Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic Fabrication Q & A

- Thread starter Turbo's Aquatics

- Start date

-

- Tags

- acrylic diy fabrication

- Tagged users None

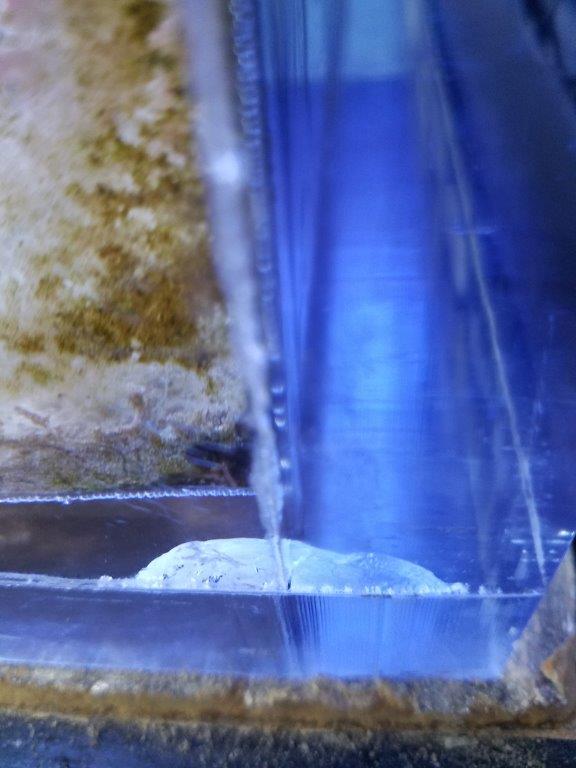

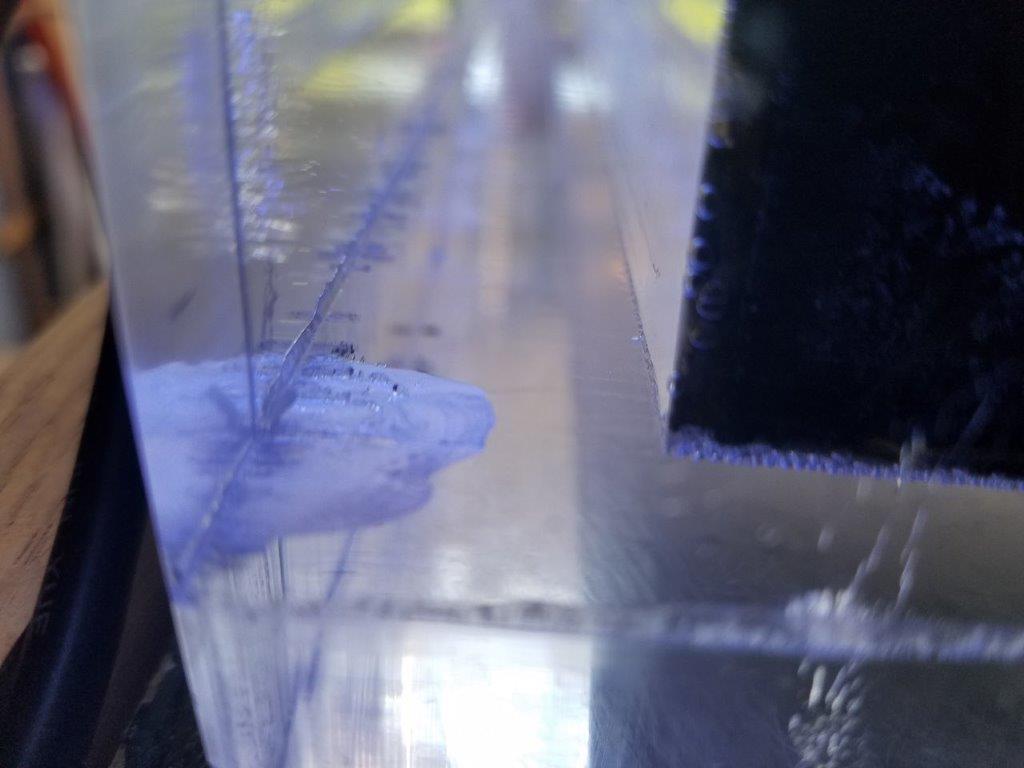

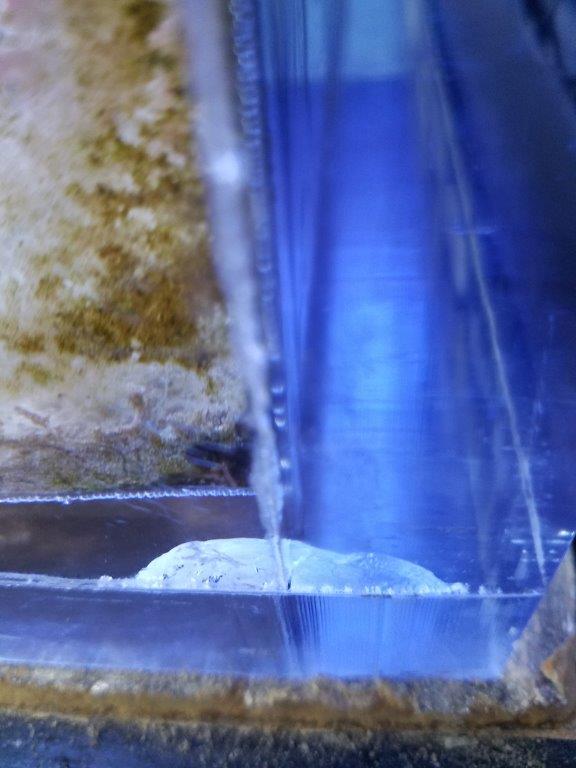

My ipinion:Is there a recommended repair for this seam? While this is the largest I have a few spots like this but it's been like this for at least 3 years and does not appear to have grown. I'm planning to move the tank and while it was empy thought would be a good time to repair it. The pics are from the same corner, side and back views.

Looks like its on the outside. Prob lack of solvent or the material was not perfectly even.

If its been 3 years I would not mess with it.

An air gap like that might be cleaned up by drilling a pin hole and shooting some solvent into the gap. However solvent is not a gap filler so its not a for sure thing. Mixing a few acrylic chips with the solvent can thicken it but it might not flow into the gap.

I did not catch the beginning of your question but wondered if you considered a black frame?So even though I'm only spanning 24" across of I go with a euro braced design I'll need 3/4"?

I have a similar spot on one of my tanks. It took around 5 years to expand it's way to the inside seam. Mine is a smaller lowboy so I used weld on 16 in a tip and pour.Is there a recommended repair for this seam? While this is the largest I have a few spots like this but it's been like this for at least 3 years and does not appear to have grown. I'm planning to move the tank and while it was empy thought would be a good time to repair it. The pics are from the same corner, side and back views.

- Joined

- Aug 8, 2015

- Messages

- 1,454

- Reaction score

- 1,251

@Turbo's Aquatics I am building some new jigs and am looking for some campermount foam. Years ago I got some of the stuff you mentioned from Menards and it worked great. I can also confirm the black stuff from HD sticks to the masking and is awful. The link you listed on the first few pages is broken now. Do you have a good place to buy that specific brand foam. I guess it is made of different material, and they never list what they are made of, so I cannot just search for "equivalent" stuff.

Is this the stuff?

Is this the stuff?

I had the same problem and looked at that. It is the brand HD sells now. I found the exact brand he advised on Amazon.@Turbo's Aquatics I am building some new jigs and am looking for some campermount foam. Years ago I got some of the stuff you mentioned from Menards and it worked great. I can also confirm the black stuff from HD sticks to the masking and is awful. The link you listed on the first few pages is broken now. Do you have a good place to buy that specific brand foam. I guess it is made of different material, and they never list what they are made of, so I cannot just search for "equivalent" stuff.

