Dosing pump runs on the same voltage as the input voltage (12v), lm2596 is used to convert the 12v input voltage to 5v , for raspberry pi.One more thing. What do I need to set the output voltage of the LM2596 at for the dosing pump module?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

reef-pi :: An opensource reef tank controller based on Raspberry Pi.

- Thread starter Ranjib

- Start date

-

- Tags

- controller raspberry-pi

- Tagged users Ranjib

@theatrus just started a separate thread on the pico board: https://www.reef2reef.com/threads/reef-pi-base-boards-pico-etc.499890/

this is going to be awesome

this is going to be awesome

Can I get a little help, my relay has vcc, gnd, com, as it's main connectors, I've plugged the ground into a ground on my pi, the vcc is connected to my 5v psu, which also power the pi, I just don't know what to do with com connection, I tried it in pi 5v and half the little leds on relay lite up so I unplugged, any help?

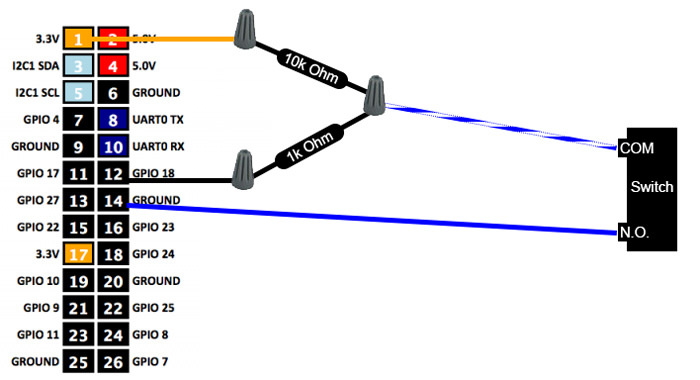

This is more complicated that what I did. I just went from the gpio to ground. No resistors, no 5v circuit. Works perfectly for meHere ya go

sorted it, vcc to 5v pi, com to 5v psu and ground to piCan I get a little help, my relay has vcc, gnd, com, as it's main connectors, I've plugged the ground into a ground on my pi, the vcc is connected to my 5v psu, which also power the pi, I just don't know what to do with com connection, I tried it in pi 5v and half the little leds on relay lite up so I unplugged, any help?

