Welcome to the development thread of reef-pi, an open-source, affordable, modular DIY reef-tank controller based on Raspberry Pi.

If you are trying to build a reef-pi controller, please check out the build guides linked below. You can use this thread to seek help and to stay updated with the latest development.

reef-pi provides following functionalities:

--------------------------- Original thread start ---------------------

Hello friends,

I am starting a master thread for a DIY reef tank controller that is based on all opensource software and hardware. I had started with this project with following goals:

- Build an opensource software and hardware based reeftank controller that anyone can use and hack

- Keep the controller well tested against a set of standard equipment I use, while make it possible for other equipment to be used

- Maintain my own tank build threads and their evolution, backed by this controller.

- Learn electronics and reef keeping along the way (I am biologist by education & software engineer by occupation)

Following are the details of what I have developed & tested till now:

Controller software:

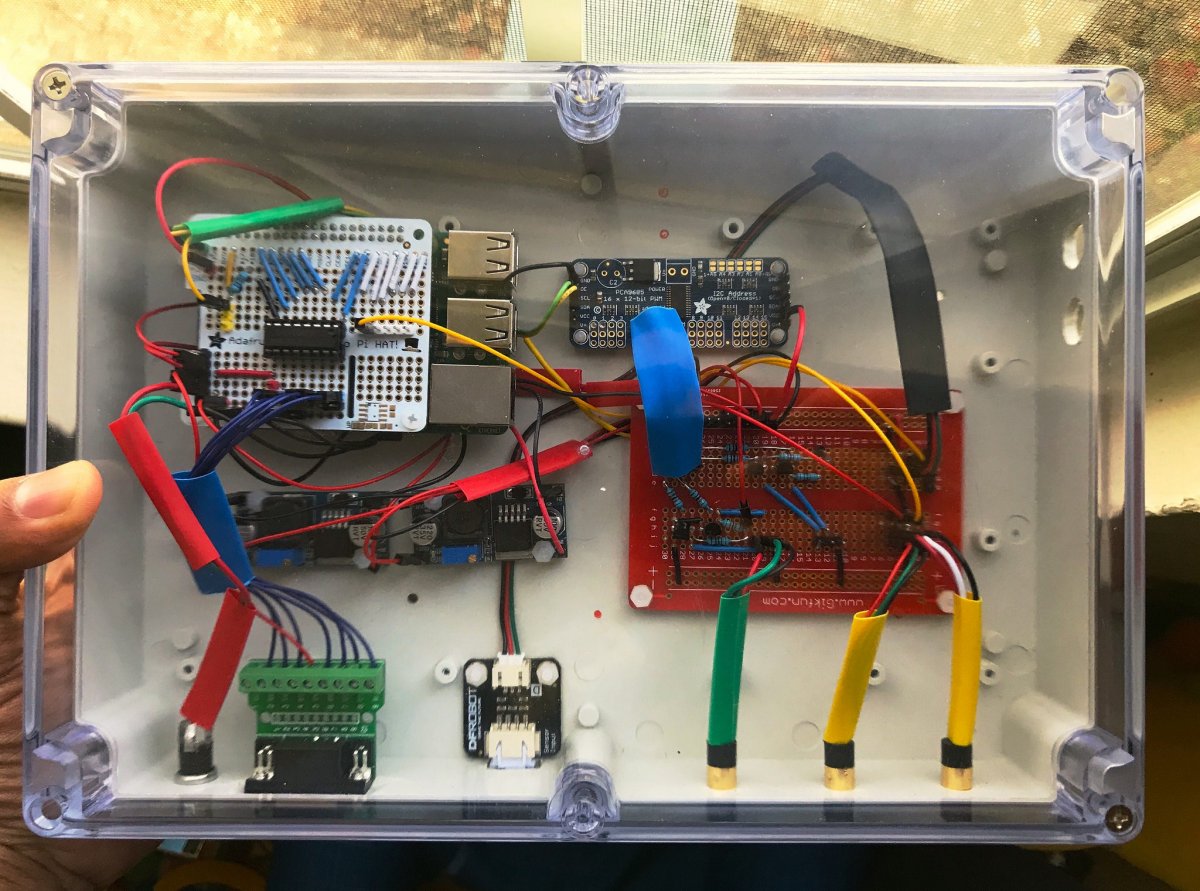

- The main controller software is called reef-pi. It is written in go, its fast and performant. It used embd for hardware communication. It also runs a little web server which provides the UI for the controller. UI is written in React , and can be accessed from anything that has web browser. As of now, the reef-pi supports following things:

- AC 110/220 V socket on/off (uses optocoupled relays underneath). This is used to remotely switch on/off return pump, LED bulb, heater etc.

- 0-20 Volt DC PWM. This is used to control things like dimmable LEDs, DC pumps. I use it to control my Kessil A80, A360. As well as a 5V DC pump (i use it as wave maker in one of my pico with SPS). PWM is done using PCA9685 breakout board from adafruit. This board supports 16 channels. I am using only 5 at max, as of now.

