- Joined

- Sep 4, 2014

- Messages

- 214

- Reaction score

- 98

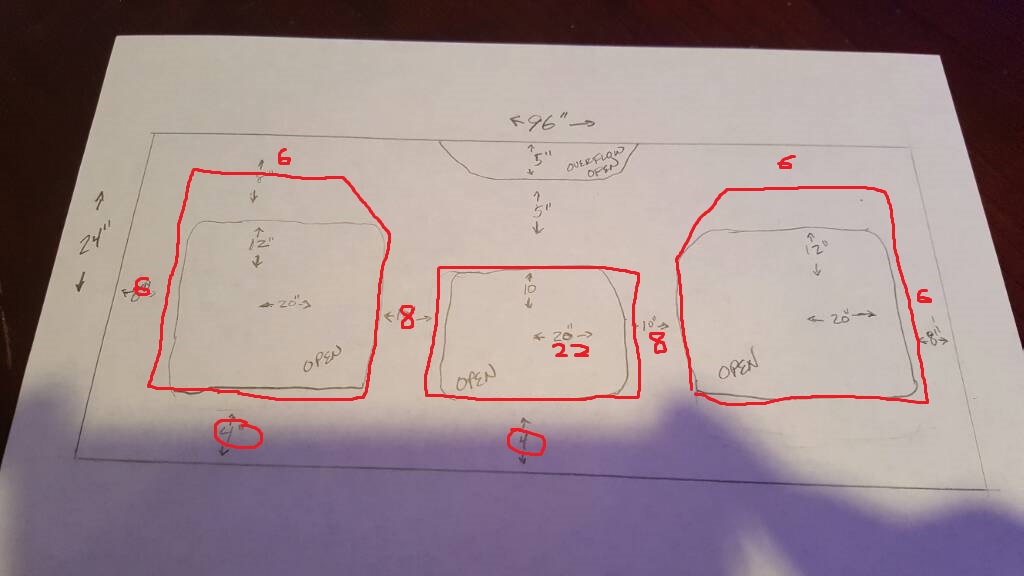

Thank you so much for the advice! Great ideas and points!Normally an 8' tank would have a 3" perimeter and 3x 6" crossbraces every 24". Removing one opening would mean you would want to add 2" to the crossbrace width, making it 8" and make the perimeter 4.5".

This also assumes that the material is good and the proper thickness. For an 8x2x2 that would be 3/4" walls (normally a 24" tall tank would be 1/2", but James/Acrylics recommends jumping up a thickness at 8' to keep deflection down). I can't tell what your material thicknesses are but it looks like it's at least 1/2" on the top and walls?

If it is 1/2" then I wouldn't narrow the perimeter to less than 6" on the sides, and you're already at 4" on the front. I'd be careful about the back euro width because of the trapezoid opening on the back, which is flush with the back panel and generally makes for a weak spot in the structure. So you don't want to expand the side holes toward the back as a square opening because that would decrease the euro width between the corners of those holes and the trap, which is exactly where it will crack out if it does. What you *could* do is expand backward making a 5-sided hole that maintains the distance like this

But even that might be pushing it. If you did this, you would want to maintain minimum 3" diameter (1.5" radius) inner corners with no jagged edges (smooth curves, all around) and then a 1/8" roundover on the top and at least scrape off the sharp edge on the underside. The point is that any sharp corner, transition from straight to inner corner, edge, etc that has a point on it is where the stress will focus. That's one thing I did learn from my discussions with a guy from Cyro...even taking a few passes with a razor blade at a 45 degree angle to a fresh router cut edge will remove all the point stress. Rounding it (either router or sanding) is even better. It's not just a presentation thing, it is a structural/stress reliever.

Water jet does not leave a weldable edge. Weld-on #16 is junk, lots of fillers, not good for structural joint. It has it's place, you can use it for non-structural items, and you can use it to build up layers on a leaky joint like a baffle in a sump, and some have used it to seal up a poor exterior joint but it's shaky even for that. That being said I've seen at least one frag tank at a show that was built with saw cut edges and probably 10 layers of 16 on the inner corners, I thought that sucker was going to blow right in front of me but he said it lasted for years!!