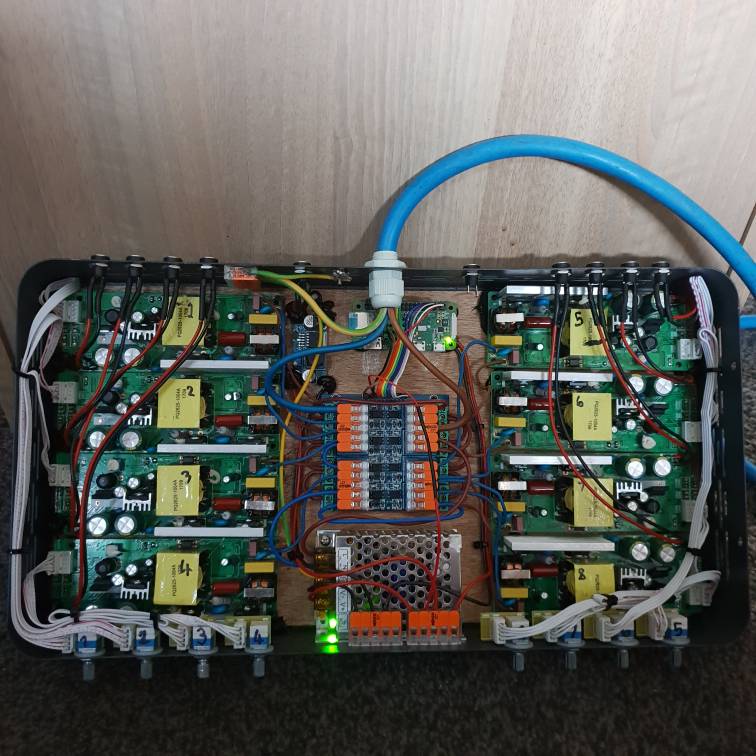

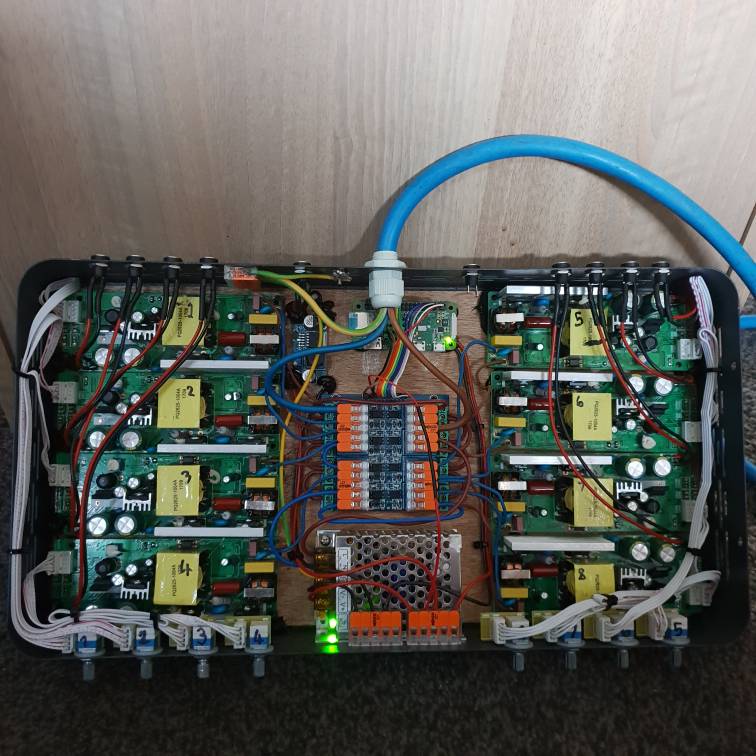

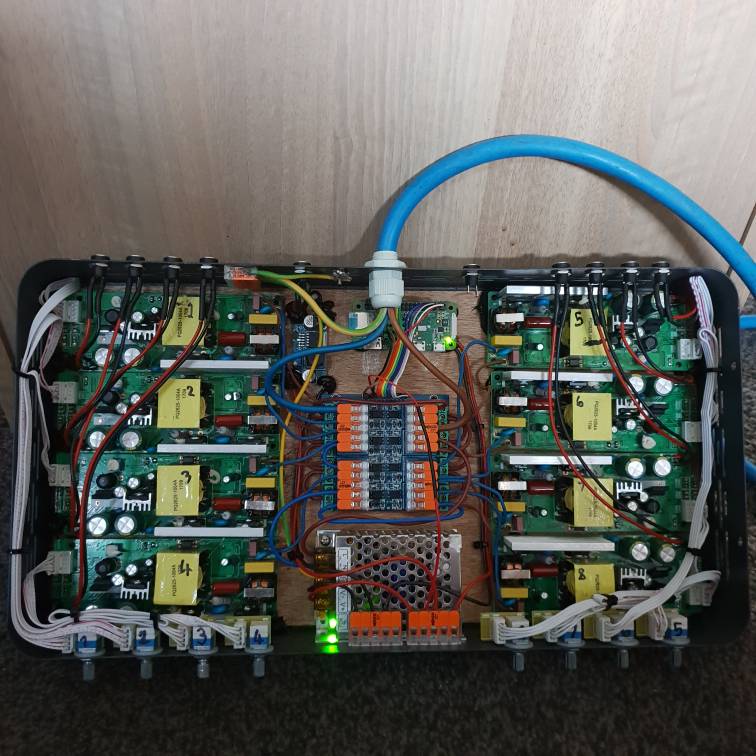

So this is my progress on light control for my black boxes, need to add a fan today so I can get some light back on my tank, only been off a day.

Pretty hard trying to modify stuff while you actually need to use it.

Think I'll go with a mesh top to allow the heat to escape but that can wait as it's going on top of my lid out the way.

Pretty hard trying to modify stuff while you actually need to use it.

Think I'll go with a mesh top to allow the heat to escape but that can wait as it's going on top of my lid out the way.

That looks awesome, very clean wiring! If you haven't already considered it, you could put a temp sensor in there and thermostatically control the fan if inclined.So this is my progress on light control for my black boxes, need to add a fan today so I can get some light back on my tank, only been off a day.