- Analog sensor support using MCP3008 analog to digital converter. This supports 8 channels. i.e. I can use up to 8 sensors/probes. As of now, I have only tested temperature sensor with it.

Other than the following basic hardware/equipment support, the controller software provides following additional features:

- Setting up daily/weekly/monthly scheduled jobs. Like turning on/off certain equipment. I use this feature to run my AC20 HOB filter nightly.

- Setting up dusk-to-dawn like lighting using PWM. The UI gives 12 vertical slider based 0-24 hours (each slider representing 2 hours gaps). I combine two of these two control the kessil LEDs.

- Authentication using Google OAuth. Since the whole controller runs on raspberry pi and provides an web frontend, security of one of my concern. To mitigate this, I have added google authentication support, which when configured will allow only certain users to log in (email specified in the configuration value).

This is the summary of the core controller software and what features it has as of now. I am constantly writing/improving things around it. As of now, I have two reef tank powered by this. I 'll have seperate threads on the individual builds that will include the housing and ancillary hardware in nano-reef.com, as my tank build threads are there, but I'll share all the controller specific common bits here, including UI screen shots, and tank pics

If you are trying to build a reef-pi controller, please check out the build guides linked below. You can use this thread to seek help and to stay updated with the latest development.

reef-pi provides following functionalities:

- Equipment control or automated power strip (including digital timers to switch on/off equipment at periodic intervals)

- LED light control (24 hour cycle), diurnal cycle, fixed dimmig

- Auto Top Off (based on photoelectric water level sensor or float switch)

