- Joined

- Oct 9, 2019

- Messages

- 234

- Reaction score

- 145

Hey,

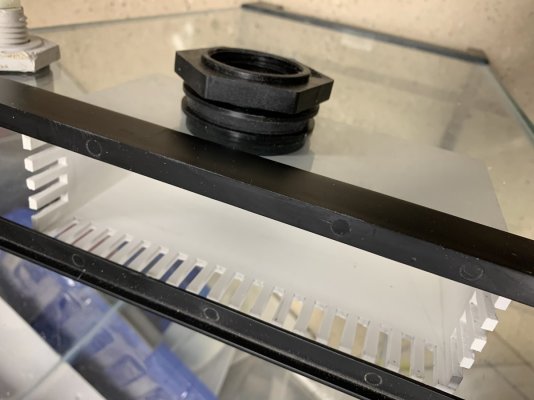

I made a 3D printed overflow for my 220 gallon and I just wanted to share my process and my blueprint in case someone wants to use it. Been using it for 2 months now no leaks or anything like that and works great. Also cost around 50 bucks, $40 for the 5 bulk heads. 10$ for the filament it self. (Much better than the 300 bucks premade one X_X)

The only part I couldnt print was the bulk heads because my printer cant print out threads. I used 2 part epoxy to bind them to the overflow box.

The print...

- PLA

- 100% infilled

- 0.16 mm layer

The back piece was far too big for my printer so I had to print them as two separate pieces, then used a solvent (dichloromethane) to bond it together.

Although I did test it out and it was water proof I did seal the entire surface with the solvent to stop leaks too.

Finished product

I made a 3D printed overflow for my 220 gallon and I just wanted to share my process and my blueprint in case someone wants to use it. Been using it for 2 months now no leaks or anything like that and works great. Also cost around 50 bucks, $40 for the 5 bulk heads. 10$ for the filament it self. (Much better than the 300 bucks premade one X_X)

The only part I couldnt print was the bulk heads because my printer cant print out threads. I used 2 part epoxy to bind them to the overflow box.

The print...

- PLA

- 100% infilled

- 0.16 mm layer

The back piece was far too big for my printer so I had to print them as two separate pieces, then used a solvent (dichloromethane) to bond it together.

Although I did test it out and it was water proof I did seal the entire surface with the solvent to stop leaks too.

Finished product