I have the same issue with anything 1/2 inch or greater. I guess im not a pro fess in ol. What worked for me when I built my tank out of 1" was to use sci grip (weld-on) #40. Its a 2 part that you mix together. You make a 1mm gap in the joint. I tilted my pieces so it made a "v" shape but 90 degrees. Put painters tape on the back side so it does not flow thru and out the other side. Then I applied the goop with a large syringe with a big metal tip. You want to be sure you have a lip on the outer side for bit of extra goop. The stuff will shrink as it dries. Overfill the inside a bit too. You can look at my build thread for more info.After a few tries using the advanced search option to find a conversation that probably already exists I figured I’d just start posting, it’s probably faster.

These air pockets are killin’ Me! Edges are square, pins method of course, I used feeler gauges to get the gap consistent to within like .004 across the entire joint, I wiped both surfaces down with denatured alcohol, pins are 28 gauge, etc.. I didn’t blow the joint out but I do all of my fitting first including all the feeler gauge work and then break it back down to clean with alcohol then set it back up to run solvent which is weld on 4.

This is 3/4” thick Acrylite.

Thanks in advance.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic Fabrication Q & A

- Thread starter Turbo's Aquatics

- Start date

-

- Tags

- acrylic diy fabrication

- Tagged users None

Looks good to meHi @Floyd R Turbo

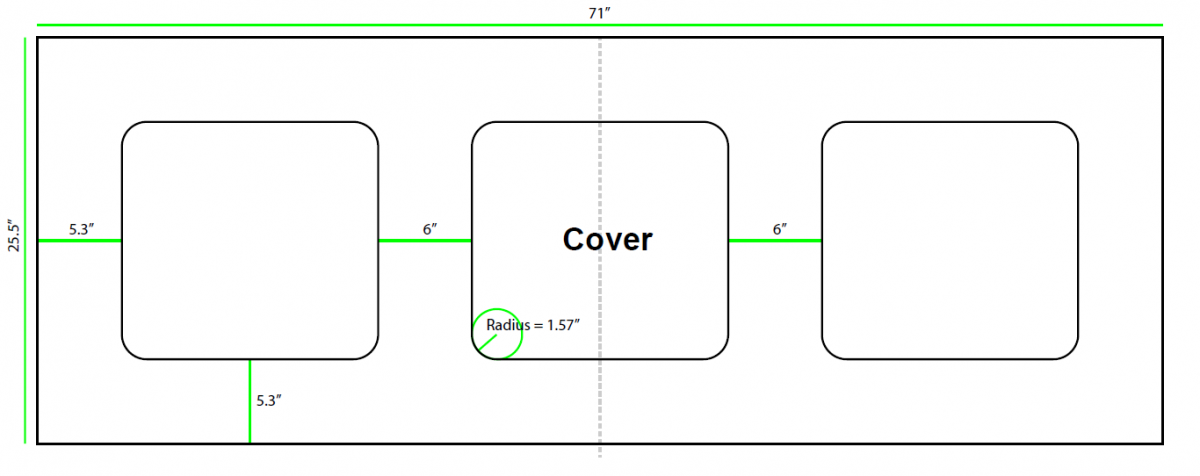

could you please validate my design? Is only the cover and I’m planning to use 5/8” thick

What's the painters tape for? I don't use this, never have. 1) on the exterior edge, you are going to flush trim this off so you generally don't care, but also I never have an issue with dripping due to capillary action (the solvent wicks into the joint instead of running out) 2) on the inside you don't want anything that would cause the solvent to wick away from the joint, or you won't get a fillet on the inside, so the tape on the flat piece might actually cause wicking under the tape resulting in the problem you might be trying to avoid.After a few tries using the advanced search option to find a conversation that probably already exists I figured I’d just start posting, it’s probably faster.