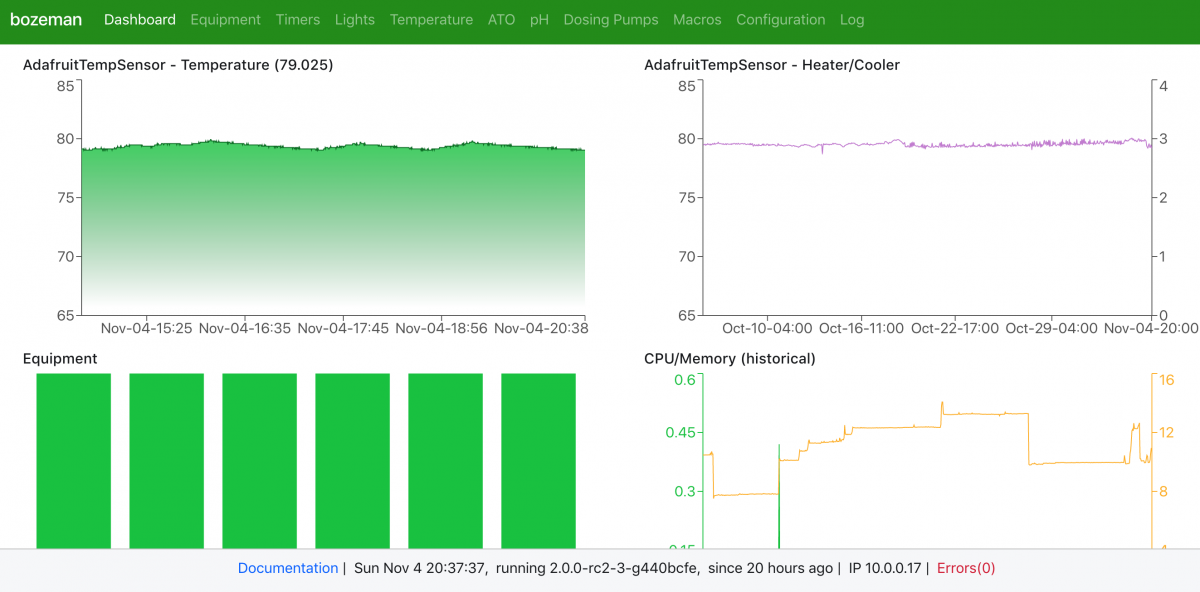

- Temperature monitoring and control (switch on/off heater & chiller)

- pH monitoring

- Dosing automation

- Macro (feed mode etc)

- And several other features like camera controls (periodic image capture and upload on google drive), telemetry (dashboard and alerting based on sensor values using adafruit.io), mobile friendly UI etc.

- Setup and installation

- Power controller

- Temperature controller

- Auto Top Off

- Light controller

- pH monitor

--------------------------- Original thread start ---------------------

Hello friends,

I am starting a master thread for a DIY reef tank controller that is based on all opensource software and hardware. I had started with this project with following goals:

- Build an opensource software and hardware based reeftank controller that anyone can use and hack

- Keep the controller well tested against a set of standard equipment I use, while make it possible for other equipment to be used

- Maintain my own tank build threads and their evolution, backed by this controller.

- Learn electronics and reef keeping along the way (I am biologist by education & software engineer by occupation)

Following are the details of what I have developed & tested till now:

Controller software:

- The main controller software is called reef-pi. It is written in go, its fast and performant. It used embd for hardware communication. It also runs a little web server which provides the UI for the controller. UI is written in React , and can be accessed from anything that has web browser. As of now, the reef-pi supports following things:

- AC 110/220 V socket on/off (uses optocoupled relays underneath). This is used to remotely switch on/off return pump, LED bulb, heater etc.

- 0-20 Volt DC PWM. This is used to control things like dimmable LEDs, DC pumps. I use it to control my Kessil A80, A360. As well as a 5V DC pump (i use it as wave maker in one of my pico with SPS). PWM is done using PCA9685 breakout board from adafruit. This board supports 16 channels. I am using only 5 at max, as of now.

- Analog sensor support using MCP3008 analog to digital converter. This supports 8 channels. i.e. I can use up to 8 sensors/probes. As of now, I have only tested temperature sensor with it.

Other than the following basic hardware/equipment support, the controller software provides following additional features:

- Setting up daily/weekly/monthly scheduled jobs. Like turning on/off certain equipment. I use this feature to run my AC20 HOB filter nightly.

- Setting up dusk-to-dawn like lighting using PWM. The UI gives 12 vertical slider based 0-24 hours (each slider representing 2 hours gaps). I combine two of these two control the kessil LEDs.

- Authentication using Google OAuth. Since the whole controller runs on raspberry pi and provides an web frontend, security of one of my concern. To mitigate this, I have added google authentication support, which when configured will allow only certain users to log in (email specified in the configuration value).

This is the summary of the core controller software and what features it has as of now. I am constantly writing/improving things around it. As of now, I have two reef tank powered by this. I 'll have seperate threads on the individual builds that will include the housing and ancillary hardware in nano-reef.com, as my tank build threads are there, but I'll share all the controller specific common bits here, including UI screen shots, and tank pics

Last edited: