at the back of the chamber that you can't see. They don't have to be completely blocked; if they're obstructed enough to impede flow then the the result will be the same. From the pics, there was more than enough buildup for this to be the case.The holes do not appear blocked?

The holes do not appear blocked?