These air pockets are killin’ Me! Edges are square, pins method of course, I used feeler gauges to get the gap consistent to within like .004 across the entire joint, I wiped both surfaces down with denatured alcohol, pins are 28 gauge, etc.. I didn’t blow the joint out but I do all of my fitting first including all the feeler gauge work and then break it back down to clean with alcohol then set it back up to run solvent which is weld on 4.

This is 3/4” thick Acrylite.

Thanks in advance.

But all of that said, that doesn't explain why you're having this problem in the pic. Not blowing out the joint may cause particles to remain in the joint (dust) that could cause the formation of a bubble, but usually that's a tiny bubble. If I had to guess, you're running the needle ahead of the capillary flow instead of allowing the solvent to wick in ahead of the direction you are moving. That can cause the solvent to get "pushed" into the joint rather than "flowing into it"....it's hard to describe, and hard to catch on video without a helper.

Basically, what you do is start adding the solvent at one end and move the needle slowly and allow the solvent to wick in ahead of the tip of the needle, and it doesn't need to be much. {edit} then once the flow is ahead of the needle, you match the speed of the flow and the needdle. I've let this get as much as 2-3 inches ahead of the needle, so I actually stop applying solvent (in some cases) a full inch from the corner, because the solvent has already beat me there.

What happens if you have a line of solvent flowing out of the needle and then filling in an open joint is you can cause air to get sucked into joint along with the flow of the solvent. If you are adding the solvent in an area that is already filled with solvent, then the you don't have much of a risk of air getting pushed in, and the solvent flows from the application area toward the unfilled gap, because it has no where else to go (and it won't go through the joint to the other side, unless you are squeezing too hard

Also with joints 1/2" and over, I switch to the 16 gauge needle (at least for the top/bottom joints). This takes a deeeeep breath the first time you do it, because you are using a 2 oz bottle and the solvent comes out of there super freakin fast. That's a double edge sword, because while it's really easy to mis-apply the pressure (and blow solvent through the joint) it is also much faster, and on long joints (like the top of bottom joints on a 6 or 8 foot tank) you can get around that entire joint (so, 20 feet of joint) in about 30 seconds. Try that with a 22 gauge needle...but once you get used to it, it's the only way to do these types of joints (thick material and/or long joints)

Edited to add matching solvent flow and needle speed

I always add the solvent just slightly above the seam and I find a bigger needle works better to stop air from getting sucked into the seam. I let the flow get ahead by a foot or more and just keep moving a bit and doing sections rather than trying to follow the flow. If the needle gets pointed into the seam and you accidentally give it a quick squirt cause the needle sticks I find that’s when air gets into the seam the most.

Its for use with weld-on #40. #3 and #4 dry in seconds. 40 mixes to a motor oil like viscosity. Working time is about 15 min. It will run out the back of a joint if the joint is not taped off. You still need the lip for the fillet and yes it will be flush trimmed.Looks good to me

What's the painters tape for? I don't use this, never have.

Thanks gentlemen! I never thought about the tape being something that the solvent would be drawn to but it makes total sense. I masked it off to protect the surfaces I didn’t want the solvent on. I even thought that the tape on the inside might also help direct the fluid toward the joint but what it’s really doing is creating some of its own surface tension. More practice runs are what I need after the great advice you guys have given.

Understood, but he's not using 40, which is why I asked. FWIW you don't need to use anything other than MC based solvents for materials under 2" thick. Most people think that 40 is stronger, but that's not necessarily true. I would have to dig up a old old rant post by @acrylics regarding this issue to back up that statement, but for now I'll just leave it at the "the guy who has been building tank for 25+ years and never had one fail due to improper welding told me that" argument. Also I've had discussions with the "big name" manufacturers about how they came up with that "2-part is stronger than solvent" argument, and their critical flaw is that they don't use the pins method in their solvent joint tests. They also don't almost exclusively build aquariums. So people need to stop listening to them...Its for use with weld-on #40. #3 and #4 dry in seconds. 40 mixes to a motor oil like viscosity. Working time is about 15 min. It will run out the back of a joint if the joint is not taped off. You still need the lip for the fillet and yes it will be flush trimmed.

