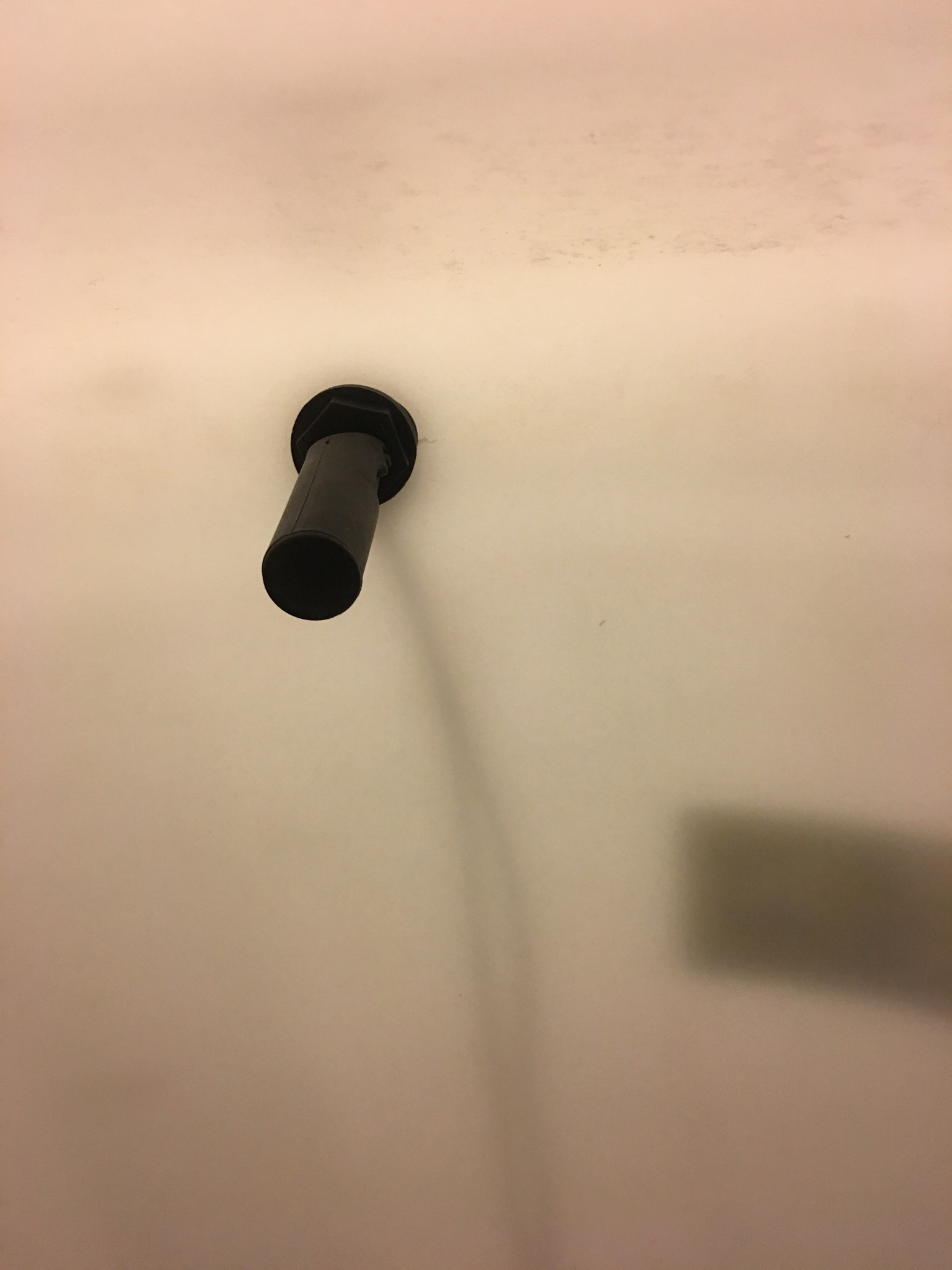

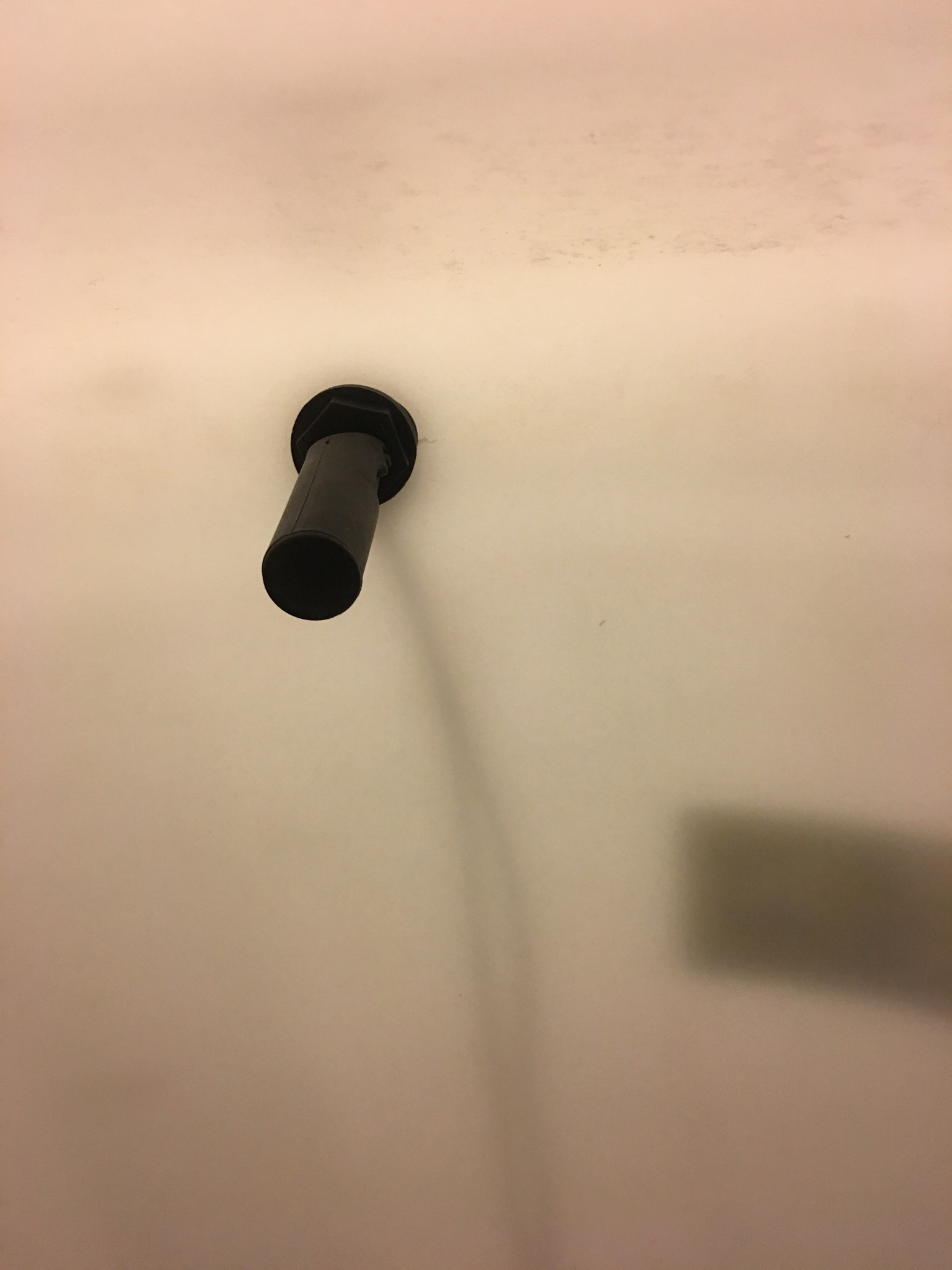

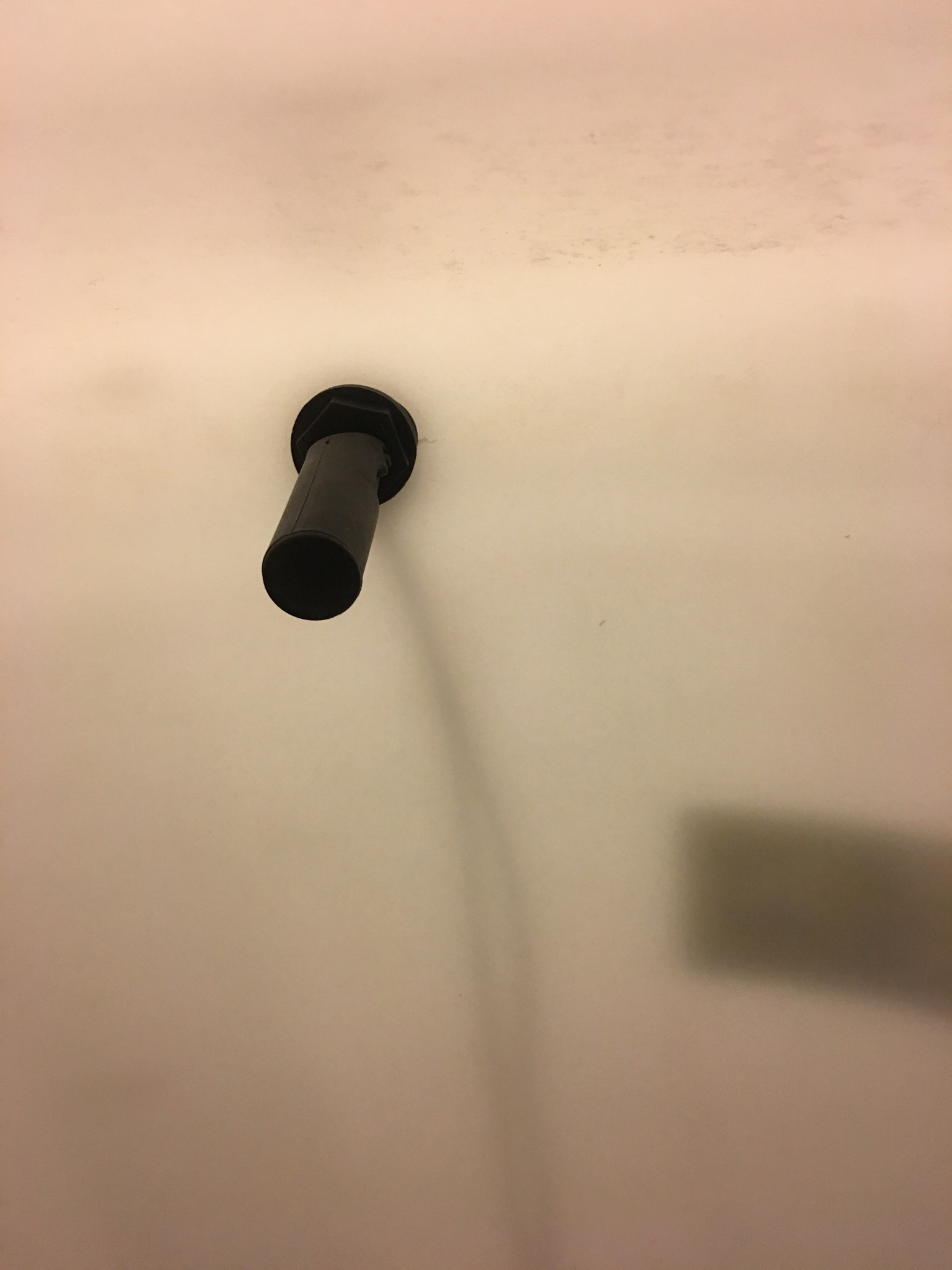

Recently bought this RO container used. It has a float switch installed, but I'm not sure how I would go about making it functional. Does anyone know how to go about getting an RO unit hooked up to this float switch? See pictures.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Do you have a controller?

This float switch is basically an on/off switch. When the water level is low, the switch is "on" and electricity flows through it. When the water level is high, the switch closes and doesn't allow electricity through.

If you wanted to use this switch, you could use a solenoid, which is basically a valve controlled by electricity. When the water level is low, electricity would flow to the solenoid and open it. When the water level is high, the switch would close and no electricity would flow to the solenoid, causing it to close and shut off water.

Personally, I would replace this with a float valve that shuts off the water using a simple floating arm.

It's basically works like a light switch, 1 in 1 out. need a drawing ?

For what reason would you do that? Simplicity, ease of installation, reliability?

It's more about simplicity. While the floating-type shutoff valves can fail, the system is less complex. The arm raises when the water gets too high and this simple action closes a valve.

In theory, a solenoid would work the same way, but there is more involved. For one, you need to supply DC power to the switch and then wire it to the solenoid. If the DC power supply dies, your valve won't open and new water won't get made. If the solenoid fails in the closed position, new water won't get made. If the solenoid malfunctions or sticks in the "on" position, which can happen with electrically-operated switches, the water will never shut off. The float valve is $15 shipped while the solenoid is $22, and that doesn't even include a DC power supply.

Even if reliability is the same, the floating shutoff valve is simpler and cheaper. Solenoids work fine and they have their place in more complex setups. My preference is just for "simple" when possible. Just my two cents.