I am building a 72x36x24 Aquarium. I will be picking up the Acrylic sheets next week, they are 1/2" and already laser cut. I have done hours and hours of research prior to starting this. The one thing that I am now unsure of is between #4 and #42. I've done enough reading and Youtubing that I am fairly confident in using #4 correctly. I have noticed a lot of people mentioning #42. Will I be okay with #4? Thank you for all advice.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weld-On #4 vs #42

- Thread starter JustinForMayor

- Start date

- Tagged users None

I know a lot of pros use 40/42 but I’ve heard it’s harder to work with but it’s stronger. I’ve always used 3 & 4 and then run a bead of 16 in all the seems and I’ve never had a leak or an issue with what I’ve built. I’ve made a few sumps and frag tanks/all in one tanks. Never made a large tank. I can say I doubt you could pull apart the seems using 3 or 4 if you wanted to. The acrylic would break before the seem would

This will be my first tank build so Im trying to avoid 40/42 if #4 will get the job done.

If it were me I’d use 3 or 4This will be my first tank build so Im trying to avoid 40/42 if #4 will get the job done.

I use 3, but would not try it for my first tank. I would get some scraps to try first. Those bubbles dont go away.

And if you get bubbles, then what? Screwed?I use 3, but would not try it for my first tank. I would get some scraps to try first. Those bubbles dont go away.

Not screwed but weaker seam. I use 42 but started with 4. Wherever your getting your sheets from find out how they’re cut. Saw vs CNC. See if you can take scraps or “drops” for practice. Practice some longer seams before you try on the the tank. 300 is a big tank to start with I built a bunch of smaller ones first. Or at least they resembled tanks. Take it slow and be as precise as possible. Are you going pins or capillary method.And if you get bubbles, then what? Screwed?

They are CNC cutting. I know if it's saw cut then I would need to go and sand the edges before bonding. I plan on the pin method, but Im not sure how that's how to workout with the front/back being so long. I am assuming I will need to get the weld done pretty quick so I can go back and pull the pins?Not screwed but weaker seam. I use 42 but started with 4. Wherever your getting your sheets from find out how they’re cut. Saw vs CNC. See if you can take scraps or “drops” for practice. Practice some longer seams before you try on the the tank. 300 is a big tank to start with I built a bunch of smaller ones first. Or at least they resembled tanks. Take it slow and be as precise as possible. Are you going pins or capillary method.

Yeah you’ll most likely want a second set of hands to help I try and have at least 2 people on 6 foot or longer runs. I’d still recommend a bit of practice If possible. Also invest in a stand for support especially on 1/2” thicknessThey are CNC cutting. I know if it's saw cut then I would need to go and sand the edges before bonding. I plan on the pin method, but Im not sure how that's how to workout with the front/back being so long. I am assuming I will need to get the weld done pretty quick so I can go back and pull the pins?

- Joined

- Feb 1, 2018

- Messages

- 505

- Reaction score

- 669

You can’t use a laser cut edge. Ask for a CNC router cut edge or a table saw. I would do a mixture of 97% methylene chloride and 3% acetic acid applied using a syringe and the pin method. I would then reinforce the seams with weldon 40 by tipping the tank on an angle and pouring a fillet. 3/4” material would be a better option.

I would second the 3/4 material. I build 48" frag tanks out of 1/2" and it will eventually bow. Are you going to put a top plate on this tank for support??

