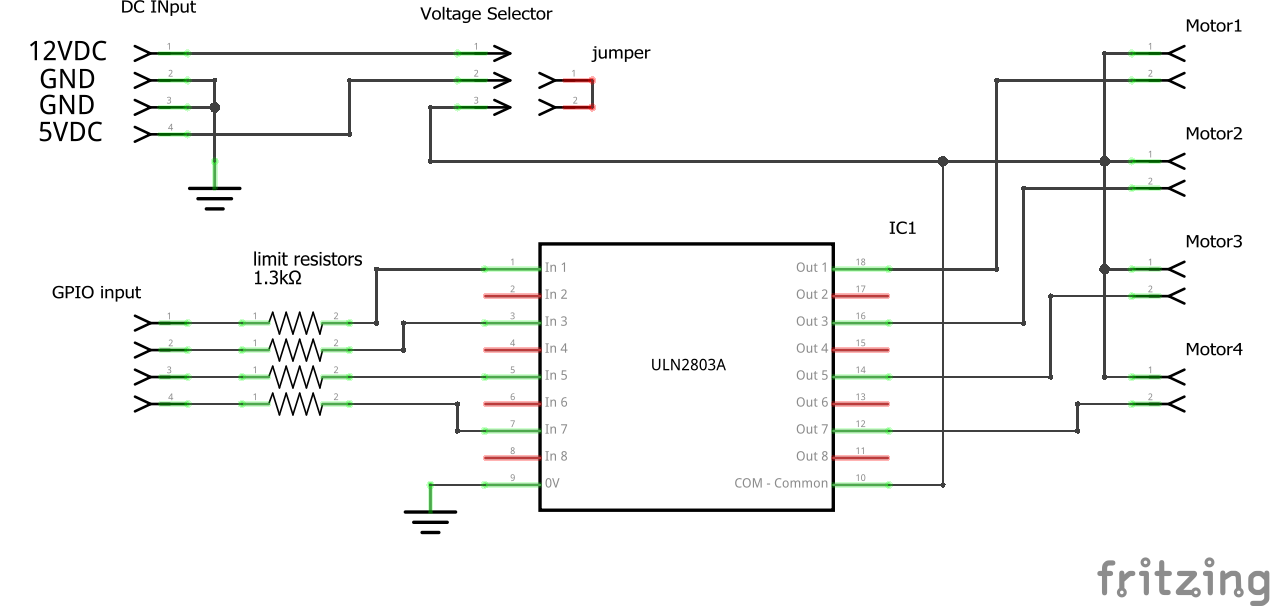

I want to build a DIY Doser, similarly to the Adafruit Guide. Sadly I couldn't find L293 ICs, so I decided to run with standard monodirectional bipolar transistors (ULN2801 with input resistors).

The current plan and circuit diagram can be found on my project's GitHub page.

A few quirks:

I remember @robsworld78 mentioning something like this in one of his great videos here.

The current plan and circuit diagram can be found on my project's GitHub page.

A few quirks:

- I'm concerned about the PCA9685's reliability over I2C, I therefore want to run the pumps on the PI's GPIOs

- My Pumpsrun nominally on 12V, 200-300mA and 100ml/min, e.g. 0.6s / ml

- I'm concerned that this is way to fast for typical daily dosing of trace elements

- I therefore have several methods, as far as I can see

- dose less often with a then higher amount

- dose more often, but with diluted fluid (as @Ranjib)

- decrease the pumps' speed

- I'm currently favoring to decrease the pump speed

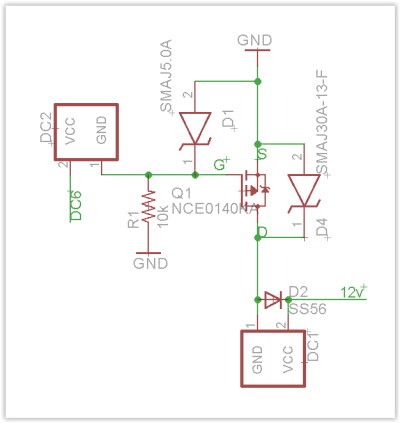

- I could do this via PWM

- uses more parts and makes the circuit more complicated

- I could simply run the pumps with 5V instead of the nominal 12V

- If the resistance stays the same (which it probably won't) I decrease the electrical power by ( 5v/12V )^2 which is about 1/100

- that means I would instead of dosing 1ml every 0.6 seconds, dose 1ml every 6-60 seconds, depending on how the pump reacts

- I could do this via PWM

I remember @robsworld78 mentioning something like this in one of his great videos here.

Last edited: