Hello R2R Members,

I am looking into plumbing a 40gallon w/ a 20 gallon sump. I usually set up my sump high and off to the side, so I don't have to reach down and service it, but in this case, I do not have room. So the sump has to go under the DT.

The aquarium is going to house 5 small fish, and no more than 10 soft/LPS corals.

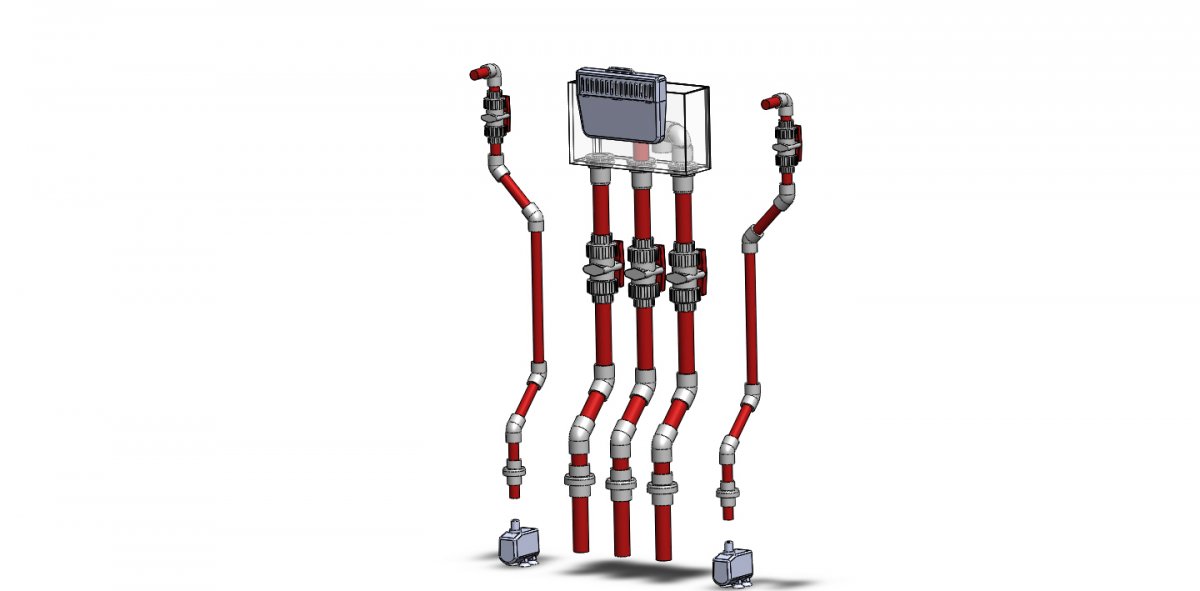

My plumbing features the following.

1" drains

1/2" returns

Return pumps in the model are Sicce Syncra 1.0 - I think I am going to have to upgrade to a 2.0 or bigger to avoid losing too much flow.

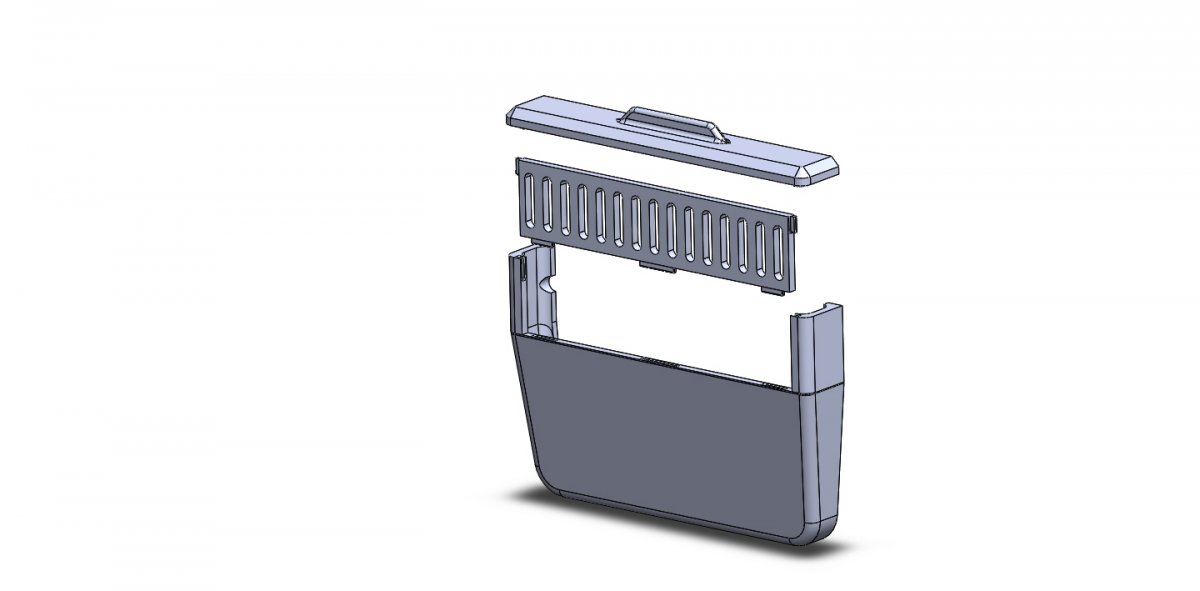

Overflow is 8" W, 3D printed and silicone to glass.

The length of the return plumbing, from the pump to the tank loc-line outputs is approx 40" long.

So my questions are:

Do you guys run valves on the return lines?

For a tank this size, are 3/4" returns recommended or is 1/2" sufficient?

Please feel free to make any suggestions/recommendation.

I am looking into plumbing a 40gallon w/ a 20 gallon sump. I usually set up my sump high and off to the side, so I don't have to reach down and service it, but in this case, I do not have room. So the sump has to go under the DT.

The aquarium is going to house 5 small fish, and no more than 10 soft/LPS corals.

My plumbing features the following.

1" drains

1/2" returns

Return pumps in the model are Sicce Syncra 1.0 - I think I am going to have to upgrade to a 2.0 or bigger to avoid losing too much flow.

Overflow is 8" W, 3D printed and silicone to glass.

The length of the return plumbing, from the pump to the tank loc-line outputs is approx 40" long.

So my questions are:

Do you guys run valves on the return lines?

For a tank this size, are 3/4" returns recommended or is 1/2" sufficient?

Please feel free to make any suggestions/recommendation.