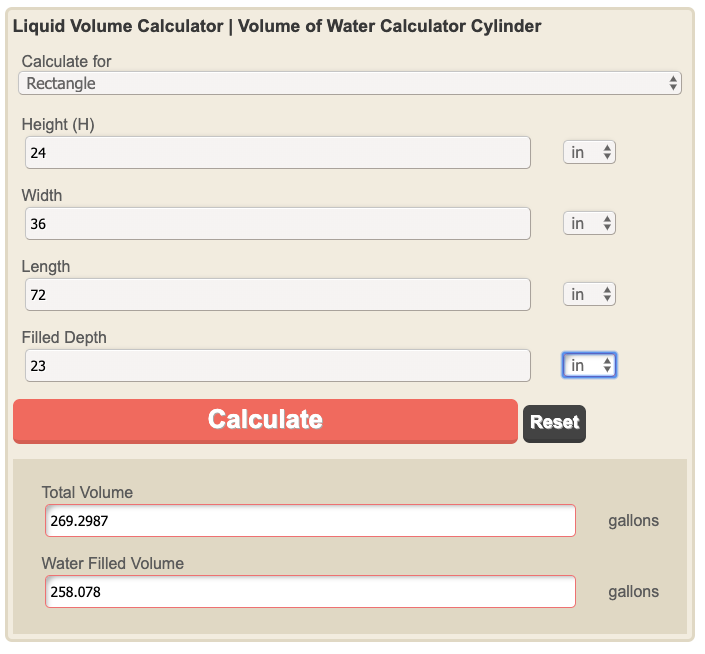

Just noticed that your first post said the parts were laser cut and then you said later they are CNC cut. I would be sure they are CNC cut. If not you must sand the edges. I start with 150 grit and work down to 400. My laser leaves micro grooves that will create gaps/bubbles. These never leak, but the bubbles look like crap on clear. Colored acrylic will hide any bubbles or cracks, but they are weaker joints. If you calculate the dimensions you have given you are looking at 250+ gallons of water.

Thats a ton of water (Literally). That is a lot of pressure on 1/2" corner joints. If you are not planning on a top with a center brace I would not attempt this project as planned. Just my opinion.

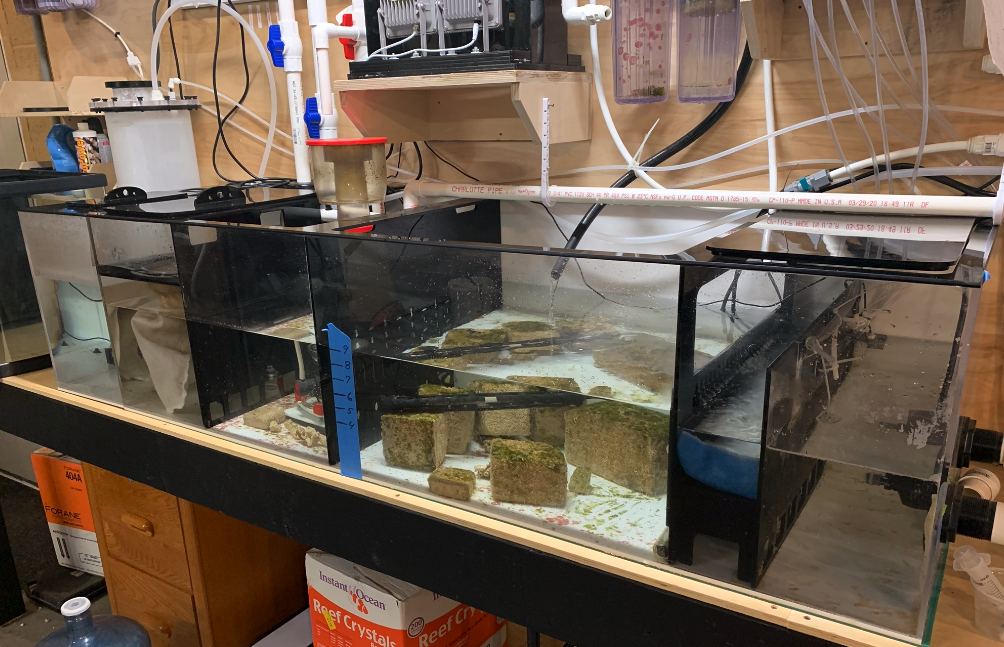

Here is a few pics of my 6 foot sump. This is all made up of 1/4" cast acrylic. The reason there are no bows in the sump walls is because of all the center braces hold/support the walls together.

Now here is a pic of my lid. This is made from 1/2" cast acrylic. Cut on my CNC machine with a recessed edge to fit in the mating hole. Notice how the lid bowed.

Thats a ton of water (Literally). That is a lot of pressure on 1/2" corner joints. If you are not planning on a top with a center brace I would not attempt this project as planned. Just my opinion.

