Hey everyone, New to the forum and was told I need to put my build here. The build is a 280 gallon mixed reef/fish. Two panels of the tank will be Starphire glass. The heart of the system will be filtered by all Bashsea components which include the Signature Series 60"x 15" x 16" 60 gallon sump with an 8-30 Twisted Skimmer, 8-30 Bio-Reactor, a Pellet Master 3, and 2 Media Reactors. Return pumps will be two Eco-Tech Vectra L1's. Skimmer gets the Vectra M1 and another Vectra L1 into a manifold for everything else. I plan on using an Apex with flow sensors to regulate flow to all components. I'm kind of old school with lighting. I like a combination of Halide and T5. My water will be made via BRS 7 stage RO/DI system with a 15 ATO resovior. I also have 65 gallon Norwesco container for mixing saltwater for water changes. Probably going to do a 50 watt sterilizer from the beginning to aid in keeping a healthy tank. I have some drawings that I did on some c.a.d. software that I will post later on and I have a couple of pictures of the start of the build process. I literally just started the actual build two days ago. So I hope you all will enjoy the progression as much as will.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RobW's 280 Gallon Build

- Build Thread

- Thread starter RobW

- Start date

- Tagged users None

- Joined

- Jan 20, 2019

- Messages

- 1,655

- Reaction score

- 1,831

WELCOME to R2R. Cool biuld

I get the same thing Rob. I can load from my iPad but not my phone

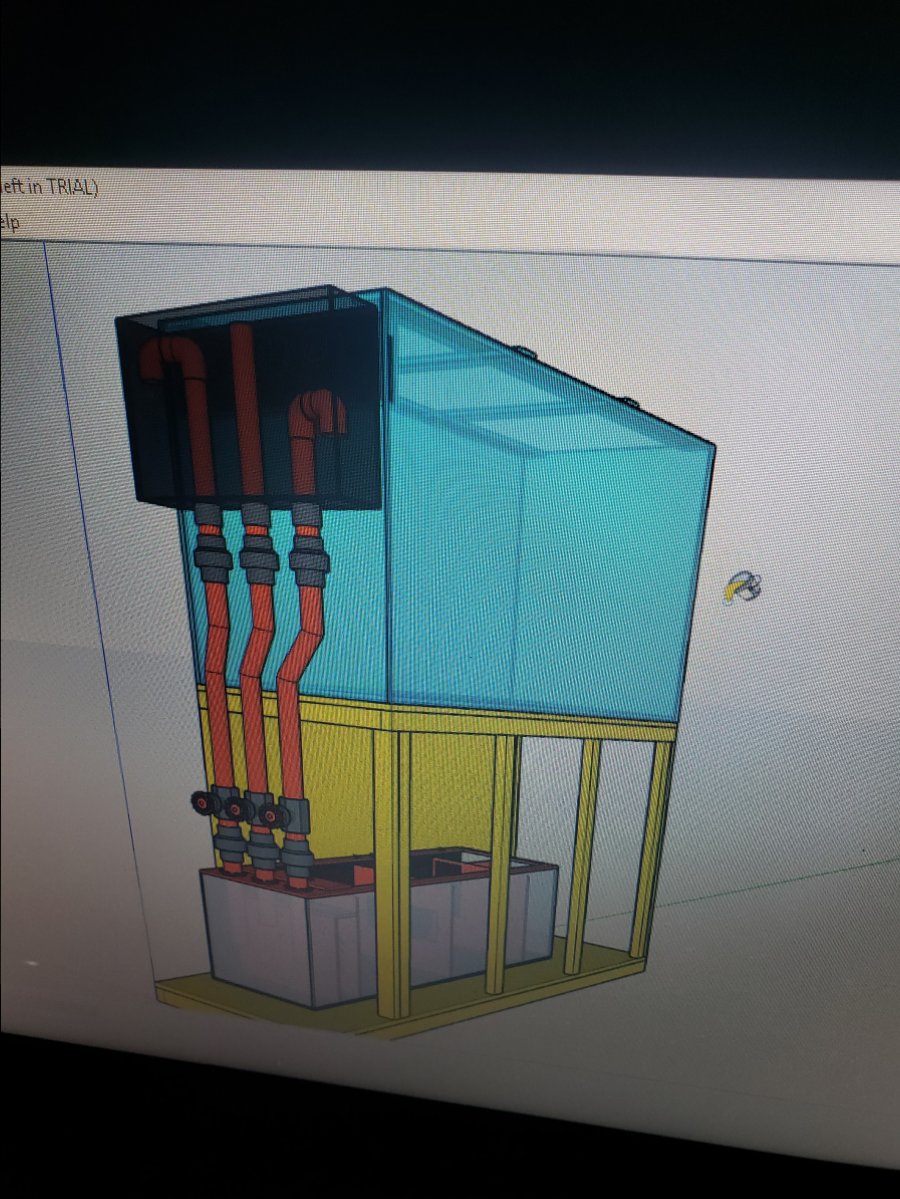

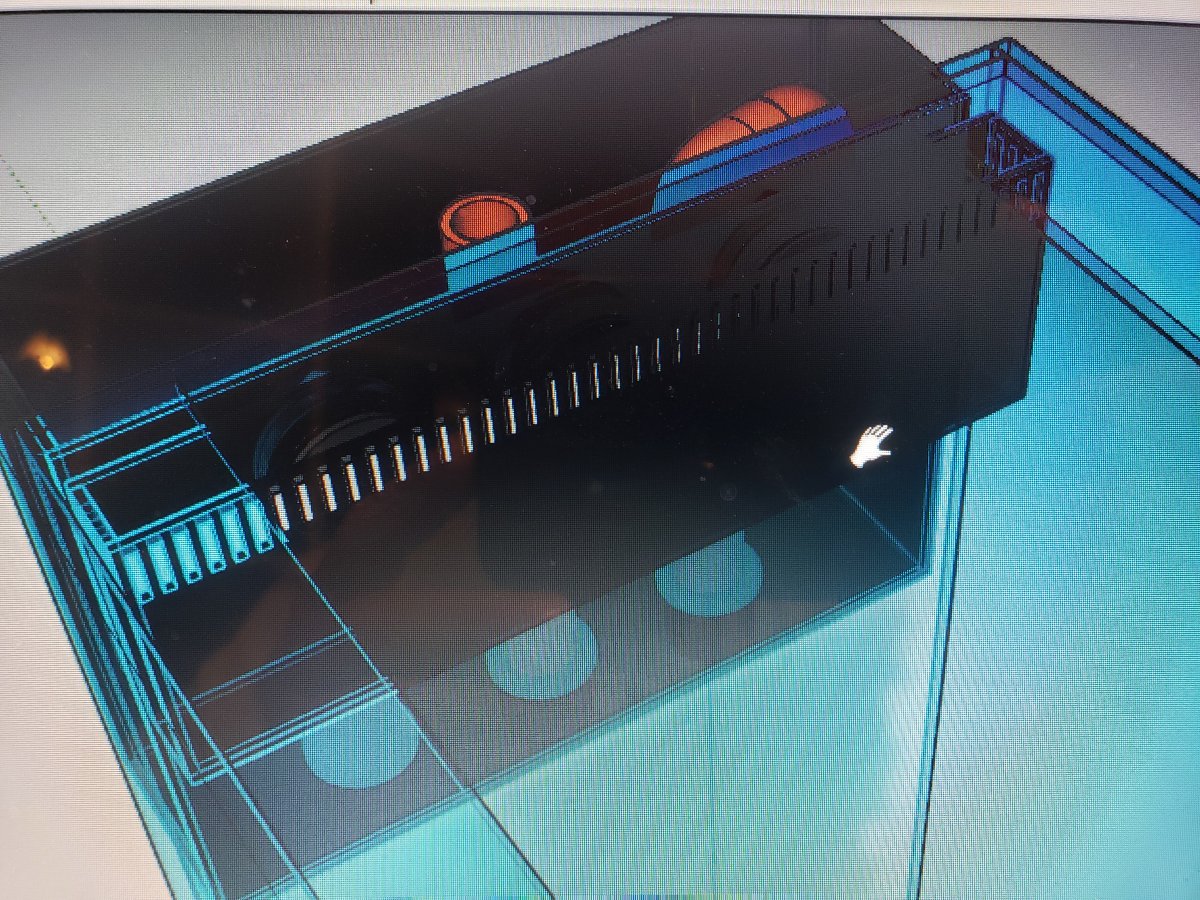

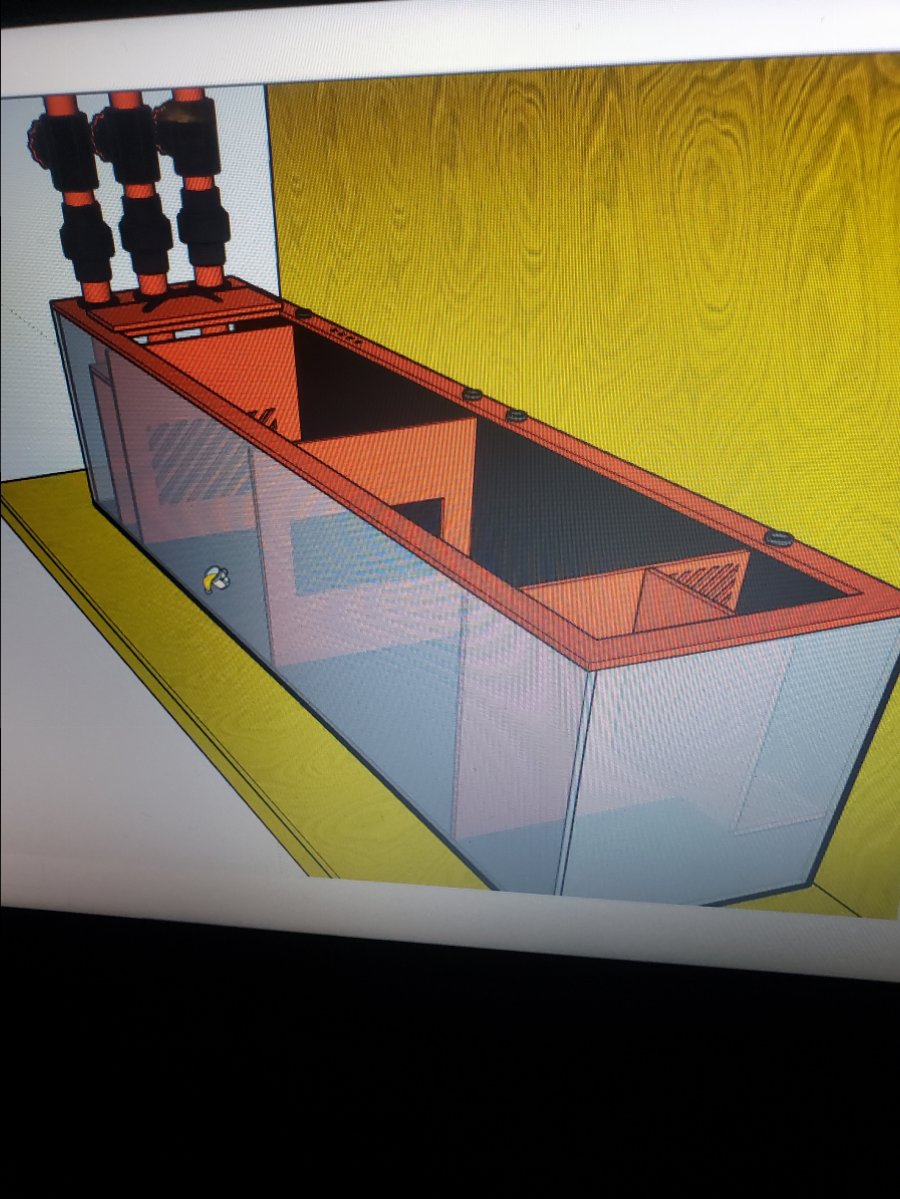

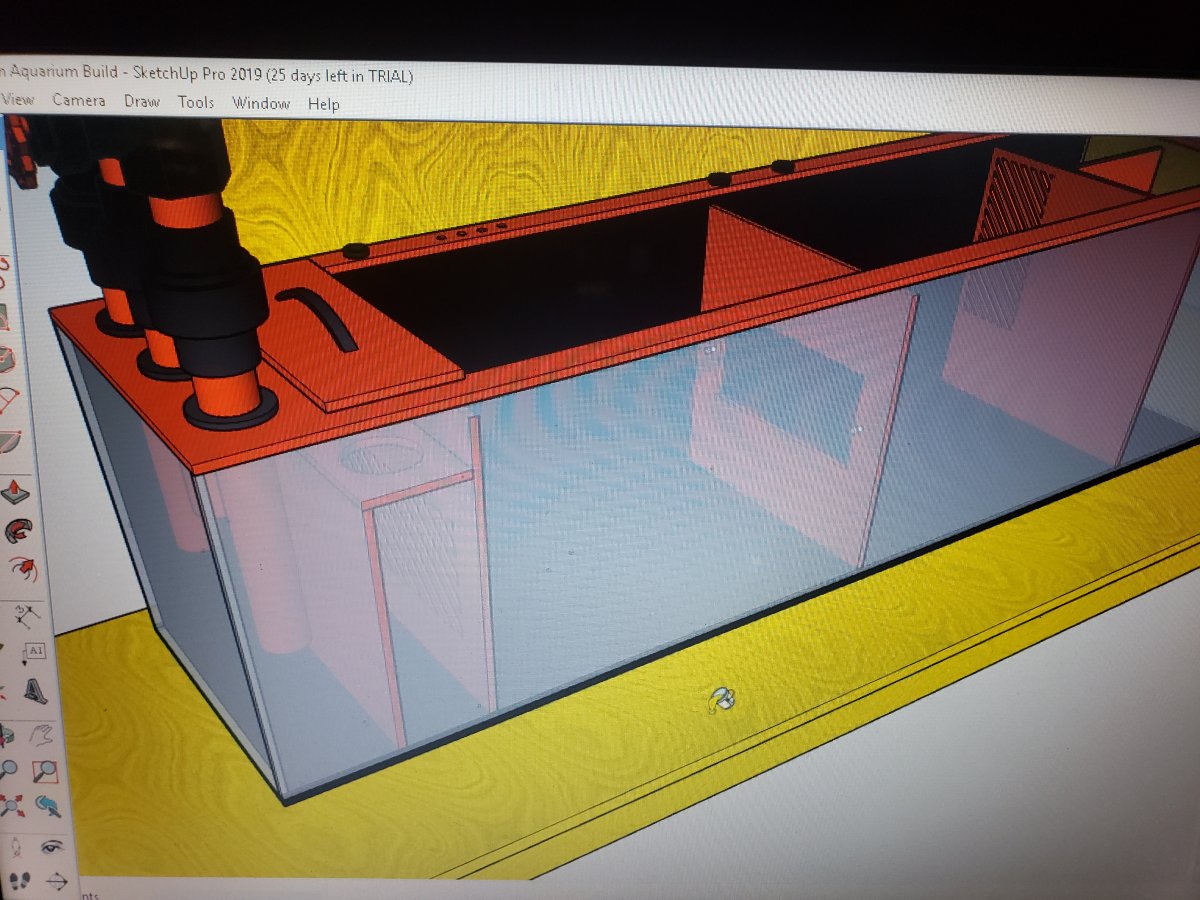

So here was a couple of ideas that I threw down in sketchup before I actually started. I have made some changes. I just wanted to get a visual reference down and have a way to check the fit of equipment. Sorry if the images look bad. They were just snap shots of my computer screen from my phone.

So as I said before... I literally just started this build. I can't wait till the weekend so I can get more done! By the time I get home from work I don't have a lot of time.

thanks for that tape idea! I can going to do that to help figure out how i want to build out my 29g into a sump

Yay! Finally the weekend is here! I went and got some more lumber last night after work. Got to have my morning coffee and then it is out to the garage to get started. Have to pull out the jointer and the planer and mill up the lumber. Got to make sure the all the boards are perfectly straight, square and true. Because lord only knows you can't find a straight piece of wood to save your life