Is this the stuff?

- Joined

- Aug 8, 2015

- Messages

- 1,454

- Reaction score

- 1,251

Yea, i looked a little closer and I think the key thing is getting foam that is closed cell pvc like this:I had the same problem and looked at that. It is the brand HD sells now. I found the exact brand he advised on Amazon.

I haven't tried it out yet, but I think this is the stuff...

It's most definitely the Menards brand - WJ Dennis. Anything else I've tried sucks but who knows, they might have changed it. All I know is the boards I have still have the same foam on them after ~10 years, and its' the Menards brand.@Turbo's Aquatics I am building some new jigs and am looking for some campermount foam. Years ago I got some of the stuff you mentioned from Menards and it worked great. I can also confirm the black stuff from HD sticks to the masking and is awful. The link you listed on the first few pages is broken now. Do you have a good place to buy that specific brand foam. I guess it is made of different material, and they never list what they are made of, so I cannot just search for "equivalent" stuff.

Is this the stuff?

I updated the post here

Acrylic Fabrication Q & A

Attached is a .zip file with the Cyro calculator. You can also get this from their website but you have to register I think http://cyro.custhelp.com/app/answers/detail/a_id/133 I will stand slightly corrected, the thickness of the sheet depends on the length of the longest side and the...

www.reef2reef.com

www.reef2reef.com

I noticed that Menards did change the brand, not sure how well that one works now. However I don't even use foam boards anymore, I've gone through 2 progressions of bonding table techniques since then. Foam boards are good when you don't have a super-flat or even surface, but when you're building 40+ sumps a month, they become tedious. I shifted to carpet & pad a few years ago and recently shifted to anti-fatigue mat. I also changed my shimming technique and found a new material for pins (basically, ligature wire)

Is there a recommended repair for this seam? While this is the largest I have a few spots like this but it's been like this for at least 3 years and does not appear to have grown. I'm planning to move the tank and while it was empy thought would be a good time to repair it. The pics are from the same corner, side and back views.