Here is a few pics of my 6 foot sump. This is all made up of 1/4" cast acrylic. The reason there are no bows in the sump walls is because of all the center braces hold/support the walls together.

Now here is a pic of my lid. This is made from 1/2" cast acrylic. Cut on my CNC machine with a recessed edge to fit in the mating hole. Notice how the lid bowed.

- Joined

- Feb 1, 2018

- Messages

- 505

- Reaction score

- 669

Do not sand edges either. you will round off or preferentially sand one side over the other. Use the cut edge produced by the router.

I imagine he was referring to a CNC laser. Have them use a CNC router instead.

I imagine he was referring to a CNC laser. Have them use a CNC router instead.

Wow. Lots of crazy suggestions in here. You can definitely sand. Get a nice auto body flat block. You'll only round edges if you over sand or push too hard. You can edge finish with a router but I 100% prefer sanding over scraping or routing.

Bubbles do not weaken the seam to any extent unless they're large. Little bit of needless fear mogering there. They're just ugly. So pin and shim, and squeeze them out before they set.

Do not use 40/42. That's a professional adhesive and if you get it wrong, it goes wrong real fast. To use effectively you have to chamfer edges and clamp carefully. Read the manual at TAP about 40/42 and you'll never want to use it because it is technically challenging.

4 is your go to for anything up to about 1.5" thick material which covers basically any sized residential tank you can think of. Pick up some 24g wire on Amazon. Cut 4" lengths, place one every 6" and with a shim under it. Lay the 4 with an applicator bottle, start pulling pins after 4 min with pliers. Shim to get the air bubbles out and you're good. If you have long welds get a helper to pull pins and push the shims after 4 min.

Practice, practice, practice. Unless you don't care about a couple air bubbles

Also would not recommend 16 for beading seams. If you think that's necessary then use the tilt method (Google it) with 40/42 but it's totally not necessary. 16 is air bubble city, so avoid it if you can.

Bubbles do not weaken the seam to any extent unless they're large. Little bit of needless fear mogering there. They're just ugly. So pin and shim, and squeeze them out before they set.

Do not use 40/42. That's a professional adhesive and if you get it wrong, it goes wrong real fast. To use effectively you have to chamfer edges and clamp carefully. Read the manual at TAP about 40/42 and you'll never want to use it because it is technically challenging.

4 is your go to for anything up to about 1.5" thick material which covers basically any sized residential tank you can think of. Pick up some 24g wire on Amazon. Cut 4" lengths, place one every 6" and with a shim under it. Lay the 4 with an applicator bottle, start pulling pins after 4 min with pliers. Shim to get the air bubbles out and you're good. If you have long welds get a helper to pull pins and push the shims after 4 min.

Practice, practice, practice. Unless you don't care about a couple air bubbles

Also would not recommend 16 for beading seams. If you think that's necessary then use the tilt method (Google it) with 40/42 but it's totally not necessary. 16 is air bubble city, so avoid it if you can.

Last edited:

I appreciate all of your guys information. I will be calling Piedmont Plastics tomorrow to double check on how they cut their material. I will also go with 3/4" of an inch as well. I plan on doing a euro brace to help with the bowing.

What about running a bead of #16 after pulling the pins and letting the #4 bond?

I appreciate all of your guys information. I will be calling Piedmont Plastics tomorrow to double check on how they cut their material. I will also go with 3/4" of an inch as well. I plan on doing a euro brace to help with the bowing.

I get my sheets from them. It's always CNC cut. But good to double check.

How do shims help with getting air bubbles out though? Once you pull the pins and clamp it together, that should push them all out, yea?I get my sheets from them. It's always CNC cut. But good to double check.

It's not necessary and will turn out badly. Seriously, if you want that rounded edge look inside mix up some 40/42 once the 4 is cured, tilt, pour and let it set.

Nah, I don't necessarily care for the rounded edge look. If #4 is good enough of a bond, then Im fine with that. I don't prefer to spend $200 on an applicator gun for the 40/42 just to have that look.

Similar threads

- Replies

- 48

- Views

- 1,507