/rant off

Correct, I’m not using 40 and really can’t imagine how I would once I got the 4 sides welded unless I rigged up a chain fall to set it.

I’m thinking there’s nothing I can do about the existing air pockets. I wish they weren’t there but I’m glad they’re at the back and I just want to avoid any more of them.

I’m thinking there’s nothing I can do about the existing air pockets. I wish they weren’t there but I’m glad they’re at the back and I just want to avoid any more of them.

You will want to add a gusset to those joints if you're going to use that in a tank - that's a really serious bubble, that will almost definitely cause a structural issue eventually.

Thanks, I’m going to have to cut it apart then and redo.You will want to add a gusset to those joints if you're going to use that in a tank - that's a really serious bubble, that will almost definitely cause a structural issue eventually.

Weld- on #40 . It was a solution that worked for me when using thicker material. A suggestion. I dont think either is stronger or weaker if done properly . I read those old threads between @acrylics and others when they were first figuring out pins ect... I made my choice based on what was best for me and my ability.

Agreed, a gusset repair is a WO40 application. The problem is, it won't end up looking very pretty without some practice. I've added gussets to shore up a 180g sump using triangle rod and WO40, it's difficult to get that looking clean & clear, but for that particular project, it didn't have to be.

So I’m setting up a 225 that currently uses 3/4 acrylic on the entire tank.

I want to know if minimally I can do a euro brace with 1/2” 94”x4” length and 22”x4” width with two additional cross braces

I want to know if minimally I can do a euro brace with 1/2” 94”x4” length and 22”x4” width with two additional cross braces

So I’m setting up a 225 that currently uses 3/4 acrylic on the entire tank.

I want to know if minimally I can do a euro brace with 1/2” 94”x4” length and 22”x4” width with two additional cross braces

You will get more strength from a bonded on top with access openings routed out. 3" radius corners will also give more strength to the cut outs. The euro braces often fail in the corners. Just my experiance. I never use euro braces versus a full top. Yes it will cost more for your top...better than a wet floor or fire. Depending on how tall the tank is 3/4" is on the thin side for this size tank.

If the tank is taller than 24 Lowell is prob right on the thickness being on the thin side. Amercian 3/4 is not a true 3/4 its .708 I also would suggest a full bonded top with cutouts if you are building this yourself.You will get more strength from a bonded on top with access openings routed out. 3" radius corners will also give more strength to the cut outs. The euro braces often fail in the corners. Just my experiance. I never use euro braces versus a full top. Yes it will cost more for your top...better than a wet floor or fire. Depending on how tall the tank is 3/4" is on the thin side for this size tank.

You will get more strength from a bonded on top with access openings routed out. 3" radius corners will also give more strength to the cut outs. The euro braces often fail in the corners. Just my experiance. I never use euro braces versus a full top. Yes it will cost more for your top...better than a wet floor or fire. Depending on how tall the tank is 3/4" is on the thin side for this size tank.