I've seen worse - but I agree this is likely due to something related to joint prep. If that corner where the joints meet isn't planed down (sanded, scraped, whatever) then there becomes a variance in the gap that might not be visible and it might seem like you can close it up when bonding/prepping, but it will eventually pull apart.

Could have been an angle on the material, again that's prep technique

Could be a variance in the flatness of the stand that put pressure or a twist on the joint, that will cause a slow separation over time

You could drill it out (or bore it out with an oscillating tool, maybe) and fill with Weld-on 40. I would not use 4 or 5 or 16 or anything else to fill it, and it will be tricky to get the mixture in while keeping bubbles out (needle, inject to deepest point, etc).

The quick and dirty fix would be to bond on a mending piece across the gap. If it's not in a highly visible place, just a piece of scrap like 3/8" that extends about an inch past the area in all possible directions. Again Weld-on 40 would be the best material here since it is a gap filler, that way you wouldn't have to sand it down and make sure the mending piece is in full contact

Mine is wandering it's way to me. I will pick up some of yours at Lowe's and compare. Weirdly, it is the MDF that has me stumped. Out of stock all over my area.Yea, i looked a little closer and I think the key thing is getting foam that is closed cell pvc like this:

I haven't tried it out yet, but I think this is the stuff...

- Joined

- Aug 8, 2015

- Messages

- 1,454

- Reaction score

- 1,251

I didn't know you made sumps also. I have seen the carpet method before and it makes sense. For me, making the small overflows, with my work flow, the foam works good. I haven't seen the fatigue mats before, but it makes sense. Where are you selling the sumps? I'd love to take a look at them.However I don't even use foam boards anymore, I've gone through 2 progressions of bonding table techniques since then. Foam boards are good when you don't have a super-flat or even surface, but when you're building 40+ sumps a month, they become tedious. I shifted to carpet & pad a few years ago and recently shifted to anti-fatigue mat. I also changed my shimming technique and found a new material for pins (basically, ligature wire)

www.cwtaquatics.comI didn't know you made sumps also. I have seen the carpet method before and it makes sense. For me, making the small overflows, with my work flow, the foam works good. I haven't seen the fatigue mats before, but it makes sense. Where are you selling the sumps? I'd love to take a look at them.

- Joined

- Aug 8, 2015

- Messages

- 1,454

- Reaction score

- 1,251

Weird. I haven't been to a lowe's or HD in a week or two, but they had all the MDF you wanted here in Houston. If they can't get any glued together sawdust, I can't imagine how the situation up there is with real wood.Mine is wandering it's way to me. I will pick up some of yours at Lowe's and compare. Weirdly, it is the MDF that has me stumped. Out of stock all over my area.

Real wood is expensive but available. More bizarre is every other type of MDF molding is in stock...just not the flat. GrrrWeird. I haven't been to a lowe's or HD in a week or two, but they had all the MDF you wanted here in Houston. If they can't get any glued together sawdust, I can't imagine how the situation up there is with real wood.

Would his work for scraping edges? My ability to make anything out of wood is zero and I do not have a router.

hello

i want to ask about pricking

we have shop is going to close and has a large new acrylic aquarium he want to sell it

size is

80" * 40" * 30"

with stand

no sump or overflow to it

how much is a good price for it? and also drilling it to add sump and like this will be easy ?

also the top of the tank is all covered as well only to open in the middle, that going to be a problem ?

i want to ask about pricking

we have shop is going to close and has a large new acrylic aquarium he want to sell it

size is

80" * 40" * 30"

with stand

no sump or overflow to it

how much is a good price for it? and also drilling it to add sump and like this will be easy ?

also the top of the tank is all covered as well only to open in the middle, that going to be a problem ?

Building a black frame acrylic tank using the pin method. Is it ok to use the frame as a jig, pin all of it (painters tape to hold them,) shim/bond the horizontal seam, let cure, and then rotate to reach the next seam??

I'm not sure what you're trying to describe

I'm not sure what you're trying to describe

Does that help?

I had no luck finding someone I could pay to do the assembly so DIY it is and I can not find flat MDF sections anywhere. I am working in a small space with pieces that fit very tight in the frame. 4 hours in an 80 degree attic got enough flex to get pins in. The frame edge is deep enough to fit shims when the pins are pulled. I found 2 extra large picture frame miter clamps at a yard sale.

If you're planning on putting the frame on the bottom of the tank, this is a big no from me. Acrylic tanks need to sit directly on a flat and fully supported surface. You would never put any kind of trim like this on the bottom of an acrylic tank, let alone assemble the tank using the trim piece. Just from a perspective of order of assembly, that would be completely incorrect if I'm interpreting what you're wanting to do

Similar threads

- Replies

- 17

- Views

- 390

New Posts

-

-

-

New Reef Parameter Monitors - Hydros Maven and Neptune Trident NP

- Latest: Rocky Mountain Reef