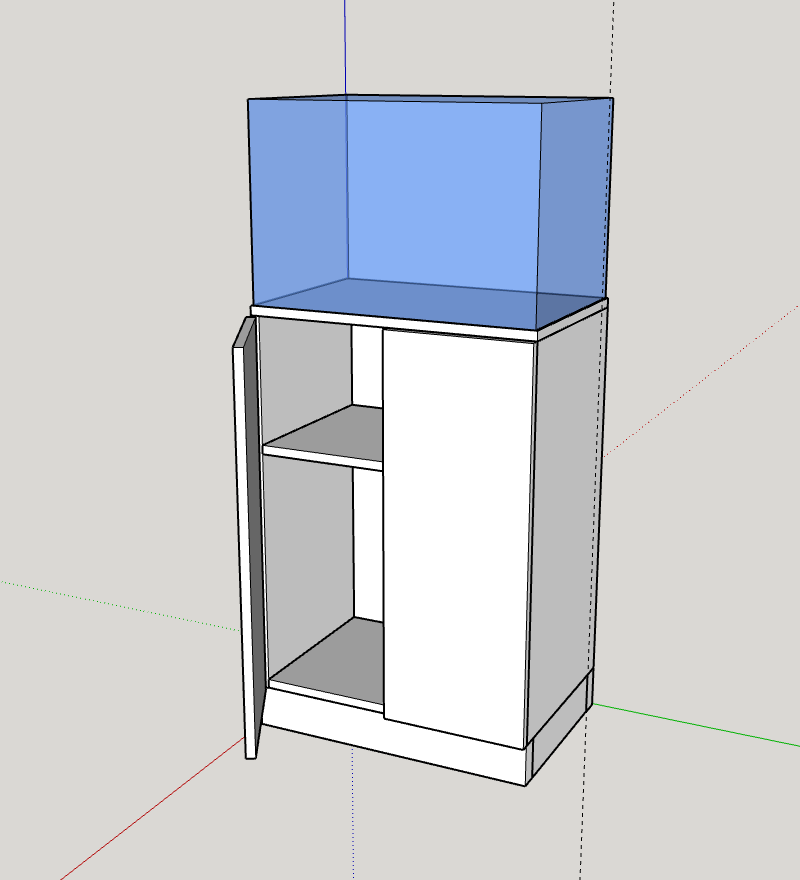

Hello, everyone! After searching for an affordable tank stand without success, I decided to design my own. Through a family member, I have access to the tools necessary to construct this build. That said, I have never built something like this and am seeking feedback from the community to make sure my design will be sturdy enough for a Waterbox 25 gallon AIO (mini peninsula model).