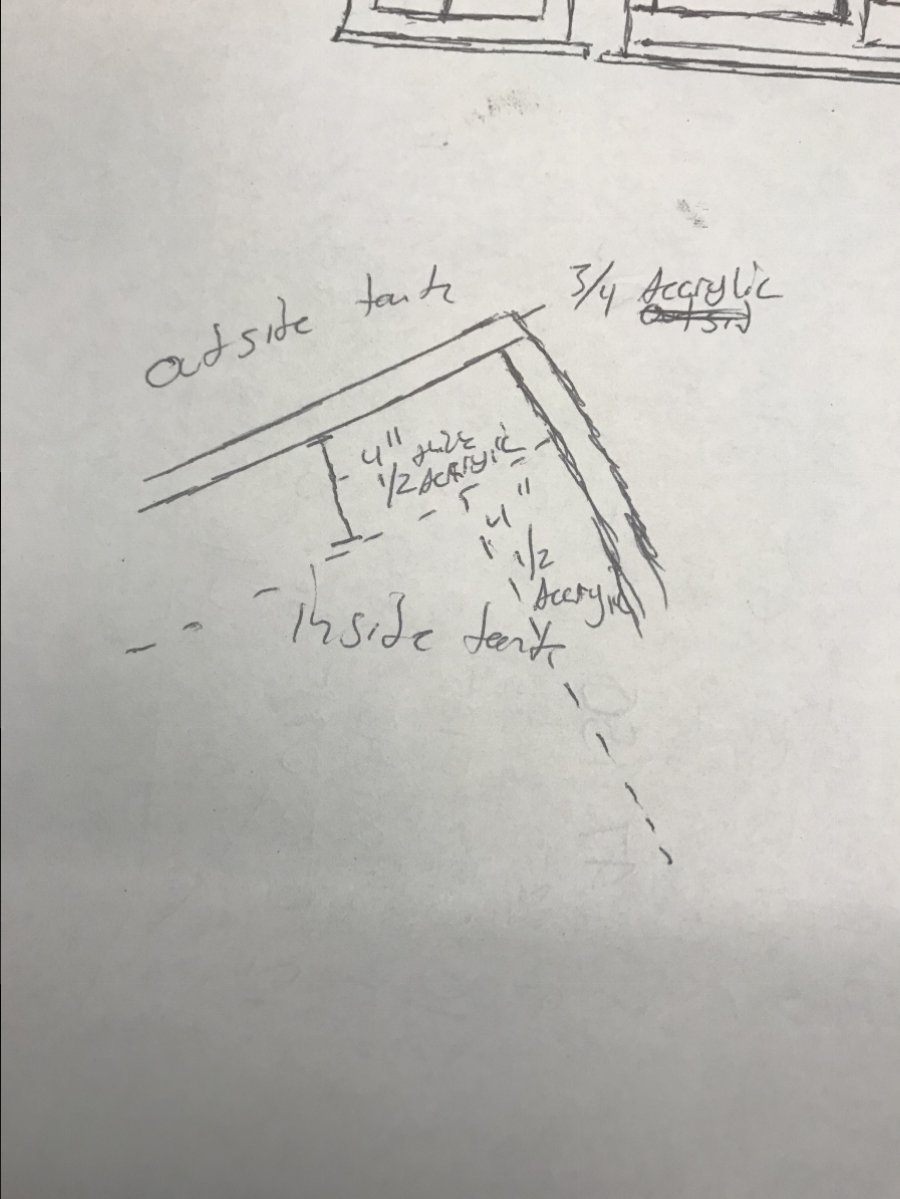

Tanks only 18” tall. Even if you bonded all straight sides to creat a cover like euro bracing? Ex

Bond straight pice and then bond the inner pieces to the outer straight pieces. Tank is in great condition.

It had them, the previous owners I guess glued them on because 3/4 broke when I was moving the tank and the last one needed a tap with a hammer and it came right off. The previous owner also had 3 cross braces that were screwed to the top of the tank. I’ve removed all braces because for lack of better words I don’t trust screwed in acrylic or glued when you can cement bond acrylic using weld on4 or like products.

Also if you see the center over flow I plan on taking that thing out as well, aside from being cracked I plan on using a ghost like product over flow.

Also if you see the center over flow I plan on taking that thing out as well, aside from being cracked I plan on using a ghost like product over flow.

Looks like a nice project tank. Be sure you clean up and flatten the corners where the triangles were "glued on". If you cant get it perfectly flat for bonding you might need to use a thicker product than sci grip 3 or 4.

Actually I was thinking of using the inside of the tank. I’ve drawn a sketch to show what I want. But still plan on flattening the top.

Similar threads

- Replies

- 17

- Views

- 394