at your local depots! You have to sight all your boards and try to find the best possible. Even after doing that, by the time you mill a standard 2x4 (which is actually 1-1/2 x 3-1/2) down I end up with a true board that measures 1-1/4 x 3. Once the base is all framed it will be wrapped all in 3/4" plywood inside and outside which will greatly increase the strength. Every single joint and mating surfaces are all coated in wood glue and fastened to interlock to make the strongest joints possible. Unfortunately, I've watched a ton of people build stands for tanks that emphasize so much on using huge sized boards and then just screw things together relying on the shear strength of the screws. Then they use so many screws that there is nothing left of the woods fiber strength. If you use the right glue... it will be stronger than the screws pulling it together after it dries. In all honesty you could take all the screws out after the glue cures and if you were to try and pull the wood apart at the joints the wood would snap and break at other points before the glue joints come apart. I see people using 4x4 pressure treated posts on tank builds a lot. Way overkill! A 4x4 pressure treated post standing up straight can literally take over 13,000 lbs of downward force before it would snap. Not to say that being over engineered is a bag thing. But in a situation like mine where space is at a premium, there is just no need for all that mess. I figure I will have close 3,000 pounds sitting on top of this stand. The foot print of the tank is 72" x 24" so that's 12 square feet. If you divide 3000 lbs of weight by 12 square feet you are actually only putting 250 lbs per square foot over the stand. With that weight distributed over that area, it really isn't that much. For 2x4 material and plywood to handle. Anyway, enough chit chat. Time to get to work. Enjoy your weekend everyone! I will post more pictures of the progress as the weekend moves along.

Welcome to R2R and what a heckuva a nice way to join with such a cool build to boot!

Liking the way you have everything mapped out with painters tape.

Liking the way you have everything mapped out with painters tape.

Welcome to R2R and what a heckuva a nice way to join with such a cool build to boot!

Liking the way you have everything mapped out with painters tape.

Thank you Sir! I love sharing. Hopefully it will inspire people to do some builds themselves. Also, I'd like any constructive feedback or any ideas that anyone would love to share. I'm always open for some good suggestions along the way.

Similar threads

- Replies

- 1

- Views

- 110

- Replies

- 4

- Views

- 217