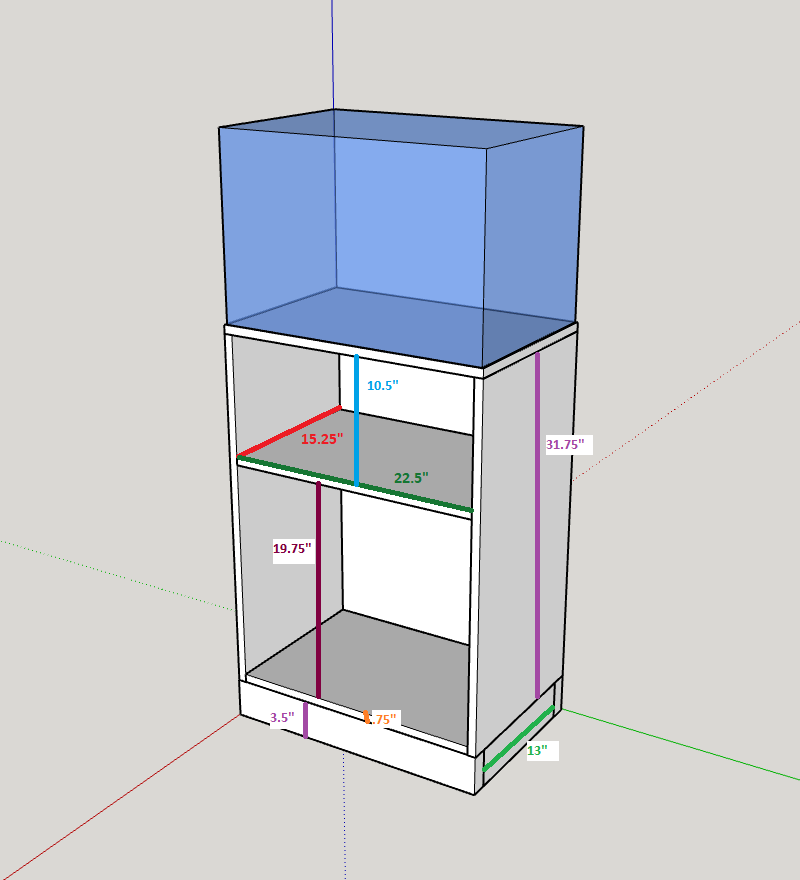

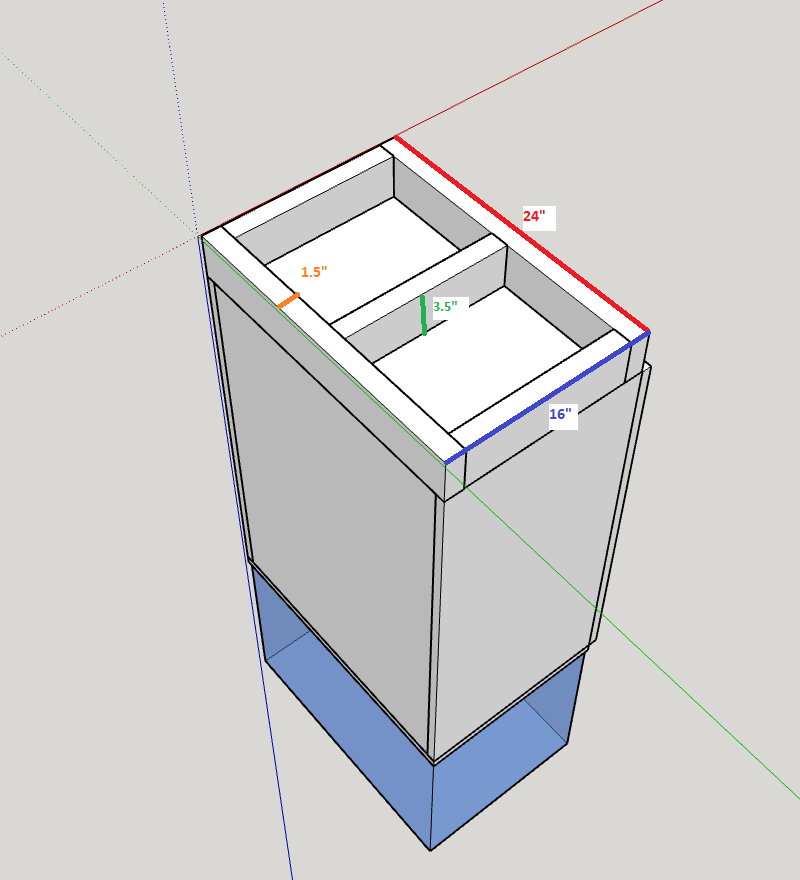

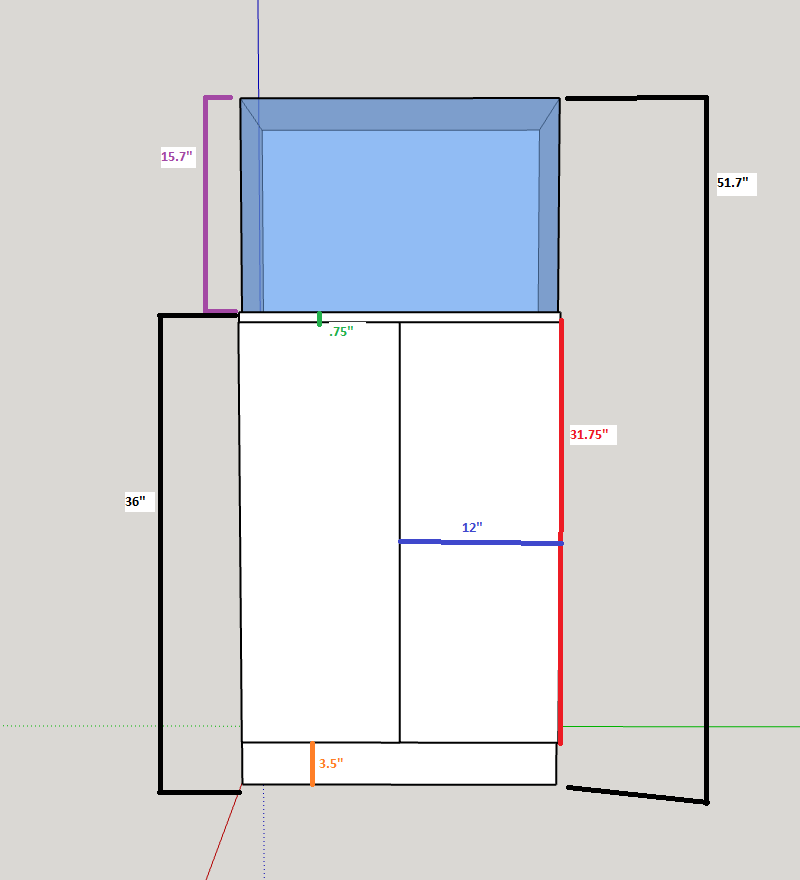

As far as materials are concerned, I plan to use 3/4" plywood for the majority of the project. To form the base of the stand, I will use 2x4's. Images of the design are included below. What do you think?

As far as materials are concerned, I plan to use 3/4" plywood for the majority of the project. To form the base of the stand, I will use 2x4's. Images of the design are included below. What do you think?