- Joined

- Apr 21, 2020

- Messages

- 118

- Reaction score

- 92

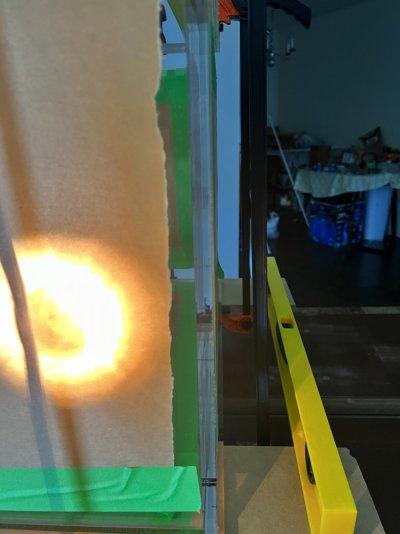

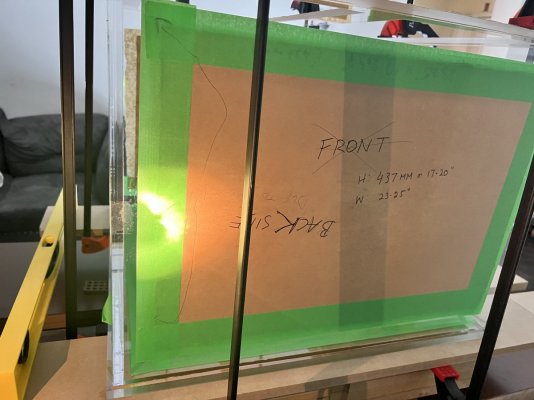

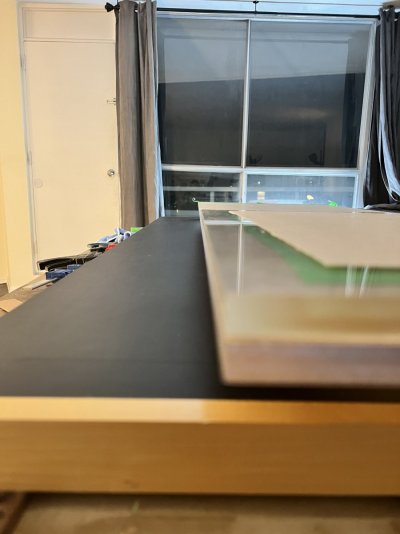

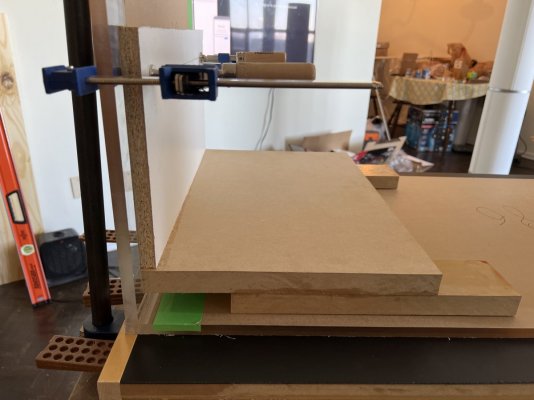

I did this to shim the tank as well as use a level. I measured every inch until it was filled about 6" . Then checked again with a level at the end and it was all good.The best way I have found to level a large tank is to put a few inches of water in the tank and then measure each corner from the top of the tank to the waterline and adjust the stand to make all the measurements the same. Hopefully that makes sense lol

I don't have any concerns about the tank being level or not.