Pretty hard trying to modify stuff while you actually need to use it.

Think I'll go with a mesh top to allow the heat to escape but that can wait as it's going on top of my lid out the way.

So this is my progress on light control for my black boxes, need to add a fan today so I can get some light back on my tank, only been off a day.

Pretty hard trying to modify stuff while you actually need to use it.

Think I'll go with a mesh top to allow the heat to escape but that can wait as it's going on top of my lid out the way.

This is awesome and neatly wired. I do worry about this being in a plastic box and it looks to be mounted on plywood. I worry that if one shorts out and caused a second to do the same it could go very wrong very Fast..

Please consider moving this to a Metal box for safety factors.... Of course its just my opinion Electricity and plastic scares me

I think the relay will work even if you don’t connect anything to comsorted it, vcc to 5v pi, com to 5v psu and ground to pi

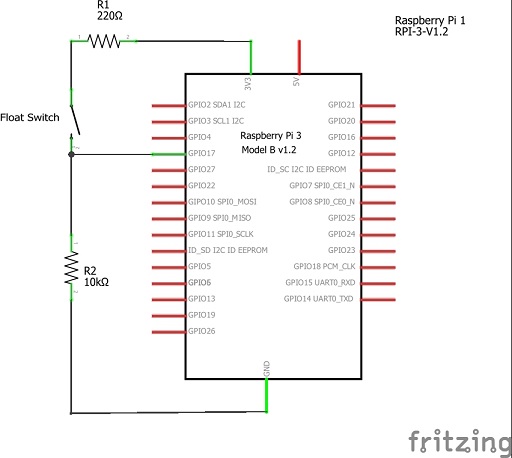

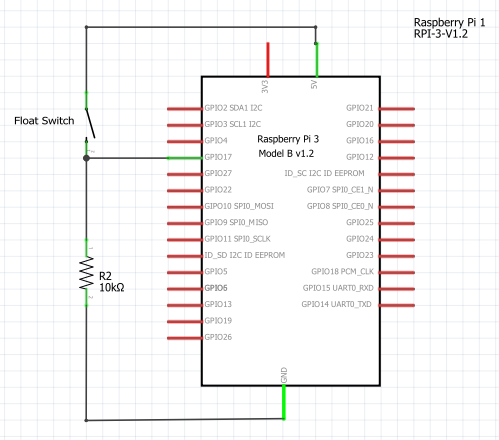

Those extra resistors are for safety . I think I have detailed what each of them does to mitigate different risks, but yes the flor switch should work even without them.This is more complicated that what I did. I just went from the gpio to ground. No resistors, no 5v circuit. Works perfectly for me

I am curious , Xbox and even track power supply has enclosed modules with plastic housing. So, is there any specific detail that we should look for ? Like wattage ? And also it must involve the type of circuit as well. Traco psu can be pretty high wattage , and still enclosed in plastic housing . They power rockets .This is awesome and neatly wired. I do worry about this being in a plastic box and it looks to be mounted on plywood. I worry that if one shorts out and caused a second to do the same it could go very wrong very Fast..

Please consider moving this to a Metal box for safety factors.... Of course its just my opinion Electricity and plastic scares me

This is a very important topic as I bet lots of folks will need this info , and I really want to keep safety as one of the most important aspect of this project. If you have any specific guidance here , I’ll gladly put it in the official docs as well. We have a specific section around safety (fire hazard and electrical shocks )

Thanks guys, I do plan to get a two fans one above each set of drivers running on temp control in the near future.

Yes I'm not too impressed with using the plywood base in there, the outer casing is metal as it's a stripped out black box

I actually removed a piece of glass for the hardboard, this is v2 of the housing.

I do still have spare housing to play with so will look at getting a metal base in v3, trouble is then the standoffs, I tried standoffs and just didn't trust them to not short something out on the drivers so ended up with silicone holding the electronics in.

Yes I'm not too impressed with using the plywood base in there, the outer casing is metal as it's a stripped out black box

I actually removed a piece of glass for the hardboard, this is v2 of the housing.

I do still have spare housing to play with so will look at getting a metal base in v3, trouble is then the standoffs, I tried standoffs and just didn't trust them to not short something out on the drivers so ended up with silicone holding the electronics in.

What drivers are you using? Most boards with mount holes leave enough room around the holes to be safe and many are grounded through the standoff holes as well. If you are still concerned, how about nylon standoffs and screws?Thanks guys, I do plan to get a two fans one above each set of drivers running on temp control in the near future.

Yes I'm not too impressed with using the plywood base in there, the outer casing is metal as it's a stripped out black box

I actually removed a piece of glass for the hardboard, this is v2 of the housing.

I do still have spare housing to play with so will look at getting a metal base in v3, trouble is then the standoffs, I tried standoffs and just didn't trust them to not short something out on the drivers so ended up with silicone holding the electronics in.

It's the standard black box drivers, the wiring is in the way on 1 off the corners and lots of small open solder joints underneath at the standoff holes and also the heatsink blocks a hole

I am curious , Xbox and even track power supply has enclosed modules with plastic housing. So, is there any specific detail that we should look for ? Like wattage ? And also it must involve the type of circuit as well. Traco psu can be pretty high wattage , and still enclosed in plastic housing . They power rockets .

This is a very important topic as I bet lots of folks will need this info , and I really want to keep safety as one of the most important aspect of this project. If you have any specific guidance here , I’ll gladly put it in the official docs as well. We have a specific section around safety (fire hazard and electrical shocks )

Most project boxes are not UL Certified for electrical use. I have taken apart items such as x-box and other items and there is Almost always a Metal shield around or under components that have high heat or large capacitors . I am not really the right person to ask what is considered safe. I just know how i do things based on how i have seen Actual Electricians have done so and how things seem to be made.

My concern with is light build is all of those open Power units .I have seen them after a short. If there were one or two and spaced way apart i would probably not have even commented..

Maybe Just reminding people to be aware of safety and Recommend ul approved or Metal box or metal shielding under or behind power components Where high AC Voltage is connected to step down converters or when many Voltage converters are in play together.. I think Lights and Relays are the two things of Concern with our builds . the ADJ Solves one of them for those that can go that rout .For me the Outlets have to be spaced out. I can ask Drew to do a small write up for us about electrical safety that applies to our designs...

Last edited:

So, the original enclosure was using edge mounts then.It's the standard black box drivers, the wiring is in the way on 1 off the corners and lots of small open solder joints underneath at the standoff holes and also the heatsink blocks a hole

OK, guys, I did a thing.....

Most project boxes are not UL Certified for electrical use. I have taken apart items such as x-box and other items and there is Almost always a Metal shield around or under components that have high heat or large capacitors . I am not really the right person to ask what is considered safe. I just know how i do things based on how i have seen Actual Electricians have done so and how things seem to be made.

Metal enclosures like this are almost always for EMI / radiated emissions. Everything becomes a radio transmitter, so these are the attenuation mechanisms.

Most plastics designed for electronics should be rated as UL 94V0, which is filled with enough flame retardant materials to not keep a flame for more than 10 seconds.

https://en.m.wikipedia.org/wiki/UL_94

My concern with is light build is all of those open Power units .I have seen them after a short. If there were one or two and spaced way apart i would probably not have even commented..

Maybe Just reminding people to be aware of safety and Recommend ul approved or Metal box or metal shielding under or behind power components Where high AC Voltage is connected to step down converters or when many Voltage converters are in play together.. I think Lights and Relays are the two things of Concern with our builds . the ADJ Solves one of them for those that can go that rout .For me the Outlets have to be spaced out. I can ask Drew to do a small write up for us about electrical safety that applies to our designs...

I agree - don’t mess with high power lightly. There are a number of factors to consider (clearance, current, wire sizing, fusing, etc).

- Joined

- Nov 4, 2018

- Messages

- 102

- Reaction score

- 150

What image should I follow for my float switch that will run my mixing station and RO/DI tank solenoid.

trying to mess arround with this again ahead of my new build doing a simple 2 channel test light, and using the GPIO 18/19 for pwm. I get massive flickering at anything but 100% its almost like its pulsing the PWM super slow so its visable to my eye. is there a setting I missed?

Similar threads

New Posts

-

-

-

-

-

Magnesium Nitrate - Greenhouse Grade

- Latest: Randy Holmes-Farley